Practical Application of Carbon Footprint of Timber Supply Chain Using Forest Machine Data

doi: https://doi.org/10.5552/crojfe.2025.3233

volume: issue, issue:

pp: 18

- Author(s):

-

- Kaulen Alexander

- Mayer Dorothea

- Franz Mark-Fabian

- Purfürst Thomas

- Article category:

- Original scientific paper

- Keywords:

- timber harvest, carbon footprint, net carbon storage of timber, forestry technique, timber logistics

Abstract

HTML

Timber harvesting tends to generate controversy in society. Some emphasize the benefits of obtaining renewable resources, while others lament the loss of forest carbon stocks and the resulting emissions. However, as long as the wood does not decompose, it continues to store carbon. Consequently, buildings and goods made of wood become carbon sinks. To illustrate this carbon storage potential, we developed an application that calculates the carbon footprint of mechanized timber harvesting using the production reporting input files »harvested production-hpr« and »machine operating monitor-mom« in the StanForD format generated by harvesters and forwarders. The »HarvestCO2-App« is a free, user-friendly web application for forest owners, machine operators/owners, and policymakers, programmed in R with an R Shiny user interface. The app aims to raise awareness of the carbon storage potential of wood use by providing a quantitative basis for discussion. The app also inquires about the conditions under which timber was harvested. By evaluating this information alongside the calculated carbon footprint, it will be possible in the medium term to conduct a sensitivity analysis of the impact of individual factors on emissions.

Practical Application of Carbon Footprint of Timber Supply Chain Using Forest Machine Data

Alexander Kaulen, Dorothea Mayer, Mark-Fabian Franz, Thomas Purfürst

https://doi.org/10.5552/crojfe.2025.3233

Abstract

Timber harvesting tends to generate controversy in society. Some emphasize the benefits of obtaining renewable resources, while others lament the loss of forest carbon stocks and the resulting emissions. However, as long as the wood does not decompose, it continues to store carbon. Consequently, buildings and goods made of wood become carbon sinks. To illustrate this carbon storage potential, we developed an application that calculates the carbon footprint of mechanized timber harvesting using the production reporting input files »harvested production-hpr« and »machine operating monitor-mom« in the StanForD format generated by harvesters and forwarders. The »HarvestCO2-App« is a free, user-friendly web application for forest owners, machine operators/owners, and policymakers, programmed in R with an R Shiny user interface. The app aims to raise awareness of the carbon storage potential of wood use by providing a quantitative basis for discussion. The app also inquires about the conditions under which timber was harvested. By evaluating this information alongside the calculated carbon footprint, it will be possible in the medium term to conduct a sensitivity analysis of the impact of individual factors on emissions.

Keywords: timber harvest, carbon footprint, net carbon storage of timber, forestry technique, timber logistics

1. Introduction

The concentration of CO2 in the atmosphere has increased by 30% since the industrial revolution and continues to rise by 0.4% annually. These emissions contribute to man-made climate change and its consequences, such as the threat to the stability and resilience of our forests and the associated risk to wood supply (Calvin et al. 2023). Active forest management is a vehicle for removing residual emissions from the atmosphere, i.e. emissions that are difficult to avoid, such as those from cement production or air and sea transport. Residual emissions from fossil fuels are difficult to avoid because there is currently no technology or strategy to replace fossil fuels in these specific areas with renewable or carbon neutral substitutes. Therefore, the emissions must be removed from the atmosphere by some other mechanism and cannot be avoided (Buck et al. 2023). Active forest management is needed to achieve the net zero target for Germany by 2045 and for the EU by 2050, (SWP 2023). Forests act as carbon sinks by absorbing CO2 from the atmosphere and storing it in biomass (forest carbon stock) through photosynthesis. When this biomass is harvested as timber through forest operations, the bound CO2 is not released back into the atmosphere, as would occur during natural decay in the forest. Instead, it is stored in long-lasting products. Both material and energy uses of wood substitute fossil raw materials (oil, gas) or more climate-damaging materials (steel, cement) (Timmermann and Dibdiakova 2014, Knauf et al. 2015, Knauf 2016, Yoshimoto 2018,). Although non-management results in higher carbon stock, it ultimately becomes a carbon source during the decay phase, and the potential to substitute fossil raw materials is lost (Eriksson 2007, Berndes 2016, Knauf 2016).

The amount of CO2 that can be removed from the atmosphere through forestry is influenced by three main factors: the types of products made from timber (in order of increasing emissions: construction wood, wood-based materials, furniture, windows), forest management practices, and the emissions generated during wood supply (Erikson 2006, Kubova 2018). The use of timber, whether for short-term bioenergy or long-term construction, has the most significant impact on carbon removal potential. There is a hierarchy of wood uses regarding their efficiency in displacing carbon. High-leverage products, such as structural timber and substitutes for steel beams and concrete, offer the highest efficiency. In contrast, biofuels derived from raw wood, which require significant energy input, have the lowest effect but can still substitute fossil fuels on a small scale. Reducing, for example, a country's energy dependence (Lippke 2012). Notably, 60% of biomass for bioenergy in the EU comes from timber, which replaced 82 million ton (t) of fossil carbon in 2018 (Sgarbossa 2020). The forest management strategy, particularly the intensity of timber harvesting and factors outlined in Section 2.3.1, primarily drives the carbon removal potential (Klein et al. 2016, Haavikko et al. 2022).

The carbon footprint quantifies the impact of forestry on climate change by describing both direct (diesel consumption) and indirect (for example, manufacture and supply of forestry machinery) carbon flows throughout a product lifecycle (Kubova 2018). Potential fuel consumption savings range from 7% to 20%, achievable through simple measures such as training forestry machine operators, utilizing fleet management software, optimizing routes, and adapting machine types for specific operations. These measures not only reduce the carbon footprint but also help avoid emissions, as fuel costs account for 7% to 15% of operating expenses. Reducing fuel consumption can therefore result in significant cost savings (Weise and Rosenbach 2011, Hella 2014, Wagner 2017).

Forestry machines, primarily harvesters and forwarders equipped with full onboard computers, generate data compliant with the StanForD 2010 standard format (a standard for forest machine data and communication) regarding both machine performance and the harvesting process (Skogforsk 2021, Woo et al. 2021). This allows the automatic collection of data needed for our application to calculate emissions from timber supply and the amount of carbon bound in timber by forestry machinery (Dias et al. 2007, Kemmerer and Labelle 2021). Calculating the carbon footprint is a comparatively simple method of utilizing forestry machine data. The carbon content of freshly harvested timber can be calculated from data records on tree species, type of assortment, and harvested volume. The carbon content of coniferous wood is approximately 734 kg CO₂/m3, while that of deciduous wood is approximately 1000 kg CO₂/m3. In contrast, emissions from trucks, harvesters, and forwarders are calculated using machine operating data records, which include variable parameters for actual diesel consumption and distance to the sawmill, as well as constant parameters for machine transportation, lubricants, operator transportation, loading, fabrication, supply, and maintenance. Kaulen et al. (2024) provided the basis for the calculations, which is described further in Section 2.4.

The present application has the potential to elucidate the climate protection performance of the timber in question by comparing the low emissions anticipated from the timber supply chain and the carbon bound in the timber (Kaulen et al. 2024). At the same time, pressure from legislative processes is growing, often torn between the ideological views of nature conservation/set-aside and utilization, which frequently result in legislation that is neither objective nor goal-oriented (Winkel and Sotirov 2016). Recent trends clearly favor conservation/set aside options, prioritizing carbon storage in forests to the detriment of the forestry and timber industry (Primmer et al. 2021). The EU Biodiversity Strategy (EUBDS) for 2030 will lead to the set-aside of between 9% and 47% of forest area, depending on implementation by member countries (Schier et al. 2022). The EU aims to place 30% of the land area under protection and 10% under strict protection (Hermoso et al. 2022). The same applies to the EU's Green Deal, which is reflected in the Fit-for-55 programs and the associated adaptation of »Land Use, Land Use Change and Forestry (LULUCF)« regulations, aimed at achieving net zero emissions for the sector. These targets will likely be achieved through set-asides, necessitating a build-up of forest carbon stocks (Farthofer 2022, Robinson et al. 2023).

This paper follows the recommendation of Yoshimoto et al. (2018), who conducted a systematic review on improving forests as carbon sinks and bioenergy resources. They concluded that the existing literature inadequately addresses the issue of wood supply and the factors that lead to either increased or decreased emissions in the supply processes. In particular, they noted a lack of analysis of the factors affecting emissions and solutions for improved technology use. To this end, they also suggest implementing systems that can better trace carbon flow. This can be achieved using biometric fingerprints on the cut surface or RFID tags, for example. Timmermann and Dibdiakova (2014) recommend utilizing real-world data from actual hauls, such as diesel consumption, to calculate a more accurate carbon footprint. For instance, forwarding distances and stand characteristics are crucial for calculating the productivity of a harvesting system and estimating resource consumption. Current methods rely on assumptions that approximate reality but cannot represent it exactly. Berndes et al. (2016) emphasized that robust information from traceable flows must be available for policymaking processes to develop models that provide policymakers with reliable information.

In line with the proposals for enhanced traceability in the wood supply chain while considering climate protection aspects (Kaulen et al. 2023), the aim of this paper is to present a practical and user-friendly method for automatically calculating a carbon footprint based on forest machine data. One aim of our study is to quantify the carbon sequestered by the use of wood in relation to the emissions caused by the wood supply process. For this purpose, we have developed the HarvestCO2-App. The app is designed to demonstrate the climate-positive effects of timber supply. The tool can also show alternatives and motivate users to save even more emissions. It allows users to input the conditions under which timber harvesting and its associated carbon footprint occur. The query is then analyzed, and the results can be utilized for future research and long-term monitoring, which will be presented in a future paper by 2026. A longer period of time is required to collect the data sets. Approximately 180 timber supply operations are required before a sensitivity analysis is robust.

The topic can be classified under the collective term »carbon management«. It consists of Carbon Capture and Storage (CCS), which involves capturing emissions produced by power generation or industrial activity, transporting them, and then permanently storing them; Carbon Capture and Utilization (CCU), which refers to the active capture of CO2 and the utilization of carbon from biomass; and Carbon Dioxide Removal (CDR), which involves actively removing CO2 from the atmosphere. With a current price per ton of CO2 removed from the atmosphere ranging from 50 to 150 euros, the active capture of CO2 and proof of storage becomes economically attractive.

Currently, forestry cannot contribute to CCS. The only way forestry could contribute to this area of carbon management would be to store timber in disused mines; however, this is not economically viable at this time. More relevant for wood supply are the areas of CCU and CDR. In CCU, the carbon bound in timber is used in products, thus delaying emissions into the atmosphere and substituting fossil raw materials such as oil and steel. These include structural wood in the building sector, furniture construction, and innovative areas of the bioeconomy, such as plastics production. Depending on the product use and durability, emissions are only delayed in the short and medium term. The manufacturing of these products typically generate emissions as well, complicating the tracing of phases of use in a life cycle assessment and affecting how a carbon footprint is derived. On the other hand, CDR is significant in forestry, as reforestation, long-term storage in the building sector, the creation of very long-lived products, and the use of plant coal in agriculture are explicitly considered measures for CDR. The LULUCF sector is particularly important on the path to the EU's net zero target because CDR is the only area where emissions that are difficult to avoid and residual in nature – such as those from aviation, shipping, and cement production – can be captured (Schenuit 2022, SWP 2023).

The opposite model that contrasts with carbon management is the practice of taking forest land out of use. As indicated, the type of management has a significant impact on forest carbon stock. While the notion that removing forest land from use has a positive overall effect on climate has gained wide acceptance among policymakers, forest and timber use must be considered holistically. With admittedly poor data on European old-growth forests (due to their scarcity), we assume that a balance between growth and decay will occur in the long term, with carbon storage in old-growth forests remaining constant. The balance of CO2 uptake and release reaches a dynamic equilibrium (Gundersen et al. 2021). However, studies suggest that old-growth forests serve as continuous carbon sinks (Baum et al. 2021). In general, a European forest that has recently been taken out of use becomes an active carbon sink for a long time (approximately 50 years) with significantly increasing living biomass. It reaches a peak of living biomass at about 150 years on average for all tree species. After 150 years, however, the decay phase begins, during which approximately as much CO2 is released as carbon was bound through photosynthesis. Forests that have been taken out of use for at least 50 years lose their sink function over time and become passive carbon storage with high biomass fractions (Nagel 2023).

2. Materials and Methods

The technical basis of the application is outlined in the methods section. For a detailed technical description and the application, itself, please refer to the following website: https://kwf2020.kwf-online.de/harvestco2/

The methodological framework, particularly the methods employed for calculating the carbon content of freshly harvested wood and estimating emissions from the timber supply chain, is derived from the work of Kaulen et al. (2024). As per the LCA standard (EN 16485), the terms »carbon content« and »carbon storage« refer to biogenic carbon retained for a specific duration. The carbon footprint is calculated by subtracting all emissions from the carbon stored in the harvested wood. The output unit, »kg CO2/m3«, also includes the remaining GHG (Greenhouse Gases) species expressed as CO₂ equivalents. However, the objective of our investigation is not to examine these individual GHGs in isolation; therefore, they have been aggregated. The term »eq.«, which denotes »equivalent«, has been omitted for enhanced readability.

2.1 R-Version and R Packages

We developed the HarvestCO2-App using R Shiny (Chang 2023) with R version 4.3.2 (R-Foundation 2023). The R Shiny package offers a range of functions that enable users to develop web-based applications. The R code generates an HTML interface that can be integrated into websites or published on a server. Additional packages used include common (Bosak and Tran 2023), conflicted (Wickham 2023), readxl (Wickham et al. 2023a), shinyBS (Bailey 2022), shinyWidgets (Perrier 2023), tidyverse (Wickham 2023), tools (Hornik et al. 2003), XML (Lang and Kalibera 2023), and xml2 (Wickham et al. 2023b).

2.2 Input Data

To calculate the carbon footprint of an individual felling event, the app requires input from the user. Users can either manually enter the data or upload .hpr (harvested production) and .mom files (operational monitoring) in StanForD 2010 format (Skogforsk 2021) generated by harvesters, forwarders, or other StanForD 2010-compatible machinery. Uploading files will automatically overwrite any previously entered manual inputs for the same values.

If users opt for manual data entry, the app allows them to input data for one species at a time, which is selected from a drop-down list. Users then enter the volume of harvested wood and the volume of diesel consumed by the harvester and forwarder during felling and skidding. Alternatively, users can upload up to three files: the .hpr file generated by the harvester, the .mom file generated by the harvester, and the .mom file generated by the forwarder. The app complies with data protection regulations, like the EU´s »General Data Protection Regulation«.

The app utilizes an Excel list containing kiln density and total shrinkage values for eight conifers and 24 deciduous European tree species, enabling species-specific calculations of carbon content in the supplied timber. The values used are drawn from Ulf Lohmann (1999) and Rudi und André Wagenführ (2022). The app recognizes species names in English, German, and French, although not all synonyms and abbreviations used in forestry have been included for each species. For all other species, the app defaults to total mean values.

Users can choose to input transport information to complete the carbon footprint calculation. The app generates three input fields for each of the species or assortment listed in the .hpr file. For manual input, only three input fields are generated, as the manual option limits the entry to one species at a time. These fields request the distance the logs were transported by truck, train, or ship, respectively.

After entering the necessary information to calculate the carbon footprint, users can choose to add supplementary details about the harvest event. This additional data highlights factors that may influence emissions during timber harvest. The following chapter explains these factors and the rationale behind their selection. A long-term study, in the form of a sensitivity analysis, is planned to explore how various carbon footprint factors related to timber provision impact emissions.

2.3 Factor Input

The following is a review of the factors identified in the literature as having the most significant impact on the carbon footprint of timber harvesting. These factors are subsequently examined during the final stages of the application process to ascertain the exact circumstances under which timber harvesting occurred.

Actual diesel consumption, based on data from forestry machines, reflects the circumstances under which the timber was harvested. Consequently, diesel consumption already accounts for many factors that influence emissions in the timber supply chain. Additional factors are assessed to enable a sensitivity analysis once sufficient data has been collected. The rationale behind selecting these surveyed factors is explained in detail in the literature review. The most significant factors, as identified in the literature, are classified into stand, operational, and technical factors.

The carbon footprint can vary significantly between regimes, and even between studies of the same regimes in the variety due to various combinations of factors. The greatest potential for emission savings lies in selecting the most efficient process, maximizing machine productivity, using GIS tools (particularly to locate log sections), varying assortments, applying silvicultural treatments, and the type of forest (close to nature vs. plantation) (Cosola 2016). Kühmaier et al. (2022) analyzed different logging methods with respect to their emissions. They found that the combination of a chainsaw, tractor and forest trailer resulted in the lowest emissions (2.3 kg CO2/m3), followed by the combination of a chainsaw, tractor, and winch (2.66 kg CO2/m3). The highest emissions (8.17 kg CO2/m3) were associated with cut-to-length (CTL) harvesting using a winch-assisted harvester and forwarder. Other combinations such as a chainsaw with a cable yarder and processor for reprocessing, or a chainsaw with a skidder and chainsaw, or a harvester and forwarder without winch assistance, were also studied. The choice of timber harvesting method plays a crucial role in emissions (Morat et al. 1998). This paper focuses on harvesting operations using a harvester and forwarder, as well as other heavy machinery capable of producing standardized data sets in the StanForD 2010 format, which are expected to provide reliable data.

2.3.1 Stand Factors

By switching from pure stands to mixed stands, Spinelli et al. (2020) showed that productivity decreased by 40–57%, stem diameters decreased by an average of 50%, machine wear increased (along with idle times), and, finally, the wounding of the trees remaining in the stand tripled (Spinelli et al. 2020). This factor is asked as part of the »silvicultural treatment« and »stand type«.

The species of trees being harvested also appears to influence the results. Dias and Arroja (2007) compared timber harvesting in eucalyptus and maritime pine stands. For eucalyptus, emissions were 5.6 kg CO2/m3, while for maritime pine, they were 4.7 kg CO2/m3 (Dias and Arroja 2007). Labelle et al. (2024) demonstrated a strong correlation between decreasing productivity (and consequently, higher fuel consumption) and increasingly complex tree structures. The more complex the tree characteristics (thick branches, poor formed, narrow sweeps, forks, thick lower stem section), the greater the fuel and time consumption. This effect typically occurs in hardwood trees and is accounted for in the timber data of the .hpr data sets.

A correlation is also observed between the distance traveled by the harvester and forwarder in relation to emissions (Kärhä et al. 2024). This factor is addressed by the variable parameter »distance driven (m)« and is derived directly from the .mom data sets. The factor reflects the stand condition, as well as the »skid road spacing«.

Furthermore, there is a clear correlation between soil properties, particularly moisture and humus content, as demonstrated by Kärhä et al. (2023). Fuel consumption on dry mineral soil is 0.11 l/m³ lower than on peatlands. This factor is labeled »soil moisture (slip)« and »obstacles«.

2.3.2 Operational Factors

De La Fuente et al. (2017) compared two timber harvesting methods – full tree and CTL – as they dominate timber harvesting worldwide. The key difference lies in how the wood is processed. In the CTL method, the harvester cuts assortments in the stand, and the forwarder picks them up individually. In contrast, with full-tree harvesting, the entire tree is removed from the stand and cut into assortments at the forest road (Hiesl 2013). Despite data heterogeneity, studies indicate that CTL methods result in fewer emissions due to the use of integrated, coordinated systems. De La Fuente et al. (2017) also showed that emissions depend on the influence of assortments. Under »technical equipment«, the factor of using integrated systems is queried. Sgarbossa et al. (2020) drew a similar conclusion – roundwood from thinnings has four times higher emissions from forest operations compared to whole trees and forest residues. This is an aspect of the »silvicultural treatment«, which is the subject of our study.

The law of piece-size-and-volume explains the increasing processing time with decreasing wood volume in forestry work systems. In other words, it describes the decrease in processing time per m3 as tree volume increases. This law was first identified by Hilf (1928, 1941) and later mathematically proven by Speidel (1952) (Hilf 1928, Hilf 1941, Speidel 1952, Bötscher 2021,). The law is based on the observation that smaller logs require more secondary operations. While larger logs also require secondary operations, the time spent on them is less relative to the log's volume (Bötscher 2021). Kärhä et al. (2024) demonstrated that stem size significantly impacts machine productivity, with larger stems resulting in higher output. This finding aligns with the observations of Gagliardi et al. (2020), who reported higher fuel consumption for shorter wood compared to longer wood. Therefore, the quantity and dimensions of the assortments are of primary importance and are reflected in the assortment data from the .hpr data records.

2.3.3 Technical Factors

Purfürst and Erler (2007) analyzed the influence of operator skills by evaluating StanForD data sets. They found that operator skills have less impact on forwarder productivity and fuel consumption compared to CTL operations using a single-grip harvester. Effectively handling a harvester requires a range of skills, including tacit knowledge, the ability to handle working elements simultaneously, harvester head control, the ability to plan several stems ahead, and precise gripping and cutting techniques. Overall, 10–15% of optimization potential is related to technical equipment, 20–30% to crane and generator control, and 50–55% to advanced planning. Productivity differences between operators can reach up to 80%. Strubergs et al. (2021) demonstrated the positive effects of operator training on efficiency in the harvesting process by analyzing harvester data as well. Additionally, an operator's awareness of fuel consumption and its constant visibility affects their performance (Rosenbach 2012). Kymäläinen et al. (2023) expanded on Purfürst's findings by highlighting that the human factor encompasses many sub-factors. Experience can lead to a 1.5% linear annual increase in productivity, giving an operator with 20 years of experience a productivity advantage of approximately 27% (Spinelli et al. 2020). Motivated and well-rested operators perform better, with factors such as sufficient sleep, periods of regeneration, and physical and mental health playing decisive roles in performance. Appropriate shift planning is particularly important in this regard. However, further research is needed to fully understand the factors influencing operator performance (Spinelli et al. 2020, Kymäläinen et al. 2023). Fuel savings of as little as 10% can be achieved through the efficient loading and unloading of the forwarder and truck by optimizing the crane settings and adapting them to the driver. Key strategies include consistently displaying fuel consumption, using telescopic technology, avoiding simultaneous driving and loading, reducing idling times, and avoiding overloading (Rosenbach 2012). Overall, it is important to note that, following the law of piece-size-and-volume, people and their abilities are the second most important factor for productivity and fuel consumption (Purfürst and Erler 2007). In a recent study, Kärhä et al. (2023) reported that the difference in fuel consumption between low-consumption (i.e., fuel-saving) and high-consumption (i.e., fuel-wasting) harvester operators averaged approximately 0.23–0.72 l/m³, when the removal stem size was 0.1–0.6 m³. Furthermore, the relative m3 based fuel consumption averaged 38–58% higher for fuel-wasting harvesters compared to their fuel-saving counterparts. Under »operator experience«, the driver's skills are queried along with all the subfactors just listed.

There are many possible combinations when applying technology, which can be explored by querying technical equipment. For example, tires and additional equipment, such as tracks, influence emissions. In addition to protecting soil, tire pressure control systems offer potential savings. Studies by Burk and Weise (2005) indicate that emission savings of 8% can be expected when driving with lower tire pressure and up to 15% without a brushwood layer on skid roads. Kärhä et al. (2023) reported that using tracks on the front bogie of the forwarder increases fuel consumption by 1.8 l/hour, recommending that unnecessary use of tracks be avoided. Moreover, the fuel consumption of forestry machines can be reduced by eliminating thermostatic fans and selecting appropriate tires (Kopseak et al. 2021). Additionally, extending service life and reducing maintenance costs can be achieved through the adaptation of tire pressure to prevailing environmental and ground conditions (Brown and Sessions 1999). Tire pressure has been shown to exert a significant influence on fuel consumption and, consequently, emissions. Accordingly, a reduction in fuel consumption can be achieved by adjusting tire pressure to the specific ground conditions (Brondex 2014).

The utilization of forwarders with rubber tracks in lieu of wheeled chassis can reduce costs, enabling a comparable, higher driving speed (Lundbäck et al. 2024). Moreover, the use of bogie tracks has the potential to result in reduced fuel consumption (Gendek and Moskalik 2016). Increased productivity when using forestry cranes is also associated with reduced fuel consumption, and optimizing crane development is essential for lowering emissions (Mendoza-Trejo et al. 2022). Additional factors that influence these outcomes are machine control systems and hybrid drives. Installing a control system on a harvester can enhance productivity while simultaneously reducing fuel consumption (Spinelli and De Arruda Moura 2019). Integrating hybrid drives can help reduce emissions, partly due to enhanced drive performance (Mergl et al. 2021). Eliasson et al. (2023) and Danilovic et al. (2015) demonstrated that larger forwarders, with a correspondingly larger payload, result in lower emissions per cubic meter of wood. These aspects are addressed in the query regarding the factors of harvester and forwarder size, as well as in »Technology«.

Both harvesters and forwarders have shown efficiency gains since entering the market, driven by advances in technology. The improved performance of the harvester is linked to higher engine output, while forwarders benefit from an increased payload capacity. As engine power and harvesting performance improve, specific emissions per cubic meter of timber decrease, as demonstrated by long-term monitoring by the German Center for Forest Work and Technology (KWF e.V.) (Weise 2022). Equipment specifications are also considered in these evaluations.

2.3.4 Factors of Timber Logistics

Wood logistics are subject to various factors that influence emissions; these are briefly outlined in this section. Busenius et al. (2015) investigated how increased maximum payloads affected efficiency gains and associated emission reductions in Germany. They found that increasing the payload for timber transport from 40 t to 44 t reduced emissions by 13.8%, from 40 t to 45 t by 18%, from 40 t to 50 t by 28%, and from 40 t to 52 t by 31%. This suggests that truck utilization plays a decisive role in emission reductions. Other influencing factors include the type of vehicle, equipment such as trailers, engine type, tires, total truck weight, road conditions, infrastructure, driver mileage, and more (Busenius 2015). However, this study and its application do not focus on identifying all factors that influence emissions from wood logistics. Instead, the focus is on identifying factors from the perspective of forest managers, who generally have access to forest machine data and can describe harvesting activities, though their access to logistic data sets is limited. We aim to explore this further in a follow-up study.

2.3.5 Chosen Factors

From the literature, several factors can be identified that either have a direct influence on emissions or affect the productivity of wood supply. We also query these factors in our app to determine the circumstances under which wood supply occurs. As previously explained, productivity is closely related to emissions. However, there are some obvious factors not found in the literature that we have taken into account.

These factors are:

.hpr descriptive data: extraction distance, harvested volume, assortment, tree species

silvicultural treatment: clear-cut, selective, beetle calamity, wind calamity, first thinning, later thinning, final felling

size of harvester: small, medium, or large

size of forwarder: small, medium, or large

technical equipment: crane tip control, fleet control software, intralogistics, hybrid engine, thermostatic fans, dual gear, high flotation tires, tire pressure control system, bogie/wheel tracks, or crawler chassis/caterpillar

slope: <35%, 35–50%, or >50%

skid road spacing: 20 m, 30 m, 40 m, or no skid roads

stand type: monoculture or mixed

obstacles: visual restrictions/rejuvenation or large boulders

experience of the operator: <5 years, 5–15 years, or >15 years

temperature outside the cabin: –5–10°, 10–20°, 20–30°, or 30–40°

Soil moisture (slip): dry, damp, or wet.

However, the literature also points to factors that we have not adopted. While these factors are relevant, we limited the selection to reduce the scope of input factors. The selection was made based on existing literature and consultations with 30 experts made up of forestry machine manufacturers, foresters, machine operators and data specialists with many years of experience and recognized expertise in the field. Ultimately, we needed to decide which additional factors should be surveyed to evaluate a sensitivity analysis in a subsequent publication.

Factors that have not been taken into account are:

Use of lights; avoidance of standing and idling; fouling of the radiator and oil cooler; training drivers to drive economically; alternative fuels (bio-diesel) (AFORA 2015, De La Fuente et al. 2017); productive harvesting time (Aalmo et al. 2021); advanced area conditions (visibility, stocking, stand density, understory, stratification, soil bearing capacity, terrain slope, driving distance, relief); climatic conditions (time of day, season, weather); quality of felling preparations (visibility of markings for the stand to be cut, skid trails); use of working systems (choice of suitable method and adapted performance of operating equipment, advancing and pre-sorting of individual assortments); overall performance of the machine operator (mental capacity, physical capacity, working technique) (Purfürst 2009, Weise and Rosenbach 2011, Hoffmann 2014, Bötscher and Cosola 2016); ownership; forest management intensity; availability of primary infrastructure; general productivity (Klein et al. 2016); engine speed and hydraulic pump pressure (Santos et al. 2020); chain model and sharpness (Jönsson et al. 2016); use of GIS tools (Cosola 2016).

2.4 Underlying Equations

The underlying equations were derived from Kaulen et al. (2024). These equations calculate the carbon content of wood, as well as the emissions generated during harvesting and transport. The carbon footprint is determined by subtracting all emissions from the carbon stored in the harvested wood.

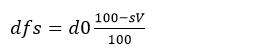

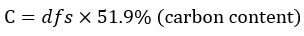

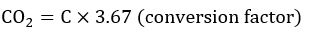

To calculate the species-specific carbon content, it is necessary to determine the wood density of the timber. This measurement indicates the amount of kiln-dried timber contained in 1 m3 of freshly cut timber. The timber properties for the tree species, provided by Wagenführ (1989) and Lohmann and Blosen (2021), include kiln density (d0) and total shrinkage of the volume (sV). These values yield the species-specific wood density of fiber-saturated timber (dfs), as demonstrated in Eqn. 1 (Lohmann and Blosen 2003, Wagenführ and Wagenführ 2021). Since it was not feasible to monitor the moisture content of the wood throughout the study, we assumed that the timber was fiber-saturated. The quantity of carbon accumulated in the supplied timber was determined by multiplying the tree species-specific wood density by the carbon content of timber (51.9%) and the conversion factor for carbon (C) to CO₂ (3.67 or 44/2, which corresponds to the molar mass of CO₂) (see Eqns. 2 and 3) (Lohmann and Blosen 2003, Scholz et al. 2018, Kollmann 2013, Bloche-Daub et al. 2016). The term »carbon content« refers to the biogenic carbon content of wood, as proposed by Lamlom and Savadige (2003).

(1)

(1)

(2)

(2)

(3)

(3)

The example of Pseudotsuga menziesii (Douglas fir) (Missouri Botanical Garden 2024) is employed to illustrate the methodology for calculating the species-specific carbon content, or the CO₂ stored in the aforementioned specimen. The shrinkage rate, which is 11.9% for Douglas fir, is subtracted from the kiln density of 470 kg/m³. This yields a wood density in fiber-saturated wood of 414.07 kg/m³. This value is then multiplied by the carbon content of the wood (51.9%), resulting in an estimated carbon content of 214.9 kg CO₂/m³. Converting these values to carbon dioxide equivalents (3.67) yields a result of 788.7 kg CO₂/m³ for Douglas fir. For Picea abies (spruce), the result is 722.39 kg CO₂/m³ (Table 2). The taxonomic nomenclature is based on Tropicos (Missouri Botanical Garden 2024).

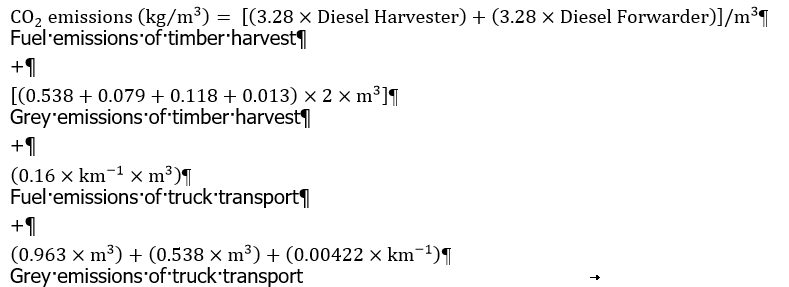

The emissions from timber harvesting are calculated based on two distinct components: real variable data from forestry machines (specifically, the .hpr and .mom files from the harvester and the .mom file from the forwarder) and constant parameters (constants) derived from averaged values that are challenging to ascertain from real data.

As illustrated in Eqn. 4, the diesel consumption of the harvester and forwarder (derived from the .mom file, in liters) is first summed, divided by the amount of timber harvested (derived from the .hpr file, in cubic meters), and then multiplied by the conversion factor (diesel to CO2, 3.28 kg CO2/liter) to calculate emissions from the fuel combustion (Handler et al. 2014). The constants for fabrication, supply, and maintenance (0.538 kg CO2/m³) (Handler et al. 2014), lubricants (0.118 kg CO2/m³), machine transport to the stand (0.013 kg CO2/m³), and operator transport to the operation site (0.079 kg CO2/m³) (Kühmaier et al. 2022) are added to this to calculate grey emissions. Grey emissions are defined as emissions necessary for the production and provision of goods or services (Paschotta 2023). In this context, grey emissions are those that cannot be directly measured as diesel consumption and are, therefore, categorized as such. These values are included twice in the equation, as they apply to both forwarders and harvesters. Additionally, emissions from fuel combustion and »grey emissions« associated with timber logistics must be considered. These are calculated by multiplying the distance traveled (in kilometers) by the constant for emissions from diesel consumption (0.16 per km and m³) (Klvač et al. 2013) and the amount of wood transported. This is then added to the product of the quantity of wood transported and the constants for loading (0.963 kg CO2/m³), fabrication, supply, and maintenance of the machine (0.538 kg CO2/m³), along with the product of the distance traveled and the constant for lubricants (0.00422 kg CO2/m³) (Handler et al. 2014).

(4)

(4)

2.5 Output Data

The app displays two output tables and an initial summary of the main results. The first table presents all variables related to the harvest and forwarding operations. Users can select which variables to include from a drop-down list. By default, the table includes tree species, assortment, wood volume, kiln density, carbon content of wood, harvest emissions, and the carbon footprint of harvest. Additional variables include total shrinkage, bulk density, carbon density, CO2-equivalent of carbon density, the fraction of assortment relative to total volume, harvest emissions per unit of wood, and the weight of carbon dioxide equivalent bound in wood. The second output table contains tree species, volume, carbon footprint excluding transport, transport emissions, and the total carbon footprint, including transport.

3. Results

The HarvestCO2-App is a functional web application that calculates the carbon footprint of the timber supply chain based on a small number of input parameters. Its user-friendly interface is designed to accommodate users with varying levels of computer proficiency: HarvestCO2-App – KWF 2030 (kwf-online.de)

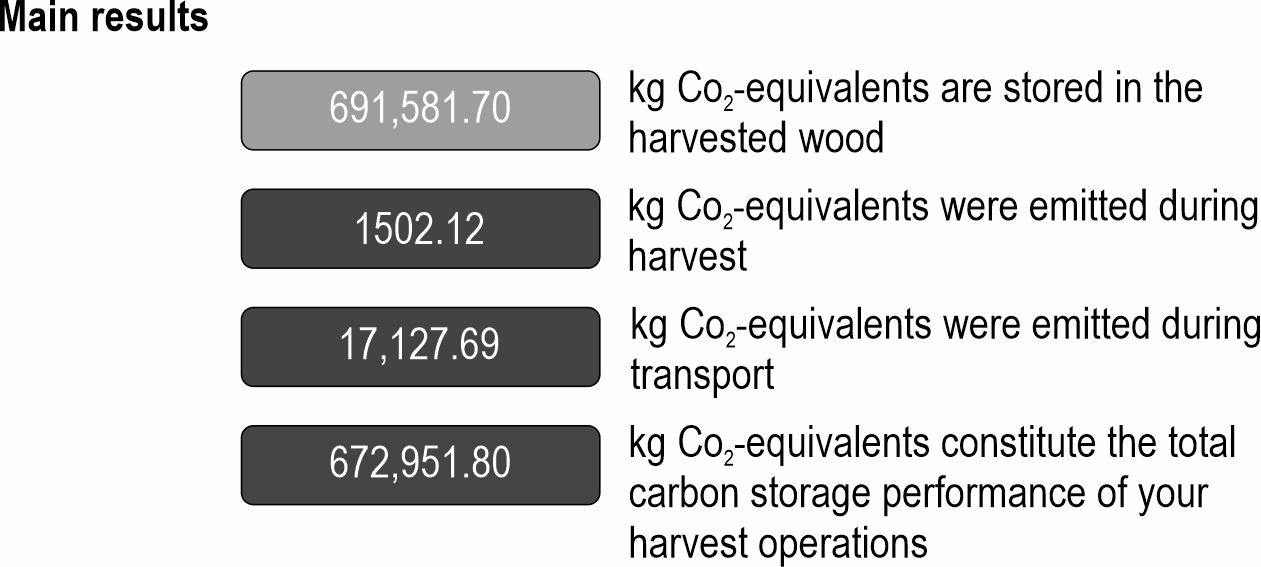

Fig. 1 Initial summary of four main results obtained from manual entries or data records

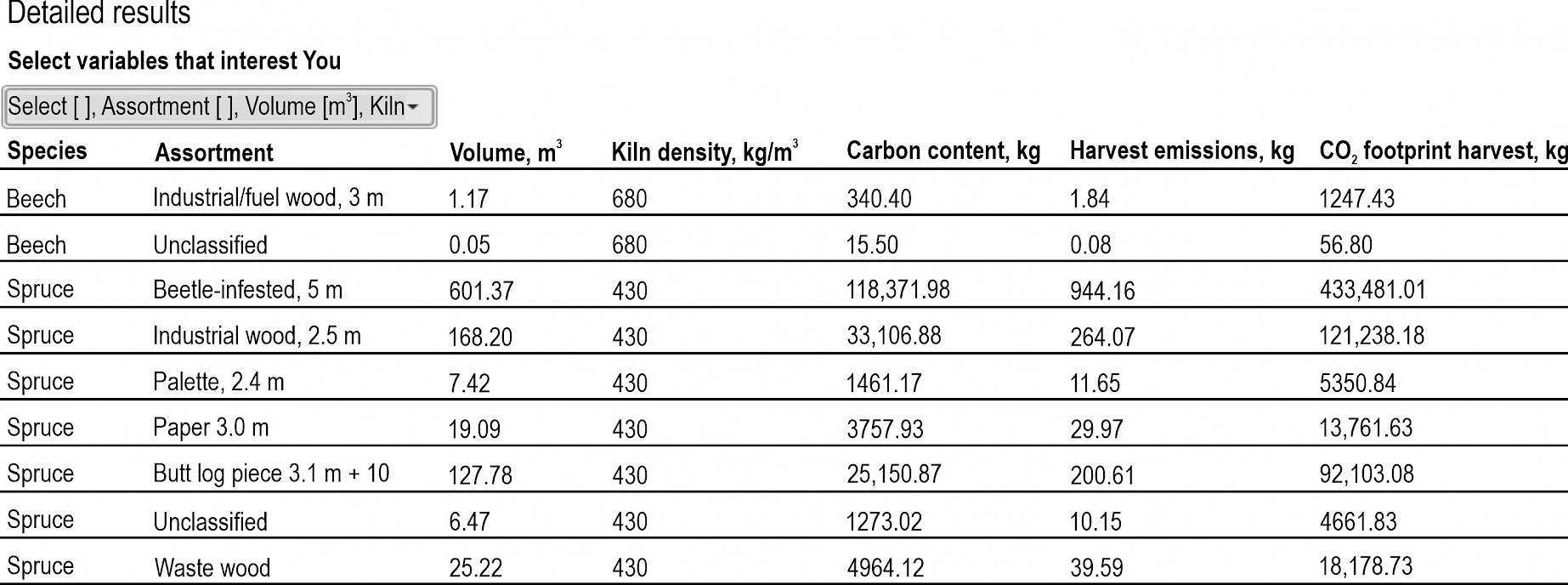

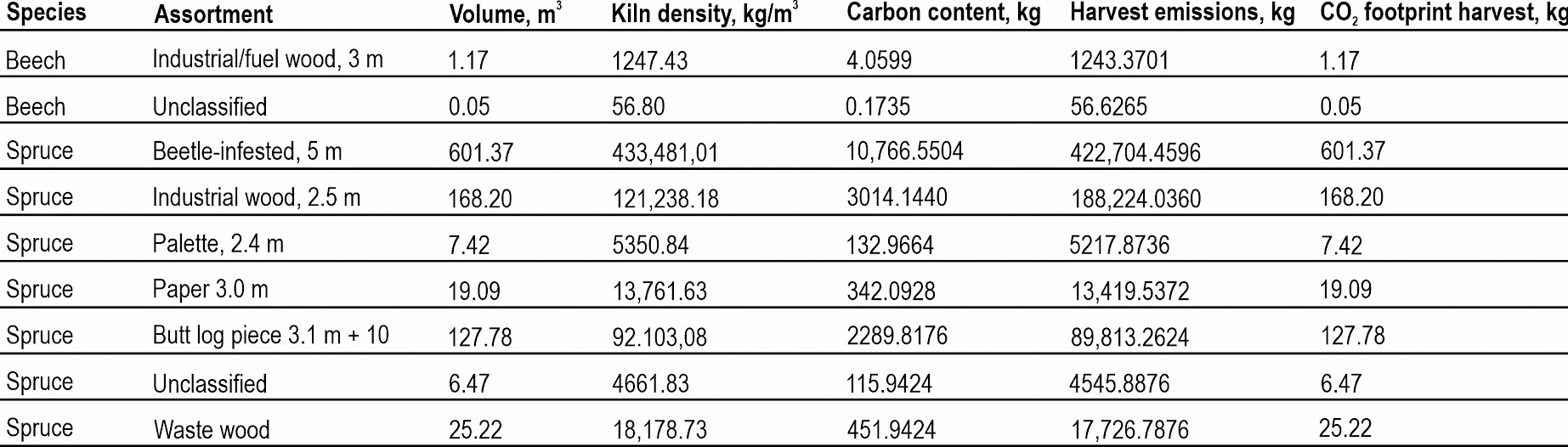

Fig. 2 Extract of user interface of HarvestCO2, featuring the first output table containing a list of assortments from a harvester file along with carbon footprint of the harvest for each assortment. Forestry machine data comes from a detailed examination of a cut in Germany (Palatia)

Fig. 1 summarizes the four most important results obtained from manual entries or uploaded data records for the selected cutting, including downstream timber logistics. The user can see at a glance the amount of CO2 equivalents stored in the wood and the amount released by harvesting the wood. Figure 2 displays the first output table, which lists assortments from a harvester file generated during a test harvesting event. The figure shows the default output variables, while a drop-down menu at the top allows users to select additional variables. Each row in the list corresponds to an assortment. Species, assortment, and volume data come from the uploaded .hpr file. Based on this information, the app selects kiln density and total shrinkage from a predefined list and calculates the carbon content of the wood, harvest emissions, and the resulting carbon footprint for each assortment. Using this table, the app generates a list of input fields where users can enter transport distances for each assortment. These added inputs are then used by the app to calculate transport emissions and the total carbon footprint (Fig. 3).

Fig. 3 Extract of user interface of HarvestCO2-App displaying the second output table with transport emissions and total carbon footprint (CO2-Footprint total). Forestry machine data is derived from a detailed examination of a cut in Germany (Palatia)

Once the results are available, users are prompted to voluntarily provide additional information, explaining the circumstances surrounding the cut. This study focuses on timber harvesting rather than logistics. Both the detailed results and the user-provided information regarding factors affecting the cut and its carbon footprint can be exported as an Excel file. Additionally, the data can be transmitted to the KWF. When the KWF has collected a sufficient number of results, a sensitivity analysis can be conducted to determine the exact impact of various factors on the carbon footprint of timber harvest.

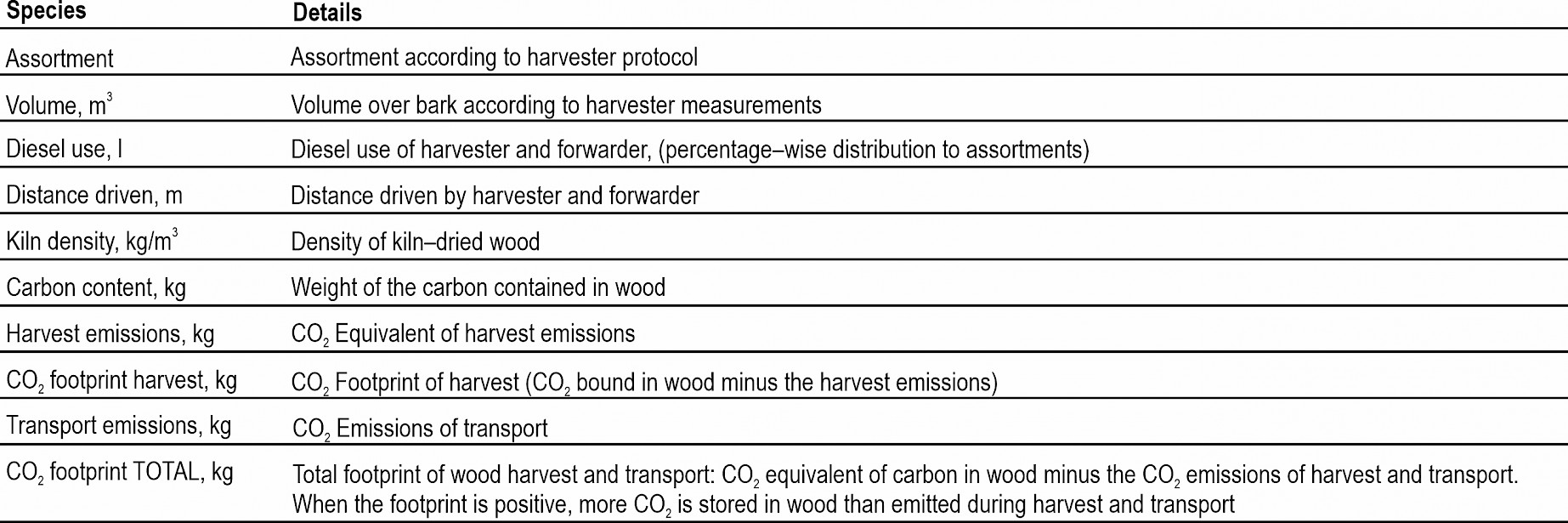

Fig. 4 Detailed explanation of variables, results and their units

4. Discussion

In this paper, the technical system boundaries encompass highly mechanized timber harvesting (CTL), including the use of harvesters, forwarders, and subsequent logistics by truck, train, or ship. This represents a significant portion of the timber supply chain. To fully capture the role of technology, it is also important to consider motor-manual timber harvesting with chainsaws and other types of forestry machinery.

According to a 20 year long-term study by KWF e.V., small harvesters with an engine output of less than 140 kW (kilowatts) consume 0.96 liters of diesel (3.15 kg CO2/m3), medium harvesters with an engine output of up to 180 kW consume 1.13 liters of diesel (3.7 kg CO2/m3), and large harvesters with an engine output of over 180 kW consume 0.95 liters of diesel (3.2 kg CO2/m3). In the same study, forwarders consumed 0.81 liters of diesel (2.64 kg CO2/m3) when operating under a payload of 10 t (small), 0.78 liters of diesel (2.56 kg CO2/m3) when carrying between 10 to 14 t (medium), and 0.74 liters of diesel (2.42 kg CO2/m3) when operating with more than 14 t (large).

So far, these results align with our findings. However, the long-term study also examined skidders without cranes, crane skidders, and combination machines. Forwarder tractors without a crane with an engine output of less than 80 kW consumd 0.55 liters of diesel (1.8 kg CO2/m3), while those with more than 80 kW consumed 1.21 liters of diesel (3.97 kg CO2/m3). Crane skidders with less than 100 kW consumed 0.65 liters of diesel (2.13 kg CO2/m3), those under 150 kW consumed 0.96 liters (3.25 kg CO2/m3), and those over 150 kW consumed 0.86 liters of diesel (3.82 kg CO2/m3). Combination machines with an engine output of less than 150 kW consumed 0.94 liters of diesel (3.08 kg CO2/m3), while those over 150 kW consumed 0.99 liters of diesel (3.25 kg CO2/m3). This data indicates that skidders in the small category emit the lowest quantities of CO2/m3 (Weise 2022).

According to KWF Report 39/2006, chainsaws in the low-performance class (<3.1 kW) use 1.4 l of diesel per working hour (load hour) and an additional 0.65 l of chain oil. In the medium-performance class (3.1 kW–4.0 kW), they use 2.05 l per working hour and an additional 1 l of chain oil. In the high-performance class (>4 kW), they consume 2.7 l per working hour and an additional 1.05 l of chain oil (Klugmann 2006). Kühmaier et al. (2022) determined an average emission of 0.26 kg CO2/m3 for felling, delimbing, and crosscutting with chainsaws.

This paper focuses on emissions in the wood supply chain within the highly mechanized timber harvesting process, from standing tree to timber logistics to mill entry. The impacts on the carbon footprint of timber, both before and after wood supply, are briefly discussed to raise awareness of these issues. Establishing and maintaining forest stands affect the carbon footprint of timber.

Kubova et al. (2018) calculated a carbon footprint of 0.1 t/ha/a for the production of seedlings, planting, and tending of forest stands, excluding timber harvesting. This compares to 9.9 t/ha/yr stored in managed stands, which would be sustainably available to extraction. Timmermann and Dibdiakova (2014) determined a constant carbon emission of 0.538 kg CO2/m3 for silvicultural treatment in eastern Norway (0.184 kg for seed and seedling production; 0.095 kg for site preparation; 0.017 kg for reforestation; 0.129 kg for tending; 0.004 kg for spraying; 0.107 kg for fertilization; and 0.001 kg for pruning). Additionally, they found that the construction of forest roads as part of pre-felling activities generated 0.308 kg CO2/m3 (0.105 kg for construction and 0.204 kg for upgrading/maintenance). Establishing and maintenance of young stocks treatments accounted for only 3%, while trail construction activities accounted only for 1.7% of emissions. Thinning, however, accounted for 10.6%, final felling for 30.9% (highly mechanized), and motor-manual felling (by chainsaw) for only 1.6%. Almost 50% of emissions are due to transport by truck (47.4%) and by train (4.7%).

De La Fuente et al. (2017) estimated carbon emissions of 4.4 kg CO2/m3 in Sweden (pre-commercial thinning, planting, site preparation, seedling production) and 7.1 kg CO2/m3 in Canada (seedling production, planting, soil preparation, piling, and burning slash). Klein et al. (2016) found an average of 3.194 kg CO2/m3 for forestry operations in Bavaria, Germany, before timber harvest (0.015 kg for clearing; 0.270 kg for planting; 0.115 kg for cleaning; 0.467 kg for fencing; 0.053 kg for liming; and 1.961 kg for road maintenance). Notably, road maintenance contributed significantly to emissions. According to Klein et al. (2016), timber harvesting (including felling, forwarding, and truck loading) generated 8.918 kg CO2/m3 and transport generated an average of 7.044 kg. This results in an average emission of non-renewable CO2 of 18.95 kg CO2/m3 for the system boundaries from planting to mill entry across all assortments (Klein et al. 2016). Silvicultural treatment (typically performed before final felling) has a minor effect on the overall carbon footprint (De La Fuente 2017, Timmermann and Dibdiakova 2014).

The wood industry is not included within the system boundaries of this paper. Nevertheless, it should be noted that the wood industry significantly influences the carbon footprint of wood-based products. In 2013, GHGs across all sawmill industry products were 43 kg CO2/m3, an increase of 8 kg since 2003, attributed to a decrease in productivity. Composites made from timber averaged as much as 325 kg CO2/m3 in 2013, with a slight reduction compared to 2003 (353 kg CO2/m3).

The wood processing industry also plays a crucial role in combating climate change and reducing the carbon footprint of wood-related products, as it consumed 56% of all renewable energy in Germany in 2012 and was the ninth most energy-intensive industry in the country. Investigations of the carbon footprint of wood products (cradle-to-customer) in the Allgaeu region in Germany provided insights into the regionality factor. They revealed that carbon savings vary across the wood products studied (thick wood panels, unfinished single-family houses, window frames, dining tables). The impact of transport, i.e., the regionality factor, decreases with the complexity of the manufacturing process. Wood supply has consistently been the largest contributor to the carbon footprint. However, all regionally manufactured products from locally sourced raw materials have a smaller carbon footprint than non-regionally manufactured products. The authors recommend optimizing savings potential on a product-specific basis (Brand 2023).

Similar results were reported by Castillo and Schweizer (2022), who compared the cradle-to-consumer carbon footprint of medium-density fiberboard (MDF) and hardwood lumber. Thus, the table made of MDF had a carbon footprint three times higher than that of the hardwood table (157 kg CO2/m3 vs. 34 kg CO2/m3). The timber supply in Europe cannot meet the demand for all conceivable uses. It is simply insufficient. As a result, only a small portion of sustainable building projects could be constructed using timber due to the limited availability. While the long-term use of timber for material purposes must remain the priority, some lower-quality or undersized timber can only be used for energy. However, this would be less of an issue if the CO2 emitted during the process were consistently captured. For example, hydrogen could be used to produce fuel from wood combustion gases. Alternatively, these assortments could undergo pyrolysis, converting them into charcoal, which could then be stored for centuries in agricultural areas, contributing significantly to soil improvement (HZB 2023). The average emissions from the wood industry are 43 kg CO2/m3, representing the combined impact of all wood products. This is offset by the emissions from timber provision, which amount to approximately 20 kg CO2/m3 (19 kg for Germany, according to Klein et al. (2022), 26 kg CO2/m3 for Austria, according to Kühmaier et al. (2022), and 15 kg CO2/m3 for the USA, according to Handler et al. (2014)).

The type of diesel used can also be a significant factor. Athanassiadis (2000) investigated three different fuel types: biodiesel from rapeseed, normal diesel, and EC1 diesel. His study included production costs, specifically the amount of CO2 emitted during production. According to Athanassiadis, biodiesel emits an average of 9.96 kg CO2/m3 of timber produced during highly mechanized harvesting in Sweden, regular diesel emits 8.06 kg, and EC1 diesel emits 8.33 kg. Therefore, fuel choice is only one of many factors that impact emissions, and its impact is relatively small. In fact, Athanassiadis's (2000) study found that biodiesel combustion actually results in higher emissions, mainly due to its costly production process. No more recent studies on forestry machines are available. However, recent research on biodiesel in general indicates that emissions from biodiesel production remain higher than the energy content of the biodiesel itself. Emissions from third-generation biodiesel are the highest (Jeswani et al. 2020). Many factors contribute to this. If production does not involve land-use changes or if the biomass does not come from animal husbandry, CO2 production costs are lower but typically still exceed the fuel energy content. More concerning are the effects on biodiversity, water consumption, land-use changes, acidification, eutrophication, soil degradation, and nitrate contamination of drinking water (Athanassiadis 2000, Dunn 2019). However, Cosola et al. (2016) found that the use of rapeseed methyl ether has a positive effect on emissions. This suggests that further research is needed in this area.

Hybrid forestry machines are expected to play an increasingly prominent role in the future. Hybrid systems that support both the drive motor and hydraulic systems already exist, with the potential to save diesel by up to 20%. However, the greatest potential for advancement lies in the energy recovery and power assistance for particularly challenging tasks (Gabriel 2019, Mergl et al. 2021, Einola and Kivi 2024). The electric chainsaw represents a significant innovation in forestry equipment, offering substantial advantages in terms of worker safety and reduced exhaust emissions. However, it is important to note that the current generation of electric chainsaws may not fully align with the desired environmental objectives. This is largely attributed to their relatively low energy efficiency and productivity compared to traditional chainsaws (Poje and Mihelic 2020, Pandur et al. 2023).

Productivity is the interaction between labor, operating resources (e.g., forestry machines, forestry equipment), and operating materials (e.g., diesel, diesel exhaust fluid, lubricants) that generates an output of timber, with efficiency varying depending on the composition of these factors. Thus, according to the law of piece-size-and-volume, productivity increases as unit volumes increase. However, Purfürst (2009) expanded this law with the concept of marginal power. Marginal power refers to the point where hyperbolic increase of productivity halts at an undefined diameter or volume and turns into negative marginal power. This is largely due to the limitations of operating equipment, such as the size of the harvester head or the engine power of the forwarder (Bötscher 2021). Building on these findings, Zhang et al. (2016) found that a 10% increase in productivity led to a 9% reduction in emissions, indicating the potential for optimized use of technology and adaptation processes. In line with this, Hoffmann (2014) stated: »A doubling of productivity therefore leads to a halving of energy consumption per cubic meter. The situation is similar with the fuel consumption of machines, the reduction or increase of which would have a significant effect on energy efficiency«.

Productivity is difficult to measure. However, it is already factored into diesel consumption per harvested volume. It also reflects the complex interplay of various contributing factors.

The reduction of emissions presents a theoretically derivable potential for the German forestry industry. Estimates suggest that emissions from timber harvesting account for around 7% of sequestered CO2 in roundwood (Schweier et al. 2019). According to international literature, emissions from harvesters and forwarders range between 1–5 kg CO2/m3 for timber sourced from non-sustainable sources (Kaulen et al. 2024). This variation arises from several factors that influence emissions, as previously described. The potential for reducing emissions in highly mechanized wood supply systems throughout Germany serves as an example.

Germany ranks at the higher end of the international emission spectrum. Klein et al. (2016) identified an average emission of 5.7 kg CO2/m3 from non-sustainable sources in highly mechanized timber harvesting. These emissions stem from operations involving harvesters, forwarders, and timber truck loading operations. For the transport of timber to sawmills, an additional 7 kg CO2/m3 is generated, covering all assortments and all distances traveled by the trucks. The studies pertain to the state of Bavaria in Germany. Thus, according to Klein et al. (2016), an average of 5.7 kg CO2/m3 is generated across all assortments in highly mechanized timber harvesting (harvesters, forwarders, and truck loading). Approximately 75% of softwood and 30% of hardwood are harvested in a highly mechanized way. According to the 2022 statistics from the German Federal Ministry of Food and Agriculture in 2022, 12.5 million m3 of hardwood and 66.2 million m3 of softwood were harvested, respectively (BMEL 2022). This translates to theoretical emissions of 21,463 t CO2 for hardwood and 284,141 t CO2 for softwood, which represents the savings potential.

The amount of CO2 released during highly mechanized timber harvesting is small compared to other industries. Nevertheless, it is worth considering this potential. In 2011, Germany's total emissions were 800 million t. Other raw materials contribute significantly higher emissions. For example, the extraction of mineral oil and its processing into intermediate products (diesel, paraffin, heating oil, etc.), along with its combustion, generated 129 million t of CO2. The production of iron and steel produced 16 million t of CO2, while the production of cement generated 33.5 million t of CO2 (Günther et al. 2015). Agriculture, and the provision of agricultural products, accounted for about 42.5 million t of CO2 in 2014 (Hoymann et al. 2021). However, only six million t are attributed to the combustion of fuels, such as those used in timber harvesting (Osterburg, 2022). Baum et al. (2021) even concluded that emissions from technical production in forestry are too low to be taken into account.

The strengths of the application lie in its ease of use and the quick availability of results. It also makes forestry machine data available, and consequently, accessible for further use, along with information about harvesting, timber data, working hours, and monitoring. Often, forestry machine data is not utilized for additional purposes. We see a significant advantage in making the climate protection performance of timber harvesting visible at a glance. After careful consideration, we determined that a web-based application would be the optimal choice. The primary advantages of this approach are straightforward versioning, cost-free access without app store fees, and compatibility across all devices with browser access. The decision was made to utilize an R Shiny application due to its user-friendly interface and comprehensive documentation. The code, formulas, and technical description are available at the web address HarvestCO2-App – KWF 2030 (kwf-online.de). Another strength of this system is its clarity. Upon uploading data regarding forestry machinery, an overview of the net carbon storage capacity is provided. If more detailed information is needed, sorted by assortment and tree species group, an abundance of specifics is available. The utilization of forestry machine data for the calculation of carbon footprints allows for the incorporation of factors that enhance the analytical process and the manner in which results are obtained. This is because the variables such as »driven distance« and »assortment«, which relate to the dimensions of individual log sections, can be derived from this data and employed for further analysis.

One weakness that has been identified is the dependence on constants, which always results in the carbon footprint being an approximation rather than reflecting actual emissions. Nevertheless, the coefficients are selected to closely represent reality. Additionally, the app does not clearly recognize every type of assortment; some special assortment names are not recognized and are assigned average values by default. Finally, the application cannot verify the accuracy or realism of the uploaded machine data. This responsibility falls on the operator. The application is limited to uploading .hpr and .mom records generated by forestry machines that use the StanForD 2010 format. Machines whose output format is in the StanForD classic, or those not mapped in the standard, cannot be integrated. This also applies to chainsaws and forestry tractors. However, data can always be entered manually. It is not possible to automatically read data from forestry machines via interfaces; therefore, this data is dependent on input and manual uploading. The interpretation of the results and their subsequent transfer to other processes are also conducted manually. This issue could be addressed by migrating our application to a system used by major forestry machine manufacturers or IT service providers. Public access is planned to facilitate the successful implementation of these measures.

Most of the identified weaknesses can be addressed over time through the accumulation of experience and the incorporation of feedback. Furthermore, an initiative is underway with the objective of mapping chainsaw data in the StanForD format. Once this process is complete, the application will be capable of mapping chainsaws.

The concept of quantifying the carbon footprint of a product with the aid of a dedicated calculation tool is not new. In particular, the timber industry has developed straightforward tools to demonstrate the carbon footprint of its products. For instance, the Metsä Group employs a straightforward input template for its two primary products, Kerto® LVL and plywood (Metsä 2024), while UPM uses a similar approach for its sawn products (UPM 2023). The World Wide Fund for Nature (WWF) and the Ministry of Forest, Lands and Natural Resource Operations of the Canadian province of British Columbia have published calculators for estimating the carbon footprint of wood products (WWF 2020, Dymond et al. 2016). These calculators are largely independent of one another and are presented in the form of Excel sheets. The »8 billion trees« initiative has also provided a tool for building with wood (Kilgore 2024). All these applications have similarities, from which ours differentiates itself. These similarities include a focus on wood products, the absence of real data sets associated with the product, a lack of consideration for emissions from harvesting and logistics, and the use of rough assumptions (constants). However, all of the tools complement ours with calculations for the timber industry.

Finally, the results from other studies are compared with those obtained from our application by entering the values from those studies into our tool.

Kärhä et al. (2024) assumed an average global value for harvester and forwarder use (final felling) of 1.57 l diesel/m3 (5.3 kg CO2/m3), based on a literature study. When we enter the same diesel consumption in our application, we get 6.64 kg CO2/m3. While there is a deviation, it falls within the permissible range. This discrepancy occurs because our application takes grey energy into account, while the study by Kärhä et al. (2024) mainly includes plantations where lower diesel consumption prevails.

Haavikko et al. (2022) determined a consumption of 1.17 l diesel/m3 (3.140 kg CO2/m3) for Finland in highly mechanized timber harvesting (final felling). We have calculated 5.33 kg CO2/m3 from this value, which is also within an acceptable range of deviation. The difference arises from the varying parameters for grey energy.

Prinz et al. (2018) focused solely on harvester use (CTL) and compared several machines. They determined an average diesel consumption of 1.1 l (3.32 kg CO2/m3). When this diesel consumption is entered into our application, the result is 5.55 kg CO2/m3. Here, too, the difference results from not taking grey energy into account. Prinz et al.'s (2018) CO2 emissions only account for diesel consumption.

Kaerhä et al. (2022) compared different brands of harvesters and forwarders, which consumed an average of 1.36 l diesel for cutting and forest haulage (4.46 kg CO2/m3). In our application, the diesel consumption equates to 5.96 kg CO2/m3.

Handler et al. (2014) calculated 22.5 kg CO2/m3 for a truck transport distance of 100 km, while our application yields 17.92 kg CO2/m3 for the same distance. This discrepancy is likely due to the age of the study, variations in payloads, and the coefficients used in the calculation.

Klein et al. (2016) calculated 16 kg CO2/m3 for truck transport of 100 km, which roughly corresponds to the result obtained using our application (18 kg CO2/m3). This similarity is due to the coefficients in the equation being adjusted for Central European conditions. Since the study by Klein et al. (2016) was conducted in Germany, they are closely aligned.

The comparison with other studies highlights that, while the results of our application are similar to those of other studies, they never match 100%. This underscores the importance of agreeing on a standardized method for deriving CO2 emissions in the near future. The comparison also reveals that the results are highly dependent on the factors and conditions under which the timber was evaluated and the coefficients included in the equation, as pointed out by Kaulen et al. (2024).

5. Conclusions

In this paper, we have demonstrated a practical integration of forestry machine data that automatically calculates the net carbon footprint for wood production. This includes the amount of carbon stored in the harvested wood, minus the emissions caused by highly mechanized timber harvesting and downstream timber logistics.

The method presented here also serves as a proposal for the standardized determination of the carbon footprint for the timber supply chain, potentially leading to a genuine CO2 certificate. Such a certificate could be used to price the climate protection performance of wood and clarify how the forestry and timber industries help combat climate change through their daily operations.

The carbon footprint of timber supply through highly mechanized timber harvesting is only the beginning of mapping all processes in forestry (silvicultural measures, tending, road construction) and the timber industry (further processing of raw wood and provision of products). In future projects, we plan to shed light on motor-manual timber harvesting, partially mechanized harvesting, and the use of special machinery (e.g., cable cranes).

The present »HarvestCO2« application also collects data on factors related to harvesting activities. Users are encouraged to submit their carbon footprints and the factors that influenced their timber harvests. In a future study, we intend to perform a sensitivity analysis based on this submitted data to identify significant factors. Currently, our understanding of emission influences is based on isolated observations and assumptions. Our goal is to clearly demonstrate how various factors impact emissions, enabling us to implement organizational measures or technical developments that reduce emissions.

6. References

Aalmo, G.O., Kerstens, P.J., Belbo, H., Bogetoft, P., Talbot, B., Strange, N., 2021: Efficiency drivers in harvesting operations in mixed Boreal stands: A Norwegian case study. International Journal of Forest Engineering 32(sup1): 74–86. https://doi.org/10.1080/14942119.2020.1778980

Baum, S., Elsasser, P., Goetzke, R., Henseler, M., Hoymann, J., Kreins, P., 2021: Handlungsfelder der Landnutzung. [Fields of action for land use]. In H. Gömann and J. Fick (Eds.), Wechselwirkungen zwischen Landnutzung und Klimawandel (pp. 71–141). Springer Fachmedien Wiesbaden. https://doi.org/10.1007/978-3-658-18671-5_3

Berndes, G., Abt, B., Asikainen, A., Cowie, A., Dale, V., Egnell, G., Lindner, M., Marelli, L., Paré, D., Pingoud, K., Yeh, S., 2016: Forest biomass, carbon neutrality and climate change mitigation. From Science to Policy, 3(7): 1–27.

Bloche-Daub, K., Hartmann, H., Hofbauer, H., Kaltschmitt, M., Pfeiffer, D., Thormann, L., Thrän, D., 2016: Einleitung und Zielsetzung. [Introduction and objectives]. In: Energie aus Biomasse, Springer, 1–76.

Bosak, D., Tran, D., 2023: Common [Software Documentation]. Solutions for Common Problems in Base R. https://cran.rstudio.com/web/packages/common/index.html

Brand, C., Briechle, M., Schulz, C., 2023: Regionalität verbessert Kohlendioxid-Bilanz. Ergebnisse einer Untersuchung zum Einfluss des Transports auf die CO2-Bilanz verschiedener Holzprodukte. [Regionality improves carbon footprint. Results of a study on the influence of transportation on the CO2 footprint of various wood products]. Holz-Zentralblatt 28: 473–474.

Brondex, J., 2014: Design of a prototype of an adaptive tire pressure system [Doctoral dissertation, Engineering and Technology, KTH, School of Engineering Sciences (SCI), Aeronautical and Vehicle Engineering, Vehicle Dynamics.]. Digitala Vetenskapliga Arkivet: https://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-177311

Brown, C., Sessions, J., 1999: Variable tire pressures for tropical forests? A synthesis of concepts and applications. Journal of Tropical Forest Science 11(2): 380–400. http://www.jstor.org/stable/43582542

Buck, H.J., Carton, W., Lund, J.F., Markusson, N., 2023: Why residual emissions matter right now. Nature Climate Change 13(4): 351–358. https://doi.org/10.1038/s41558-022-01592-2

Burk, J., Weise, G., 2005: Einfluss von Reifendruckregelanlagen auf den Kraftstoffverbrauch von Tragschleppern. [Influence of tire inflation pressure control systems on the fuel consumption of tractors]. Forsttechnische Informationen 04/2005: 49–53.

Busenius, M., Engler, B., Smaltschinski, T., Opferkuch, M., 2015: Consequences of increasing payloads on carbon emissions – An example from the Bavaria State Forest Enterprise (BaySF). Forestry Letters 108(8): 7–14.

Calvin, K., Dasgupta, D., Krinner, G., Mukherji, A., Thorne, P.W., Trisos, C., Romero, J., Aldunce, P., Barrett, K., Blanco, G., Cheung, W.W.L., Connors, S., Denton, F., Diongue-Niang, A., Dodman, D., Garschagen, M., Geden, O., Hayward, B., Jones, C., … Péan, C., 2023: IPCC, 2023: Climate Change 2023: Synthesis Report. Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change [Core Writing Team, H. Lee and J. Romero (eds.)]. IPCC, Geneva, Switzerland. (First). Intergovernmental Panel on Climate Change (IPCC). https://doi.org/10.59327/IPCC/AR6-9789291691647

Castillo, V.B., Schweizer, R., 2022: Life cycle assessment. https://civag.dimaster.io/assets/cache/media/testimonials/CIVAG%20LCA%20-%20Final%20Report.pdf

Chang, W., 2023: Shiny [Software Documentation]. RDocumentation – Shiny. https://www.rdocumentation.org/packages/shiny/versions/1.7.5

Danilović, M., Ilić, M., Ćuprić, N., Antonić, S., Stojnić, D., 2015: Fuel consumption in the transport of technical broadleaf roundwood in lowland areas. Glasnik Sumarskog Fakulteta (suppl): 25–34. https://doi.org/10.2298/GSF15S1025D

de la Fuente, T., Athanassiadis, D., Gonzalez-Garcia, S., Nordfjell, T., 2017: Cradle-to-gate life cycle assessment of forest supply chains: Comparison of Canadian and Swedish case studies. Journal of Cleaner Production 143: 866–881. https://doi.org/10.1016/j.jclepro.2016.12.034

Dunn, J.B., 2019: Biofuel and bioproduct environmental sustainability analysis. Current Opinion in Biotechnology 57: 88–93. https://doi.org/10.1016/j.copbio.2019.02.008

Dymond, C., McCullach, L., Salazar, J., 2016: A carbon calculator for harvested wood products. Users manual. https://www2.gov.bc.ca/assets/gov/environment/natural-resource-stewardship/nrs-climate-change/mitigation/users_manual_july_19_2016.pdf

Eliasson, L., Kärhä, K., Arlinger, J., 2023: Fuel consumption in logging operations in Sweden. International Journal of Forest Engineering 34(3): 366–372. https://doi.org/10.1080/14942119.2023.2229707

Einola, K., Kivi, A., 2024: Hydraulic hybrid cut-to-length forest harvester – Evaluation of effects on productivity and fuel efficiency. Actuators 13(4): 126. https://doi.org/10.3390/act13040126

EN 16485, 2014: Round and sawn timber – environmental product declarations – product category rules for wood and wood-based products for use in construction. European Committee for Standardization, Brussels, Belgium.

Eriksson, E., Gillespie, A.R., Gustavsson, L., Langvall, O., Olsson, M., Sathre, R., Stendahl, J., 2007: Integrated carbon analysis of forest management practices and wood substitution. Canadian Journal of Forest Research 37(3): 671–681. https://doi.org/10.1139/X06-257

Farthofer, A., 2022: Die LULUCF-Verordnung: Ein wirksamer Beitrag zum rechtlichen Klimaschutz? [The LULUCF Regulation: An effective contribution to legal climate protection?] [Masters Thesis, Johannes Kepler Universität Linz, Institut für Umweltrecht]. https://epub.jku.at/obvulihs/download/pdf/7732576?originalFilename=true

Gabriel, O., 2019: Erste Zahlen zum Hybridharvester von Logset. [First figures for the hybrid harvester from Logset]. Forstpraxis.de. https://www.forstpraxis.de/erste-zahlen-zum-hybridharvester-von-logset-20513

Gagliardi, K., Ackerman, S., Ackerman, P., 2020: Multi-product forwarder-based timber extraction: Time consumption and productivity analysis of two forwarder models over multiple products and extraction distances. Croatian Journal of Forest Engineering 41(2): 231–242. https://doi.org/10.5552/crojfe.2020.736

Gendek, A., Moskalik, T. (Eds.), 2016: From theory to practice: Challenges for forest engineering: proceedings and abstracts of the 49th Symposium on Forest Mechanization. Symposium on Forest Mechanization, Warsaw. Faculty of Forestry. Warsaw University of Life Sciences – SGGW.

Gundersen, P., Thybring, E.E., Nord-Larsen, T., Vesterdal, L., Nadelhoffer, K.J., Johannsen, V.K., 2021: Old-growth forest carbon sinks overestimated. Nature 591(7851): E21–E23. https://doi.org/10.1038/s41586-021-03266-z

Günther, D., Juhrich, K., Kludt, R., Kuntze, D., Rimkus, D., 2015: Entwicklung der CO2-Emissionen. [CO2 Emissions Trend]. In M. Fischedick, K. Görner, M. Thomeczek (Eds.), CO2: Abtrennung, Speicherung, Nutzung (111–149 p.). https://doi.org/10.1007/978-3-642-19528-0_6

Haavikko, H., Kärhä, K., Poikela, A., Korvenranta, M., Palander, T., 2022: Fuel consumption, greenhouse gas emissions, and energy efficiency of wood-harvesting operations: A case study of Stora Enso in Finland. Croatian Journal of Forest Engineering 43(1): 79–97. https://doi.org/10.5552/crojfe.2022.1101

Handler, R.M., Shonnard, D.R., Lautala, P., Abbas, D., Srivastava, A., 2014: Environmental impacts of roundwood supply chain options in Michigan: Life-cycle assessment of harvest and transport stages. Journal of Cleaner Production 76: 64–73. https://doi.org/10.1016/j.jclepro.2014.04.040

Hella KGaA Hueck & Co., 2014: Kraftstoffverbrauch von Forstmaschinen – Kosten und Umweltrelevanz. [Fuel consumption of forestry machines – costs and environmental relevance]. Forsttechnische Informationen 05+06/2024, 11 p.

Hermoso, V., Carvalho, S.B., Giakoumi, S., Goldsborough, D., Katsanevakis, S., Leontiou, S., Markantonatou, V., Rumes, B., Vogiatzakis, I.N., Yates, K.L., 2022: The EU Biodiversity Strategy for 2030: Opportunities and challenges on the path towards biodiversity recovery. Environmental Science & Policy 127: 263–271. https://doi.org/10.1016/j.envsci.2021.10.028

Hiesl, P., 2013: Productivity standards for whole-tree and cut-to-length harvesting systems in Maine [Doctoral dissertation, University of Maine]. https://digitalcommons.library.umaine.edu/cgi/viewcontent.cgi?article=3289&context=etd

Hilf, H., 1967: Die Arbeitsleistung im Hauungsbetrieb. [The work performance in the logging operation]. (nicht veroeffentlichte Akte, Institut f. Forstliche Arbeitswissenschaft, Eberswalde, 1928). Speidel.

Hilf, H., 1941: Die Erforschung und Verbesserung der Waldarbeit: Zwei Vorträge an der Forstlichen Hochschule Stockholm. [Research and improvement of forestry work: two lectures at the Stockholm Forestry University]. Schaper.

Hoffmann, S., 2014: Energieeffizienz forstlicher Arbeiten. [Energy efficiency of forestry operations]. Forsttechnische Informationen, 03+04/204(3+4/2014): 13–19.

Holzzentralblatt (HZB), 2023: Wald der Zukunft braucht regionale Maßanzüge. [The forest of the future needs regionally customized solutions]. 21/2023: 333–334.

Hornik, K., Leisch, F., Zeileis, A., 2003: High-Level Interface Between R and Excel. In Proceedings of DSC, 2 p.

Hoymann, J., Baum, S., Elsasser, P., Dechow, R., Gutsch, M., Fick, J., 2021: Ist-Situation der Landnutzung in Deutschland. [Current land use in Germany]. In H. Gömann and J. Fick (Eds.), Wechselwirkungen zwischen Landnutzung und Klimawandel, 21–70 p. Springer Fachmedien Wiesbaden. https://doi.org/10.1007/978-3-658-18671-5_2

Jeswani, H.K., Chilvers, A., Azapagic, A., 2020: Environmental sustainability of biofuels: A review. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 476(2243): 20200351. https://doi.org/10.1098/rspa.2020.0351

Jönsson, P., Andersson, M., Hannrup, B., Henriksen, F., Högdahl, A., 2016: Cutting capacity of saw chains – A comparative study. Avverkningskapacitet För Sågkedjor – En Jämförande Studie, 48 p.

Kärhä, K., Haavikko, H., Kääriäinen, H., Palander, T., Eliasson, L., Roininen, K., 2023: Fossil-fuel consumption and CO2eq emissions of cut-to-length industrial roundwood logging operations in Finland. European Journal of Forest Research 142(3): 547–563. https://doi.org/10.1007/s10342-023-01541-4

Kärhä, K., Eliasson, L., Kühmaier, M., Spinelli, R., 2024: Fuel consumption and CO2 emissions in fully mechanized cut-to-length (CTL) harvesting operations of industrial roundwood: A review. Current Forestry Reports 10: 255–272. https://doi.org/10.1007/s40725-024-00219-3