Suitability of Steel Wire Rope End Connectors for Ground-Based Logging Applications

doi: https://doi.org/10.5552/crojfe.2025.3027

volume: issue, issue:

pp: 8

- Author(s):

-

- Huber Christoph

- Richter Jürgen

- Haas Christoph

- Article category:

- Original scientific paper

- Keywords:

- winch, end termination, end connection, rope failure, timber harvesting

Abstract

HTML

Rope end connectors are a cricital component for attaching logs and trees to winches in ground-based harvesting operations. Knowing their strength not only in theory, but also under real working conditions, is crucial for selecting and dimensioning suitable end connectors in order to ensure compliance with the respective safety factors. Currently, there are limited published testing data on the strength and failure types of various end connectors. Furthermore, no information is available how end connectors perform if they are used in combination with rope sliders. Thus, different end connectors suitable for 12 mm steel wire ropes were developed and break-tested under conditions close to reality to determine their suitability for logging operations, considering different load type combinations by including rope sliders. The aim of the study was to give an overview of the suitablity of end connectors and different rope slider – end connector combinations for ground-based harvesting operations and to become aware of where and at which forces failures occure first. The results show that if the load is only attached directly to the end connector, turn-back eyes and wedge sockets provided consistent performance in breaking strengths. Attaching loads only to rope sliders led to siginifcant reductions of the end connectors performance in general. A comparatively high loss of performance was assessed if turn-back eyes were used in combination with rope sliders. This raises the question of their suitability as an appropriate end connector in ground-based logging. The most common cause of failure was found to be rope breakage, which mainly occurs due to the strong deflection angles of the rope during pulling.

Suitability of Steel Wire Rope End Connectors for Ground-Based Logging Applications

Christoph Huber, Juergen Richter, Christoph Haas

https://doi.org/10.5552/crojfe.2025.3027

Abstract

Rope end connectors are a cricital component for attaching logs and trees to winches in ground-based harvesting operations. Knowing their strength not only in theory, but also under real working conditions, is crucial for selecting and dimensioning suitable end connectors in order to ensure compliance with the respective safety factors. Currently, there are limited published testing data on the strength and failure types of various end connectors. Furthermore, no information is available how end connectors perform if they are used in combination with rope sliders. Thus, different end connectors suitable for 12 mm steel wire ropes were developed and break-tested under conditions close to reality to determine their suitability for logging operations, considering different load type combinations by including rope sliders. The aim of the study was to give an overview of the suitablity of end connectors and different rope slider – end connector combinations for ground-based harvesting operations and to become aware of where and at which forces failures occure first. The results show that if the load is only attached directly to the end connector, turn-back eyes and wedge sockets provided consistent performance in breaking strengths. Attaching loads only to rope sliders led to siginifcant reductions of the end connectors performance in general. A comparatively high loss of performance was assessed if turn-back eyes were used in combination with rope sliders. This raises the question of their suitability as an appropriate end connector in ground-based logging. The most common cause of failure was found to be rope breakage, which mainly occurs due to the strong deflection angles of the rope during pulling.

Keywords: winch, end termination, end connection, rope failure, timber harvesting

1. Introduction

Steel wire ropes are still used universally in ground-based harvesting for extracting trees, stems or logs as well as for securing winch-assisted forestry machines. For both applications, a considerable focus has been laid on the wire rope itself, including research on cable tensile forces in winch-assist harvesting (Holzleitner et al. 2018, Mologni et al. 2018, Mologni et al. 2021) and on rope wear in general (Harrill et al. 2017). In ground-based harvesting, ropes are very often used under harsh and rough conditions as they are dragged along the ground, pulled around trees and over rocks. This accelerates abrasion, reduces the lifetime of the rope, and raises the risk of sudden rope failures. To minimize the risk of accidents, a working coefficient for the rope of at least 2, related to the nominal pulling force of the winch, is required by international standards for ropes used in winch-assisted harvesting (ISO 2022) and ground-based harvesting (CEN 2010). Furthermore, guidelines for rope inspection and discard criteria are provided in published Best Practice Guidelines all over the world (Competenz 2005, WorkSafeBC 2006, Nemestóthy et al. 2014).

However, the weakest point in a cable system often occurs at the end of the rope when end connectors are used. It is already well known that end connectors reduce the breaking force of the rope (Studier and Binkley 1974, Harrill et al. 2017, Pfeifer 2018), often resulting in rope failures at or near the end connector. The failures mostly occure because either the rope gets damaged at the time when the connection is made, the housing breaks or the rope gets bent too sharply. If end connections are used where the rope needs to get bent, the bending radius is often very small, reducing the strength and the lifetime of the rope (FPInnovations 2017). According to CEN (2023a), the minimum ratio between the diameter of a steel wire rope and its bending diameter shall not come below 1:10, which usually cannot be achieved by using end connectors. FPInoovations (2017) even suggest to maintain a ratio of at least 1:16.

In order to avoid failures, the Best Practice Guidelines for cable logging (Competenz 2005) as well as the British Columbia cable yarding system handbook (WorkSafeBC 2006) recommend replacing an end connecter if only a single broken wire is recognized near an end connector. However, the normative discard criterion is reached at the latest when two wires of the rope are broken next to an end connector (ISO 2017). According to European Committee for Standardization (2010) either a turn-back eye with a pressed ferrule or a ferrule secured Flemish eye have been permitted for pulling logs on the ground with forestry winches so far. Wedge sockets, spelter sockets, and swaged sockets can be used additionally as rope end connectors for securing winch-assisted forestry machines according to ISO (2022).

Currently, the maximum permissible loss in breaking force is regulated by different standards for each end connector and varies between the connector types. Ferrule secured turn-back eyes and ferrule secured Flemish eyes must withstand a force of at least 90% of the minimum breaking force of the rope without rupture according to CEN (2023b). In contrast, sockets used for securing winch-assisted machinery only need to withstand a force of at least 80% of the minimum breaking force (CEN 2009).

In order to keep productivity high when working with forestry winches, it is often necessary to attach multiple logs to the rope to make up an optimal load. Therefore, rope slide eyelets and choker hooks are widely used in addition to an end connector to increase the number of possible attachment points for choker chains and choker ropes. If a load gets attached to one of these rope slide elements, the rope slider pushes against the end connector and thus initiates an additional force impact on the latter. However, end connectors in forestry are only tested by applying a force to the attachment point. Forces that may occur on the rope entrance point of the end connectors (e.g. by rope slide elements) have not been considered for testing so far, increasing the uncertainty as to what force the end connectors can be loaded from the backside.

This study was designed with two main objectives to investigate steel wire rope end connectors and their mechanical performance under different loading conditions. The first objective was to quantify the breaking forces of various end connectors to determine each end connector suitability for ground-based logging. The second objective was to investigate and analyze the type of failure of each end connector and loading condition.

The objectives of this paper are:

to test the breaking strenghts of different types of end connectors to assess their suitability for ground-based logging, including scenarios in which the end connectors get laoded indirectly by rope sliders, and

to assess the sources of errors.

Furthermore breaking tests with two different type of knots should gain clarity about whether knots, which are sometimes used as a temporary end connection after rope breakage, are a safe end connection.

2. Materials and Methods

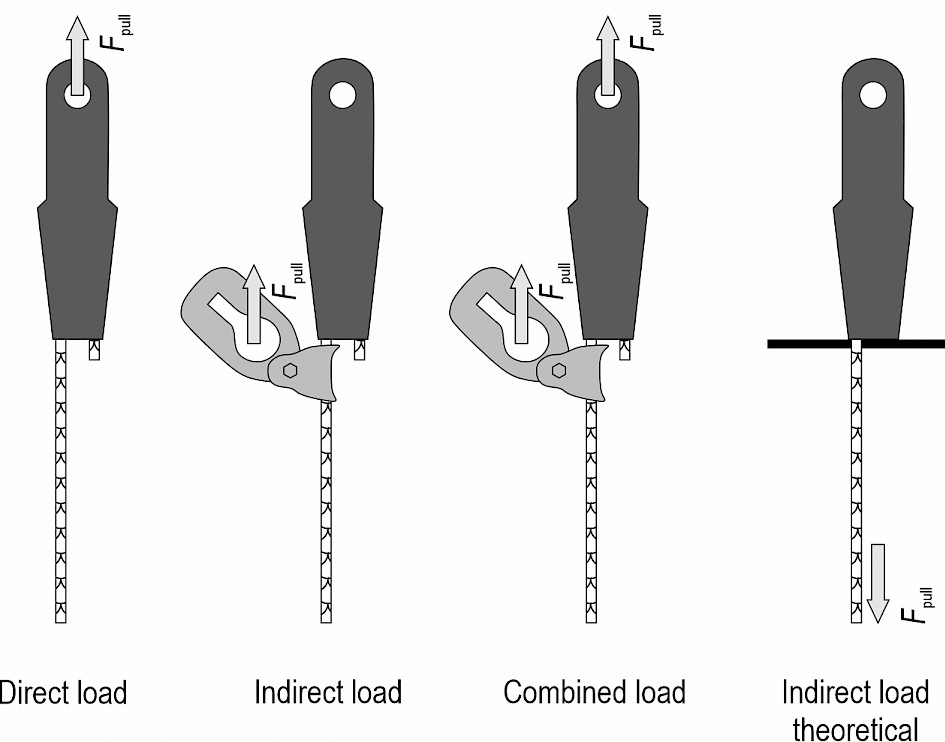

Ground-based logging with machine-mounted winches offers several opportunities for the operator to hook on a load: A single log can either be attached to an end connector or (if available) to a rope slide element. If a load consists of multiple logs, both the end connector and rope sliders are used as attachment points at the same time. To take these different attachment options into account, the following attachment variants were considered for this study:

an end connector was loaded on its attachment point (direct load, Fig. 1a)

a rope slide eyelet was loaded and pulled against the end connector (indirect load, Fig. 1b)

both an end connector and a rope slide eyelet were loaded at the same time with equal loads (combined load, Fig. 1c)

an end connector was loaded from behind using its full contact surface (indirect load – theoretical, Fig. 1d)

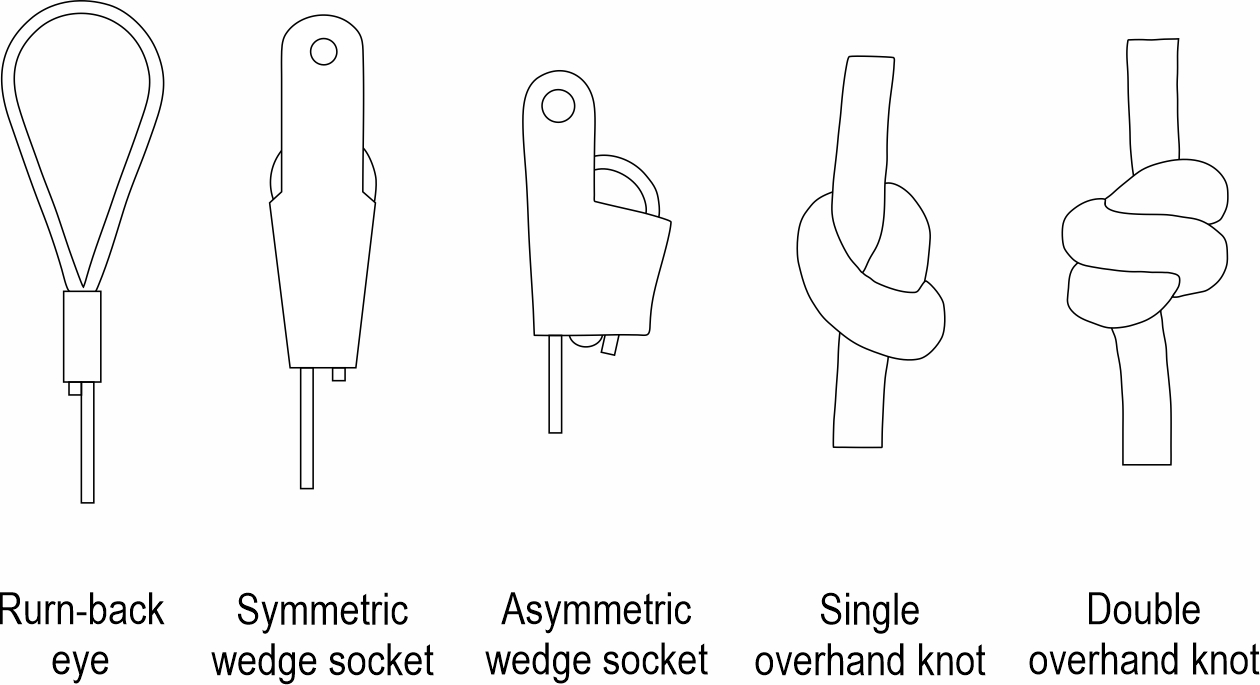

The following end connectors were used for testing (Fig. 2):

turn-back eye with a pressed aluminum ferrule according to CEN (2023b)

symmetric wedge sockets according to CEN (2022)

asymmetric wedge sockets according to CEN (2009)

single overhand knot

double overhand knot.

Fig. 1 Overview of attachment variants tested

Fig. 2 Tested end connectors

Sockets of the type »SE-O« from the company SFS were used for testing the performance of symmetric wedge sockets. They are equipped with a welded bracket at the end at which chains with a maximum diameter of 10 mm can be attached. These end connectors are suitable for a rope diameter between 8 and 12 mm and can be loaded with a maximum pulling force of 60 kN according to the operator's manual.

A cast, asymmetric wedge socket of the type »Force-S« from the company Pewag was used. According to the operator's manual, this end connection can be used for rope diameters between 11 and 14 mm. Its breaking force corresponds to the breaking force of the rope used.

Rope slide eyelets from the GB.Pro series (suitable for 8 mm chains, minimum breaking force = 14 kN) and GBGV series (suitable for 10 mm chains, minimum breaking force = 19 kN), both from the company Pewag, were used to apply indirect forces on the five different end connector types. Tests, simulating the indirect loading of a ferrule secured turn-back eye with a rope slide eyelet, were performed using a thrust washer between the ferrule and the rope slider. This prevented the rope sliders to get stuck on the ferrules during testing, preventing the former from rotating and aligning itself according to the load.

The rope used in this study was a 12 mm, strand compacted 6 x K19-PWRC steel wire rope of the type »Teufelberger F-30 Woodrunner«, which is commonly found on winch-assisted logging operations in Europe as well as on ground-based logging operations in general for winches with a nominal pulling force of 70 to 75 kN. The rope shows a minimum breaking force of 155 kN at a tensile strength of 1960 N/mm².

Fig. 3 Example of a laboratory break test. An asymmetric wedge socket was loaded indirectly by a rope slide eyelet causing the rope to be strongly bent at the end of the rope slide eyelet

The breaking tests were applied in a laboratory of the company Teufelberger (Fig. 3). All test sample end connections were tested against the minimum breaking force of the rope. At one end, the rope showed a ferrule secured turn-back eye, with which it was fixed to the anchoring point using a bolt. Once the test sample was fixed between the anchoring point and the hydraulic ram, the test specimen was loaded to failure traveling at 50 mm per minute, fulfilling the speed requirements for testing of wire ropes specified by ASTM (2018). After each test, the test sample was visually examined for broken strands and inspected at the end connection, at the rope sliding eyelet and at the failure point. The measurement diagram (time-force diagram) was retained, and the cause, type and location of the failure were documented. In the end, the failures were categorized using four categories (Table 1).

Table 1 Overview of failure categories

|

Failure category |

Description of a typical failure |

|

End connector failure |

Breakage of the wedge housing, causing the release of the rope Breakage of the ferrule Rope failure within the knot |

|

Rope failure near end connection |

Breakage of the rope near its entrance to the end connection |

|

Rope failure near rope slide eyelet |

Breakage of the rope near its entrance or its outlet of the rope slider |

|

Others |

Breakage of the rope slider Self-loosening of the ferrule |

Each treatment combination, except the ones including knots, was tested at least 10 times, resulting in a total number of 156 tests. Knots were only tested 5 to 6 times because preliminary tests already showed that they all failed even at low forces, proving not to be suitable for end connection.

3. Results

3.1 Impacts on Breaking Force

The breaking strengths of the different end connection and attachment variants were highly variable (Table 2).

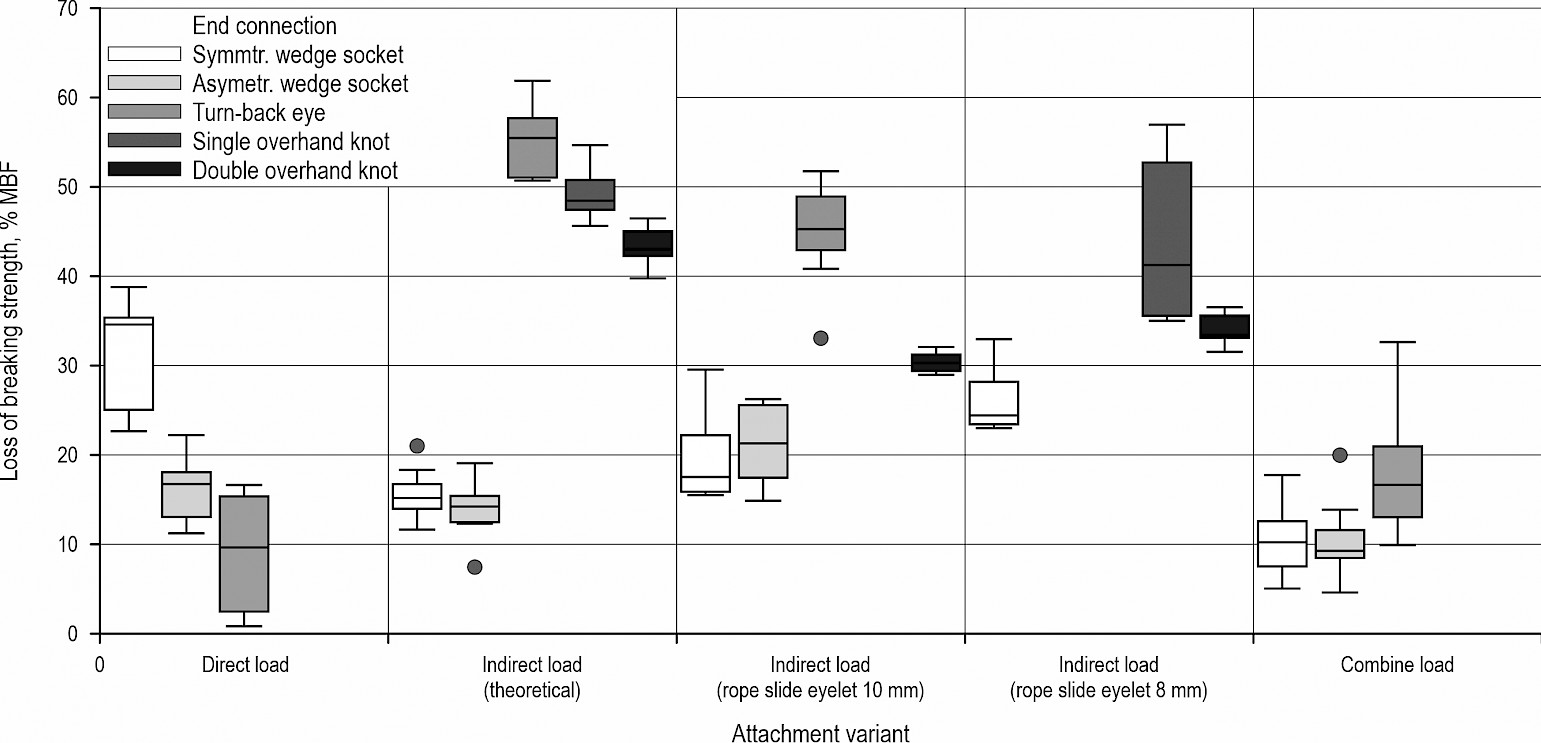

Fig. 4 Loss of breaking force for different attachment variants tested. A value of 0% would mean that the attachment variant would not impact the breaking force of the rope. A safety coefficient of 2 can be guaranteed. A value of 50% represents the maximum allowed nominal line pull of a winch

Overall, the directly loaded turn-back eye achieved the lowest loss of breaking strengths (Fig. 4). It averaged of 141,500 N and 91.3% of the minimum breaking force (MBF) and thus largely meets the requirements defined by CEN (2023b). However, as soon as the turn-back eye got loaded indirectly by a rope slide eyelet from the backside, the connection type already failed between 38.2 and 67.1% of the MBF.

Both, the asymmetric and the symmetric wedge sockets performed worse than the turn-back eye when they were directly loaded. These rope end connections obtained between 61.6% and 88.8% of the MBF and did not fulfill the requirements of CEN (2009) and CEN (2022) in most of the tests. However, the wedge sockets performed best when they were loaded indirectly from the back with rope slide eyelets.

Table 2 Average breaking strengths, deviations, minimum and maximum values for variants tested

|

Attachment variant |

End connection |

n |

Mean breaking strength kN |

Standard deviation kN |

Minimum kN |

Maximum kN |

Mean % of MBF |

Minimum % of MBF |

|

Direct load |

Symmetric wedge socket |

10 |

106.553 |

8.902 |

95.470 |

120.420 |

68.7 |

61.6 |

|

Asymmetric wedge socket |

10 |

130.199 |

5.178 |

120.810 |

137.670 |

84.0 |

77.9 |

|

|

Turn-back eye |

10 |

141.500 |

10.441 |

129.560 |

153.960 |

91.3 |

83.6 |

|

|

Indirect load (theoretical) |

Symmetric wedge socket |

10 |

131.181 |

4.247 |

122.690 |

137.090 |

84.6 |

79.2 |

|

Asymmetric wedge socket |

10 |

133.580 |

4.742 |

125.620 |

143.730 |

86.2 |

81.1 |

|

|

Turn-back eye |

10 |

69.801 |

6.271 |

59.180 |

76.620 |

45.0 |

38.2 |

|

|

Single overhand knot |

5 |

78.606 |

5.400 |

70.420 |

84.460 |

50.7 |

45.4 |

|

|

Double overhand knot |

5 |

88.082 |

4.023 |

83.150 |

93.640 |

56.8 |

53.7 |

|

|

Indirect load (rope slide eyelet 10 mm) |

Symmetric wedge socket |

10 |

125.317 |

6.944 |

109.510 |

131.270 |

80.9 |

70.7 |

|

Asymmetric wedge socket |

10 |

122.350 |

6.748 |

114.590 |

132.240 |

78.9 |

73.9 |

|

|

Turn-back eye |

10 |

85.536 |

8.411 |

74.930 |

103.940 |

55.2 |

48.3 |

|

|

Double overhand knot |

5 |

108.058 |

1.929 |

105.470 |

110.270 |

69.7 |

68.1 |

|

|

Direct load (rope slide eyelet 8 mm) |

Symmetric wedge socket |

10 |

114.914 |

5.672 |

104.110 |

119.550 |

74.1 |

67.2 |

|

Single overhand knot |

6 |

87.278 |

14.370 |

66.920 |

100.920 |

56.3 |

43.2 |

|

|

Double overhand knot |

5 |

102.524 |

3.156 |

98.590 |

106.330 |

66.2 |

63.6 |

|

|

Combined load |

Symmetric wedge socket |

10 |

139.205 |

5.870 |

127.650 |

147.390 |

89.8 |

82.4 |

|

Asymmetric wedge socket |

10 |

139.299 |

6.497 |

124.320 |

148.050 |

89.9 |

80.2 |

|

|

Turn-back eye |

10 |

128.040 |

10.610 |

104.640 |

139.950 |

82.6 |

67.5 |

Due to their design, knots could only be loaded indirectly with rope slide eyelets, which were pushing against the knots as soon as they were loaded. Overall, the knots performed not well and often led to a loss of the breaking strength of more than 50%. This would already cause a release of the load during normal operation.

As expected, the highest breaking strength was attained by the attachment variant »combined load«. With this variant, both the end connector and the rope slide eyelet were loaded with equal loads. Doing so, the asymmetric and the symmetric wedge socket both obtained more than 90% of the MBF. Only the turn-back eye showed a lower breaking strength, attaining only 82.6% of the MBF on average.

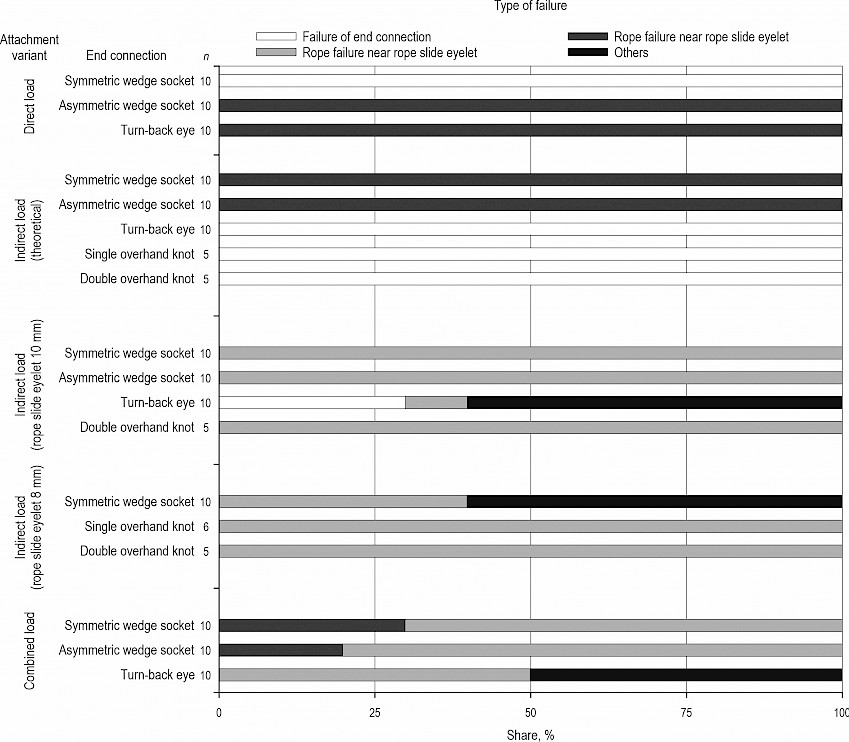

3.2 Types of Failure

Different types of failures were monitored during the study period (Fig. 5). All direct loaded turn-back eyes, which achieved the highest breaking strength within the pulling tests, failed because single wires broke next to the aluminum ferrule. The same cause of failure was also found with all asymmetric wedge sockets, where single wires broke next to the entry point of the rope into the end connector.

However, the symmetric wedge sockets could not withstand the applied forces. All of them were badly deformed after the pulling tests, leading to a breakage of the keyhole, into which the chain was attached. Although the housing of the symmetric wedge sockets was deformed after testing, the rope remained fixed inside the end connector.

Different types of failures were recorded if the load was applied indirectly onto the end connectors by using rope slide eyelets. During these tests, the breaking of the rope typically occurred near the entry of the rope slider. However, turn-back eyes are an exception. In some cases, the aluminum ferrule of the turn-back eye broke apart before the breaking force of the rope was reached, in other cases the ferrule became loose, causing it to slide backwards along the rope.

Fig. 5 Types of failure for different attachment variants tested in four categories. Indifferent failures like a setback of the aluminum ferrule or failure of the choker chain are in category »others«

4. Discussion

4.1 Breaking Forces of End Connections

Breaking strength and its variability are the most important key factors in determining overall suitability of end connections and its attachment variants for use in logging operations. From a technical point of view, attachment variants need to exceed the 50% MBF value so that they do not fail under typically expected operation conditions. Thus, this point was used as an initial cut-off value to decide whether end connections are suitable from a technical point or not.

In addition, CEN (2010) demands a minimum operation coefficient of 2 for the rope, meaning that the rope shall only be loaded up to a maximum of 50% of the MBF. This standard already considers that end connectors may reduce the breaking strength during use, allowing only Flemish eyes and turn-back eyes to be used in forest operations. These end connections need to withstand at least 90% of the MBF when they are loaded directly within the eye.

In this study, the directly loaded turn-back eyes achieved this requirement only partially. Almost half of the tests attained lower breaking strengths and thus failed to meet the requirements defined by CEN (2023b). Despite their high variability in breaking strengths, ferrule secured turn-back eyes were the most suitable end connection tested in this study if the load was directly attached to them. However, they did not perform well if they were loaded indirectly by a rope slider in combination with a washer. On average, the ferrule got destroyed at 55.2% of the MBF. Some of the tests even failed below the 50% MBF value resulting in a high probability of failure during normal operations, which highly increases the risk of fatal accidents. Since winches are often used in combination with rope slide elements, the suitability of turn-back eyes as an end connection must be questioned. However, based on the results, it cannot be recommended to only attach the load to one of the rope slide elements. If only one log gets attached to the rope, it should be fixed at the end connector and not on the rope slide eyelet. If a load consists of multiple logs, at least one log (the biggest one) should be attached to the end connector.

The wedge sockets tested are much more suitable than turn-back eyes if a load consists of multiple logs. Although the results showed that a direct loading of wedge sockets leads to an earlier failure of the end connection as it does when a turn-back eye is used, they have a clear advantage if they are indirectly loaded from the back end by a rope slide eyelet. The performance difference between symmetric and asymmetric wedge sockets in the direct pulling tests is mainly due to the quality of the materials used and is probably not correlated with the symmetry characteristics of the wedge sockets. To conclude, both symmetric and asymmetric wedge sockets are the most suitable end connectors tested within this study as soon as the load consists of more than one log.

Single and double overhand knots turned out to be the most unsuitable and most unpredictable if they are used as end connectors. They often did not exceed the 50% MBF value and thus should not be used for winching operations.

4.2 Failures of End Connections

The most common cause of failures was the breakage of the rope. The rope always broke next of its entry point to the end connector or the rope slide eyelet. At these points a large deflection of the rope was found during testing, which leads to heavy loads on single wires, causing them to break. The results suggest that the form of the sliders may have an influence on the breaking force loss. The indirect pulling tests with 8 mm rope sliders show significantly higher breaking force losses than those with 10 mm sliders. This may be caused by the different bending angles at the edge of each slider, which seemed to be similar. This matter would need further studies.

The symmetric wedge sockets performed worse than the asymmetric wedge sockets when they were loaded directly. The cause of the damage to the symmetric wedge sockets was a failure of the keyhole, whereas the asymmetric wedge sockets broke because of a rope failure. The poorer performance of the symmetrical sockets was to be expected because the manufacturer limits the maximum permissible pulling force to 60 kN in the operating instructions. In no case the rope was released from the end connector.

5. Conclusions

A variety of end connectors is used for ground-based harvesting, although only a few of them are permitted by the relevant standards. Right now, the different end connectors have to fulfill different requirements to be considered suitable by the standards. For instance, turn-back eyes need to withstand 90% of the minimum breaking force of the rope, whereas wedge sockets only need to withstand 80% of the minimum breaking force. This study has shown a high variability of the breaking forces even for the same type of end connectors, not always meeting the requirements of the standards.

Furthermore, the suitability of end connectors is only determined by attaching a load directly at their end. The use of rope slide elements, which is typical in forestry especially if low diameter logs are winched, is not considered in the relevant standards. This study clearly demonstrated that indirect pulling using rope slide eyelets leads to a performance loss of all end connectors. The loss of breaking force was particularly pronounced when using turn-back eyes. The aluminum ferrule was not able to withstand the forces applied by the rope slide eyelet, causing it to fail at forces of approximately half the breaking force of the rope. Thus, it is highly recommended to adapt the standard specifications by also considering the use of rope slide elements.

Acknowledgments

Funding for this research was provided by the Federal Ministry of Agriculture, Forestry, Regions an Water Management of the Republic of Austria, the Cooperation Platform »FHP«, and the Austrian Forest Association. We thank Dominik Secklehner and Adam Oezcelik of the Teufelberger Fiber Rope ltd. for their valuable assistance during testing as well as Nikolaus Nemestóthy for the hard work on the project.

6. References

A931-18, 2018: Standard Test Method for Tension Testing of Wire Ropes and Strand. American Society for Testing and Materials, 4 p.

EN 13411-6, 2009: Terminations for steel wire ropes – Safety – Part 6: Asymmetric wedge socket. European Committee for Standardization, 27 p.

EN 14492-1, 2010: Cranes – Power driven winches and hoists – Part 1: Power driven winches. European Committee for Standardization, 83 p.

EN 13411-7, 2022: Terminations for steel wire ropes – Safety – Part 7: Symmetric wedge socket. European Committee for Standardization, 22 p.

EN 17822, 2023a: Forestry machinery. Requirements for sling gear and deflection pulleys for forestal hauling operations. European Committee for Standardization 24 p.

EN 13411-3, 2023b: Terminations for steel wire ropes – Safety – Part 3: Ferrules and ferrule-securing. European Committee for Standardization, 30 p.

Competenz., 2005: Best practice guidelines for cable logging. Competenz New Zealand.

Boswell, B., Matute, P., Amishev, Dz., 2017: Wire Rope Integrity in Winch-Assisted Harvesting Operations. A Guide to wire Rope handling and inspection for machine operators. FPInnovations, Research report, 24 p. http://dx.doi.org/10.13140/RG.2.2.36427.90401

Harrill, H., Visser, R., Byron, J., 2017: Inspecting wire ropes and end connectors on winch-assist machines. In Proceedings of the 50th Anniversary of the International Symposium on Forestry Mechanization: »Innovating the competitive edge: From research to impact in the forest value chain«, 25–29 September, Brasov, Romania.

Holzleitner, F., Kastner, M., Stampfer, K., Höller, N., Kanzian, C., 2018: Monitoring cable tensile forces of winch-assist harvester and forwarder operations in steep terrain. Forests 9(2): 1–13. https://doi.org/10.3390/f9020053

ISO 4309, 2017: Cranes – Wire ropes – Care and maintenance, inspection and discard. International Organization for Standardization, 59 p.

ISO 19472-2, 2022: Machinery for forestry-Winches-Part 2: Traction aid winches. International Organization for Standardization, 52 p.

Mologni, O., Dyson, P., Amishev, D., Proto, A.R., Zimbalatti, G., Cavalli, R., Grigolato, S., 2018: Tensile Force Monitoring on Large Winch-Assist Forwarders Operating in British Columbia. Croat. j. for. eng 39(2): 193–204.

Mologni, O., Nance, E.D.T., Lyons, C.K., Marchi, L., Grigolato, S., Cavalli, R., Roeser, D., 2021: Cable tensile forces associated to winch design in tethered harvesting operations: A case study from the pacific north west. Forests 12(7): 1–15. https://doi.org/10.3390/f12070827

Nemestóthy, N., Sperrer, S., Stampfer, J., 2014: Holzernte im Seilgelände. Methodische Arbeit 4(9). FHP Kooperationsplattform Forst Holz Papier.

Pfeifer, 2018: Wire ropes – Technical information (3). Pfeifer Seil- und Hebetechnik GMBH.

Studier, D.D., Binkley, V.W., 1974: Cable logging systems. Division of Timber Management, Forest Service, US Department of Agriculture.

WorkSafeBC, 2006: Cable Yarding systems handbook. Worker's compensation board of British Columbia.

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Christoph Huber, PhD *

e-mail: christoph.huber@bfw.gv.at

Jürgen Richter, MSc

e-mail: juergen.richter@bfw.gv.at

Christoph Haas, MSc

e-mail: christoph.haas@bfw.gv.at

Austrian Research Center for Forests

Department of Forest Engineering

Forstpark 1

4801, Traunkirchen

AUSTRIA

* Corresponding author

Received: April 25, 2024

Accepted: September 04, 2024

Original scientific paper

11