Amounts of Unutilized Forest Biomass Resources Under Sustainable Forest Management, Limited by Labor–Input Constraints

doi: https://doi.org/10.5552/crojfe.2025.2938

volume: issue, issue:

pp: 12

- Author(s):

-

- Yoshioka Takuyuki

- Kaneko Shunsuke

- Kim Hyun-Bae

- Nitami Toshio

- Article category:

- Original scientific paper

- Keywords:

- regional forestry operations management model, labor-input constraint, logging residue, small-diameter tree, unutilized thinnings

Abstract

HTML

In anticipation of the utilization of logging residues and small-diameter trees after the completion of the Feed-in Tariff Scheme for Renewable Energy (FIT) in Japan, this study (i) calculated the available amount of unutilized forest biomass resources over a long term by using the developed »regional forestry operations management model« and (ii) estimated the period and the ratio of the generation of small-diameter trees during cleaning and pre-commercial thinning operations to the whole biomass resources. These analyses revealed that in the first 60 years, the clearcut and reforestation of 763 ha of planted forests (average age 66 years) with the labor input of approx. 2000 man-days per year were promoted, and thus 71% of the whole area was returned to the regular harvesting cycle. During that period, the average amounts of log production and biomass generation were 7184 m3/y and 875.6 Mg/y on a dry-weight basis, respectively. During the next 60 years, when the clearcut of older, high–accumulation forests and the subsequent reforestation were stabilized, the average amounts of log production and biomass generation under sustainable forest management were 5239 m3/y and 774.8 Mg/y on a dry–weight basis, respectively, exhibiting lower amounts than those of the first 60 years. Small-diameter trees were generated by cleaning and pre-commercial thinning operations stably from 16 years after the beginning of clearcut and reforestation. Especially after 61 years, the average annual amount of small-diameter trees generation accounted for around 10% of that of the whole biomass resources and more than 50% of that of unutilized thinnings.

Amounts of Unutilized Forest Biomass Resources Under Sustainable Forest Management, Limited by Labor–Input Constraints

https://doi.org/10.5552/crojfe.2025.2938

Takuyuki Yoshioka, Shunsuke Kaneko, Hyun-Bae Kim, Toshio Nitami

Abstract

In anticipation of the utilization of logging residues and small-diameter trees after the completion of the Feed-in Tariff Scheme for Renewable Energy (FIT) in Japan, this study (i) calculated the available amount of unutilized forest biomass resources over a long term by using the developed »regional forestry operations management model« and (ii) estimated the period and the ratio of the generation of small-diameter trees during cleaning and pre-commercial thinning operations to the whole biomass resources. These analyses revealed that in the first 60 years, the clearcut and reforestation of 763 ha of planted forests (average age 66 years) with the labor input of approx. 2000 man-days per year were promoted, and thus 71% of the whole area was returned to the regular harvesting cycle. During that period, the average amounts of log production and biomass generation were 7184 m3/y and 875.6 Mg/y on a dry-weight basis, respectively. During the next 60 years, when the clearcut of older, high–accumulation forests and the subsequent reforestation were stabilized, the average amounts of log production and biomass generation under sustainable forest management were 5239 m3/y and 774.8 Mg/y on a dry–weight basis, respectively, exhibiting lower amounts than those of the first 60 years. Small-diameter trees were generated by cleaning and pre-commercial thinning operations stably from 16 years after the beginning of clearcut and reforestation. Especially after 61 years, the average annual amount of small-diameter trees generation accounted for around 10% of that of the whole biomass resources and more than 50% of that of unutilized thinnings.

Keywords: regional forestry operations management model, labor-input constraint, logging residue, small-diameter tree, unutilized thinnings

1. Introduction

The Feed-in Tariff Scheme for Renewable Energy (FIT) was launched in Japan in 2012, and the implementation of this scheme has increased the energy utilization of Japan forest biomass. Electric utilities have committed to buying the electricity derived from the forest biomass at a higher price rather than the normal retail biomass for 20 years (Yoshioka 2021); the price of forest biomass for electricity production is lower than that of pulp chips without the support of the FIT. Thus, power-generation plants that accept »unused forest biomass« defined within the framework of the FIT scheme (e.g., thinnings and logging residues rather than wood-based waste materials such as mill residues and imported woods) have been built and the initiation of plant operations are progressing, in part due to the scheme purchase price incentive. As a result, 4.52 teragrams (Tg) of wood chips on a dry-weight basis derived from thinnings and logging residues were used as energy in Japan in 2022 (Ministry of Agriculture, Forestry and Fisheries 2023). In practice, however, thinnings are the main source of this utilization (rather than logging residues), and the use of logging residues has not progressed much. If this situation continues, there may be a risk that the amount of forest biomass used will decline sharply with the end of the FIT scheme, which is expected to occur in 15–20 years. To avoid this decline, a system must be put in place to allow the use of logging residues (as the original unutilized resource) before thinnings become unusable as »unused forest biomass« (since trees will grow in 15–20 years and the amount of thinnings generation is expected to decrease in Japan).

The use of small-diameter trees is also promising. The area of Japan covered by planted forests that have undergone final cutting and subsequent reforestation is now gradually increasing. A cleaning operation in young planted forests will therefore be necessary when the FIT expires. The development of an efficient harvesting technology for small-diameter trees can thus be expected to contribute not only to securing a source of forest biomass for power-generation plants but also to the continuous tending of young planted forests after regeneration.

In anticipation of the utilization of logging residues and small-diameter trees after the completion of the FIT scheme in Japan, this study calculated the available amount of unutilized forest biomass resources generated in the process of promoting final cutting and a subsequent reforestation of planted forests that have a relatively high proportion of older growth, by using the developed »regional forestry operations management model« (Kaneko et al. 2023). The period and the ratio of the generation of small-diameter trees during cleaning and pre-commercial thinning operations to the whole biomass resources were also estimated.

The authors' research group has studied technologies and systems for harvesting, transporting, and chipping logging residues on steep terrain in Japan (Yoshioka et al. 2000, 2002, 2005a, 2005b, 2005c, 2006a, 2006b, and 2011). In the case of logging residues, the calculation of procurement costs begins from the harvesting operation at a logging site where limbing and bucking processes are carried out. Felling and accumulating processes must also be considered to calculate the procurement cost of small-diameter trees. In the Biomass Nippon Strategy, the forest biomass from small-diameter trees in Japan is thus considered a resource that is secondary to the resource from logging residues (Anon. 2005).

1.1 Literature Review

Harvesting technologies for small-diameter trees have been developed and examined in North America (Han et al. 2004, Pan et al. 2008a and 2008b, Hiesl and Benjamin 2013, de Souza et al. 2016) and Europe (Spinelli et al. 2007, Spinelli and Maganotti 2010, Erber et al. 2016). In Nordic countries, the accumulative function of feller-bunchers and harvesters is used in the harvesting of small-diameter trees for bioenergy use (Kärhä et al. 2005, Laitila et al. 2010, Bergström et al. 2012, Nuutinen et al. 2016). For example, Belbo (2010) compared two working methods for small-tree harvesting with a multi-tree felling head mounted on a farm tractor, and Laitila et al. (2007) examined the forwarding of whole trees after manual and mechanized felling and bunching in pre-commercial thinning. In the efforts to clarify the optimal method(s) of harvesting small-diameter trees as unutilized forest biomass appropriate for Japan, the authors' research group has assumed a simplified model forest and conducted experiments and time studies of the harvesting of small-diameter trees with a truck-mounted multi-tree felling head (Yoshioka et al. 2021).

It is necessary to consider the background of the development of the »regional forestry operation management model« described by Kaneko et al. (2023). Labor productivity must be increased in order to compensate for the declining number of forestry workers in Japan, and the numbers and areas of forests that have reached the period of final cutting are increasing. It is therefore desirable to establish an efficient operation system using large forestry machines. In the operation of such large and efficient forestry machines, it is necessary to set up intensive forestry management sites to ensure that the workload is commensurate with the machine costs (Aruga et al. 2013, Górriz-Mifsud et al. 2019). However, the labor input is a constraint on operational planning because there is a quantitative limit to the amount of work that operators can perform. When a forest management plan is being designed, it is important to predict the future amount of operations and balance it with a feasible labor input from the point of view of sustainability.

Forests are dynamic biological systems that require an accurate understanding of the relationships between forest biomass changes and forestry operations when making operational decisions (Peng 2000). Modeling methods such as statistical and simulation models are a means of quantifying these relationships. The harvesting volume has been estimated mainly using the Gentan probability to predict both the amount of operations and the changes in a forest biomass. The Gentan probability method is used to statistically predict the amount of harvesting operations by applying the probability of harvesting for each forest age or age class (Hiroshima 2011, Yamada 2018). In general, a statistical model requires sufficient data so that the application of the model is limited to specifically localized conditions. The establishment of a nationwide model would thus require a high level of effort.

Mathematical programming is also used to quantify forestry business scenarios. Mathematical programming is a method of maximizing objective functions such as the harvesting volume or profits by imposing constraints on resources (Kaya et al. 2016). Troncoso and Garrido (2005) and Suzuki et al. (2018) predicted the amount of log production under certain constraints, and Buongiorno (1996) applied both mathematical programming and system dynamics (SD) to optimize forestry supply chains. Although it is possible to derive a solution by formulating the objective function and constraints, such a formulation requires a high degree of specialization. It is thus desirable to establish a feasible and quantified method of operational planning for a wide range of practitioners.

In the »regional forestry operation management model«, SD was proposed as a forecasting and forestry management method to overcome these problems. System dynamics has been applied to future predictions and scenario analyses at various scales and in various fields (Machado et al. 2015). A characteristic of SD is that the structure of the model can be explicitly described. For this reason, various forecasts can be described by arbitrarily changing the variables in the model or by adding appropriate sub-models according to the actual conditions or desirable scenarios. In addition, SD can be applied to solving optimization problems since it is relatively effortless to formulate objective functions in the SD model.

2. Materials and Methods

2.1 Development of Regional Forestry Operations Management Model

2.1.1 System Dynamics Model

System dynamics predicts future changes by describing the attributes and behavior of the target system using mathematical equations, and it is possible to deal with multiple real-world problems since SD can handle non-linear state changes. System dynamics-based models have various applications in forestry. On a macro-scale, e.g., the scope of an entire wood-related industry, Schwarzbauer and Stern (2010) revealed the impacts of increased wood energy use on the upstream forestry and the downstream wood industry. On a micro-scale, Visser et al. (2004) conducted a productivity analysis of harvesting systems at forestry operation sites. The forest-stand-changes model (Vanclay 2014) and single-tree-growth model (Lönnstedt and Randers 1979) were also constructed, but there are no previous models in which forestry operations were formulated for regional forest management.

In order to understand the dynamics of regional forests, the authors' research group thus created a model that represents changes in forest resources due to an operational system in which the sustainability of log production and forest biomass generation can be secured by optimization. The SD modeling tool Stella® was used to construct the simulation model.

2.1.2 Forestry Operations Management System

The company in this study model was assumed to perform planting, weeding, cleaning, pre-commercial thinning, commercial thinning, final cutting, and long-term cutting. The targeted stand age and efficiency of each operation, which are based on a typical forest management system in Japan (Nakajima et al. 2018), are listed in Table 1. Planting was carried out at a density of 3000 trees/ha at 1 year after clearcutting. There is a 3–10% probability of spontaneous death every year in young forest stands that are 2–10 years old (Fukumoto et al. 2017). Cleaning was conducted at a tree density of 20% at 15 years of age.

Table 1 Targeted stand age and efficiency of each operation

|

Operation * |

Targeted stand age year |

Operational efficiency * |

|

Planting |

1 |

0.06 ha/man-day |

|

Weeding |

2–6 |

0.14 ha/man-day |

|

Cleaning |

15 |

0.08 ha/man-day |

|

Pre-commercial thinning ** |

20 |

3 m3/man-day |

|

Commercial thinning ** |

40 |

4 m3/man-day |

|

Final cutting |

50-99 |

7 m3/man-day |

|

Long-term cutting ** |

100-200 |

5 m3/man-day |

|

* Manual operation was the assumed system for planting, weeding, and cleaning, while the operation system for pre-commercial and commercial thinning, final cutting, and long-term cutting was assumed to be partly mechanized, i.e., chainsaw felling, cable yarding, processor limbing and bucking, and forwarder hauling. Listed operational efficiency was based on Nakajima et al. (2018) ** The operational efficiency of thinning increases in the order of pre-commercial, commercial, and long-term cutting stages since the productivity increases in proportion to the stem volume of a tree |

||

With respect to thinning, 25% of the 20-year-old trees were thinned at a pre-commercial stage and 30% of the 40-year-old trees were thinned at the commercial stage. Clearcutting was assumed for the final cutting, targeting stands aged 50–99 years old. For long-term cutting, either thinning or clearcutting was supposed to be carried out in the long-rotation management; that is, stands aged 100–200 years old were targeted. The ages of the final and long-term cuttings were not fixed but were adjusted annually during the simulation period.

2.1.3 Formulation of System Dynamics-Based Optimization

The amount of operations in the ith year, Wi (man-day/y), was calculated by summing the amount of work required for planting, weeding, cleaning, pre-commercial thinning, commercial thinning, final cutting, and long-term cutting. For the decision regarding forest stands to be in operation in each year, the model considered the age, locational advantage class, and distance from a forest road of each stand. The locational advantage class is an index that comprehensively quantifies the ease of logging based on natural conditions such as topography, slope, and the distances from forest roads.

The company in the model was assumed to have 10 workers working 200 days annually, which were typical numbers of workers and working days for a business unit in Japan; that is, a total workforce of 2000 man-days per year was optimized. The model adjusted the operation content, i.e., the number of forest stands or the size of the forest area where the operations were carried out, so that Wi was balanced with the workforce. The simulation period used in this study was set as 60 years. The parameter sets were repeatedly selected and optimized so that the difference was within approx. 10% (200 man-day/y) for all years.

The optimization was divided into two stages in the order of final cutting and long-term cutting because the rotation of the final cutting was the basis of log production, and the shortage was supposed to be supplemented by long-term cutting. In other words, to prioritize the securing of the amount of final cutting, the first stage was to fix the operation amount of the final cutting each year by optimizing the parameters concerning that operation, and the second stage was to adjust the amount of the long-term cutting operation. For the parameter search, a grid search implemented in the Stella® optimization function was used. The grid search is an algorithm that is used mainly for optimizing nonlinear functions by determining the optimal parameters. Since a grid search can pass through all possible values in the parameter space, it is less likely to fall into a local optimum. Optimization was performed using the age and rate of cutting as the model parameters.

First, the amount of final cutting operations was optimized. The final cutting amount varied depending on the final cutting age in each year, while the target forest stand for the final cutting was selected according to geographical conditions. Above all, when the final cutting age changed, the year of subsequent reforestation also changed. Thus, the operation content of final cutting was derived so that the sum of the squared difference between the total amount of operation, Wi, and the workforce, 2000 man-day/y, was minimized during the simulation period. The objective function is expressed as:

minimize ∑i=160(Wi-2000)2 (1)

In the second stage of optimization, the age and the thinning rate of long-term cutting were adjusted. As shown in Table 1, the long-term cutting was carried out in forest stands between 100 and 200 years old. However, clearcutting is not always performed during long-term cutting but the thinning rate can be determined as 0–100%. When the value of the objective function of Eq. (1) cannot be further minimized because of the optimization of the final cutting in the previous stage, long-term cutting will not occur for a few years. The operation content of long-term cutting was derived with the same objective function as that used in the first step.

2.1.4 Target Area and Dataset

The study site for the constructed model was located at the central part of Japan, and the data used in this study covered a total area of 20,147 ha and 34,059 stands. Forest registers and a geographic information system (GIS) were used to obtain the data. The age, tree density, and volume of each stand were obtained from the forest registers, and the stand area was calculated using a GIS function. Thus, the area, age, tree density, and volume of forest stands were used as geographic data.

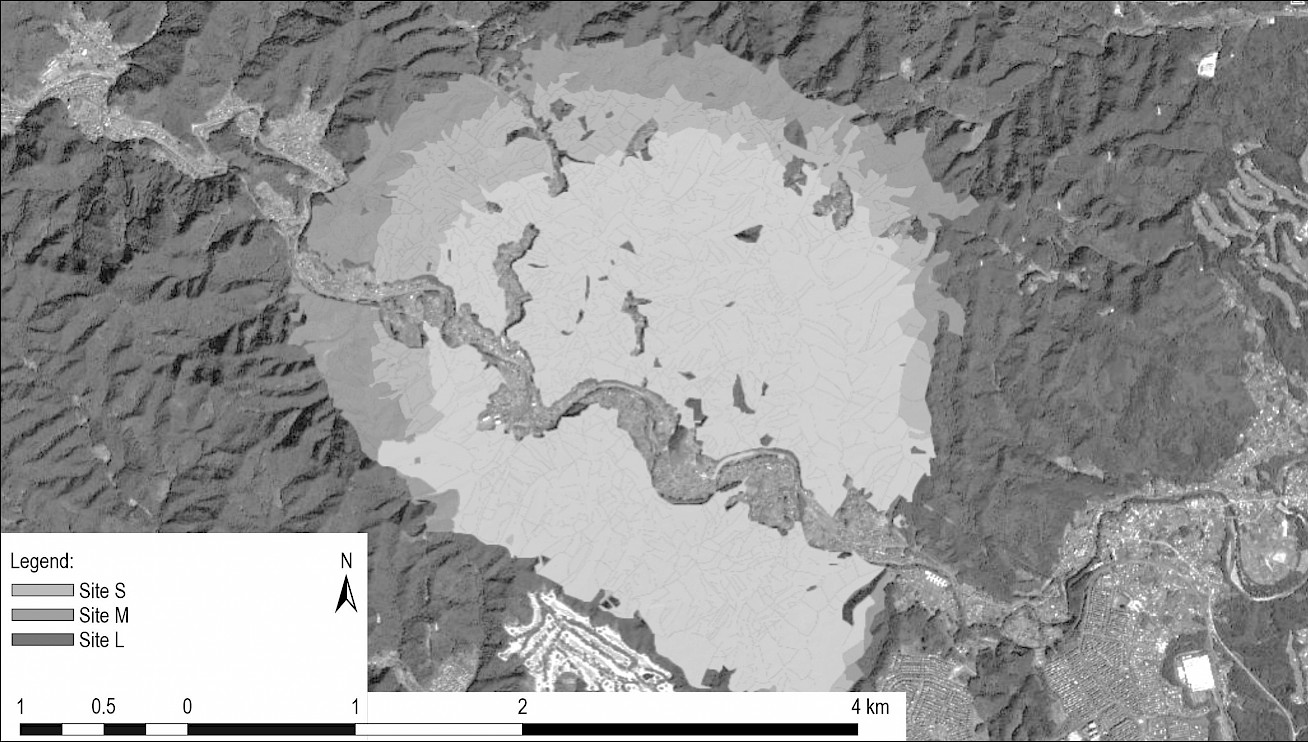

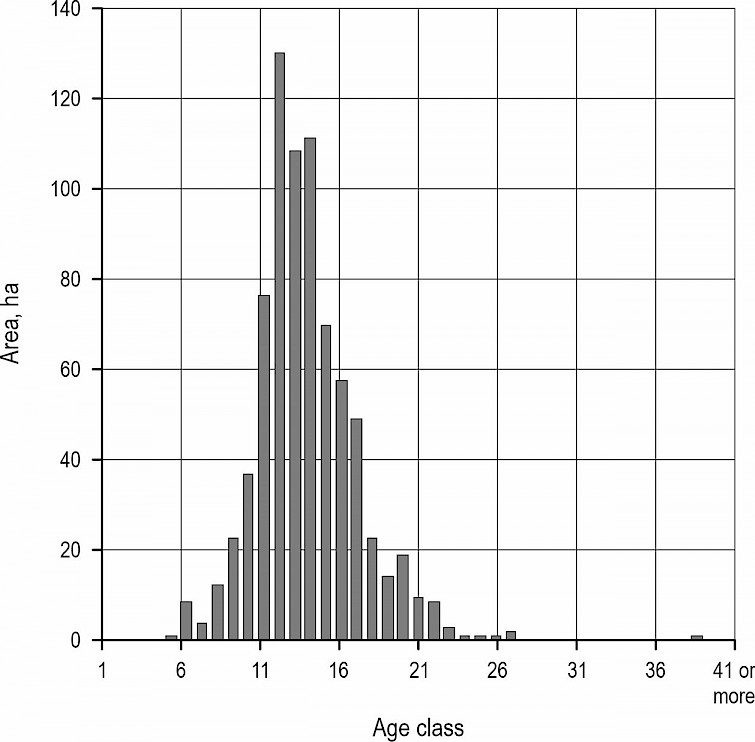

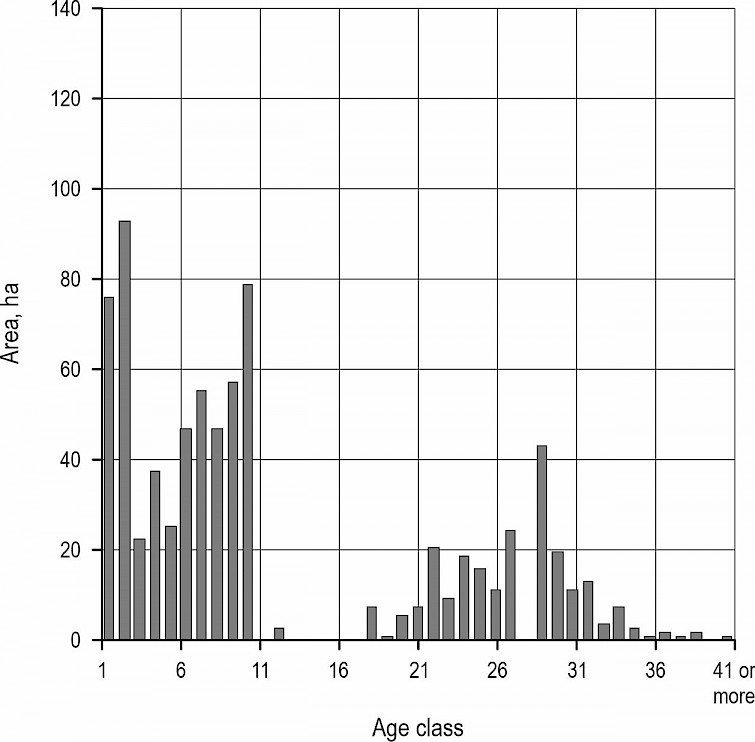

This study selected three candidate sites, i.e., Site S (small), Site M (medium), and Site L (large), in order to use different total areas in the model and to evaluate the various scenarios (Table 2). The sites were located along a watershed, and intensive forest management was considered (Fig. 1). As an example, the age-class distribution of Site M at the beginning of simulation is shown in Fig. 2. The average stand age for Site M was 66 years old, and the area of forest stands of which the age-class was 11th or more (i.e., >50 years old and subject to final cutting) was 681 ha, occupying nearly 90% of the total forest area.

Table 2 Description of small (S), medium (M), and large (L) candidate sites

|

Item |

Site S |

Site M |

Site L |

|

Planted forest area, ha |

616 |

763 |

932 |

|

No. of stands |

1058 |

1351 |

1724 |

|

Rate of planted forest area to the total area, % |

91 |

94 |

93 |

Fig. 1 Three sites (S [small], M [medium], and L [large]) located along a watershed, with consideration of intensive forest management

Fig. 2 Age-class distribution of planted forests at Site M at the beginning of the simulation

To calculate the operation amount of log production, this study determined the single-tree volume using the volume equation for Japanese cedar (Cryptomeria japonica D. Don) (Inoue 2006) with reference to tree height and diameter at breast height (Kobayashi et al. 2021). These parameters were based on the stand age.

2.2 Estimation of Amounts of Log Production and Unutilized Forest Biomass Generation

The amounts of log production and unutilized forest biomass generation were estimated from the area, S (ha), or the harvested stem volume, V (m3), of the stands targeted for cleaning, pre-commercial thinning, commercial thinning, final cutting, and long-term cutting. In this study, unutilized forest biomass was considered to consist of small-diameter trees, unutilized thinnings, and logging residues. The equations used for these estimations are given in Table 3. These equations were established based on the local forest-management master plan. Trees felled during a cleaning operation were considered small-diameter trees. In the pre-commercial thinning stage, 10 m3 per ha of operation area was harvested as unutilized thinnings, and the remaining felled trees were considered small-diameter trees. Here, the unutilized thinnings are not essentially different from small-diameter trees, but in the FIT scheme the harvested thinnings are assumed to qualify as »unused forest biomass«.

Table 3 Equations used for estimating the amounts of log production and unutilized forest biomass generation

|

Operation |

Resource |

Equation * |

|

|

Cleaning |

Small-diameter trees |

V × 1.57 × 0.314, Mg |

|

|

Pre-commercial thinning |

Unutilized thinnings |

S × 10 × 0.314, Mg |

|

|

Small-diameter trees |

V × 1.57 × 0.314 – S × 10 × 0.314, Mg |

||

|

Commercial thinning |

Logging residues |

V × 0.25 × 0.314, Mg |

|

|

Unutilized thinnings |

V × 0.98 × 0.4 × 0.314, Mg |

||

|

Log |

V × 0.98 × 0.6, m3 |

||

|

Final cutting and long-term cutting |

Logging residues |

V × 0.30 × 0.314, Mg |

|

|

Log |

V × 0.93, m3 |

||

|

* The mass values of forest biomass resources are expressed on a dry-weight basis (Mg: megagram) S – area, ha V – harvested stem volume, m3 Mass of 1 m3 of Japanese cedar is 0.314 Mg/m3 on a dry basis. The percentage of branches to stem volume for the cleaning and pre-commercial thinning stages and that for the commercial thinning and final and long-term cutting stages are 57% and 23%, respectively, while the percentage of tree tops and others (e.g., bent or butt logs) to stem volume for the commercial thinning and final and long-term cutting stages are 2% and 5%, respectively (Forest and Forest Products Research Institute n.a.). |

|||

In the case of commercial thinning, the model assumed that tree tops (2% to stem volume) and branches (23%) generated during limbing and bucking would become logging residues (25%), while the remaining portion (98%) would be unutilized thinnings (40% of the remaining portion) and logs (60% of the remaining portion), based on an interview with a company that produced wood chips for power-generation plants. In the final and long-term cutting operations, the tree tops (2% to stem volume), branches (23%), and others (e.g., bent or butt logs; 5%) generated during limbing and bucking were considered logging residues (30%), and the other parts (93%) were considered logs.

3. Results

3.1 Appropriate Planted Forest Area for Sustainable Forest Management

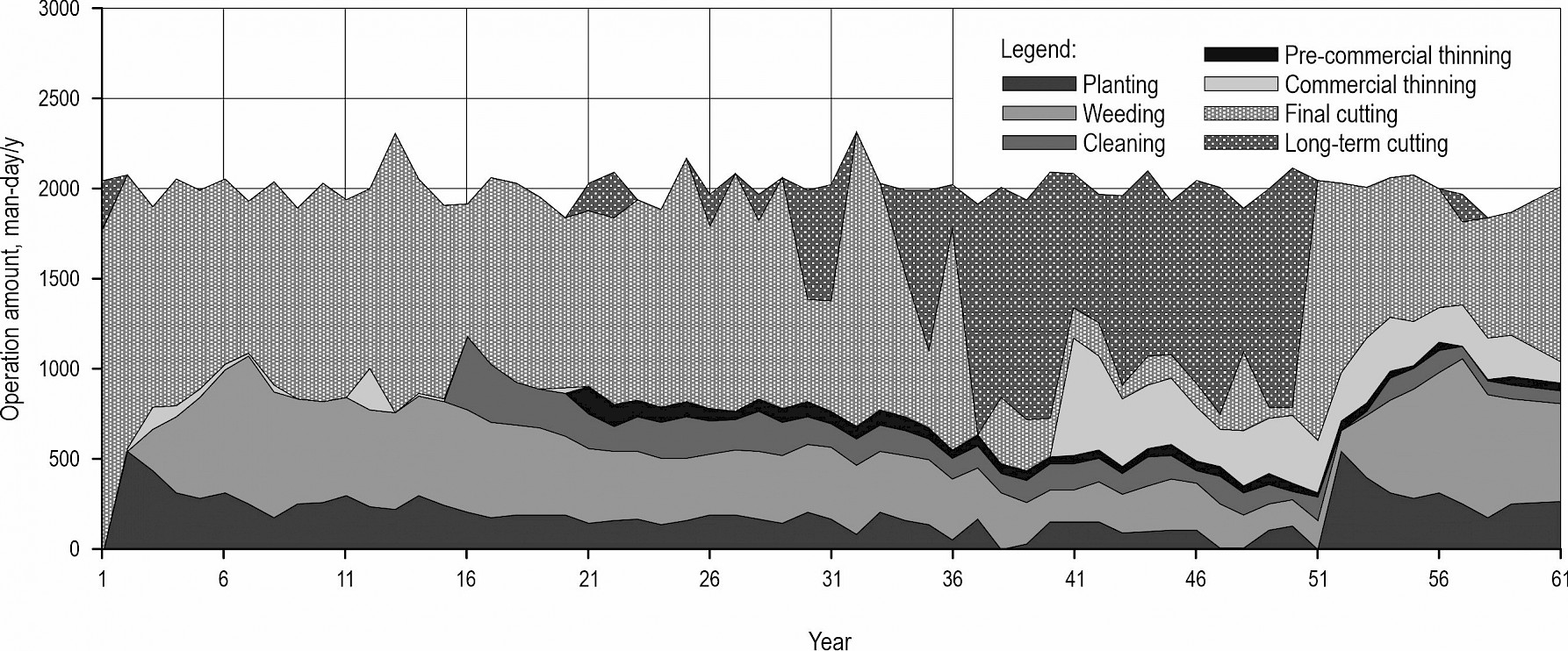

As a result of the optimization, the annual operation amount for each year was balanced against the constrained labor input at all three sites. The average amounts of operation at Sites S, M, and L were 1984±103.6, 2013±89.49, and 1983±93.84 man-day/y, respectively. Fig. 3 shows the details of the operation amounts at Site M. In the first half of the 60-year period, final cutting was the main business, and long-term cutting gradually increased. After the 50th year, the final cutting increased again.

Fig. 3 Details of operation amounts at Site M

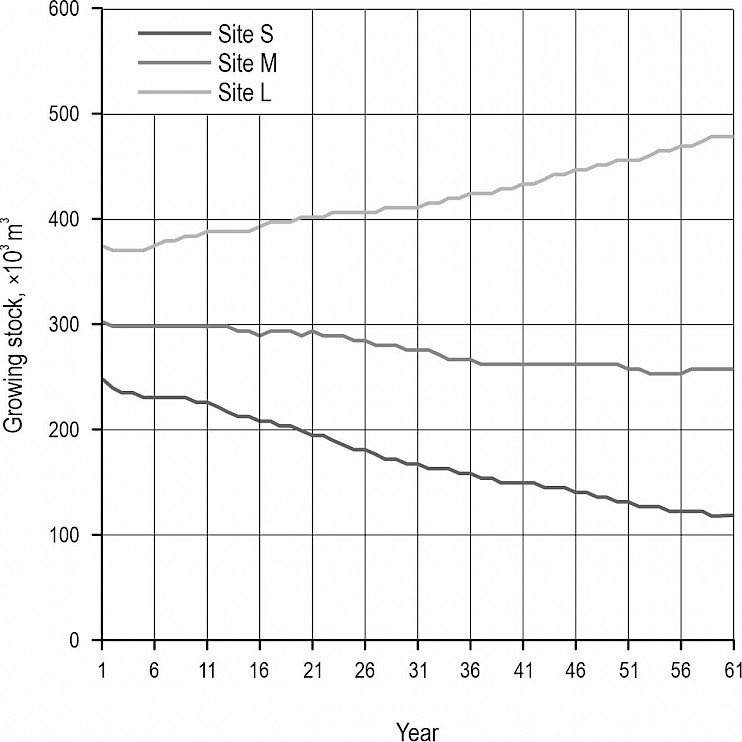

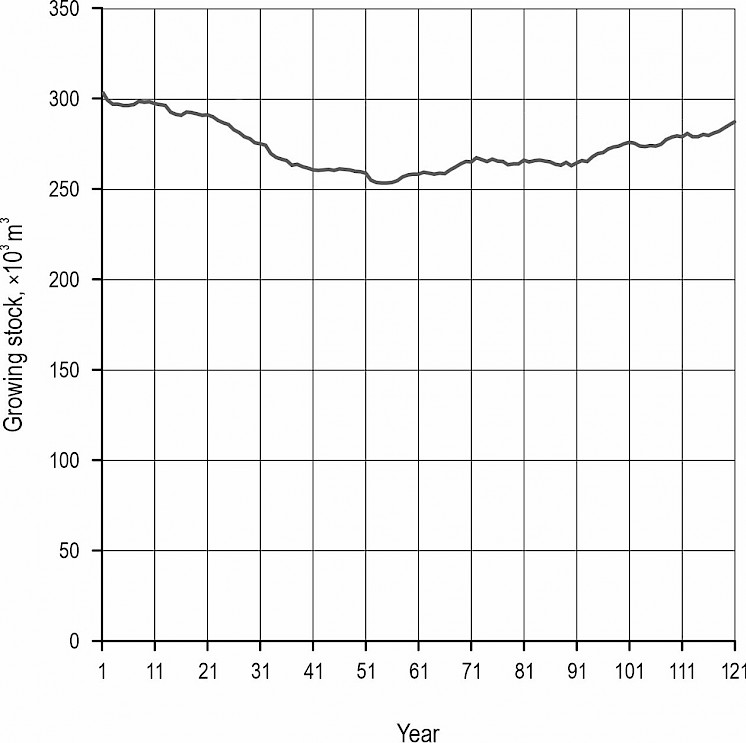

The changes in the growing stock, i.e., the total stem volume of standing trees, of the three sites are depicted in Fig. 4. From the beginning of the simulation, the Site M growing stock gradually decreased due to the clearcutting of older planted forests, but it began to stabilize around the 40th year, thus suggesting that approx. 760 ha of planted forest could be an appropriate size of the area for sustainable forest management with a labor input of roughly 2000 man-day/y.

Fig. 4 Changes in growing stock of three sites

The results derived from the above calculations can be interpreted as follows: Mature forest stands belonging to the 21st class or more (>100 years old) are subject to long-term cutting and serve as backup forests when the amount of operation is insufficient in the first stage of optimization. Site M has a certain amount of backup forest so that business can continue sustainably without a shortage of forest resources.

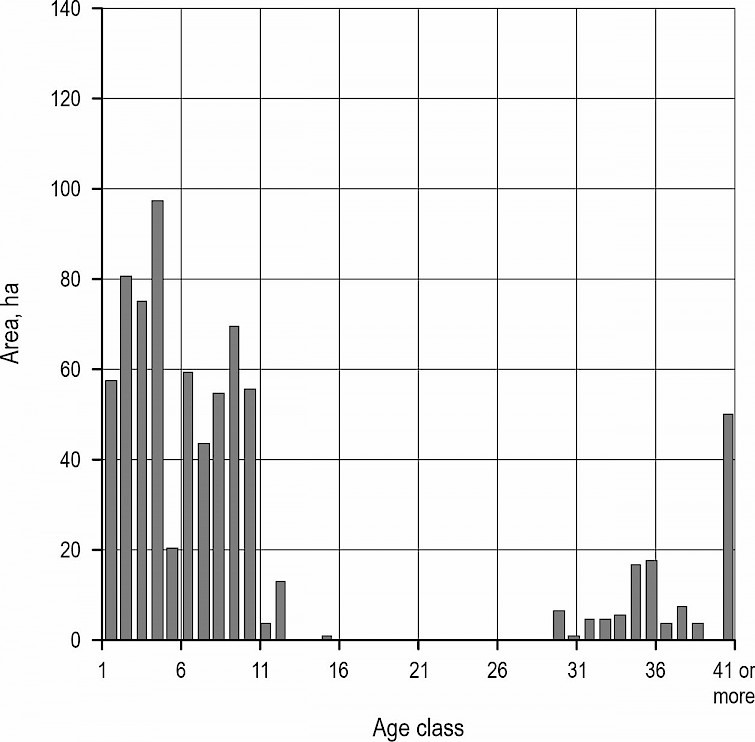

Fig. 5 illustrates the age-class distribution of Site M at the 60th year (the end of the simulation). After 60 years, compared to Fig. 2, the clearcutting in the forest stands from the 11th to the 20th age class was almost completed, and only 2% (15 ha) of the total area of the planted forest remained for a final cutting operation, while 27% (207 ha) was transferred to the forest stands for long-rotation management.

Fig. 5 Site M age-class distribution at the 60th year

3.2 Amounts of Log Production and Unutilized Forest Biomass Generation

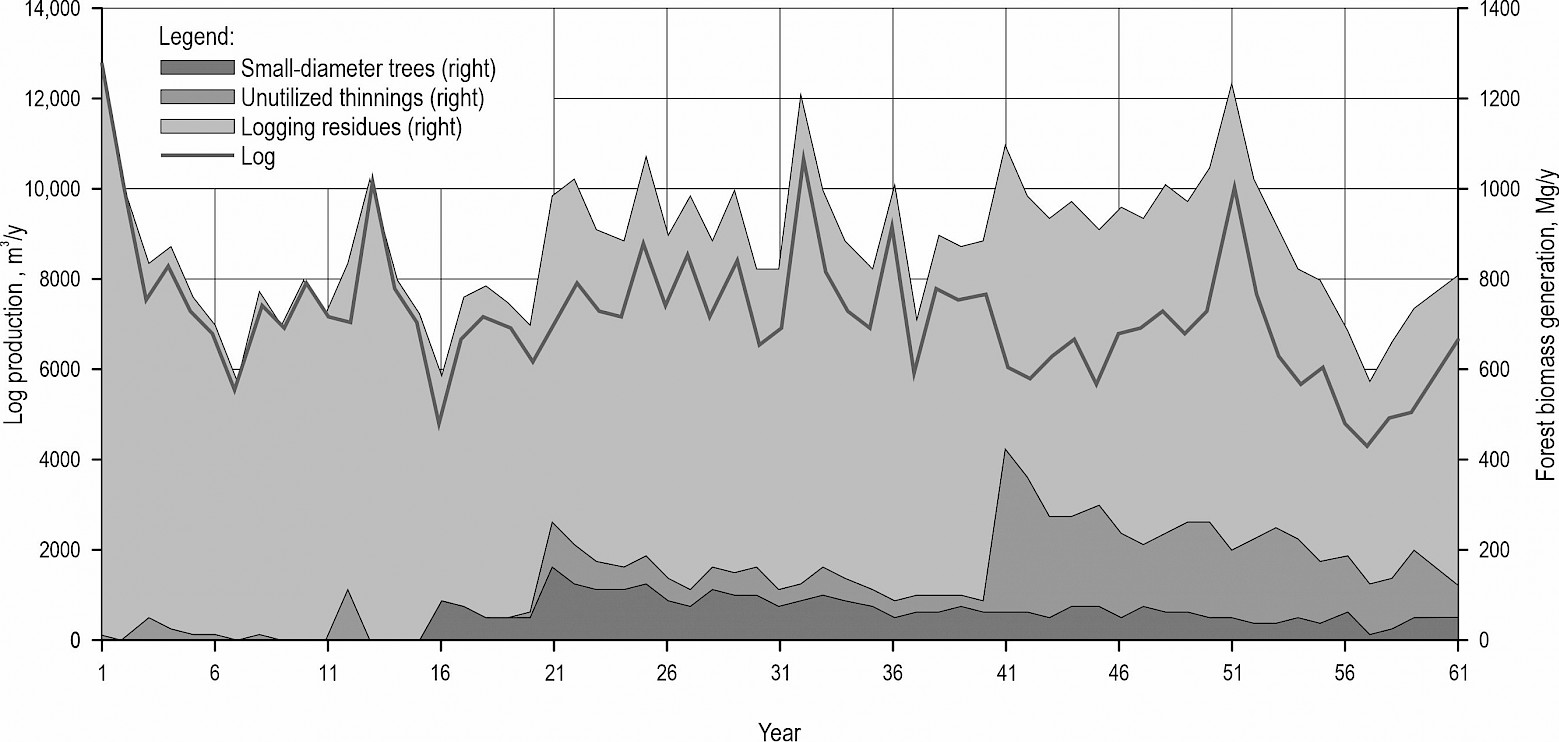

The changes in the annual amounts of log production and unutilized forest biomass generation at Site M are shown in Fig. 6. During the simulation, 7184±1474 m3/y of logs was produced, and 875.6±152.4 Mg/y of unutilized forest biomass (56.50±40.87 Mg/y for small-diameter trees, 82.69±81.80 Mg/y for unutilized thinnings, and 736.5±145.4 Mg/y for logging residues on a dry-weight basis) was generated. These amounts can be interpreted as the log production and unutilized forest biomass generation in the process of promoting the clearcutting of 763 ha of planted forest with the average age of 66 years, ~2000 man-day/y of labor input and 71% of the whole area returning to the regular harvesting cycle.

Fig. 6 Changes in annual amounts of log production and unutilized forest biomass generation

4. Discussion

The results obtained above can be interpreted as the amounts of log production and unutilized forest biomass generation during the process of clearcutting of older, high-accumulation planted forests and the return of many forests to the regular harvesting cycle over a 60-year period. This study thus extended the Site M simulation by using the »regional forestry operation management model« to the 120th year, and calculated the amounts of logs and forest biomass resources generated under sustainable forest management as well.

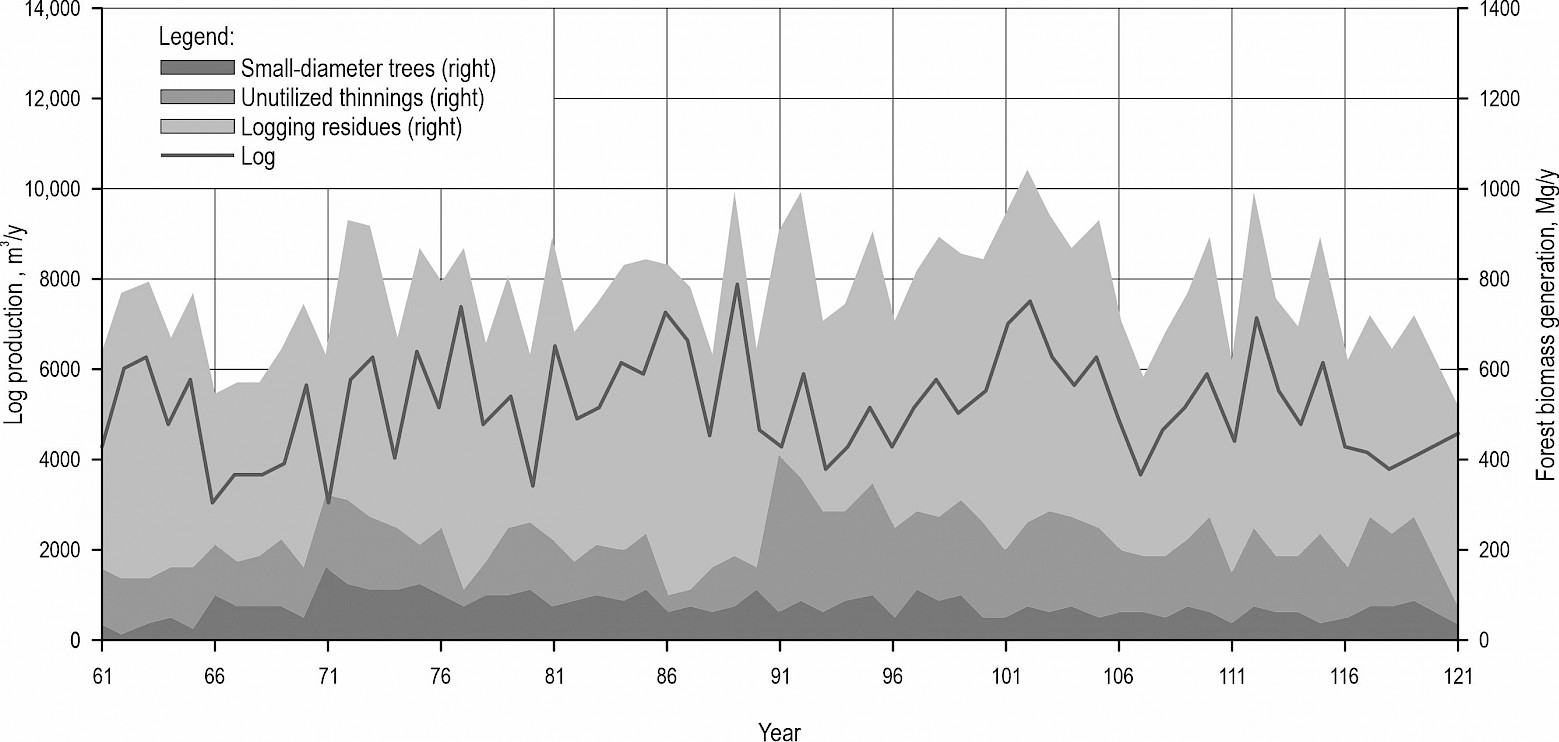

Fig. 7 lays out the changes in the growing stock over a 120-year period, and the age-class distribution at the 120th year is shown in Fig. 8. The growing stock increased slowly during the next 60 years, and after 120 years, 19 ha of the forest area was subject to final cutting and 125 ha of the forest area was subject to long-term cutting, with 78 ha newly returned to the regular harvesting cycle. From 61 to 120 years, 5239±1149 m3/y of logs was produced and 774.8±125.0 Mg/y of unutilized forest biomass (79.55±27.06 Mg/y for small-diameter trees, 147.4±55.86 Mg/y for unutilized thinnings, and 547.8±115.3 Mg/y for logging residues on a dry-weight basis) was generated (Fig. 9). These amounts can be interpreted as the established log production and unutilized forest biomass generation under sustainable forest management under the coexistence of the circulation of planted forest and the long-rotation forest management, while maintaining the growing stock of local forest resources. Both the log production and the biomass generation from 61 to 120 years decreased compared to those of the original 60-year period, probably due to the fact that the clearcutting of older, high-accumulation planted forests had settled down by the 60th year, resulting in a decrease in log production and the resulting generation of logging residues over the 60-year period up to the 120th year.

Fig. 7 Changes in Site M growing stock over a 120-year period

Fig. 8 Site M age-class distribution at the 120th year

Fig. 9 Changes in annual amounts of log production and unutilized forest biomass generation from 61 to 120 years

The period and the ratio to the whole biomass resources of the generation of small-diameter trees and unutilized thinnings were influenced by two factors:

there were few forest stands subject to cleaning, pre-commercial thinning, and commercial thinning at the beginning of the simulation

planting began 1 year after final cutting.

Therefore, the major generation of small-diameter trees began in the 16th year when the cleaning operation started, and the major generation of unutilized thinnings began in the 41st year when the commercial thinning operation started (see Fig. 6). The average amounts of small-diameter trees and unutilized thinnings generated during the original 60 years was lower than that of logging residues. However, small-diameter trees and unutilized thinnings were generated stably from the 16th year and the 41st year, respectively, after the beginning of clearcutting and subsequent reforestation. Especially after the 61st year shown in Fig. 9, the average amount of the generation of small-diameter trees, 79.55 Mg/y, accounted for approx. 10% of the amount of the whole biomass resources, i.e., 774.8 Mg/y, and >50% of the amount of unutilized thinnings, 147.4 Mg/y, providing precise estimates of the resource amount of small-diameter trees.

Although the developed model targeted Japanese cedar plantation, the model could be applied to hardwood forests by correcting parameters and reconsidering logging systems. However, it might be difficult for the hardwood forests model to introduce the process of harvesting small-diameter trees with a truck-mounted multi-tree felling head studied by the authors of this paper (Yoshioka et al. 2021), since the previous study considered just the model forest for small-diameter trees. This study found that a company with 10 workers could sustainably manage 763 ha of plantation forest, meaning that more than 26 companies would be needed to cover a total area of 20,147 ha, but this study has never discussed the profitability. In the case of Japan, it is generally said that the profitability of logging business must be improved to encourage new companies to enter the business, thus further discussion on profitability in the studied area would be necessary.

5. Conclusions

In anticipation of the utilization of logging residues and small-diameter trees after the completion of the Feed-in Tariff Scheme for Renewable Energy (FIT) in Japan, this study calculated the available amount of unutilized forest biomass resources over a long term by using the developed »regional forestry operations management model«, and estimated the period and the ratio of the generation of small-diameter trees during cleaning and pre-commercial thinning operations to the whole biomass resources. The following conclusions have been derived from the results and discussion:

the developed model simulated that, in the first 60 years, the clearcutting and reforestation of 763 ha of planted forests (average age 66 years) with labor input of approx. 2000 man-days per year were promoted, and thus 71% of the whole area was returned to the regular harvesting cycle. During that period, the average amounts of log production and biomass generation were 7184 m3/y and 875.6 Mg/y on a dry-weight basis, respectively

during the next 60 years, when the clearcutting of older, high-accumulation forests and subsequent reforestation were stabilized, the average amounts of log production and biomass generation under sustainable forest management were 5239 m3/y and 774.8 Mg/y on a dry-weight basis, respectively, at lower amounts than those in the first 60 years

small-diameter trees and unutilized thinnings were generated stably from the 16th year and the 41st year, respectively, after the beginning of clearcutting and subsequent reforestation. Especially after the 61st year, the average amount of small-diameter tree generation accounted for approx. 10% of the amount of the whole biomass resources and >50% of that of unutilized thinnings, providing precise estimates of the resource amount of small-diameter trees.

Acknowledgements

This study was financially supported in part by JSPS KAKENHI Grant Number JP20K06121.

Conflicts of Interest

The authors declare no conflict of interest. The funding sponsor had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

6. References

Anon., 2005: Appendix: Biomass-Nippon Strategy (Provisional Translation) Decided at the Cabinet Meeting, Government of Japan, December 27, 2002. Biomass Bioenerg. 29(5): 375–398. https://doi.org/10.1016/j.biombioe.2005.06.002

Aruga, K., Hiyamizu, G., Nakahata, C., Saito, M., 2013: Effects of aggregating forests, establishing forest road networks, and mechanization on operational efficiency and costs in a mountainous region in Japan. J. For. Res. Chn. 24(4): 747–754. https://doi.org/10.1007/s11676-013-0414-1

Belbo, H., 2010: Comparison of two working methods for small tree harvesting with a multi tree felling head mounted on farm tractor. Silva Fenn. 44(3): 453–464. https://doi.org/10.14214/sf.142

Bergström, D., Bergsten, U., Hörnlund, T., Nordfjell, T., 2012: Continuous felling of small diameter trees in boom-corridors with a prototype felling head. Scand. J. For. Res. 27(5): 474–480. https://doi.org/10.1080/02827581.2012.663404

Buongiorno, J., 1996: Forest sector modeling: A synthesis of econometrics, mathematical programming, and system dynamics methods. Int. J. Forecast. 12(3): 329–343. https://doi.org/10.1016/0169-2070(96)00668-1

de Souza, D.P.L., Gallagher, T., Mitchell, D., McDonald, T., Smidt, M., 2016: Determining the effects of felling method and season of year on the regeneration of short rotation coppice. Int. J. For. Eng. 27(1): 53–65. https://doi.org/10.1080/14942119.2015.1135616

Erber, G., Holzleitner, F., Kastner, M., Stampfer, K., 2016: Effect of multi-tree handling and tree-size on harvester performance in small-diameter hardwood thinnings. Silva Fenn. 50(1): 1428. https://doi.org/10.14214/sf.1428

Forestry and Forest Products Research Institute, n.a.: Amount of carbon fixed in one tree. Available online: https://www.ffpri.affrc.go.jp/research/dept/22climate/kyuushuuryou/documents/page1-2-per-a-tree.pdf (accessed 7 March 2025)

Fukumoto, K., Ota, T., Mizoue, N., Iwanaga, F., Yoshida, S., Teraoka, Y., Kajisa, T., 2017: Effect of weeding frequency, slope aspect and initial tree density on the mortality and accidental cutting of planted Sugi (Cryptomeria japonica) trees: A case study in the Kagoshima University Research Forest, southwestern Japan. Jpn. J. For. Plan. 51(1): 1–7. https://doi.org/10.20659/jjfp.51.1_1

Górriz-Mifsud, E., Olza Donazar, L., Montero Eseverri, E., Marini Govigli, V., 2019: The challenges of coordinating forest owners for joint management. For. Policy. Econ. 99: 100–109. https://doi.org/10.1016/j.forpol.2017.11.005

Han, H.S., Lee, H.W., Johnson, L.R., 2004: Economic feasibility of an integrated harvesting system for small-diameter trees in southwest Idaho. For. Prod. J. 54(2): 21–27.

Hiesl, P., Benjamin, J.G., 2013: A multi-stem feller-buncher cycle-time model for partial harvest of small-diameter wood stands. Int. J. For. Eng. 24(2): 101–108. https://doi.org/10.1080/14942119.2013.841626

Hiroshima, T., 2011: Calculation of yields on a national level by combining yields of each prefecture using the Gentan probability. J. For. Res.Jpn. 16(2): 98–107. https://doi.org/10.1007/s10310-010-0216-7

Inoue, A., 2006: Application of theoretical of volume equation to Japanese cedar. Appl. For. Sci. 15(1): 33–36. https://doi.org/10.20660/applfor.15.1_33

Kaneko, S., Kim, H.-B., Yoshioka, T., Nitami, T., 2023: Developing a model for managing sustainable regional forest biomass resources: System dynamics-based optimization. Biomass Bioenerg. 174: 106819. https://doi.org/10.1016/j.biombioe.2023.106819

Kaya, A., Bettinger, P., Boston, K., Akbulut, R., Ucar, Z., Siry, J., Merry, K., Cieszewski, C., 2016: Optimisation in forest management. Curr. For. Reports 2(1): 1–17. https://doi.org/10.1007/s40725-016-0027-y

Kobayashi, Y., Horiuchi, S., Suzuki, K.F., Mori, A.S., 2021: Tree height-diameter allometry of 75 major tree species in Japan. J. Jpn. For. Soc. 103(2): 168–171. https://doi.org/10.4005/jjfs.103.168

Kärhä, K., Jouhiaho, A., Mutikainen, A., Mattila, S., 2005: Mechanized energy wood harvesting from early thinnings. Int. J. For. Eng. 16(1): 15–25. https://doi.org/10.1080/14942119.2005.10702504

Laitila, J., Asikainen, A., Nuutinen, Y., 2007: Forwarding of whole trees after manual and mechanized felling bunching in pre-commercial thinnings. Int. J. For. Eng. 18(2): 29–39. https://doi.org/10.1080/14942119.2007.10702548

Laitila, J., Heikkilä, J., Anttila, P., 2010: Harvesting alternatives, accumulation and procurement cost of small-diameter thinning wood for fuel in Central Finland. Silva Fenn. 44(3): 465–480. https://doi.org/10.14214/sf.143

Lönnstedt, L., Randers, J., 1979: Wood Resource Dynamics in the Scandinavian Forest Sector. Swedish University of Agricultural Sciences: Uppsala, Sweden.

Machado, R.R., Conceição, S.V., Leite, H.G., de Souza, A.L.D., Wolff, E., 2015: Evaluation of forest growth and carbon stock in forestry projects by system dynamics. J. Clean. Prod. 96(1): 520–530. https://doi.org/10.1016/j.jclepro.2013.09.049

Ministry of Agriculture, Forestry and Fisheries, 2023: FY2022 Results of the Survey on Woody Biomass Energy Utilization Trends in Japan. Available online: https://www.maff.go.jp/j/tokei/kekka_gaiyou/mokusitu_biomass/r4/index.html (accessed 9 April 2024)

Nakajima, T., Nakajima, J., Shiraishi, N., 2018: An evaluation of the future prospect of the age class distribution of Japanese plantation forests based on labor requirements, harvested timber, and nursery tree supply. Jpn. J. For. Plan. 51(2): 57–67. https://doi.org/10.20659/jjfp.51.2_57

Nuutinen, Y., Petty, A., Bergström, D., Rytkönen, M., Di Fulvio, F., Tiihonen, I., Lauren, A., Dahlin, B., 2016: Quality and productivity in comminution of small-diameter tree bundles. Int. J. For. Eng. 27(3): 179–187. https://doi.org/10.1080/14942119.2016.1223926

Pan, F., Han, H.S., Johnson, L.R., Elliot, W.J., 2008a: Net energy output from harvesting small-diameter trees using a mechanized system. For. Prod. J. 58(1/2): 25–30

Pan, F., Han, H.S., Johnson, L.R., Elliot, W.J., 2008b: Production and cost of harvesting, processing, and transporting small-diameter (≤5 inches) trees for energy. For. Prod. J. 58(5): 47–53

Peng, C., 2000: Understanding the role of forest simulation models in sustainable forest management. Environ. Impact Assess. Rev. 20(4): 481–501. https://doi.org/10.1016/S0195-9255(99)00044-X

Schwarzbauer, P., Stern, T., 2010: Energy vs. material: Economic impacts of a »wood-for-energy scenario« on the forest-based sector in Austria–A simulation approach. For. Policy. Econ. 12(1): 31–38. https://doi.org/10.1016/j.forpol.2009.09.004

Spinelli, R., Cuchet, E., Roux, P., 2007: A new feller-buncher for harvesting energy wood: Results from a European test programme. Biomass Bioenerg. 31(4): 205–210. https://doi.org/10.1016/j.biombioe.2006.08.002

Spinelli, R., Magagnotti, N., 2010: Comparison of two harvesting systems for the production of forest biomass from the thinning of Picea abies plantations. Scand. J. For. Res. 25(1): 69–77. https://doi.org/10.1080/02827580903505194

Suzuki, K., Tatsuhara, S., Nakajima, T., Kanomata, H., Oka, M., 2018: Predicting effects of logging systems and bucking strategies for privately owned sugi (Cryptomeria japonica) plantations in Atsumi District, Tsuruoka City, Yamagata Prefecture. J. For. Plan. 24(2): 15–27. https://doi.org/10.20659/jfp.24.2_15

Troncoso, J.J., Garrido, R.A., 2005: Forestry production and logistics planning: An analysis using mixed-integer programming. For. Policy. Econ. 7(4): 625–633. https://doi.org/10.1016/j.forpol.2003.12.002

Vanclay, J.K., 2014: Unsuspected implications arising from assumptions in simulations: Insights from recasting a forest growth model in system dynamics. For. Ecosyst. 1: 1–10. https://doi.org/10.1186/2197-5620-1-7

Visser, R.J.M., McDonagh, K.D., Meller, R.D., McDonald, T.P., 2004: Harvesting system simulation using a systems dynamic model. South J. Appl. For. 28(2): 91–99. https://doi.org/10.1093/sjaf/28.2.91

Yamada, Y., 2018: Can a regional-level forest management policy achieve sustainable forest management? For. Policy. Econ. 90: 82–89. https://doi.org/10.1016/j.forpol.2018.01.013

Yoshioka, T., 2021: Current situation and future outlook of forest biomass production and its utilization in Japan. In Biotechnological Applications of Biomass; Basso, T.P., Basso, T.O., Basso, L.C., Eds.; IntechOpen: London, UK, 129–147 p. http://dx.doi.org/10.5772/intechopen.93433

Yoshioka, T., Aruga, K., Nitami, T., Kobayashi, H., Sakai, H., 2005a: Energy and carbon dioxide (CO2) balance of logging residues as alternative energy resources: System analysis based on the method of a life cycle inventory (LCI) analysis. J. For. Res.-Jpn. 10(2): 125–134. https://doi.org/10.1007/s10310-004-0126-7

Yoshioka, T., Aruga, K., Nitami, T., Sakai, H., Kobayashi, H., 2006a: A case study on the costs and the fuel consumption of harvesting, transporting, and chipping chains for logging residues in Japan. Biomass Bioenerg. 30(4): 342–348. https://doi.org/10.1016/j.biombioe.2005.07.013

Yoshioka, T., Aruga, K., Sakai, H., Kobayashi, H., Nitami, T., 2002: Cost, energy and carbon dioxide (CO2) effectiveness of a harvesting and transporting system for residual forest biomass. J. For. Res.-Jpn. 7(3): 157–163. https://doi.org/10.1007/BF02762605

Yoshioka, T., Hirata, S., Matsumura, Y., Sakanishi, K., 2005b: Woody biomass resources and conversion in Japan: The current situation and projections to 2010 and 2050. Biomass Bioenerg. 29(5): 336–346. https://doi.org/10.1016/j.biombioe.2004.06.016

Yoshioka, T., Iwaoka, M., Sakai, H., Kobayashi, H., 2000: Feasibility of a harvesting system for logging residues as unutilized forest biomass. J. For. Res.-Jpn. 5(2): 59–65. https://doi.org/10.1007/BF02762520

Yoshioka, T., Sakai, H., 2005c: Amount and availability of forest biomass as an energy resource in a mountainous region in Japan: A GIS-based analysis. Croat. J. For. Eng. 26(2): 59–70.

Yoshioka, T., Sakurai, R., Aruga, K., Nitami, T., Sakai, H., Kobayashi, H., 2006b: Comminution of logging residues with a tub grinder: Calculation of productivity and procurement cost of wood chips. Croat. J. For. Eng. 27(2): 103–114.

Yoshioka, T., Sakurai, R., Aruga, K., Sakai, H., Kobayashi, H., Inoue, K., 2011: A GIS-based analysis on the relationship between the annual available amount and the procurement cost of forest biomass in a mountainous region in Japan. Biomass Bioenerg. 35(11): 4530–4537. https://doi.org/10.1016/j.biombioe.2011.03.029

Yoshioka, T., Tomioka, T., Nitami, T., 2021: Feasibility of a harvesting system for small-diameter trees as unutilized forest biomass in Japan. Forests 12(1): 74. https://doi.org/10.3390/f12010074

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Assoc. prof. Takuyuki Yoshioka, PhD *

e-mail: tyoshioka@fr.a.u-tokyo.ac.jp

Former Graduate Student Shunsuke Kaneko, MSc

e-mail: dpedr01a@outlook.jp

Former Assoc. prof. Toshio Nitami, PhD

e-mail: toshio.nitami@gmail.com

The University of Tokyo

Graduate School of Agricultural and Life Sciences

Department of Forest Science

1-1-1 Yayoi, Bunkyo-ku

Tokyo 113-8657

JAPAN

Assist. prof. Hyun-Bae Kim, PhD

e-mail: hyunbae.kim27@gmail.com

Chungnam National University

College of Agriculture and Life Sciences

Department of Environmental Materials Engineering

99 Daehak-ro, Yuseong-gu

Daejeon 34134

REPUBLIC OF KOREA

* Corresponding author

Received: April 09, 2024

Accepted: March 07, 2025

Preliminary note

11