Impact of Rainy and Dry Seasons on Eucalypt Fuelwood Quality Logs Stored in Piles: a Case Study in Brazil

doi: 10.5552/crojfe.2021.776

volume: 42, issue:

pp: 10

- Author(s):

-

- Eufrade-Junior Humberto de Jesus

- Spadim Emanuel Rangel

- Rodrigues Sérgio Augusto

- Pai Enzo Dal

- Ballarin Adriano Wagner

- Guerra Saulo Phillipe Sebastião

- Article category:

- Original scientific paper

- Keywords:

- heating value, proximate analysis, energy log woodpile

Abstract

HTML

The natural drying of fuelwood is a common practice to improve its quality and increase the efficiency in the biomass-based energy supply chain. The objective of this work was to analyze the effect of seasons on the physical and chemical properties of wood logs stored in piles for energy purposes. The logs of Eucalyptus urophylla were stored in two periods of 160 days each throughout the year, autumn–winter (dry season) and spring–summer (rainy season). During the 320 days, the moisture content of wood and the weather parameters were measured daily. After the natural drying, the moisture content (wet basis) of wood reached 29.6%, and there was an increase of 47.6% in the low heating value (12.4 MJ kg-1 wet basis) after the storage in the autumn–winter, which is the most suitable period for air–drying of logs. The rainy storage reduced the higher heating value of wood, which suggested a biological degradation of biomass.

Impact of Rainy and Dry Seasons on Eucalypt Fuelwood Quality Logs Stored in Piles: a Case Study in Brazil

Humberto de Jesus Eufrade-Junior, Emanuel Rangel Spadim, Sérgio Augusto Rodrigues, Enzo Dal Pai, Adriano Wagner Ballarin, Saulo Philipe Sebastião Guerra

Abstract

The natural drying of fuelwood is a common practice to improve its quality and increase the efficiency in the biomass-based energy supply chain. The objective of this work was to analyze the effect of seasons on the physical and chemical properties of wood logs stored in piles for energy purposes. The logs of Eucalyptus urophylla were stored in two periods of 160 days each throughout the year, autumn–winter (dry season) and spring–summer (rainy season). During the 320 days, the moisture content of wood and the weather parameters were measured daily. After the natural drying, the moisture content (wet basis) of wood reached 29.6%, and there was an increase of 47.6% in the low heating value (12.4 MJ kg-1 wet basis) after the storage in the autumn–winter, which is the most suitable period for air–drying of logs. The rainy storage reduced the higher heating value of wood, which suggested a biological degradation of biomass.

Keywords: heating value, proximate analysis, energy log woodpile

1. Introduction

The lignocellulosic biomass can be converted into a variety of chemicals and energy, including solid, liquid, and gaseous fuel used in processes to produce its thermal, mechanical, and electrical forms (Londo et al. 2018). In the power generation from wood, the knowledge of moisture content, basic density, proximate composition, and heating value is essential; these properties also have implications for handling, transportation, drying, biomass storage, energy conversion systems and significantly impact their costs (Sosa et al. 2015, Acuna et al. 2012, Moskalik and Gendek 2019).

The moisture content (MC) is one of the most important forest biomass properties, particularly for its combustion. The lowest value of MC is desirable to increase process efficiency in the energy systems. After harvesting, Eucalyptus logs have high MC (from 50 to 60% – wet basis), at least half of their total weight are represented by water (from 50 to 60% – wet basis) and need to be dried before being submitted to industrial processes.

Another significant wood property is the basic density (defined by the ratio between the dry mass and saturated volume). The lower densities suggest a more permeable wood structure (a greater presence of sapwood than heartwood), which tends to dry faster (Bergman 2010, Silva et al. 2010).

The proximate composition is also essential for quality control in energy processes. For example, an increase of ash content can cause severe damage to metal equipment used in direct combustion, such as abrasive wear, and the ash content has a negative relationship with calorific value (Monti et al. 2008). The ash contents are partly composed of soil or sand particles, and the storage step may be directly related to the variation and transport of these particles with biomass for thermoelectric plants (Afzal et al. 2010).

Another critical parameter to characterize biomass as combustible is the heating value, which can be defined as the number of energy units produced by the combustion of a unit mass of fuel (Telmo and Lousada 2011). At a practical level, the Low Heating Value on a wet basis is a measure of energy content available after deducting losses from water evaporation during burning (Telmo and Lousada 2011, Glowacki et al. 2018).

Storage is an essential operation in the forest supply chain as it promotes moisture content reduction and increases the material energy potential. In the southeast of Brazil, the logs are stored outdoors for a maximum period of six months, and then air–drying conditions promote the reduction of Eucalyptus wood moisture less than 35% w.b. (Zanuncio et al. 2015, Resende et al. 2018). In this context, the log diameter and length, the coverage, and weather conditions are critical due to reach an optimal solution (Brand et al. 2011, Resende et al. 2018, Manzone 2018). Brazilian experience is concentrated in short logs storage – length ranging from 1 m to 3.6 m (Zanuncio et al. 2015, Resende et al. 2018); there are still doubts about the behavior of these properties after storage of logs longer than 6 m length.

The main objective of this work was to evaluate the effect of seasons and diameter class of stored long logs overtime on the proximate analysis, basic density, and heating value of wood from Eucalyptus urophylla tree plantation.

2. Materials and Methods

2.1 Characterization of Forest, Site, and Log Woodpiles

Trees came from a clonal Eucalyptus plantation (Table 1) located in the experimental area of the Lageado Experimental Farm belonging to the School of Agriculture (FCA/UNESP) in Botucatu, Sao Paulo State/Brazil, (22º48'13"S and 48º25'47"W).

Table 1 Forest plantation parameters

|

Silvicultural parameters |

Unit |

|

|

Species |

– |

Eucalyptus urophylla S.T. Blake |

|

Clone |

– |

AEC 0144 |

|

Age |

year |

7 |

|

Planting density |

tree ha-1 |

1667 |

|

Average height |

m |

21.7 |

|

Average DBH |

cm |

16.9 |

|

MAI |

m3 ha-1 year-1 |

42.4 |

|

DBH – diameter at breast height; MAI – Mean annual increment |

||

The forest was located at 727 m a.s.l, in a region with an average rainfall of 1400 mm year-1 and an average annual air temperature of 20°C. The soil of the site is identified as red nitosol with a clay texture. Sixty trees were harvested with the chainsaw, and three to four 6.2 m long logs were cut from each one with a minimum commercial diameter of 5 cm. The logs were identified and classified in the field in three diameter classes, according to Table 2.

Table 2 Diameter class of logs

|

Diameter class |

Limit of class, cm |

Center class, cm |

|

Lower |

6.2–12.7 |

9.5 |

|

Middle |

12.8–19.2 |

16.0 |

|

Upper |

19.3–25.7 |

22.5 |

The logs with bark were stored randomly in four piles (3 m3 each) assembled under a fixed scale structure set up in the outside area of the Laboratory of Agroforestry of Biomass and Bioenergy – LABB (coordinates 22º50'53"S and 48º26'08"W) at the School of Agriculture (FCA/UNESP). The dimensions of log woodpiles were 6.2×1.5×0.6 m, length, width, and height, respectively (Fig. 1).

Fig. 1 Air-drying of uncovered log wood piles (6.2 m length) during experiment

Experimental procedures were repeated in two different seasons (dry and rainy), for a period of 160 days each:

Þ dry season – harvest and storage from April 5, 2017 to September 12, 2017, including the autumn and winter seasons

Þ rainy season – harvest and storage from September 27, 2017 to March 6, 2018, including the spring and summer seasons

During the rainy season, an increase of almost 70% in the precipitation was observed compared to the dry season (Table 3).

Table 3 Weather conditions during storage of logs

|

Storage season |

DS |

P, mm |

T, °C |

W, m s-1 |

RU, % |

SR, MJ m-2 |

|

Dry, autumn and winter |

160 |

542.3 |

19.0±2.9 |

1.9±0.7 |

71.8±15.5 |

15.2±5.3 |

|

Rainy, spring and summer |

160 |

919.0 |

22.2±2.1 |

2.0±0.6 |

78.3±13.1 |

19.0±6.4 |

|

DS – Duration of storage (days), P – Precipitation accumulated, W – Daily mean speed wind and standard deviation, T – Mean daily temperature and standard deviation, RU – Mean daily relative humidity of the air and standard deviation, SR – Mean daily solar radiation and standard deviation; Daily data came from Lageado´s Farm Meteorological Station, lat (22º50'48"S), long (48º26'06"W) |

||||||

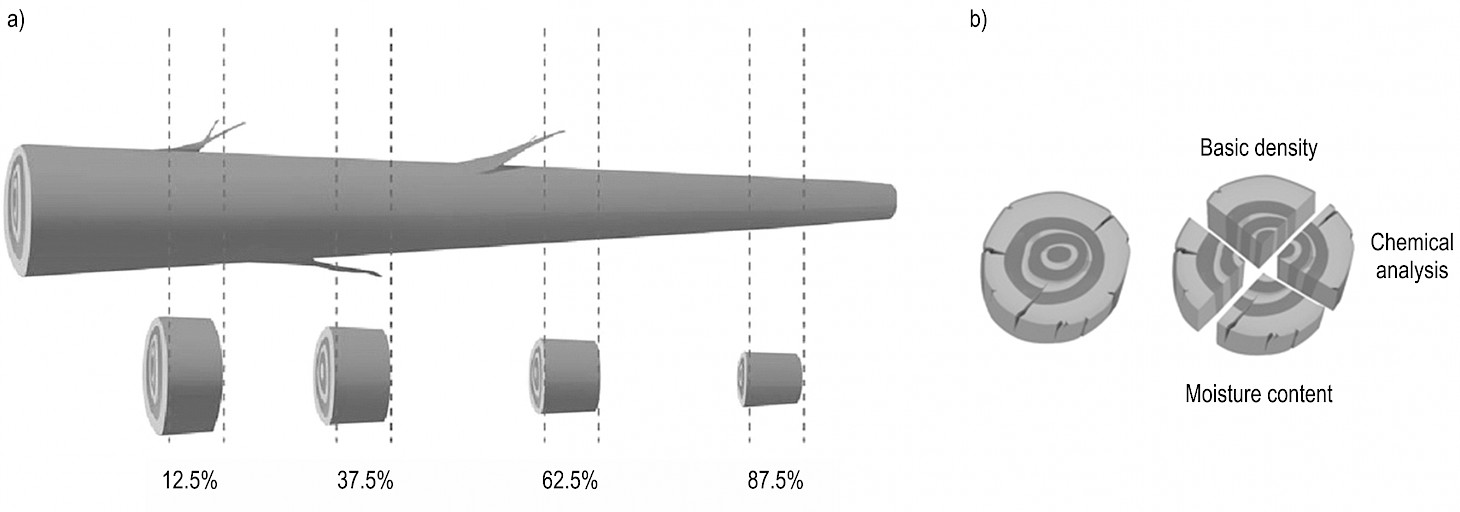

2.2 Fuelwood Quality

Six logs from each class center diameter were selected in two moments to characterize the physical and chemical properties: in the experiment setup – 0 storage day – and at 160 days after storage, for both evaluated seasons, the dry and the rainy. The logs were sampled using 5 cm thick discs in the 12.5%, 37.5%, 62.5%, and 87.5% positions along the length, excluding the tops as recommended by the European standard EN 14778 (CEN 2011). The discs per logwood were debarked and ground to 40 mesh (0.420 mm) – 60 mesh (0.250 mm) fraction to form a representative sample for each selected log after the quartering process (Fig. 2). Thus, a composed sample (24 discs from 6 logs) per class diameter and season was used for laboratory analysis in triplicate.

Fig. 2 a) Sampling of entire logwood; b) Quartering of wood discs to obtain subsamples used to determine physical and chemical properties

The moisture content, basic density, proximate composition (ash, volatile materials, and fixed carbon), and the wood heating value were determined according to the techniques described in Table 4.

Table 4 Standards and methods

|

Wood properties |

Initials |

Standards or references |

|

Ash |

A |

ASTM D1102-84 (2007) |

|

Fixed carbon |

FC |

ASTM E870-82 (2006) |

|

Volatile matter |

VM |

ASTM E872-82 (2006) |

|

Higher Heating Value |

HHV |

ASTM E711-87 (2004) |

|

Low Heating Value, dry basis |

LHVdb |

Telmo, Lousada (2011) |

|

Low Heating Value, wet basis |

LHVwb |

Telmo, Lousada (2011) |

|

Basic density |

BD |

NBR 11941 (2003) |

|

Moisture content |

MC |

ASTM E871-82 (2006) |

In this paper, the calorific value of wood was expressed as higher heating value at constant volume (dry basis); low heating value at constant pressure (dry basis); low heating value at constant pressure (wet basis or as received), according to the definition reported by Telmo and Lousada (2011). In addition to the properties, the heartwood/sapwood ratio was also determined in each diameter class wood disc. The heartwood was delimited by changing the wood color. Two perpendicular lines were drawn through the pith of wood disc, defining the quadrants. The ratio was established after calculating the heartwood and sapwood area by the difference between the total and heartwood areas for each quadrant, considering that both had a circular projection in the sample.

2.3 Statistical Approach

A triple factorial design (3×2×2) was considered with variation factors: three diameter classes (lower, middle and upper), storage periods (0 and 160 days), and two storage seasons (dry and rainy). The normality of the data was previously measured by the Shapiro-Wilk test (p<0.05). Thus, the effect of the various factors was observed after the repeated measures analysis of variance (ANOVA), followed by the Bonferroni mean test (p<0.05). All data were analyzed in the R statistical software environment (R Development Core Team, 2017).

3. Results

All wood properties were affected by at least one variation factor in the analysis of variance (Table 5).

Table 5 Summary of the p-value of repeated measures ANOVA physical and chemical properties of wood

|

Variation factor |

p-value |

|||||||

|

MC |

BD |

A |

VM |

FC |

HHV |

LHVDB |

LHVWB |

|

|

Storage season, S |

3×10-4* |

5×10-1 |

2×10-2* |

8×10-1 |

8×10-1 |

4×10-1 |

5×10-1 |

4×10-13* |

|

Diameter class, C |

3×10-4* |

6×10-1 |

4×10-7* |

7×10-3* |

1×10-2* |

5×10-1 |

5×10-1 |

3×10-15* |

|

Storage period, D |

5×10-12* |

2×10-4* |

5×10-2* |

8×10-4* |

1×10-3* |

8×10-5* |

8×10-5* |

2×10-24* |

|

S×C |

2×10-1 |

5×10-3* |

2×10-9* |

5×10-1 |

6×10-1 |

1×10-2* |

1×10-2* |

1×10-12* |

|

S×D |

5×10-4* |

2×10-1 |

9×10-8* |

9×10-1 |

7×10-1 |

7×10-4* |

7×10-4* |

9×10-16* |

|

C×D |

5×10-7* |

2×10-1 |

3×10-10* |

1×10-1 |

1×10-1 |

8×10-2 |

8×10-2 |

3×10-17* |

|

S×C×D |

2×10-1 |

6×10-1 |

4×10-3* |

7×10-2 |

7×10-2 |

1×10-1 |

1×10-1 |

2×10-6* |

|

MC – Moisture content, BD – Basic density, A – Ash, VM – Volatile matter, FC – Fixed carbon, HHV – Higher heating value, LHVDB – Lower Heating value – dry basis, LHVWB – Lower heating value – wet basis; *p-value is significant by F-test (α=0.05) |

||||||||

The following results were shown considering the greater significant interactions among variation factors for each property.

3.1 Effect of Outdoor Storage on Wood Physical Properties

The diameter classes and storage period had a significant effect on wood water content (Table 6). A significant reduction in wood moisture content at the end of storage (160 days) was found for all log diameter classes.

Table 6 Wood moisture content (% – wet basis) in different diameter classes and storage period (D)

|

Storage period, days |

Diameter class |

||

|

Lower |

Middle |

Upper |

|

|

0 |

55.9±1.8 Aa |

53.1±2.3 Aa |

49.7±2.5 Aa |

|

160 |

23.7±9.1 Ba |

37.5±7.4 Bb |

41.4±3.1 Bb |

The means that do not differ from each other at the 0.05 significance level by Bonferroni's test are marked with the same small letters (in the same line) and the same capital letters (in the same column).

For the results reported in this work, the low MC for the lower diameter class can be explained by the heartwood proportion of logs (Table 7).

Table 7 Heartwood/sapwood ratio before and after storage in different diameter classes of logs

|

Diameter class |

Relation heartwood/sapwood |

|

Lower |

0.31±0.14 B |

|

Middle |

0.53±0.21 B |

|

Upper |

1.13±0.18 A |

The means that do not differ from each other at the 0.05 significance level by Bonferroni's test are marked with the same capital letters in the same column.

Another significant double interaction for wood moisture content is shown in Table 8, in which the dry season promoted a more severe drying of the logs, directly related to precipitation regime (around 70% less than the rainy season as previously reported).

Table 8 Wood moisture content – wet basis (%) before and after storage period

|

Storage period |

Storage season |

|

|

Dry |

Rainy |

|

|

0 |

53.2±4.0 Aa |

52.6±2.8 Aa |

|

160 |

29.6±10.6 Ba |

38.9±7.7 Bb |

The means that do not differ from each other at the 0.05 significance level by Bonferroni's test are marked with the same small letters (in the same line) and the same capital letters (in the same column).

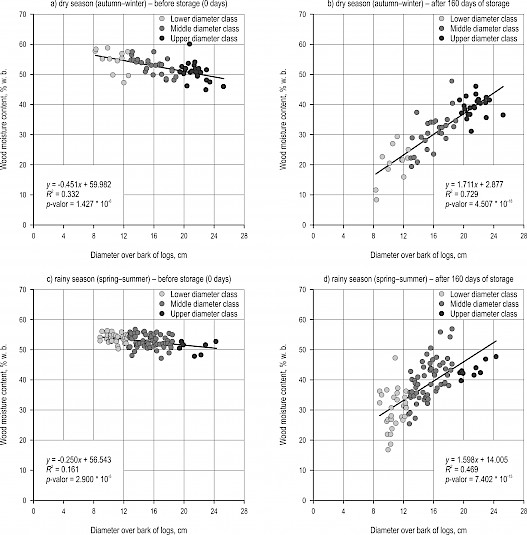

Fig. 3 shows the relation between the diameter of the logs and their moisture content at different storage periods.

Fig. 3 Relation between log diameter and wood moisture content in different seasons

3.2 Effect of Outdoor Storage on Wood Chemical Properties

Proximate analysis was influenced by the diameter class and the storage period (Table 9).

Table 9 Mean and standard deviation of proximate analysis of wood according to diameter class and storage period

|

Factors |

Fixed carbon, % |

Volatile matter, % |

Ash, %* |

|

|

Diameter class |

Lower |

16.2±0.6 A |

83.37±0.6 B |

0.42±0.1 |

|

Middle |

15.4±0.8 B |

84.25±0.9 A |

0.37±0.0 |

|

|

Upper |

15.5±0.9 AB |

84.10±0.9 A |

0.35±0.1 |

|

|

Storage period, days |

0 |

15.0±0.8 B |

84.28±0.8 A |

0.37±0.1 |

|

160 |

15.7±0.8 A |

83.54±0.8 B |

0.39±0.1 |

|

|

The means that do not differ from each other at the 0.05 significance level by Bonferroni's test are marked with the same capital letters in the same column for each wood property and variation factor; * Triple interaction was found for ash content, and the statistical test was reported separately |

||||

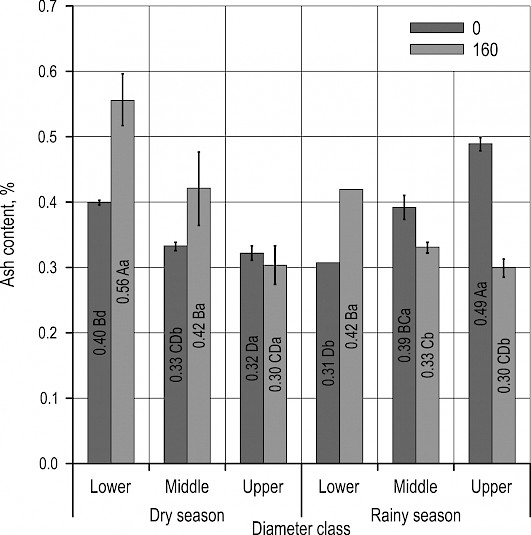

Wood ash content also presented a triple interaction among the variation factors (Fig. 4).

Fig. 4 Triple interaction (diameter class, season, and storage period) on Eucalyptus wood ash content; the same small letters (in the same diameter class and season) and the same capital letters (in the same storage period) do not differ statistically by Bonferroni’s test (α=0.05)

The higher heating value and the low heating value (dry basis) remained constant for the dry storage season, while for the rainy season, there was a small statistically significant reduction, as reported in Table 10.

Table 10 Mean and standard deviation of heating value (MJ kg-1) of wood before and after logs outdoor storage

|

Storage period, days |

Season |

||

|

Dry |

Rainy |

||

|

Higher Heating Value, d.b. |

0 |

19.1±0.2 Aa |

19.3±0.5 Aa |

|

160 |

19.0±0.3 Aa |

18.6±0.2 Bb |

|

|

Low Heating Value, d.b. |

0 |

17.7±0.2 Ab |

18.1±0.5 Aa |

|

160 |

17.7±0.3 Aa |

17.4±0.2 Ba |

|

|

Low Heating Value, w.b. * |

0 |

8.4±0.3 Bb |

8.6±0.6 Ba |

|

160 |

12.4±1.6 Aa |

10.6±1.1 Ab |

|

|

The means that do not differ from each other at the 0.05 significance level by Bonferroni's test are marked with the same small letters (in the same line) and the same capital letters (in the same column) for each wood property; *Triple interaction was found for Low Heating value (w.b.), and the statistical test was reported separately |

|||

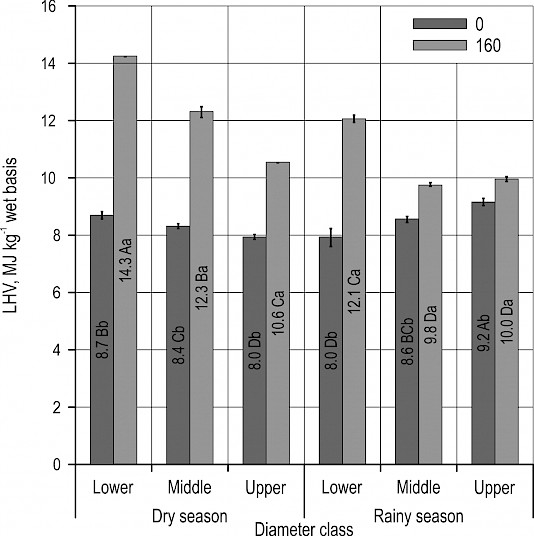

The LHV increased for all diameter classes of logs after the storage period, as observed in Fig. 5. Huge variations can be addressed in the lower class of logs (6.2 cm to 12.7 cm) for both storage seasons.

Fig. 5 Triple interaction (diameter class, season, and storage period) on low heating value (LHV – wet basis) of Eucalyptus wood; the same small letters (in the same diameter class and season) and the same capital letters (in the same storage period) do not differ statistically by the Bonferroni test (α=0.05)

4. Discussion

The lower-class logs lost 42.2% of their initial weight after 160 days, much more than the middle and upper classes, 25.0% and 14.1%, respectively. This trend has also been reported in the literature for short logs by Rezende et al. (2010) and Brand et al. (2011) in the southeast and south of Brazil. In comparison, Manzone (2015) did not find the log diameter effect when the storage period was more than 30 days long in Turin/Italy in a dry climate closed to southern Europe. These results showed that local weather condition is critical, as well the size of logwood.

We observed that MC did not differ between the logs of the middle and upper diameter classes after storage, corresponding to the diameter of 12.8 cm to 25.7 cm, while the lowest MC found was assigned to logs below 12.7 cm. The greater MC for the upper diameter class can be related to the heartwood/sapwood area proportion, which is much higher in this class, making drying more difficult, mainly due to the obstruction of vessels by tylos. It is known that the liquid permeability (K) of sapwood in the fiber direction (longitudinal) is much higher than that of heartwood. For Eucalyptus grandis, the K is about 470 cm3. (cm atm s)-1 and 0.420 cm3. (cm atm s)-1, for sapwood and heartwood, respectively (Silva et al. 2010).

Noteworthy is the increase of variability (more significant standard deviation) of moisture at the end of storage for both periods evaluated. This fact can be explained by the characteristics that distinguish the log woodpiles for each storage season since they were assembled randomly with different diameter class or even different position of logs in the pile.

The behavior of class diameter and wood moisture content were observed. It was concluded that there was a positive correlation between these variables after 160 days of storage, and that the variation of 1 cm in diameter of logs caused an increase of 1.71 and 1.59 percentage points in final wood moisture content for the dry and rainy seasons, respectively. The results suggested that greater MC control may occur with the classification and storage of the separated logs in the field. Although this practice requires a complex operational and logistical arrangement for large forestry companies, it may be an option for small and medium-sized producers considering the multiple uses of forests.

At the end of 160 storage days, there was a reduction in basic density, decreasing from 481±28 (kg m-3) to 459±28 (kg m-3), suggesting a loss of dry matter (0.86% month-1), although the method of determination of basic density has a lower technical sensitivity for this purpose; a complete study about the primary sources of wood degradation is needed – fungus, insects, and weather (Shupe et al. 2008). For wood stored under temperate field conditions, the dry matter degradation is close to 1% month-1 for logs and 2% month-1 for forest residues (Laitila 2006).

In the proximate analysis of wood, if analyzing the effect of logs, the upper diameter class presented the lowest contents of fixed carbon and volatile materials. The differences found may be related to wood maturity, heartwood presence in the logs. For ash content, the most substantial amount was observed in smaller logs with a more significant presence of sapwood. This occurrence is corroborated by Silva et al. (2010) who reported double the amount of ash in the sapwood compared to the heartwood of Eucalyptus grandis and Corymbia citriodora; this is associated with the number of inorganic substances that come mainly from raw sap, which is made up of water and mineral salts, and carried by vessels in the sapwood.

Considering only the effect of the storage period, there was an increase in fixed carbon and a reduction in wood volatile materials since both are inversely proportional. The outdoor storage also promoted ash content growth for all log diameter classes during the dry season; however, it did not happen for the rainy season. This behavior in the dry season is undesirable because it does not contribute to the energy content and harms boilers (Monti et al. 2008), although the more significant ash content was 0.56%, which is acceptable for eucalypt wood species.

In calorific terms, there was a reduction of HHV in the rainy season, suggesting a biological degradation of biomass in spring–summer; however, a depth control study is needed to confirm and understand the effect of rainy conditions in the logs decomposition process. In the literature, a slight reduction of HHV was observed in the experiments of Brand et al. (2011) and Nurmi (1995) only after four months of storage in Brazil and Finland, respectively. While Manzone (2018) did not observe this effect in uncovered storing of firewood piles in Italy.

The outdoor storage increased the LHV (w.b.) to 47.6% in the dry season and 23.3% in the rainy season. The same trend was observed in firewood piles under roofs and in six-month uncovered storage of Poplar, Beech, and Black Locust species, where the LHV increased to at least 140%, 105%, and 59%, respectively (Manzone 2018).

The dry season showed the greater LHV at the end of storage, which is the best season to obtain a higher energy aggregated wood product. The same trend was observed by Brand et al. (2011) for short logs (less than 3.6 m in length); they also evidenced the change in the energy quality of wood over time in different seasons in Brazil.

As observed by other studies (Tomczak et al. 2020, Erber et al. 2018), the effective method of wood drying is cutting it into logs (preferably short logs) and storing them in piles. It is essential to highlight that the storage time to reach the desired moisture content can be affected by log woodpile arrangement, wood characteristics of each species, and local weather conditions.

Another relevant point to be discussed concerning fuelwood quality in outdoor conditions is the presence of bark used for energy purposes; the authors suggest that samples be debarked to achieve standard results in accordance with further studies, as the bark was naturally removed by the meteorological conditions (like wind and rain) during the storage.

5. Conclusions

Wood moisture content, low heating value (w.b.), and ash content are the properties most influenced by storage period and season. The presence and quantity of heartwood and sapwood significantly influence the wood properties when analyzing different log diameter classes. From the energetic point of view, the logs with smaller diameters and stored in the dry season would be the most suitable for direct combustion use, as they had the highest LHV wet basis (14.3 MJ kg-1) and lower moisture content (23.7%). In general, the increase of one unit (cm) in log diameter caused at least a 1.59 percentage point increase in wood moisture content (wet basis) after outdoor storage in the southeast of Brazil.

Acknowledgements

The authors thank the support of the Brazilian National Council for Scientific and Technological Development (CNPq), the School of Agriculture (FCA/UNESP), Marrari Automação, and the Laboratory of Agroforest Biomass and Bioenergy (LABB) at the Institute of Bioenergy Research (IPBEN).

5. References

Acuna, M., Anttila, P., Sikanen, L., Prinz, R., Asikainen, A., 2012: Predicting and controlling moisture content to optimise forest biomass logistics. Croatian Journal of Forest Engineering 33(2): 225–238.

Afzal, M.T., Bedane, A.H., Sokhansanj, S., Mahmood, W., 2010: Storage of comminuted and uncomminuted forest biomass and its effect on fuel quality. BioResources 5(1): 55–69.

American Society for Testing and Materials, 2007: ASTM D1102-84: standard test methods for ash in wood. West Conshohocken, PA, 2 p.

American Society for Testing and Materials, 2004: ASTM E711-87: standard test methods for gross calorific value of refuse-derived fuel by the bomb calorimeter. West Conshohocken, PA, 8 p.

American Society for Testing and Materials, 2006: ASTM E870-82: standard test methods for analysis of wood fuel. West Conshohocken, PA, 2 p.

American Society for Testing and Materials, 2006: ASTM E871-82: standard test methods for moisture analysis of particulate wood fuels. West Conshohocken, PA, 2 p.

American Society for Testing and Materials, 2006: ASTM E872-82: standard test methods for volatile matter in the analysis of particulate wood. West Conshohocken, PA, 3 p.

Associação Brasileira de Normas Técnicas, 2003: NBR 11941: madeira – determinação da densidade básica. Rio de Janeiro, 6 p.

Bergman, R., 2010: Chapter 13: Drying and Control of Moisture Content and Dimensional Changes. In: Wood handbook: wood as an engineering material, centennial ed., Forest Service, Forest products laboratory, Madison, 13.1–13.20 p.

Brand, M.A., Muñiz, G.I.B., Quirino, W.F., Brito, J.O., 2011: Storage as a tool to improve wood fuel quality. Biomass and Bioenergy 35(7): 2581–2588. https://doi.org/10.1016/j.biombioe.2011.02.005

Erber, G., Huber, C., Stampfer, K., 2018: To split or not to split: Feasibility of pre-storage splitting of large poplar (Populus spp. L.) fuelwood logs. Fuel 220: 817–825. https://doi.org/10.1016/j.fuel.2018.02.029

European Committee for Standardization, 2011. CEN EN 14778:2011. Solid Biofuels: Sampling. Brussels, 68 p.

Głowacki, S., Tulej, W., Sojak, M., Bryś, A., Kaczmarczyk, J., Wróbel, M., Jewiarz, M., Mudryk, K., 2018: Analysis of the Combustion Process of Selected Wood Biomass. In: Mudryk K., Werle S. (eds) Renewable Energy Sources: Engineering, Technology, Innovation. Springer Proceedings in Energy. Springer, Cham, 725–733.

Laitila, J., 2006: Cost and sensitive analysis tools for forest energy procurement chains. Forestry Studies 45: 5–10.

Londo, M., van Stralen, J., Uslu, A., Mozaffarian, H., Kraan, C., 2018: Lignocellulosic biomass for chemicals and energy: an integrated assessment of future EU market sizes, feedstock availability impacts, synergy and competition effects, and path dependencies. Biofuels, Bioproducts and Biorefining 12(6): 1065–1081. https://doi.org/10.1002/bbb.1926

Manzone, M., 2015: Energy and moisture losses during poplar and black locust logwood storage. Fuel Processing Technology 138: 194–201. http://dx.doi.org/10.1016/j.fuproc.2015.05.026

Manzone, M., 2018: Performance evaluation of different techniques for firewood storage in Southern Europe. Biomass Bioenergy 199: 22–30. https://doi.org/10.1016/j.biombioe.2018.09.004

Monti, A., Virgílio, N., Venturi, G., 2008: Mineral composition and ash content of six major energy crops. Biomass and Bioenergy 32(3): 216–223. https://doi.org/10.1016/j.biombioe.2007.09.012

Moskalik, T., Gendek, A., 2019: Production of chips from logging residues and their quality for energy: a review of European literature. Forests 10(3): 2–14. https://doi.org/10.3390/f10030262

Nurmi, J., 1995: The effect of whole-tree storage on the fuelwood properties of short rotation Salix crops. Biomass and Bioenergy 8(4): 245–249. https://doi.org/10.1016/0961-9534(95)00032-3

R Development Core Team, 2017: R: A language and environment for statistical computing. Vienna: R Foundation for Statistical Computing. http://www.R-project.org/

Resende, R.T., Carneiro, A. de C.O., Ferreira, R.A.D.C., Kuki, K.N., Teixeira, R.U., Zaidan, U.R., Santos, R.D., Leite, H.G., Resende, M.D.V., 2018: Air-drying of eucalypts logs: Genetic variations along time and stem profile. Industrial Crops and Products 124: 316–324. https://doi.org/10.1016/j.indcrop.2018.08.002

Rezende, R.N., Lima, J.T., da Silva, J.R.M., Napoli, A., Andrade, H.B., Faria, A.L.R., 2010: Air drying of logs from a Eucalyptus urophylla clone for carbonization use. Cerne 16(4): 565–572. https://doi.org/10.1590/S0104-77602010000400016

Shupe, T., Lebow, S., Ring, D., 2008: Causes and control of wood decay, degradation and stain. Louisiana Cooperative Extension Service, Pub.2703 (5M), Baton Rouge, LA.

Silva, M., Machado, G.O., Deiner, L.J., Calil-Junior, C., 2010: Permeability Measurements of Brazilian Eucalyptus. Materials Research 13(3): 281–286. https://doi.org/10.1590/S1516-14392010000300002

Sosa, A., Acuna, M., Mcdonnell, K., Devlin, G., 2015: Controlling moisture content and truck configurations to model and optimise biomass supply chain logistics in Ireland. Applied Energy 137(1): 338–351. https://doi.org/10.1016/j.apenergy.2014.10.018

Telmo, C., Lousada, J., 2011: Heating values of wood pellets from different species. Biomass and Bioenergy 35(7): 2634–2639. https://doi.org/10.1016/j.biombioe.2011.02.043

Tomczak, K., Tomczak, A., Jelonek, T., 2020: Effect of Natural Drying Methods on Moisture Content and Mass Change of Scots Pine Roundwood. Forests 11(6): 668. https://doi.org/10.3390/f11060668

Zanuncio, A.J.V, Carvalho, A.G., da Silva, L.F., Lima, J.T., Trugilho, P.F., da Silva, J.R.M., 2015: Predicting moisture content from basic density and diameter during air drying of Eucalyptus and Corymbia logs. Maderas, Ciencia y Tecnología 17(2): 335–344. https://doi.org/10.4067/S0718-221X2015005000031

© 2020 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors’ addresses:

Humberto de Jesus Eufrade-Junior

e-mail:h.eufrade@unesp.br

Emanuel Rangel Spadim

e-mail: emanuel.spadim@unesp.br

Sérgio Augusto Rodrigues

e-mail: sergio.rodrigues@unesp.br

Enzo Dal Pai

e-mail: enzo-dal.pai@unesp.br

Adriano Wagner Ballarin

e-mail: adriano.ballarin@unesp.br

Saulo Philipe Sebastião Guerra *

e-mail: saulo.guerra@unesp.br

School of Agriculture (FCA)

Sao Paulo State University (UNESP)

Av. Universitária, 3780

Altos do Paraíso. Botucatu/SP

BRAZIL

* Corresponding author

Received: April 23, 2020

Accepted: October 21, 2020

Original scientific paper