Effect of Excavator Design on Performances, Costs, and Environmental Impact in Harvesting Operations

doi: https://doi.org/10.5552/crojfe.2025.2587

volume: issue, issue:

pp: 14

- Author(s):

-

- Bertone Federico

- Manzone Marco

- Article category:

- Original scientific paper

- Keywords:

- excavators, productivity, fuel consumption, energy cost, CO2 emission, costs

Abstract

HTML

The harvesting of low-value trees, primarily utilized for energy production, demands heightened productivity and reduced costs, necessitating the adoption of mechanized methods. Excavators are frequently employed in mechanized harvesting due to their affordability (often being used machines) and high adaptability. However, their operation often results in tree damage when swinging the upper structure. Consequently, recent advancements have led to the development and utilization of machines with smaller footprints, primarily applied in urban settings, aiming to enhance maneuverability.

This study aimed to analyze the operational and environmental benefits of employing reduced-tail swing excavators in forestry operations in contrast to conventional tail swing excavators. In thinning operations, the productivity of the reduced-tail swing excavator surpasses that of the conventional tail swing excavator by 18.5%, accompanied by a 41.8% reduction in fuel consumption. Moreover, the reduced-tail swing excavator exhibits a 41% decrease in energy consumption, resulting in a notable 65.8% reduction in CO2 emissions compared to its conventional counterpart. Additionally, the hourly operational cost is 10% lower than that of the conventional tail excavator.

While comparing the performance of both machines in clear-cutting, the differences observed are less than 5% and deemed statistically insignificant. Hence, it can be inferred that reduced-tail swing excavators present a viable alternative to conventional-tail excavators.

Effect of Excavator Design on Performances, Costs, and Environmental Impact in Harvesting Operations

Federico Bertone, Marco Manzone

https://doi.org/10.5552/crojfe.2025.2587

Abstract

The harvesting of low-value trees, primarily utilized for energy production, demands heightened productivity and reduced costs, necessitating the adoption of mechanized methods. Excavators are frequently employed in mechanized harvesting due to their affordability (often being used machines) and high adaptability. However, their operation often results in tree damage when swinging the upper structure. Consequently, recent advancements have led to the development and utilization of machines with smaller footprints, primarily applied in urban settings, aiming to enhance maneuverability.

This study aimed to analyze the operational and environmental benefits of employing reduced-tail swing excavators in forestry operations in contrast to conventional tail swing excavators. In thinning operations, the productivity of the reduced-tail swing excavator surpasses that of the conventional tail swing excavator by 18.5%, accompanied by a 41.8% reduction in fuel consumption. Moreover, the reduced-tail swing excavator exhibits a 41% decrease in energy consumption, resulting in a notable 65.8% reduction in CO2 emissions compared to its conventional counterpart. Additionally, the hourly operational cost is 10% lower than that of the conventional tail excavator.

While comparing the performance of both machines in clear-cutting, the differences observed are less than 5% and deemed statistically insignificant. Hence, it can be inferred that reduced-tail swing excavators present a viable alternative to conventional-tail excavators.

Keywords: excavators, productivity, fuel consumption, energy cost, CO2 emission, costs

1. Introduction

Many forests in Southern Europe have been neglected in recent years, owing primarily to rural migration to cities and the use of fossil fuels instead of firewood (Buckley 2020). In the last two decades there has been a renewed interest in forests, particularly in the protective, ecological, cultural and social functions associated with the health of forests themselves (Spiecker 2003). Furthermore, increased fossil fuel prices contributed to an increase in the use of wood as an energy vector (Schweier et al. 2015). In addition, forest treatments, such as thinning, are often used to increase resistance to abiotic damages, pests and diseases. By removing less valuable trees that inhibit the growth of preferred tree species, the remaining trees grow faster (Jiroušek et al. 2007). While the trees can consolidate the river bank (Abernethy and Rutherfurd 2001), they can also obstruct the waterway (Wipf et al. 2012), making it necessary to manage the trees on the banks. Working conditions in these forests are unfavourable: the trees are often small, branched and often crooked, and the terrain is generally rough (Suchomel et al. 2011). The low-value trees harvested are characterized by low productivity and high manual input. Therefore, it is necessary to resort to mechanized felling by increasing productivity (Jiroušek et al. 2007, Spinelli et al. 2016), reducing costs (Picchio et al. 2009), increasing operator safety and reducing all fatal risks associated with motor manual felling operations (Bell 2002, Albizu-Urionabarrenetxea et al. 2013). The transition from manual to mechanized operations is based on two pillars: first, a significant reduction in manual inputs; secondly, the use of general-purpose machines adapted to forestry work, rather than more expensive purpose-built machine forestry equipment (Spinelli et al. 2021). Tracked excavators are the most widely used general-purpose machines (Laitila and Väätäinen 2021, Laitila and Väätäinen 2023). The excavators are preferred because they can offer good productivity (Nakagawa et al. 2010) and a lower purchase price than the purpose-built machines (Laitila and Väätäinen 2023) and often second-hand general-purpose machines are bought. In addition, the versatility of the machines means that they can be used all year round, removing the harvesting equipment and using the basic machine for the work for which it was originally designed (Väätäinen et al. 2004, Laitila and Väätäinen 2013). Typical excavators used for harveting are medium-size excavators (13–16 tonnes) (Bergroth et al. 2006). Firms that process hardwood to produce firewood or woodchip use a feller head or a grapple-saw because broadleaf trees often present heavy branching (Magagnotti et al. 2013). Feller heads are more compact than harvester heads and have a lower purchase price (Schweier et al. 2015).

Common tasks where excavators can be used in the forest include ditching, forest road construction and site preparation (Bergroth et al. 2006). Excavators are also preferred because they are equipped with tracks, which reduce ground pressure and damages caused to the ground (Bergroth et al. 2006) compared to wheeled machines. In fact, the ground pressure can cause root and soil damage (Vasiliauskas 2001, Spinelli et al. 2014). For these reasons, it is suggested that ground contact pressure of machines that move in forests should be no more than 50 kPa (Kormanek and Dvořák 2021). With excavators, however, arm operation requires the upper structure to rotate, which causes the machine to rotate and increases the footprint, which can damage trees in the forest, reducing their economic value (Hartsough 2003), and increasing the spread of wounding pathogens (Vasiliauskas 2001). In fact, operators have difficulty detecting the presence of objects, people or other machinery in blind spots. The blind spot that causes most of the collisions and accidents is the rear swing radius (Bedi et al. 2021), whereas on purpose-built harvesters, only the arm can rotate, and sometimes the arm and cab can rotate together (Gerasimov and Sokolov 2009). In recent times, machines with smaller overall dimensions have been specifically designed to reduce the maneuvering area of the upper structure, thereby enhancing maneuverability within confined spaces at construction sites, notably in urban areas (Väätäinen et al. 2004, Bergroth et al. 2006), while maintaining similar load capacity. This design variation allows excavators to be categorized by their tail swing radius: conventional or reduced (short tail). Reduced tail swing excavators are those with a rotating upper structure capable of swinging within 120% of the width of the undercarriage. It is common practice to utilize second-hand excavators to lower the purchase price of the machines (Spinelli et al. 2021), although these typically feature a conventional tail swing configuration.

To determine the viability of reduced-tail excavators as a potential alternative to conventional tail excavators in forestry, particularly in thinning to minimize damage to remaining trees, this study aimed to analyze the operational advantages of using a reduced-tail excavator in forestry operations compared to a conventional tail excavator. Specifically, productivity, damage to the remaining trees, and fuel consumption were analyzed. Fuel consumption has a significant environmental impact; thus, comparisons were made regarding energy consumption and CO2 emissions. Lastly, hourly costs were assessed to establish the economic advantage of using the reduced-tail excavator compared to the conventional-tail excavator.

2. Materials and Methods

2.1 Sites and Stand Characteristics

Tests were carried out in coppice forest, in two different sites in Piedmont in Northwest Italy, using two different excavators by tail swing: conventional and reduced. The first site was a Querco-carpinetum with a slope lower than 1%, the species were Quercus robur L. (50%), Carpinus betulus L. (30%) and Robinia pseudoacacia L. (20%) and the average DBH (diameter at breast height) of the trees felled was 0.15 m. The second site was a riparian forest with 45% slope, the species were Salix spp. and Populus spp. and the average DBH was 0.30 m. Each excavator was tested in 4 plots for each site; the first one was used to familiarize with the stand, and it was not considered for the trial, while the other three were used for the replications (Spinelli et al. 2023). The plots were square (30×30 m) and the average number of trees inside the plot was 53, while in the riparian forest it was 48 equal to 589 and 533 trees per hectare, respectively.Trees with half of their diameter within the plot edge were considered inside, otherwise outside. Considering forest treatments, thinning was applied in the first site and clear-cut in the second. In the thinning operation, 30% of the trees were removed. All the trees were felled with with the excavator-mounted feller head, starting from the middle of the edge of the plot, after which they were bunched and subsequently skidded by the excavator in the centre of the side of the plot, in order to crate a single stack for each plot (Table 1).

Table 1 Sites description

|

Site |

Number of plot, n |

Plot size, m |

Number of trees, n |

Species |

Average DBH, cm |

Treatment |

Slope |

|

#1 |

3+1 |

30x30 |

53 |

Quercus robur L. Carpinus betulus L. Robinia pseudoacacia L. |

15 |

Thinning |

<1% |

|

#2 |

3+1 |

30x30 |

48 |

Salix spp. Populus spp. |

30 |

Clear-cut |

45% |

The trees were cross-cut using the feller head, resulting in logs of 4 m length (±0.5 m). A defined quality standard ensured consistent work for both operators, aiming for stable stacks and facilitating subsequent chipping operations. Logs and branches were required to have a predominant orientation, limiting any protrusion to within 1 m on any side. Completion of all phases, from tree felling to stacking, occurred within 2 days to prevent moisture content loss and subsequent weight reduction.

Additionally, throughout the entire test period, there was no rainfall, potentially impacting the study's results.

2.2 Description of Machines and Operators

The excavators utilized in the study differed in their design: conventional tail-swing and reduced tail-swing. Morover the excavators used in the study were selected on the basis of their technical characteristics: gross mass and nominal power. In particular their gross mass was selected according to the range (13–16 tonnes) established by Bergroth for excavator used in forestry . The gross mass considered is the operating weight, including working equipment and all the safety devices necessary for carrying out forestry work. In order to avoid differences, the machines were of the same nominal power. Machines with the same type of boom (mono-boom) were also selected to reduce variabiles. Both the excavators used in this study were equipped with the same feller heads.

Additionally, to mitigate performance discrepancies arising from mechanical wear, the machines were required to have operated for fewer than 3000 hours at the time of testing . The selection of operators was also a crucial factor; each operator had a minimum of 500 hours of experience working with their respective machines before the start of the trials, they had to be skilled and competent, and they were instructed to work at their normal speed (Spinelli et al. 2019). The operators had to be experts in using the excavator for the type of work being carried out in the trials. This choice was necessary for greater efficiency during the different operations.

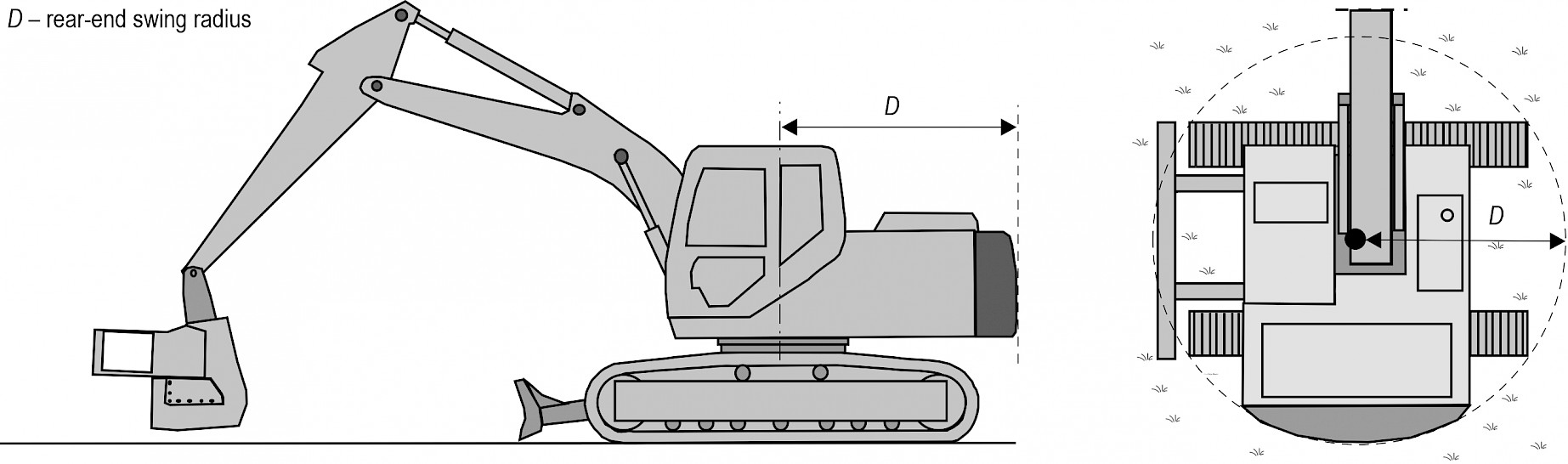

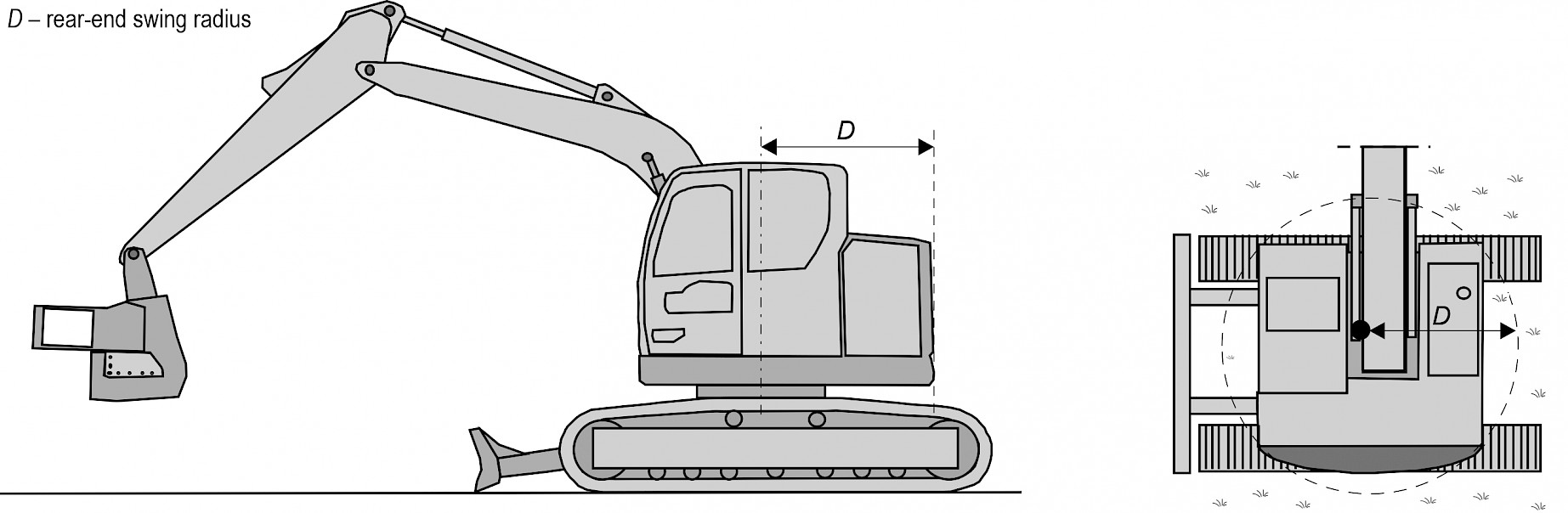

The rear-end swing radius was 2.31 m for the conventional-tail excavator (Fig. 1), while it was 1.49 m for the reduced-tail excavator (Fig. 2).

Fig. 1 Excavator with conventional tail swing (lateral view and top-down view)

Fig. 2 Excavator with (lateral view and top-down view)

The conventional tail excavator had a gross mass of 14.9 t and the nominal power of its engine was 86 kW. On the other hand, the reduced tail excavator had a gross mass of 14.8 t and the nominal power of its engine was 86 kW. Both the excavators were equipped with triple grouser tracks, with 0.60 m wide tracks shoes, and with dozer blade. The total length of the undercarriage was 3.75 m and 3.58 m, respectively, for conventional-tail excavator and for reduced-tail excavator; in fact the length of the undercarriage is directly proportional to the length of the upper structure. Consequently, the distance between the centre of the front idle and the center of final drive was 3.00 m (conventional-tail) and 2.88 m (reduced-tail ) and the ground pressure was 41 kPa and 42 kPa, for the conventional-tail excavator and reduced-tail excavator, respectively. The total arm length was 6.70 m.

The size of the feller heads mounted on the excavators were in function of the load capacity of the machine (Spinelli et al. 2019). Furthermore, feller head required operating flow lower than harvester head, so the latter was selected to avoid overcharging the excavator oil pumps. In particular, the flow required by feller head used in this study ranged between 120 l min-1 and 160 l min-1. The rated flow of the pump was 260 l min-1 for the conventional-tail and 228 l min-1 for the reduced-tail excavator. The measured clamp openings of the feller head were 1.65 m, while the cutting capacity was 0.60 m for both machines analyzed. The saw bar chains shared similar characteristics: a 0.404" pitch and a 1.6 mm gauge.

The excavators had to operate with the engine and hydraulic fluid at the optimum operating temperature. To ensure equal conditions, the chainsaw was replaced with a new one at the start of each plot.

2.3 Productivity

In this study, following the methodology proposed by Magagnotti and Spinelli (2012), working times were recoded at a cycle level (Magagnotti and Spinelli 2012), where felling, bunching and stacking of all the biomass present in each plot was considered as a unique cycle. The time for each cycle was recorded using a centesimal stopwatch. Both productive time and delay time were recorded (Björheden 1995). Delay time and productive time were observed separately. Delays caused by the study itself were excluded from further data processing (Spinelli et al. 2021).

2.3.1 Time Elements

In each cycle the time was divided in 4 principal activities: felling, processing, clearing and stacking. However, the cycles were split into 7 time elements (Wang and Haarlaa 2002, Kärhä et al. 2004, Nurminen et al. 2006, Laitila and Väätäinen 2013). In the time study the following work activities were observed:

Moving: Begins when the excavator starts to move and ends when the excavator stops moving to perform some other activity

Positioning: Begins when the upper structure starts to swing and ends when the swing stops moving to perform some other activity. For example: swings towards a tree that ends when the feller head is resting on a tree and the felling cut begins

Felling: Begins when the felling cut starts and ends when the tree is on the ground

Processing (cross-cutting, bunching): Begins when the tree was on the ground and ends when the last cross-cut log is dropped onto the pile. Bunching is defined as arranging logs into piles

Clearing: Clearing of disturbing undergrowth

Stacking: Moving logs, tops and branches to the edge of the plot and bunching the biomass (outside the processing phase)

Delays: Time that is not related to effective work, e. g. repairing and maintenance, phone calls, etc.

For this work, the sum of the two phases of movement and positioning were considered as maneuvers because rotation of the upperstructure alone was sometimes not enough to avoid contact with the remaining trees, thus making it necessary to move the machine with the tracks.The excavators were used to stack all the biomass harvested on the side of the plot since in thinning the the density of the trees would not allow the work and manoeuvring of other machines, while in clear cutting the slope was too steep.

To avoid influencing the tests, the same chipper was used for all replications: it was a drum chipper, mounted on a truck, powered by the truck engine through a dedicated power take-off. Productivity was calculated with an analytic method considering the amount of biomass felled and stacked per unit of time. The working rate was expressed in terms of mass (t h-1) (Manzone and Balsari 2015), since the material size was too variable to allow an accurate calculation of the volume. Moreover, when the diameters were small, there were many logs in a single clamping during bunching and stacking (Spinelli et al. 2021). Moisture content determination was conducted on three samples per trailer, at different heights during the chipping operation, collected in sealed bags and weighed fresh and after drying for 24 h at a temperature of 103 °C in a ventilated oven (Manzone and Spinelli 2013). The percentage of moisture content was calculated from the loss in mass of the sample (Toscano et al. 2016). The average moisture content was about 52%. Subsequently, the trucks equipped with a »large volume« container (100 m3) for transporting the woodchip were weighed on the weighbridge certified (within 3 km) after each plot. A »large volume« was used to avoid losses generated by using several containers/trailers. The mass of chipped material resulting from each plot combined with the time of each cycle was useful for measuring productivity.

2.4 Damages

During harvesting operations in thinning, trees damaged only by the shocks caused by the upperstructure of the excavators, in particular with counterweight, were marked with a paint mark. The damages due to the shock caused during moving the load, caused by inattention of the machine operator, are not marked. The wound with an exposed surface smaller than 10 cm2 were not recorded, as they had little consequences on the tree health or wood quality (Whitney 1991). The number of trees remaining after felling and of the trees damaged, in each plot, were counted (Spinelli et al. 2014).

2.5 Fuel Consumption

Fuel consumption was determined using a »topping-off system«. In this method, the fuel consumption was determined by refilling the machine after and before each plot. The fuel necessary to fill the tank was assumed to have been consumed for a plot (Manzone 2018). A glass pipe with a measurement accuracy of 0.02-l, was used to refill the tank (Manzone 2015). To be more accurate, an inclinometer was placed into the tank of the machine so that the inclination was 2° and the difference was not significant with a tank pipe diameter of 7.50 cm. Moreover, the tank was filled to a specific point in the tank pipe (±2 mm), marked with a specific marker, to avoid fuel leaks when inserting the cap and during the machine movements. It was not possible to divide the fuel consumption into the different phases, as it was impossible without altering the normal course of work phases.

2.6 Energy Consumption

In this work, the energy consumption was determined considering direct energy consumption, such as fuel and lubricant consumption, and indirect energy consumption, which is the energy used for the machines manufacturing and implementation (Mikkola and Ahokas 2010). Lubricant consumption was calculated as a 2% of fuel consumption (Piccarolo 1989). The direct energy input was determined using 37.0 MJ l-1 for fuel (Bailey et al. 2003) and 83.7 MJ kg-1 for lubricant (Jarach 1985). Furthermore, a value of 1.2 MJ kg-1 was used for both the fuel and lubricant as additional energy consumption for their production and transport (Pellizzi 1992). Indirect energy was calculated using a value of 92.0 MJ for excavators and 69.0 MJ for equipment per each kilogram of machine mass (Jarach 1985, Bailey et al. 2003). A service life of 10 years and an annual usage of 1200 hours were assumed for all the machines. Energy spent in maintenance and repair was considered as 55% of the energy needed for machine manufacturing (Fluck 1985).

2.7 Environmental Assessment

The environmental impact of the harvesting operations was determined by the analysis of CO2 emissions. CO2 emissions from usage (fuel and lubricant), machinery production and for maintenace and repair were considered. An amount of 3.76 kg CO2eq emitted per litre of fuel (Šarauskis et al. 2014) and 4.22 kg CO2eq per kg of lubricant (Handler et al. 2014) were considered to be emitted into the atmosphere. Both values included emissions for production and transport. Moreover, the environmental impact of production, maintenance and repair was calculated using an emission factor equal to 0.159 kg CO2eq per MJ of energy content in the machines (Fiala and Bacenetti 2012).

2.8 Costs

The hourly costs of the excavators were calculated for thinning and clear cut, following the methodology proposed by Ackerman et al. (2014). The hourly cost of the excavator was calculated in detail according to the procedure proposed by Miyata (1980). For the excavator equipped with a feller head an annual use of 1200h and a purchase price of 176,000 € and 178,000 € were considered for conventional excavator and reduced-tail excavator, respectively. In all cases, a depreciation period of ten years was assumed and a salvage value of 20% of the original investment was used in the evaluation. Maintenance and repair costs and insurance of the machine were calculated directly from the machine owner. A cost of 21€ h-1 was assumed for manpower, including obligatory health and social insurance (Proto et al. 2018). In addition, a cost of 1.50 € l-1 and 5.50 € kg-1, respectively, was assumed for fuel and lubricant. Overheads and profit were calculated as 20% of the total cost .

2.9 Data Analysis

Each plot was considered as a replication for a total of 6 replications per treatment (2 excavators per 3 replications per 2 forest treatment). Data were processed using Microsoft Excel software and SPSS 28 (2023) advanced statistic software to determine the statistical significance of the difference between excavators using ANOVA (Wickens and Keppel 2004). The difference between machines was determined using Tukey's HSD test because it has a higher statistical power with this data distribution (Tukey 1949).

3. Results

3.1 Productivity

The time required to complete a cycle in thinning was 3.23 h for conventional-tail excavator and 2.72 h for reduced-tail excavator (Table 2). It is possible to highlight that the time consumption in moving is more incident on the total with the conventional-tail excavator (22%), than the reduced-tail excavator (18%). In fact, the conventional-tail excavator had to carry out more manoeuvres to avoid impacting the remaining trees, while reduced-tail excavator could position itself by only rotating the upper structure. The incidence of the other elements on the total is very similar between the two excavators analyzed. The productive time was 78% for the conventional tail excavator and 80% for the reduced-tail excavator.

Table 2 Time consumption in thinning operation

|

Conventional tail |

Reduced tail |

|||||||

|

Time consumption h |

SD |

Incidence on total % |

Time consumption min t-1 |

Time consumption h |

SD |

Incidence on total % |

Time consumption min t-1 |

|

|

Moving |

0.71 |

0.036 |

22 |

8.24 |

0.48 |

0.026 |

18 |

5.57 |

|

Positioning |

0.43 |

0.053 |

13 |

4.99 |

0.41 |

0.020 |

15 |

4.76 |

|

Felling |

0.20 |

0.015 |

6 |

2.28 |

0.19 |

0.020 |

7 |

2.21 |

|

Processing |

0.63 |

0.026 |

20 |

7.31 |

0.50 |

0.015 |

18 |

5.76 |

|

Clearing |

0.23 |

0.026 |

7 |

2.67 |

0.24 |

0.015 |

9 |

2.75 |

|

Stacking |

0.33 |

0.025 |

10 |

3.87 |

0.35 |

0.031 |

13 |

4.10 |

|

Delay |

0.71 |

0.036 |

22 |

8.24 |

0.56 |

0.035 |

20 |

6.46 |

|

Total |

3.23a |

0.080 |

100 |

37.45 |

2.72b |

0.074 |

100 |

31.61 |

|

Notes: different letters indicate significant differences between the excavators α=0.05 |

||||||||

The total time consumption for a cycle in clear-cut was 6.42 h for the conventional-tail excavator and 6.59 h for the reduced-tail excavator (Table 3). There are not significant differences between the excavators used in the test. The delays have an incidence of about 21% for both the machines analyzed.

Table 3 Time consumption in clear-cut

|

Conventional tail |

Reduced tail |

|||||||

|

Time consumption h |

SD |

Incidence on total % |

Time consumption min t-1 |

Time consumption h |

SD |

Incidence on total % |

Time consumption min t-1 |

|

|

Moving |

0.56 |

0.042 |

9 |

0.63 |

0.62 |

0.031 |

9 |

0.71 |

|

Positioning |

0.66 |

0.045 |

10 |

0.76 |

0.72 |

0.032 |

11 |

0.82 |

|

Felling |

0.76 |

0.044 |

12 |

0.87 |

0.82 |

0.031 |

12 |

0.93 |

|

Processing |

2.35 |

0.026 |

37 |

2.68 |

2.21 |

0.021 |

34 |

2.52 |

|

Clearing |

0.10 |

0.020 |

2 |

0.11 |

0.10 |

0.031 |

2 |

0.12 |

|

Stacking |

0.66 |

0.036 |

10 |

0.75 |

0.67 |

0.046 |

10 |

0.76 |

|

Delay |

1.32 |

0.042 |

20 |

1.50 |

1.45 |

0.026 |

22 |

1.65 |

|

Total |

6.42c |

0.132 |

100 |

7.33 |

6.59c |

0.106 |

100 |

7.52 |

|

Notes: different letters indicate significant differences between the excavators α=0.05 |

||||||||

By placing the manoeuvring phases (moving and positioning) within the different activities evaluated (felling, processing, cleaning, stacking), it can be seen that the activity that requires the higher time consumption in thinning was processing (Table 4). However, higher values in time consumption for manoeuvring were recorded in felling activities. Moreover the incidence of manoeuevring in felling activity was 50% for the conventiontional-tail excavator and 47% for the reduced-tail excavator. Nevertheless, with conventional-tail excavator in felling activity, the moving element had higher incidence in manoeuvring, while with reduced-tail excavator it was positioning.

Table 4 Time consumption of different activities in thinning

|

consumption, h |

||||||||||

|

Conventional tail |

Reduced tail |

|||||||||

|

Main activity |

Moving |

Positioning |

Delay |

Total time |

Main activity |

Moving |

Positioning |

Delay |

Total time |

|

|

Felling |

0.20 |

0.26 |

0.15 |

0.20 |

0.81 |

0.19 |

0.13 |

0.18 |

0.15 |

0.65 |

|

Processing |

0.63 |

0.08 |

0.10 |

0.16 |

0.97 |

0.50 |

0.07 |

0.06 |

0.14 |

0.77 |

|

Clearing |

0.23 |

0.13 |

0.10 |

0.19 |

0.65 |

0.24 |

0.08 |

0.04 |

0.12 |

0.48 |

|

Stacking |

0.33 |

0.24 |

0.08 |

0.17 |

0.82 |

0.35 |

0.20 |

0.13 |

0.15 |

0.83 |

|

Total |

1.39 |

0.71 |

0.43 |

0.71 |

3.23 |

1.27 |

0.48 |

0.41 |

0.56 |

2.72 |

In clear-cut, higher time consumption was observed in processing activity for both the excavators analyzed (Table 5). The incidence of manoeuvring in felling activity was about 23%, since operators do not have to pay attention to the remaining trees and are able to move freely, reducing the number of manoeuvres.

Table 5 Time consumption of the different activities in clear-cut

|

Time consumption, h |

||||||||||

|

Conventional tail |

Reduced tail |

|||||||||

|

Main activity |

Moving |

Positioning |

Delay |

Total time |

Main activity |

Moving |

Positioning |

Delay |

Total time |

|

|

Felling |

0.76 |

0.14 |

0.18 |

0.33 |

1.41 |

0.82 |

0.16 |

0.19 |

0.36 |

1.53 |

|

Processing |

2.35 |

0.12 |

0.21 |

0.32 |

3.00 |

2.21 |

0.15 |

0.23 |

0.34 |

2.93 |

|

Clearing |

0.10 |

0.09 |

0.11 |

0.31 |

0.61 |

0.10 |

0.09 |

0.11 |

0.38 |

0.68 |

|

Stacking |

0.66 |

0.21 |

0.16 |

0.36 |

1.39 |

0.67 |

0.22 |

0.19 |

0.37 |

1.45 |

|

Total |

3.88 |

0.56 |

0.66 |

1.32 |

6.42 |

3.80 |

0.62 |

0.72 |

1.45 |

6.59 |

In thinning, a higher value of productivity (1.90 t h-1) was obtained by the reduced-tail excavator, whereas the lowest value was obtained by the conventioanal-tail excavator (1.60 t h-1) (Table 6).

Table 6 Productivity of excavators for each treatment tested

|

Excavator |

Productivity, t h-1 |

Productivity, t h-1 kW-1 |

Productivity, t h-1 t-1 of gross mass |

||||

|

Mean |

SD |

Mean |

SD |

Mean |

SD |

||

|

Thinning |

Conventional tail |

1.60a |

0.025 |

0.019 |

0.0003 |

0.11 |

0.0017 |

|

Reduced tail |

1.90b |

0.031 |

0.022 |

0.0004 |

0.13 |

0.0021 |

|

|

Clear-cut |

Conventional tail |

8.20c |

0.031 |

0.095 |

0.0004 |

0.55 |

0.0021 |

|

Reduced tail |

8.13c |

0.015 |

0.094 |

0.0004 |

0.55 |

0.0010 |

|

|

Notes: different letters indicate significant differences between the excavators α=0.05 |

|||||||

The difference in productivity in thinning is due to the time consumed for the manouevring. In fact the conventional-tail excavator is the less productive machine.

On the contrary, in clear-cut, the higher value of productivity was obtained by the conventional-tail excavator, while the lowest value was obtained by the reduced-tail excavator, 8.20 t h-1 and 8.13 t h-1, respectively. However the difference in productivity between the excavator analyzed is less than 1% and not significant. The higher productivity expressed per unit of nominal power of the engine mounted on the machine was obtained with the conventional-tail excavator in clear-cutting (0.095 t h-1 × kW), while the lowest value (0.019 t h-1 × kW) was obtained with the same machine in thinning operations. The lowest value of the working rate expressed per unit of the excavator gross mass was 0.11 t h-1 × t obtained with the conventional-tail excavator in thinning.

3.2 Damages

In thinning operations, the plots harvested by the reduced-tail swing excavator had 4 remaining damaged trees, while those managed by the conventional-tail swing excavator had 11, accounting for 12% and 29% damage, respectively, (Table 7). These damages primarily occurred during the maneuvering phase.

Table 7 Remaining trees after thinning operation and number of damaged trees

|

Number of trees, n |

||||

|

Before |

After |

Damaged |

Incidence of damaged trees after thinning, % |

|

|

Conventional tail |

53 |

37 |

11 |

29 |

|

Reduced tail |

53 |

37 |

4 |

12 |

Generally, the higher number of damaged trees was observed in felling. In partucular, the higher number of damaged trees were recored in the plot where the conventional-tail excavator was used (5) (Table 8).

Table 8 Number of trees damaged in plot by different activities

|

Number of trees damaged by activity |

||

|

Conventional tail |

Reduced ail |

|

|

Felling |

5 |

2 |

|

Processing |

2 |

1 |

|

Clearing |

3 |

1 |

|

Stacking |

1 |

- |

|

Total |

11 |

4 |

3.3 Fuel Consumption

Fuel consumption in thinning was 13.3 l h-1 and 9.5 l h-1, obtained by conventional-tail excavator and reduced-tail, respectively. (Table 9). In the clear-cut, instead, the highest value was achieved by reduced-tail excavator (18.3 l h-1) and the lowest value by conventional-tail excavator (17.2 l h-1); however, the difference between is not significant.

Table 9 Fuel consumption during thinning and clear-cut

|

Excavator |

l |

Fuel consumption per hour |

|||||||

|

l kW-1 |

l t-1 of gross mass |

l t-1 of productivity |

|||||||

|

Mean |

SD |

Mean |

SD |

Mean |

SD |

Mean |

SD |

||

|

Thinning |

Conventional tail |

13.3a |

0.436 |

0.15 |

0.005 |

0.89 |

0.029 |

8.33 |

0.174 |

|

Reduced tail |

9.5b |

0.306 |

0.11 |

0.004 |

0.64 |

0.021 |

4.99 |

0.238 |

|

|

Clear-cut |

Conventional tail |

17.2c |

0.300 |

0.20 |

0.003 |

1.16 |

0.020 |

2.10 |

0.040 |

|

Reduced tail |

18.3c |

0.306 |

0.21 |

0.004 |

1.23 |

0.021 |

2.25 |

0.041 |

|

|

Notes: different letters indicate significant differences between the excavators α=0.05 |

|||||||||

The difference between the data obtained in clear-cut by the excavators analyzed was very low, while in thinning the difference between the two machines was high. In particular, fuel consumption of felling, processing and clearing with reduced-tail excavator were about 45% lower than with conventional-tail excavator (Table 10).

Table 10 Fuel consumption by activity

|

Fuel consumption for activity, l × activity × cycle |

||||

|

Thinning |

Clear-cut |

|||

|

Conventional tail |

Reduced tail |

Conventional tail |

Reduced tail |

|

|

Felling |

10.8 |

6.2 |

24.3 |

27.9 |

|

Processing |

12.9 |

7.3 |

51.6 |

53.7 |

|

Clearing |

8.6 |

4.6 |

10.5 |

12.5 |

|

Stacking |

10.8 |

7.9 |

23.9 |

26.5 |

3.4 Energy Consumption

The total energy consumption values were higher in clear-cut than in thinning. However, the specific energy consumption (MJ t-1) obtained in thinning is higher than in clear-cut. The higher value of energy consumption per unit of harvested biomass was obtained in thinning with conventional-tail excavator (437.89 MJ t-1), while the lowest value was obtained in clear-cut by the same excavator (109.99 MJ t-1) (Table 11). On the contrary, reduced-tail swing excavator obtained the lowest value in thinning and a higher value in clear cut.

Table 11 Energy consumption of excavators

|

Excavator |

Energy consumption |

|||||

|

Direct MJ h-1 |

Indirect MJ h-1 |

Total MJ h-1 |

Incidence of direct on total % |

Energy per biomass harvested MJ t-1 |

||

|

Thinning |

Conventional tail |

524.3 |

174.9 |

747.9 |

74.98 |

437.89a |

|

Reduced tail |

373.2 |

173.8 |

581.0 |

68.23 |

288.50b |

|

|

Clear-cut |

Conventional tail |

678.0 |

174.9 |

914.8 |

79.50 |

104.05c |

|

Reduced tail |

720.1 |

173.8 |

959.6 |

80.56 |

109.99c |

|

|

Notes: different letters indicate significant differences between the excavators α=0.05 |

||||||

In addition, all machine analyzed showed an incidence of direct energy consumption on total energy consumption between 68.23% and 80.56%, with the higher values in clear-cut operations.

The difference between the data obtained in clear-cut by the excavators analyzed was very low, while in thinning the difference between the two machines was high. In particular, energy consumption of felling, processing and clearing with reduced-tail excavator were about 45% lower than with conventional-tail excavator (Table 12).

Table 12 Energy consumption by activity

|

Energy consumption for activity, MJ × activity × cycle |

||||

|

Thinning |

Clear-cut |

|||

|

Conventional tail |

Reduced tail |

Conventional tail |

Reduced tail |

|

|

Felling |

10.8 |

6.2 |

24.3 |

27.9 |

|

Processing |

12.9 |

7.3 |

51.6 |

53.7 |

|

Clearing |

8.6 |

4.6 |

10.5 |

12.5 |

|

Stacking |

10.8 |

7.9 |

23.9 |

26.5 |

3.5 Environmental Assessment

Data processing showed that the lowest emission value was obtained in thinning with reduced-tail excavator (63.70 kg CO2eq h-1), while the highest value was obtained with the same excavator in clear-cutting (97.39 kg CO2eq h-1). The incidence of fuel and lubricant consumption on total CO2 emission ranged between 56.75% and 71.69% (Table 13).

Table 13 CO2 emissions of excavator analyzed

|

Excavator |

CO2 emission |

|||

|

Total kg CO2eq h-1 |

Incidence on total of fuel and lubricant, % |

kg CO2eq t-1 harvested |

||

|

Thinning |

Conventional tail |

78.76a |

64.69% |

49.33 |

|

Reduced tail |

63.90b |

56.75% |

33.70 |

|

|

Clear-cut |

Conventional tail |

93.68c |

70.33% |

11.43 |

|

Reduced tail |

97.60c |

71.69% |

12.01 |

|

|

Notes: different letters indicate significant differences between the excavators α=0.05 |

||||

In thinning the higher values were obtained by conventional-tail excavator, while the lower values were calculated for the reduced-tail excavator (Table 14). In particular, in the different activities the emissions ranged between 50.80 kg CO2eq and 76.40 kg CO2eq for the conventional-tail excavator, while for the reduced-tail excavator the values ranged between 30.62 kg CO2eq and 52.94 kg CO2eq. The difference to perform the same work was 81.04 kg CO2eq.

Table 14 Emissions by activity

|

Emission for activity, kgCO2eq × activity × cycle |

||||

|

Thinning |

Clear-cut |

|||

|

Conventional tail |

Reduced tail |

Conventional tail |

Reduced tail |

|

|

Felling |

63.79 |

41.46 |

132.09 |

149.01 |

|

Processing |

76.40 |

49.11 |

281.05 |

286.05 |

|

Clearing |

50.80 |

30.62 |

57.15 |

66.70 |

|

Stacking |

64.19 |

52.94 |

130.22 |

141.52 |

3.6 Costs

The higher hourly costs in thinning operation were calculated for the excavator with conventional-tail swing and the lowest were calculated for reduced-tail swing excavator, corresponding to 76 € h-1 and 68 € h-1, respectively. Moreover, the cost per unit of productivity was 47.4 € t-1 (conventional-tail excavator) and 35.9 € t-1 (reduced-tail excavator). In the clear-cut, the higher hourly cost per unit of productivity was calculated for the reduced-tail swing excavator (10.9 € t-1) while the lowest for the conventional-tail excavator (10.2 € t-1) (Table 15).

Table 15 Machine costing

|

Thinning |

Clear-cut |

||||

|

Conventional- ail |

Reduced tail |

Conventional tail |

Reduced tail |

||

|

Purchase price |

€ |

176,000 |

178,000 |

176,000 |

178,000 |

|

Salvage value |

€ |

35,200 |

35,600 |

35,200 |

35,600 |

|

Service life |

Years |

10 |

10 |

10 |

10 |

|

Annual use |

h |

1200 |

1200 |

1200 |

1200 |

|

Manpower |

€ h-1 |

21 |

21 |

21 |

21 |

|

Interest |

% |

8 |

8 |

8 |

8 |

|

Depreciation |

€ year-1 |

14,080 |

14,240 |

14,080 |

14,240 |

|

Interest |

€ year-1 |

9152 |

9256 |

9152 |

9256 |

|

Insurance |

€ years-1 |

150 |

150 |

150 |

150 |

|

Maintenance & repair |

€ years-1 |

1500 |

1200 |

1500 |

1200 |

|

Fuel |

€ years-1 |

23,940 |

16,920 |

30,960 |

34,200 |

|

Lubricant |

€ years-1 |

1756 |

1241 |

2270 |

2508 |

|

Personnel |

€ years-1 |

25,200 |

25,200 |

25,200 |

25,200 |

|

Overhead & profit |

% |

20 |

20 |

20 |

20 |

|

Overhead & profit |

€ years-1 |

15,156 |

13,641 |

16,662 |

17,351 |

|

Total cost |

€ years-1 |

90,933 |

81,848 |

99,975 |

104,105 |

|

Total cost |

€ h-1 |

76 |

68 |

83 |

85 |

|

Total cost |

€ t-1 |

47.4 |

35.9 |

10.2 |

10.7 |

In thinning, the higher values were obtained by conventional-tail excavator, while the lower values were calculated for the reduced-tail excavator (Table 16). In particular, in the different activities the cost ranged between 48.88 € and 73.50 € for the conventional-tail excavator, while for the reduced-tail excavator the values ranged between 32.74 € and 56.61%. The difference to perform the same work was about 60 € in thinning.

Table 16 Machine costing by activities

|

Cost for activity, € × activity × cycle |

||||

|

Thinning |

Clear-cut |

|||

|

Conventional tail |

Reduced tail |

Conventional tail |

Reduced tail |

|

|

Felling |

61.38 |

44.33 |

117.47 |

130.28 |

|

Processing |

73.50 |

52.52 |

249.94 |

250.32 |

|

Clearing |

48.88 |

32.74 |

50.82 |

58.31 |

|

Stacking |

61.76 |

56.61 |

115.80 |

123.74 |

4. Discussion

4.1 Thinning

The time consumption in thinning showed that the reduced-tail excavator, compared to the conventional-tail excavator, had the lower value. Indeed, the incidence of time in moving of the conventional-tail excavator is 22% of the total time required to complete a cycle. The incidence on total time required to complete a cycle of the reduced-tail excavator is 18%. This result is due to the greater difficulty in manoeuvring the machines during thinning. In particular, in the logging activity, 50% of the time was consumed for manoeuvring with the conventional-tail excavator, and only 47% for manoeuvring with the reduced-tail excavator.

The incidence of the time elements considered in this study are in line with those obtained in harvesting using purpose-built machines in thinning (Nurminen et al. 2006). The machines analyzed showed a delay factor of about 20%, values not in line with the delay factor of 49.7% indicated for natural stand by Spinelli and Visser (2008), while they are in line with delay factor for short rotation plantations (Spinelli and Visser 2008). Productive time in thinning operation is 60% lower than that obtained by the excavator equipped with a felling head designed for continuous cutting and accumulation (Laitila and Väätäinen 2023). Time consumption is influenced by the tree density in thinning; in fact, in the study of Laitila and Väätäinen (Laitila and Väätäinen 2023) there were 5671 trees per hectare, while in this study there were only 589.

The productivity obtained in thinning is lower than that obtained in a study in which the same operation was carried out in a pine forest with purpose-built machines (Kärhä et al. 2004). The productivity of the excavators with reduced-tail swing is 18.5% higher than that obtained with the machine with conventional-tail swing, because the reduced-tail excavator has higher productivity since it has a smaller swing radius and therefore greater manoeuvrability.

The fuel consumption measured in this study is in line with that of other studies on excavators in forest operations (Johansson 1995, Schweier et al. 2015, Magagnotti et al. 2017). In thinning operations, the excavator had a 30% lower fuel consumption than that obtained by a harvester (Mederski 2006), while in other forest treatments, generally, purpose-built machines had a lower fuel consumption than excavator-based machines (Magagnotti et al. 2017). In fact, excavators are not specifically engineered for forestry work like purpose-built machines (Spinelli and Moura 2019). Furthermore, in thinning operations, the fuel consumption of the conventional-tail swing excavator was 41.8% higher than that of the reduced-tail swing excavator, because the first excavator had to make more manoeuvres to avoid damages to the remaining trees. The reduced-tail swing excavator allows for fewer manoeuvres with a consequent reduction in potential damage to the remaining trees .

The damages to the remaining trees after thinning are in line with those obtained in other studies (Vasiliauskas 2001, Spinelli et al. 2014). Moreover, with the reduced-tail swing excavator there is a reduction of the damaged trees of 64%. The reduction of damaged trees is due to the reduced number of manoeuvres required for the reduced-tail excavator. It should be underlined that the excavator oscillates during the operating phases, and therefore it is necessary to increase the distance from the trees remaining after forestry treatment by approximately 0.30 m in addition to the rotation radius of the machine.

Wounds possibly caused to the trees involve damages due to harvesting operations, but also due to ground pressure (Vasiliauskas 2001). Although excavators have a reduced ground pressure below the 50 kPa limit (Kormanek and Dvořák 2021), it would be interesting to analyze how the ground pressure varies during different phases of work and during excavators boom movement.

The ground pressure of the analyzed excavator (41.5 kPa) is lower than the ground pressure of a purpose-built harvester (73.9 kPa), as shown by another research (Nugent et al. 2003).

The total energy consumption of the analyzed machines (748.2 MJ) is approximately 35% lower than that reported in a study on chippers. Furthermore, the share of direct energy consumption to the total (75.82%) is lower compared to the figures obtained for chippers (84.31%) (Manzone 2015). This difference in value is related to the fuel consumption of the chippers, which is in fact much higher than that of excavators. The difference in indirect energy consumption between the two excavators is not relevant (0.60%). In thinning operation, the direct energy consumption of the reduced-tail excavator is about 29% lower than the direct energy consumption obtained by the conventional-tail excavator. This is because in thinning the short-tail excavator performs fewer manoeuvres than the conventional-tail machine, which reduces fuel consumption. In particular, in the thinning operation with the reduced-tail excavator, there is a reduction in CO2 emissions of about 18%. The hourly costs of the excavator in both forest treatments are in line with those obtained in other studies dealing with excavators (Schweier et al. 2015, Spinelli et al. 2020, Laitila and Väätäinen 2023). The hourly cost of the purpose-built machines in thinning operation is in line with those obtained in this work with excavators, only increasing the annual working hours from 1200 h to 2570 h (Kärhä et al. 2004). Moreover, the cost in thinning operation is strongly impacted by the fuel consumption of the conventional-tail excavators. In fact, this machine had greater difficulty in manoeuvring compared to the reduced-tail excavator. The hourly cost of the machine with reduced-tail swing is 10% lower than that of the conventional-tail swing machine.

4.2 Clear-cut

The time consumption in clear-cut is similar between the machines analyzed: 6.42 h and 6,59 h, obtained by conventional-tail excavator and reduced-tail excavator, respectively. The incidence of the time elements considered in this study are in line with those obtained in harvesting using purpose-built machine in final felling (Nurminen et al. 2006). The delay factor (20%) is in line with the factor obtained by Spinelli and Visser (2008) for short rotation plantations (Spinelli and Visser 2008).

In clear-cut, instead, conventional excavator had a higher productivity, but the difference with the productivity obtained by reduced-tail excavator is less than 1%.

The productivity in clear-cutting is 58% lower than that obtained in a poplar plantation (Spinelli et al. 2021) because the disposition of the trees is not regular in the forest, therefore the excavators need a greater number of manoeuvres. Furthermore, the productivity of excavators is lower than that obtained by excavator-based harvesters in a eucalyptus forest with a slope of 20%, because productivity is influenced by the slope; in fact, it decreases by 0.048 m3 for every 1% increase in slope (Ackerman et al. 2018). The dozer blade of the machines in this study can help the operator to maintain the excavator levelled and more stable during the felling operation.

In the clearcutting, the fuel consumption obtained of the reduced-tail excavator was 6% higher than that obtained by the other excavator analyzed. This is due to the fact that the machine operated at a higher engine speed to cope with the machine requirements, thus increasing fuel consumption (Santos 2020). Also, the steep terrain in the riparian forest affects the fuel consumption of the excavators (Visser and Stampfer 2015).

In clear-cutting, the direct energy consumption of the reduced tail excavator was about 5% higher than that of the conventional-tail excavator. Energy consumption has an impact on CO2 emissions. Moreover, the reduced-tail swing excavator had an increase of about 4% in CO2 emissions. The reasons for these values are the same as those that affect direct energy consumption. Using both excavators, there is a reduction of emissions per unit of productivity in clear-cut, due to the higher working rate. In clear-cut, data obtained in CO2 t-1 is 11.72 kg CO2 t-1, which is 10% lower than data obtained by Zhang et al. (2016).

In clear-cut, short-tail excavator had a cost 2% higher than the other machine analyzed. In thinning operations, the cost per unit of productivity of the conventional-tail excavator is 32% higher than the cost of the machine with reduced-tail . In clear-cut, the cost per unit of productivity of the reduced-tail excavator is only 5% higher than the conventional-tail machine.

5. Conclusions

This work showed that the reduced-tail excavator can be a viable alternative to conventional-tail excavator. The differences in values obtained in clear-cut operation are not significant and are very low (<5%). However, in the thinning process, the reduced-tail excavator ensures higher productivity and lower fuel consumption. This latter feature is particularly significant as it reduces maneuvers, thereby minimizing damage to the remaining trees. The lower fuel consumption of reduced-tail excavators results in an overall reduction in energy consumption and CO2 emissions. Furthermore, employing the reduced-tail excavator incurs lower hourly costs compared to the conventional tail excavator. These findings highlight how the adoption of the reduced-tail excavator can not only improve the efficiency of forestry operations but also contribute to the environmental and economic sustainability of the logging and harvesting process.

6. References

Abernethy, B., Rutherfurd, I.D., 2001: The distribution and strength of riparian tree roots in relation to riverbank reinforcement. Hydrol Process 15(1): 63–79. https://doi.org/10.1002/hyp.152

Ackerman, P., Belbo, H., Eliasson, L., de Jong, A., Lazdins, A., Lyons, J., 2014: The COST model for calculation of forest operations costs. International Journal of Forest Engineering 25(1): 75–81. https://doi.org/10.1080/14942119.2014.903711

Ackerman, P., Martin, C., Brewer, J., Ackerman, S., 2018: Effect of slope on productivity and cost of Eucalyptus pulpwood harvesting using single-grip purpose-built and excavator-based harvesters. International Journal of Forest Engineering 29(2): 74–82. https://doi.org/10.1080/14942119.2018.1431491

Albizu-Urionabarrenetxea, P.M., Tolosana-Esteban, E., Roman-Jordan, E., 2013: Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. For Syst. 22(3): 392–400. https://doi.org/10.5424/fs/2013223-02714

Bailey, A.P., Basford, W.D., Penlington, N., Park, J.R., Keatinge, J.D.H., Rehman, T., Tranter, R.B., Yates, C.M., 2003: A comparison of energy use in conventional and integrated arable farming systems in the UK. Agric Ecosyst Environ. 97(1–3): 241–253. https://doi.org/10.1016/S0167-8809(03)00115-4

Bedi, J.K., Rahman, R.A., Din, Z., 2021: Heavy Machinery Operators: Necessary Competencies to Reduce Construction Accidents. In: IOP Conf Ser Earth Environ Sci. Vol. 641. Universiti Malaysia Pahang, Malaysia: IOP Publishing; 1–11 p. https://doi.org/https://doi.org/10.1088/1755-1315/641/1/012007

Bell, J.L., 2002: Changes in logging injury rates associated with use of feller-bunchers in West Virginia. J Safety Res 33(4): 463–471. https://doi.org/https://doi.org/10.1016/S0022-4375(02)00048-8

Bergroth, J., Palander, T., Kärhä, K., 2006: Excavator-based harvesters in wood cutting operations in Finland. Forestry Studies 45: 74–88.

Björheden, R., 1995: Forest work study nomenclature. Swedish University of Agricultural Science, Dept. of Operational Efficiency.

Buckley, P., 2020: Coppice restoration and conservation: a European perspective. Journal of Forest Research 25(3): 125–133. https://doi.org/https://doi.org/10.1080/13416979.2020.1763554

Fiala, M., Bacenetti, J., 2012: Economic, energetic and environmental impact in short rotation coppice harvesting operations. Biomass Bioenergy 42: 107–113. https://doi.org/10.1016/j.biombioe.2011.07.004

Fluck, R.C., 1985: Energy sequestered in repairs and maintenance of agricultural machinery. Transactions of the ASAE 28(3): 738–744. https://doi.org/10.13031/2013.32330

Gerasimov, Y., Sokolov, A., 2009: Ergonomic characterization of harvesting work in Karelia. Croat. j. for. eng. 30(2): 159–170.

Handler, R.M., Shonnard, D.R., Lautala, P., Abbas, D., Srivastava, A., 2014: Environmental impacts of roundwood supply chain options in Michigan: Life-cycle assessment of harvest and transport stages. J Clean Prod 76: 64–73. https://doi.org/10.1016/j.jclepro.2014.04.040

Hartsough, B., 2003: Economics of harvesting to maintain high structural diversity and resulting damage to residual trees. Western journal of applied forestry 18(2): 133–142. https://doi.org/10.1093/wjaf/18.2.133

Jarach, M., 1985: On equivalence values for analysis and balance energy in agriculture. Riv Ing Agr 2: 102–114.

Jiroušek, R., Klvač, R., Skoupý, A., 2007: Productivity and costs of the mechanised cut-to-length wood harvesting system in clear-felling operations. Journal of forest science 53(10): 476–482. https://doi.org/https://doi.org/10.17221/2088-JFS

Johansson, J., 1995: Excavators as base machines in logging operations. Journal of Forest Engineering 7(1): 7–17. https://doi.org/https://doi.org/10.1080/08435243.1995.10702674

Kärhä, K., Rönkkö, E., Gumse, S-I., 2004: Productivity and Cutting Costs of Thinning Harvesters. International Journal of Forest Engineering 15(2): 43–56. https://doi.org/10.1080/14942119.2004.10702496

Kitani, O., 1999: Energy and biomass engineering, CIGR handbook of agricultural engineering. ASAE, St Joseph, MI.

Kormanek, M., Dvořák, J., 2021: Ground pressure changes caused by mht 8002hv crawler harvester chassis. Croat. j. for. eng. 42(2): 201–211. https://doi.org/10.5552/crojfe.2021.844

Laitila, J., Väätäinen, K., 2013: The cutting productivity of the excavator-based harvester in integrated harvesting of pulpwood and energy wood. Balt For 19(2): 289–300.

Laitila, J., Väätäinen, K., 2021: Productivity and cost of harvesting overgrowth brushwood from roadsides and field edges. International Journal of Forest Engineering 32(2): 140–154. https://doi.org/10.1080/14942119.2021.1903790

Laitila, J., Väätäinen, K., 2023: The productivity and cost of harvesting whole trees from early thinnings with a felling head designed for continuous cutting and accumulation. International Journal of Forest Engineering 34(1): 76–89. https://doi.org/10.1080/14942119.2022.2094192

Magagnotti, N., Spinelli, R., 2012: Good practice guidelines for biomass production studies. Sesto Fiorentino, Italy: CNR Ivalsa.

Magagnotti, N., Pari, L., Spinelli, R., 2017: Use, utilization, productivity and fuel consumption of purpose-built and excavator-based harvesters and processors in Italy. Forests 8(12): 485. https://doi.org/10.3390/f8120485

Magagnotti, N., Picchi, G., Spinelli, R., 2013: A versatile machine system for salvaging small-scale forest windthrow. Biosyst Eng 115(4): 381–388. https://doi.org/10.1016/j.biosystemseng.2013.05.003

Manzone, M., 2015: Energy consumption and CO2 analysis of different types of chippers used in wood biomass plantations. Appl Energy 156: 686–692. https://doi.org/10.1016/j.apenergy.2015.07.049

Manzone, M., 2018: CO2 emissions and energy consumption of loaders in woodchip loading operation. Biomass Bioenergy 109: 10–15. https://doi.org/10.1016/j.biombioe.2017.12.012

Manzone, M., Balsari, P., 2015: Productivity and woodchip quality of different chippers during poplar plantation harvesting. Biomass Bioenergy 83: 278–283. https://doi.org/10.1016/j.biombioe.2015.10.010

Manzone, M., Spinelli, R., 2013: Wood chipping performance of a modified forager. Biomass Bioenergy 55: 101–106. https://doi.org/10.1016/j.biombioe.2013.01.006

Mederski, P.S., 2006: A comparison of harvesting productivity and costs in thinning operations with and without midfield. For Ecol Manage 224(3): 286–296. https://doi.org/10.1016/j.foreco.2005.12.042

Mikkola, H.J., Ahokas, J., 2010: Indirect energy input of agricultural machinery in bioenergy production. Renew Energy 35(1): 23–28. https://doi.org/10.1016/j.renene.2009.05.010

Miyata, E.S., 1980: Determining fixed and operating costs of logging equipment. U.S. Department of Agriculture, Forest Service, North Central Forest Experiment Station. https://doi.org/10.2737/nc-gtr-55

Nakagawa, M., Hayashi, N., Narushima, T., 2010: Effect of tree size on time of each work element and processing productivity using an excavator-based single-grip harvester or processor at a landing. Journal of Forest Research 15(4): 226–233. https://doi.org/10.1007/s10310-010-0180-2

Nugent, C., Kanali, C., Owende, P.M.O., Nieuwenhuis, M., Ward, S., 2003: Characteristic site disturbance due to harvesting and extraction machinery traffic on sensitive forest sites with peat soils. For Ecol Manage 180(1–3): 85–98. https://doi.org/10.1016/S0378-1127(02)00628-X

Nurminen, T., Korpunen, H., Uusitalo, J., 2006: Time consumption analysis of the mechanized cut-to-length harvesting system. Silva Fennica 40(2): 335–363. https://doi.org/https://doi.org/10.14214/sf.10379

Pellizzi, G., 1992: Use of energy and labour in Italian agriculture. Journal of Agricultural Engineering Research 52: 111–119.

Piccarolo, P., 1989: Selection criteria and management of agricultural machinery. Macchine e Motori Agricoli 12: 28–32. https://doi.org/10.1016/0021-8634(92)80054-V

Picchio, R., Maesano, M., Savelli, S., Marchi, E., 2009: Productivity and energy balance in conversion of a Quercus cerris L. coppice stand into high forest in Central Italy. Croat. j. for. eng. 30(1): 15–26.

Proto, A.R., Macrì, G., Visser, R., Russo, D., Zimbalatti, G., 2018: Comparison of timber extraction productivity between winch and grapple skidding: A case study in southern Italian forests. Forests 9(2): 61. https://doi.org/10.3390/f9020061

Santos, D., 2020: Technical, economic, and environmental parameters of excavator-based harvester in function of engine speed and hydraulic pump flow. Croat. j. for. eng. 41(2): 1–12. https://doi.org/https://doi.org/10.5552/crojfe.2020.761

Šarauskis, E., Buragiene, S., Masilionyte, L., Romaneckas, K., Avižienyte, D., Sakalauskas, A., 2014: Energy balance, costs and CO2 analysis of tillage technologies in maize cultivation. Energy 69: 227–235. https://doi.org/10.1016/j.energy.2014.02.090

Schweier, J., Spinelli, R., Magagnotti, N., Becker, G., 2015: Mechanized coppice harvesting with new small-scale feller-bunchers: Results from harvesting trials with newly manufactured felling heads in Italy. Biomass Bioenergy 72: 85–94. https://doi.org/10.1016/j.biombioe.2014.11.013

Spiecker, H., 2003: Silvicultural management in maintaining biodiversity and resistance of forests in Europe – Temperate zone. J Environ Manage 67(1): 55–65. https://doi.org/10.1016/S0301-4797(02)00188-3

Spinelli, R., Cacot, E., Mihelic, M., Nestorovski, L., Mederski, P., Tolosana, E., 2016: Techniques and productivity of coppice harvesting operations in Europe: a meta-analysis of available data. Ann For Sci 73(4): 1125–1139. https://doi.org/10.1007/s13595-016-0578-x

Spinelli, R., Lombardini, C., Magagnotti, N., 2014: The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations. Silva Fennica 48(1): article id 1003. https://doi.org/10.14214/sf.1003

Spinelli, R., Lombardini, C., Marchi, E., Aminti, G., 2019: A low-investment technology for the simplified processing of energy wood from coppice forests. Eur J For Res 138(1): 31–41. https://doi.org/10.1007/s10342-018-1150-z

Spinelli, R., Magagnotti, N., Kovacs, B., Heger, P., Mihelic, M., 2023: Productivity and cost assessment of two harvesting methods for medium-rotation poplar plantations. Scand J For Res 38 (1–2): 78–86. https://doi.org/10.1080/02827581.2023.2177336

Spinelli, R., Magagnotti, N., Lombardini, C., 2020: Low-investment fully mechanized harvesting of short-rotation poplar (populus spp.) plantations. Forests 11(5): 502. https://doi.org/10.3390/F11050502

Spinelli, R., Magagnotti, N., Lombardini, C., Mihelič, M., 2021: A Low-Investment Option for the Integrated Semi-mechanized Harvesting of Small-Scale, Short-Rotation Poplar Plantations. Small-scale Forestry 20(1): 59–72. https://doi.org/10.1007/s11842-020-09456-3

Spinelli, R., Moura, A.C. de A., 2019: Decreasing the fuel consumption and CO2 emissions of excavator-based harvesters with a machine control system. Forests 10(1): 43. https://doi.org/10.3390/f10010043

Spinelli, R., Visser, R., 2008: Analyzing and Estimating Delays in Harvester Operations. International Journal of Forest Engineering 19(1): 36–41. https://doi.org/10.1080/14942119.2008.10702558

Suchomel, C., Becker, G., Pyttel, P., 2011: Fully mechanized harvesting in aged oak coppice stands. For Prod J 61(4): 290–296. https://doi.org/https://doi.org/10.13073/0015-7473-61.4.290

Toscano, G., Duca, D., Foppa Pedretti, E., Pizzi, A., Rossini, G., Mengarelli, C., Mancini, M., 2016: Investigation of woodchip quality: Relationship between the most important chemical and physical parameters. Energy 106: 38–44. https://doi.org/10.1016/j.energy.2016.03.037

Tukey, J.W., 1949: Comparing individual means in the analysis of variance. Biometrics 5(2): 99–114. https://doi.org/https://doi.org/10.2307/3001913

Väätäinen, K., Sikanen, L., Asikainen, A., 2004: Feasibility of Excavator-Based Harvester in Thinnings of Peatland Forests. International Journal of Forest Engineering 15(2): 103–111. https://doi.org/10.1080/14942119.2004.10702502

Vasiliauskas, R., 2001: Damage to trees due to forestry operations and its pathological significance in temperate forests: a literature review. Forestry 74(4): 319–336. https://doi.org/https://doi.org/10.1093/forestry/74.4.319

Visser, R., Stampfer, K., 2015: Expanding ground-based harvesting onto steep terrain: A review. Croat. j. for. eng. 36(2): 321–331.

Wang, J., Haarlaa, R., 2002: Production analysis of an excavator-based harvester: a case study in Finnish forest operations. For Prod J 52(3): 85–90.

Whitney, R.D., 1991: Quality of eastern white pine 10 years after damage by logging. The Forestry Chronicle 67(1): 23–26. https://doi.org/https://doi.org/10.5558/tfc67023-1

Wickens, T.D., Keppel, G., 2004: Design and analysis: A researcher's handbook: Pearson Prentice-Hall Upper Saddle River, NJ.

Wipf, T.J., Phares, B.M., Dahlberg, J.M., 2012: Debris mitigation methods for bridge piers. Iowa State University. Institute for Transportation.

Zhang, F., Johnson, D.M., Wang, J., Yu, C., 2016: Cost, energy use and GHG emissions for forest biomass harvesting operations. Energy 114: 1053–1062. https://doi.org/10.1016/j.energy.2016.07.086

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Federico Bertone *

e-mail: federico.bertone@unito.it

Assoc. prof. Marco Manzone, PhD

e-mail: marco.manzone@unito.it

Department of Agricultural, Forest, and Food Science

University of Turin

Largo Braccini 2, 10095 Grugliasco, Turin

ITALY

* Corresponding author

Received: December 04, 2023

Accepted: January 03, 2025

Original scientific paper