Forest Machinery Fires: Trends in New Zealand Forest Harvesting Sector

doi: 10.5552/crojfe.2021.702

volume: 42, issue:

pp: 9

- Author(s):

-

- Visser Rien

- McDell Samuel Lloyd

- Obi Okey Francis

- Article category:

- Original scientific paper

- Keywords:

- fires, forestry, machinery, safety

Abstract

HTML

Fires in forest machines are typically catastrophic in terms of machine destruction and can develop rapidly to be a risk to the machine operator. They are an issue worldwide and there can be larger consequences such as starting a major forest fire. This paper describes trends in machine fire occurrences in the New Zealand forest harvesting sector. A total of 224 machinery fire incidents were recorded over an 8 year period from 2007 to 2014. Trends in forest machinery fires in the sector were identified and summarized. Late morning (10 am-noon) and mid-afternoon (2–4 pm) showed the highest incidence of machine fire, corresponding to periods with the highest level of work. Excluding the main holiday months, there was a correlation of machine fires to average monthly temperature. Summary statistics on causes of fire ignition showed that 40% were attributed to electrical and hydraulic faults; however, some remain unidentified as the fires commenced after work was completed. A short survey of industry managers was carried out to ascertain machine fire perceptions. 67% agreed that machine fire was an issue, and only 33% thought the current industry procedures were sufficient to mitigate them. The report concludes with proactive measures to reduce the incidence of forest machine fire risk.

Forest Machinery Fires: Trends in New Zealand Forest Harvesting Sector

Rien Visser, Samuel Lloyd McDell, Okey Francis Obi

Abstract

Fires in forest machines are typically catastrophic in terms of machine destruction and can develop rapidly to be a risk to the machine operator. They are an issue worldwide and there can be larger consequences such as starting a major forest fire. This paper describes trends in machine fire occurrences in the New Zealand forest harvesting sector. A total of 224 machinery fire incidents were recorded over an 8 year period from 2007 to 2014. Trends in forest machinery fires in the sector were identified and summarized. Late morning (10 am-noon) and mid-afternoon (2–4 pm) showed the highest incidence of machine fire, corresponding to periods with the highest level of work. Excluding the main holiday months, there was a correlation of machine fires to average monthly temperature. Summary statistics on causes of fire ignition showed that 40% were attributed to electrical and hydraulic faults; however, some remain unidentified as the fires commenced after work was completed. A short survey of industry managers was carried out to ascertain machine fire perceptions. 67% agreed that machine fire was an issue, and only 33% thought the current industry procedures were sufficient to mitigate them. The report concludes with proactive measures to reduce the incidence of forest machine fire risk.

Keywords: fires, forestry, machinery, safety

1. Introduction

Fires are a source of concern in all industries, but especially in forestry as they can cause significant damage in terms of cost and social disturbance (Byram 1959, Chandler et al. 1983, Luke and McArthur 1986). In forestry, it is not only the forest itself that is at risk, but machinery used during forest harvesting operations can self-ignite (Baxter 2002). Combustion of vehicles and forest related operations have been identified as causes of larger scale forest fires (Bernardi 1974, Cameron et al. 2007). Factors capable of initiating machinery fires are diverse; common known causes of machinery fires include exhaust heat and frictional parts igniting built up organic debris around the engine, ignition of leaking fuel or hydraulic fluids on hot surfaces, and electrical malfunction resulting in sparks in the presence of flammable materials. With high internal fuel loading in terms of both diesel and hydraulic oils, machine fires are typically catastrophic in terms of machine loss. In addition to the economic loss of the machine, other losses include lost working hours, damage to immediate and surrounding forest areas, damage to the environment including soil and water quality, and losses associated with personal injuries and in some cases, fatality.

The problem of forest machinery fires has received little or no attention as evident in the scarce literature on this subject. Causes of forest machine fires have been identified and there are operational guides for the prevention of fires (Fogarty et al. 1998, Davis et al. 1999). In practical terms, it is suggested that fires occur mostly as a result of lack of attention to details, especially when operators do not know how to prevent fire occurrence due to lack of relevant guidance (DNV 2007). A well-known risk factor is the build-up of duff material around the engine that, when dried, can readily self-ignite (Kaminski 1974, Xanthopoulos and Wakimoto 1993). Although literature on forest machinery fires is limited, machinery fires research in the field of crop production is well documented with losses estimated in millions of US dollars (Venem and Shutske 2002, Shutskeet al. 1990).

Regions with large-scale forest industries often encourage the reporting of fire incidents and accidents. The primary goal is not just to maintain statistics of causes and consequences, but also to learn from previous incidents. For example, both Washington and British Columbia safety entities keep extensive and publicly available incident reports on their respective websites, as does the Forest Resources Association (OSHA 2019, BC Forestry Safety 2019, FRA 2019). In New Zealand, the Incident Recording Information System (IRIS) was set up in 1990 (previously known as Accident Reporting Scheme) and has continuously been accumulating data as submitted by the industry (Parker 1996). Prompted by a spate of machine fires in the southern region of New Zealand, this paper seeks to identify trends and knowledge of forest machinery fires using New Zealand as a case study. This study was facilitated by the retrieval of data from IRIS covering an 8 year period, where relatively detailed information on all incidents were recorded.

2. Methods

Data were obtained from the IRIS database managed by the New Zealand Forest Owners Association (NZFOA), where all member companies are strongly encouraged to submit data on incidents and accidents that occur within the industry. IRIS provides information about the type, frequency and severity of incidents, and helps identify key contributing causes to machinery fires (https://safetree.nz/resources/iris-reports/). With regard to machine fires, an important strength of the database is that it covers incidents from minor to major fires, not just incidents that have resulted in worker harm. A total of 224 machinery fire incidents were identified in the IRIS database over the 8 year period, from 2007 to 2014. Using only valid data entries, trends characterizing forest harvesting machinery fires in New Zealand were identified. Additionally, to ascertain industry perception of machine fires, a questionnaire was developed and sent to selected 20 forest industry professionals knowledgeable in forest machinery fires; 75% of the professionals responded to the questionaire. The questions asked include the following: Are machinery fires an issue in New Zealand?; Are only old machines susceptible to fires?; Are the current industry procedures sufficient to mitigate machinery fires?; Should there be an industry standard that addresses prevention of forest machinery fires?; Are modern machinery fires designed to mitigate potential fire hazards?

3. Results and Discussion

3.1 Industry Perception of Forest Machinery Fires

The survey questions and the responses received are presented in Table 1. The majority of the responders (67%) are of the opinion that machine fire is an issue in New Zealand forest industry. Although 42% of the responders suggest that current industry procedures are not sufficient to mitigate machinery fire hazards, 50% of the total responders agree that there is the need for an industry standard for the prevention of possible machinery fires.

Table 1 Survey results on forest machinery fires in New Zealand (N=15)

|

Questions |

Responses, % |

||

|

Disagree |

Neutral |

Agree |

|

|

1. Machinery fires are an issue in New Zealand forest industry? |

0 |

33 |

67 |

|

2. Only old machines are susceptible to fires? |

33 |

17 |

50 |

|

3. The current industry procedures are sufficient to mitigate machinery fires? |

42 |

25 |

33 |

|

4. There should be an industry standard for the prevention of forest machinery fires? |

25 |

25 |

50 |

|

5. Modern forest machineries are designed to mitigate potential fire hazards? |

8 |

25 |

67 |

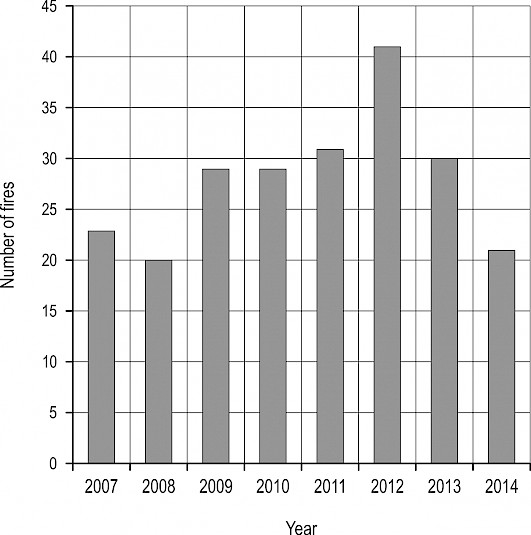

3.2 Machinery Fires – Yearly and Monthly Trends

Fig. 1 presents the annual number of machinery fire incidents in New Zealand forest harvesting sector; an average of 28 machine fires per year was recorded. It was observed that the number of machinery fires had generally been on the increase from 2007 and peaked in 2012 with a total of 41 reported machinery fires. This corresponds to a period of rapid expansion in the industry. The figure shows a decline in 2013 and 2014, perhaps because of the greater awareness of machine fire risk. The lowest number of machinery fires was reported in 2008 (20 fire incidents), which corresponds to a year when harvesting levels were in contraction in response to the Global Financial Crisis.

Fig. 1 Yearly machinery fires in the New Zealand forest harvesting industry

To put these numbers into perspective, there are approximately 410 ground-based harvesting crews operating on average 4.2 machines (Harrill and Visser 2019), and 310 cable yarding crews operating 4.9 machines (Visser 2013, Visser 2016), for an approximate total of 3250 forestry machines. This still means that 1 in 115 machines are affected by fire each year.

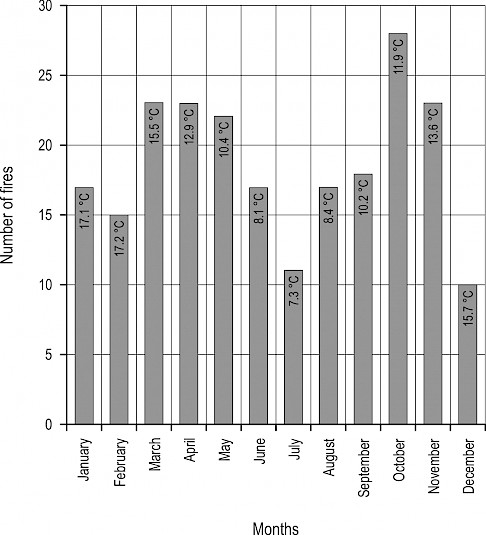

Fig. 2 shows the breakdown by month for the 8 year period. The number of machinery fires peaked in March and April, which corresponds to New Zealand late summer / early autum. Another peak is seen in the month of October, which is the start of spring, with no clear known reason for this spike.

Fig. 2 Monthly trend in forest machinery fires and the average monthly temperatures in New Zealand

In addition to the number of fires reported monthly, Fig. 2 shows the mean monthly temperatures in New Zealand over the 8 year period of 2007 to 2014 as obtained from the National Institute of Water and Atmospheric Research (2016). Removing the months of December and January, being the summer holiday months in New Zealand when work hours are relatively low, a strong correlation can be found between temperature and fire incidents – as given by Eq. 1. So, for an average month temperature increase from 10 to 15 degrees, the total incidents increase from 18.9 to 25.8, or a 36% increase.

(1)

(1)

Where:

Machine Fires (#) the total number per month for the 8 year period

Temp (degree) the average mean daily high temperature for the month.

Weather condition is known to be a significant factor in the occurrence of wildfires (Pearce and Clifford, 2008). The data analyzed in this paper suggest that the ambient temperature may have an effect on the potential ignition of forest machinery fires, even though the data is not significantly conclusive. This is understandable considering that forestry machines usually operate at temperatures much higher than the ambient (San Dimas EDC 1980). Intensity or total hours of machine usage is an important factor that could also influence machine fire occurrence, however, such information is not available to further explain the trend and the relationship between ambient temperature and number of machine fire incidents. Additional information on machine usage could be helpful in identifying mechanisms that cause forestry machine fires and may lead to changes in machine design and practices with the goal of reducing potential fire hazards.

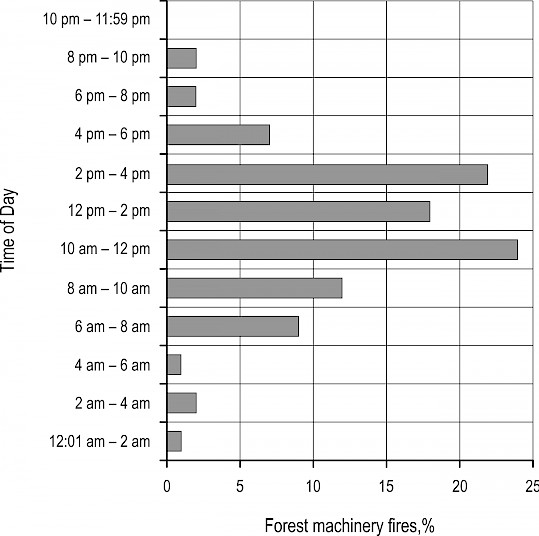

3.3 Time of Fire Incidents

46 of the 224 incident reports did not have a valid time stamp included. A default time stamp setting of midnight (12:00 am) was reported in a further 27 entries. These are more likely to reflect an unknown time, not the actual time of the fire. As such, Fig. 3 presents only the forest machinery fire entries with known incident time spanning the period from 12:01 am to 11:59 pm. All of the forest machinery fires occurred between 12:01 am and 10:00 pm, with 89% of the fires occurring before 4 pm. Machinery fires from the hours of 10:00 am and 04:00 pm accounted for 64% of total machinery fires. While many harvesting crews commence work prior to 8 am, typical ambient temperature conditions, higher early morning humidity and lower average engine temperature during startup make this an expected result. Conversely, lower relative humidity after 10 am with warmer ambient temperatures, and possible drier state of flammable accumulated plant materials on machine parts could all contribute to the high incident of forest machine fires (Blackmarr 1972). The highest percentage of the machinery fires (24%) occurred between the hours of 10:00 am – 12:00 pm, followed by the hours of 02:00 – 04:00 pm (22%). The drop during the 12 pm to 2 pm period can be explained by many logging crews taking their lunch break at this time, resulting in a lower overall activity. It can be expected that incidents occurring after 8pm or before 6am might be arson.

Fig. 3 Time of occurrence of forest machinery fires

3.4 Forest Region of Fire Occurrence

The IRIS database recognizes nine forest regions in New Zealand namely Central North Island, Hawkes Bay, Northland, Canterbury, Otago/Southland, East Coast, Nelson/Marlborough and West Coast. Fig. 4 presents a graph of the percentage of forest machinery fire incidents in the different forest regions of New Zealand based on 221 valid entries from 2007 to 2014, and the mean harvest volume for the period 2007–2014 (MPI 2018). Forest machinery fires in Central North Island, Hawkes Bay, Northland, and Canterbury accounted for 78% of the total reported forest machinery fires in New Zealand. The Central North Island has the highest percentage of forest machinery fires accounting for 41%. It is believed that the high occurrence of machinery fires in some regions could be attributed to high forest machinery activities relative to the regions with low percentage of machinery fires. To support this view, the mean harvest volume of round-wood for each of the regions from 2007 to 2014 as presented in Fig. 4 was correlated with the number of machinery fires using Pearson’s correlation coefficient. The average round-wood harvest volume was used as an indication of the intensity of machinery usage. The result of the correlation was as expected, a strong positive correlation coefficient of 0.94, suggesting that the more the intensity of machinery use in harvest operations, the more likely the occurrence of forest machinery fires. This could explain the high machinery fire incidents in the Central North Island as the round-wood harvest volume in that region (10 434 000 m3) was the highest compared to other forest regions for the period 2007 to 2014 (Fig. 4). The harvest volume for the regions generally followed a similar trend as the percentage of machinery fires.

Fig. 4 Mean round-wood harvest volume (2007 to 2014; MPI 2018) and machinery fires in forest regions in New Zealand

3.5 Source of Ignition

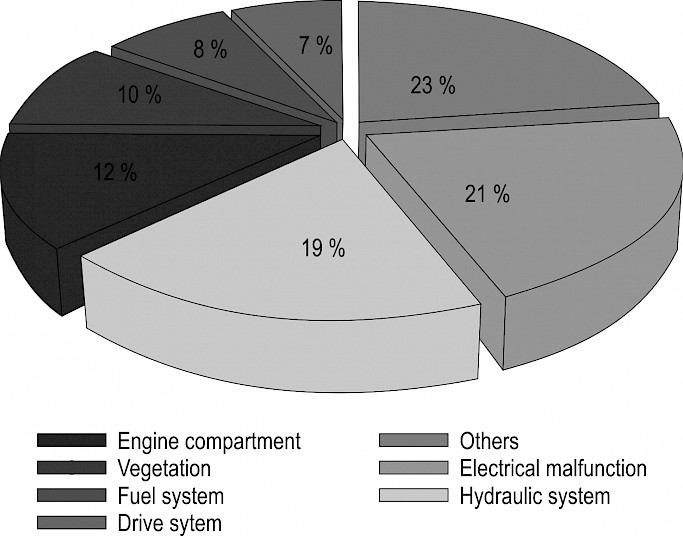

Fig. 5 shows the source of fire ignition for the 198 forest machinery fires where a source was identified in the IRIS database. Ignition refers to the process by which a »rapid exothermic reaction is initiated, which then propagates and causes the material involved to undergo change, producing temperatures greatly in excess of ambient« (Drysdale 2011). A total of seven different sources of forest machinery fires were identified; electrical malfunction, hydraulic system, engine compartment, vegetation, fuel system, machinery drive system and others. Electrical malfunctions in forest machinery (including faults in the starter motor, batteries, and arcing of wires) accounted for 21% of machine fires, closely followed by faults in hydraulic system. Hydraulic system faults include punctured hydraulic oil pipes resulting in the spray of hydraulic oil on hot machine surfaces or leakage that ignites as it drops on hot surfaces. These accounted for 19% of the total machinery fires. About 12% of the fires started within the machinery engine compartment, while 10% was attributed to accumulation of organic debris onto hot machinery surfaces such as exhaust pipes, mufflers, turbochargers, and the engine structure itself. Fires from the fuel system has an 8% share of the total source of machinery fires; such fires are started as a results of leakage or punctured fuel pipe lines, sparks close to the fuel system, and fuel splashing onto hot machinery parts during refueling.

Fig. 5 Percentage of machinery fires from different sources

Based on the information presented on hydraulic and fuel system sources of machine fires, flammable liquid initiated fires could be said to be the highest source of forest machinery fires accounting for 27% of forest machinery fires recorded in the IRIS database. This is in line with results from previous studies on machinery fires in other industries that identified flammable liquid leakages as the major cause of machinery fires (Ikeagwuani and John 2013). Flammable liquids drop on hot surfaces that provide the required threshold energy to initiate the production of flammable vapours and triggers their combustion with oxygen in the presence of combustible materials (mostly vegetative matter) to initiate fire ignition (Daeid 2004). In situations of high energy release, flaming combustion or large scale fire occur. Faults in the machinery drive system accounted for 7% of the fires; such faults identified in the IRIS database include overheating of poorly lubricated axle bearings, and malfunction of the machinery brake system often overheating the rims and igniting the tyres. The second highest source of the forest machinery fires, 23%, is attributed to those classified as »others«, which include fires started as a result of sparks from welding and cable-cutting related activities, human element or »carelessness and misuse« (such as dropping lit cigarettes close to the fuel line, and leaving flammable materials on hot machinery surfaces). A breakdown of this »other« class of forest machinery fire source shows that 66% of the fires were from unknown sources, 29% were as a result of hot works including sparks from welding, grinding and cutting related activities, while 5% of the fires were as a result of human activity. Most of the reported intense fires that resulted in the total destruction of the forest machinery were those attributed to unknown causes. Such fires are mostly on parked machinery and only noticed after the fire had engulfed the machine. The often remote location of forest machines and the less likelihood of continuous monitoring could also be a factor. Based on available information in the IRIS database, it is difficult to attribute such fires to arson, however, arson has been identified as one of the major causes of fires in plantation forests (Ganteaume et al. 2013, Cameron et al. 2007).

An important observation in many of the machinery fire incidents was the availability of fire extinguisher on the machinery and on site that was used to put-out some of the fires where possible. About 29% of the fires were reported to have been safely and successfully extinguished using two to seven fire extinguishers on the machinery and/or on site. For the rest of the fires, it is either the fires were too intense and thus unsafe to be extinguished using fire extinguishers or the use of fire extinguishers was not reported. Sufficient information was not provided as to the type and size of fire extinguishers used in successfully putting-out the fires. Fire extinguishers are often very effective at putting out small fires but have limited capacity in containing large fires. It is believed that the 29% reported for fires successfully extinguished using fire extinguishers could be higher as it is likely that many small-in-nature forest machinery fires successfully extinguished by crews may be unreported as incidents in IRIS.

3.6 Machinery Fires Prevention

Although major changes in fire prevention regulations and practices in most industries are often initiated after a catastrophic fire incident, it is better to take proactive steps in preventing possible occurrence of such incidents and prevent the possible loss of lives and properties. As mentioned earlier, there is very limited published information on forest machinery fires including specific design criteria for manufacturers, and operational procedures for minimizing potential machinery fires. Consequently, safety standards and codes of best practice should be developed that address forest machinery fire prevention from the design and manufacturing perspective, as well as operational procedures by the operators or users. In view of this, the forest harvesting industry should develop regulations, guidelines and operational procedures in partnership with the insurance industry to tackle potential machinery fires, and embrace practices directed towards minimizing and/or eliminating fires. An example is seen in the recommendations on code of best practice on hot work by the Loss Prevention Council in the United Kingdom and the Republic of Ireland detailing potential risk and hazards inherent in hot work and precautions necessary for their safe operations (NBS 2019). Such a code of best practice should be developed with a view to reducing uncertainties surrounding machinery fires to »as low as reasonably practicable«, a term that has been adopted in safety research (Rosqvist and Tuominen 2004). Such an approach does not assume that the risk has been eliminated, rather it is focused on precaution which in itself should reduce the risk of machinery fires. Operators should make conscious effort to eliminate or isolate potential fuels capable of igniting machinery fires, and adhere to fire prevention and safety practices.

On the part of machinery manufacturers, machines should be designed and built in view of safety measures to minimize the possibility of machinery fires by isolating potential sources. Efforts should be directed towards scientific and technological solutions to preventing and minimizing fires, and detecting and containing fires on forest machinery. When dealing with machinery fires, the most common tools for reducing loss severity are fire extinguishing systems (Vogltance and Wiles 2007, Shutskeet al. 1994). Incorporating permanently fixed automatic actuating extinguishers with fire sensors, particularly in machinery parts with high potential source of machinery fires, would help in the early detection and suppression of fires thus providing enough time for evacuation and minimizing damage to machinery. In all the reported machinery fires in the IRIS database, there was not a single mention of such fire extinguishing system in the forest machinery. This is an opportunity for machinery manufacturers to improve safety features in the design of forest machines.

Leakage of flammable liquids (diesel, hydraulic oil, etc.) has been identified as the most common cause of forest machinery fires; it is important that these materials be contained and not allowed to come in contact with flammable materials. Efforts should be made by machinery designers to isolate potential ignition sources and flammable materials; hot surfaces which tend to accumulate vegetation should be shielded, or enclosed to prevent residue accumulation and consequent ignition. The Nebraska Forest Service published some daily operational guides on early detection and prevention of potential machinery fire hazards (Vogltance and Wiles 2007, Vogltance et al. 2007). This includes safe storage and fueling of machinery, checking for buildup of vegetation around hot machinery parts (exhaust system, engine compartment, etc.), checking for signs of leaking fluids and damaged electrical wirings, and keeping oily rags away from machines. Information specific to fire prevention on individual forest machinery should also be provided by machine manufacturers. Industry stakeholders including manufacturers, the insurance industry, operators, and other parties with knowledge of machinery fire detection, prevention, and suppression all have different roles to play in bringing the incidences of machinery fires to the barest minimum.

4. Conclusions

This study provides empirical evidence as to the occurrence of machinery fires in New Zealand forest harvesting sector. Flammable liquid leakages are identified as the major cause of machinery fires in the industry. Establishing regulations and standards to guide operational procedures, including forest machinery design is suggested as a first step in curtailing potential machinery fire hazards. This study can be a background for future studies on forestry machinery fires in the New Zealand forest harvesting industry. Additional machinery fire data, such as point of initial fire ignition, day of fire incidence, and hours of machine use at the time of fires, would be helpful to further understand various forest machinery fire risk factors, and also to identify potential mitigation strategies. As noted by Ganteaume et al. (2013), knowledge of the causes of fires, and of the risk factors of ignition, are indispensable in developing effective fire prevention measures. As research in this field of study gains momentum, it is hoped that fire hazards in the industry will be recognized and appropriate standards developed to address the problem. As such standards are incorporated into forestry machine designs, and in the operational procedures for crews, there is the potential for reducing the frequency and magnitude of forest machinery fires.

Acknowledgments

We would like to thank the New Zealand forest industry members that took the time to support this research initiative by contributing ideas and participating in the survey.

7. References

Anderson, S., 2005: Forest and rural fire danger rating in New Zealand. In Forestry Handbook, Colley, M., Ed., New Zealand Institute of Forestry: Christchurch, 241–244 p.

Baxter, G., 2002: All terrain vehicles as a cause of fire ignition in Alberta forests. Advantage Report 3(44): 1–7.

BC Forestry Safety, 2019: Safety Alerts. Available online: http://www.bcforestsafe.org/safety_info/alerts_bulletins.html (Accessed 12 June 2019).

Bernardi, G.C., 1974: Fires caused by equipment used during critical fire weather in California, 1962–1971. Research Note PSW-289, Pacific Northwest Forest and Range Experiment Station, US Forest Service, Berkeley, CA, 6 p.

Blackmarr, W.H., 1972: Moisture content influences ignitability of slash pine litter. Research Note SE-73; USDA Forest Service, Southeastern Forest Experiment Station Asheville, North Carolina, 1–7.

Byram, G.M., 1959: Combustion of forest fuels. In Forest Fire: Control and Use; K.P. Davis, Ed.; McGraw-Hill: New York, 61–89.

Cameron, G., Pearce, H.G., Moore, J.R., Bulman, L.S., 2007: Report to the New Zealand Forest Owners Association on aspects of rural fire management in New Zealand’s plantation forests. Geoff Cameron & Associates, Wellington, in association with Scion, Rotorua, 115 p.

Chandler, C., Cheney, P., Thomas, P., Trabaud, L., Williams, D., 1983: Fire in Forestry. Vol. 1: Forest fire behavior and effects; John Wiley & Sons, Inc.: New York, 450 p.

Daeid, N.N., 2004: Fire Investigation. CRC Press, Taylor & Francis: London, UK.

Davis, G., Nichols, M.D., Tuttle, A.E., 1999: Industrial Operations Fire Prevention Field Guide. Department of Forestry and Fire Protection: Sacramento, California, 148 p.

Det Norske Veritas (DNV), 2007: Engine room fires can be avoided, managing risk. Available online: https://exchange.dnv.com/Documentation/Maritime/FireSafety/FIRE%20mappe%202.qxd.pdf (Accessed 23 August 2017).

Doherty, J.J., Anderson, S.A.J., Pearce, H.G., 2008: An analysis of wildfire records in New Zealand: 1991–2007. Scion Report No. 12789; Scion: Christchurch, 61 p.

Drysdale, D., 2011: An Introduction to Fire Dynamics, 3rd ed,; John Wiley & Sons Ltd.: West Sussex, United Kingdom.

Fogarty, L.G., Pearce, H.G., Catchpole, W.R., Alexander, M.E., 1998: Adoption vs. adaptation: Lessons from applying the Canadian forest fire danger rating system in New Zealand. Paper presented at the Proceedings, 3rd International Conference on Forest Fire Research and 14th Fire and Meteorology Conference, Luso, Coimbra, Portugal, 16-20 November, 1011–1028 p.

FRA, 2019: Safety Alerts. Available online: https://forestresources.org/resources/safety/safety-alerts (Accessed 10 June 2019).

Ganteaume, A., Camia, A., Jappiot, M., San-Miguel-Ayanz, J., Long-Fournel, M., Lampin, C., 2013: A review of the main driving factors of forest fire ignition over Europe. Environmental management 51(3): 651–662. https://doi.org/10.1007/s00267-012-9961-z

Harril, H., Visser. R. 2019: A survey of ground-based harvesting systems in New Zealand. Future Growers Research Harvesting Technical Note HTN12-04; Rotorua, New Zeland.

Ikeagwuani, U., John, G., 2013: Safety in maritime oil sector: Content analysis of machinery space fire hazards. Safety science 51(1): 347–353. https://doi.org/10.1016/j.ssci.2012.08.003

Kaminski, G.C., 1974: Ignition time vs. temperature for selected forest fuels. University of California, US Department of Agriculture, Forest Service: Riverside, California, 1–8.

Luke, R.H., McArthur, A.G., 1986: Bushfires in Australia. CSIRO Division of Forest Research, Commonwealth Scientific and Industrial Research Organisation, Forestry and Timber Bureau, Department of Primary Industry: Canberra, 359 p.

Ministry of Primary Industries, 2018: Forestry – wood processing: estimated roundwood removals from New Zealand forests by wood supply region, 2002 to 2018. Available online: http://www.mpi.govt.nz/news-and-resources/open-data-and-forecasting/forestry/wood-processing/ (Accessed 20 June 2018)

NBS, 2019: REC RC 7 Risk control. Recommendations for hot work, incorporating interactive hot work permit. Fire Protection Association, London United Kingdom. Available online: https://www.thenbs.com/PublicationIndex/documents/details?Pub=LPC&DocID=325975 (Accessed 5 May 2019).

NIWA, 2016: Climate data and activities – mean monthly temperatures (oC). Available online: https://www.niwa.co.nz/education-and-training/schools/resources/climate/meanairtemp (Accessed 23 August, 2017).

Parker, R., 1996: Analyses of Lost Time Aciidents – 1995 Logging (Accident Reporting Scheme Statistics). Logging Industry Research Organization Report 21(21), Rotorua, New Zealand.

Pearce, H.G., Clifford, V., 2008: Fire weather and climate of New Zealand. New Zealand Journal of Forestry 53(3): 13–18.

Rosqvist, T., Tuominen, R., 2004: Qualification of formal safety assessment: an exploratory study. Safety Science 42(2): 99–120. https://doi.org/10.1016/S0925-7535(03)00005-5

San Dimas EDC, 1980: Ignition characteristics of internal combustion engine exhaust products. San Dimas, California: U.S. Department of Agriculture, Forest Service, San Dimas Equipment Development Center. Project Record 8051 1205, 4 p.

Shutske, J., Field, W., Chaplin, J., 1994: Grain combine fires: a loss reduction approach. Applied Engineering in Agriculture 10(2): 175–182. https://doi.org/10.13031/2013.25838

Shutske, J., Field, W., Gaultney, L., Parsons, S., 1990: Agricultural machinery fire losses: A preventative approach. Applied Engineering in Agriculture 6(5): 575–581.

Venem, M., Shutske, J., 2002: Combine Fire Prevention and Control Summit. 2002 ASAE Annual Meeting of the American Society of Agricultural and Biological Engineers, Chicago, Illinois, USA, July 28-July 31, 1–11.

Visser, R., 2013: Survey of cable yarders used in New Zealand. Future Forest Research Harvesting Technical Note 06-03; Rotorua, New Zealand.

Visser, R., 2016: Trends in harvesting cost and productivity. Future Forest Research Harvesting Technical Note 09-03; Rotorua, New Zealand.

Vogltance, B., Wiles, L., 2007: Preventing Farm Equipment Fires. Publications, etc. – Nebraska Forest Service, 31. Available online: http://digitalcommons.unl.edu/nebforestpubs/31 (Accessed 10 June, 2019).

Vogltance, B., Wiles, L., Bassett, J., 2007: Fire Prevention on the Farm and Ranch: What every country homeowner needs to know about fire! Publications, etc. – Nebraska Forest Service, 36. Available online: http://digitalcommons.unl.edu/nebforestpubs/36 (Accessed 10 June, 2019).

Xanthopoulos, G., Wakimoto, R.H., 1993: A time to ignition-temperature-moisture relationship for branches of three western conifers. Canadian Journal of Forest Research 23(2): 253–258. https://doi.org/10.1139/x93-034

© 2020 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors’ addresses:

Prof. Rien Visser, PhD *

e-mail: rien.visser@canterbury.ac.nz

University of Canterbury

New Zealand School of Forestry

Christchurch

NEW ZEALAND

Samuel Lloyd McDell

e-mail: sam_mcdell@hotmail.co.nz

PF Olsen Ltd.

Gisborne 4010

NEW ZEALAND

Okey Francis Obi, PhD

e-mail: francis.obi@unn.edu.ng

University of Nigeria

Faculty of Engineering

Agricultural and Bioresources Engineering Department

41001, Nsukka

Enugu state

NIGERIA

* Corresponding author

Received: July 3, 2019

Accepted: March 17, 2020

Original scientific paper