An Analysis of Chainsaw Operator Safety Between Asian and European Countries

doi: 10.5552/crojfe.2022.1539

volume: 43, issue:

pp: 16

- Author(s):

-

- Robb William

- Zemánek Tomáš

- Kaakkurivaara Nopparat

- Article category:

- Original scientific paper

- Keywords:

- work safety, forestry, accidents, chainsaw, PPE, OSH, training, loggers, arborists

Abstract

HTML

Work safety in the forestry industry, where chainsaws are used for tree felling, continues to be a top priority. The mobility of workers involved in chainsaw operations between Europe and Asia has become more common in today’s global workplace. Therefore, sharing knowledge about the types of work safety issues found in both regions can be beneficial. Increased knowledge and safety awareness in the workplace can contribute to a reduction in chainsaw accidents. This paper identifies and addresses four key related areas, namely: regulatory frameworks; chainsaw accidents; personal protective equipment and chainsaw training. Information for both regions was evaluated via interviews, questionnaires, direct observation, desk studies, field studies and descriptive statistical analysis. A total of 234 participants responded to the main research questionnaire, which resulted in data analysis of significant questions related to the use of personal protective equipment (PPE) and possible causes of accidents. Key findings included a need for more information relating to the effect of regulations in individual countries and chainsaw accident and fatality statistics within Asia. A requirement for further research into the suitability of PPE used in Asia was identified. Inadequate training was seen as a primary factor causing accidents in Asia, while in Europe, it was due to chainsaw operators taking shortcuts. Inadequate workplace supervision and a lack of uniform and affordable training provision were common issues identified within both regions. Field tests carried out in accordance with the International/European chainsaw (ICC/ECC) qualification standards of the »non-profit« Awarding Body Association (ABA) International were successful in demonstrating the benefits of uniform training to participants in Europe and Asia. Overall, the study raises awareness of the fatal consequences of risk-taking behaviour to work safety, requiring a better understanding of the problem from a social psychology perspective. It identifies the self-employed or temporary worker groups as high-risk categories in both regions, with younger workers seen to be more at risk of injury in Asia and older workers more at risk in Europe. The findings demonstrate that, while there are differences between the two regions (at least within the participating countries), it is essential to provide quality education and raise skills by training and promotion of supervision in order to prevent chainsaw accidents. This can lead to the development of the building blocks of a holistic approach to safety in forestry work, which, as shown in this paper, can result in a decrease in the occurrence of accidents.

An Analysis of Chainsaw Operator Safety Between Asian and European Countries

William Robb, Tomáš Zemánek, Nopparat Kaakkurivaara

Abstract

Work safety in the forestry industry, where chainsaws are used for tree felling, continues to be a top priority. The mobility of workers involved in chainsaw operations between Europe and Asia has become more common in today’s global workplace. Therefore, sharing knowledge about the types of work safety issues found in both regions can be beneficial. Increased knowledge and safety awareness in the workplace can contribute to a reduction in chainsaw accidents. This paper identifies and addresses four key related areas, namely: regulatory frameworks; chainsaw accidents; personal protective equipment and chainsaw training. Information for both regions was evaluated via interviews, questionnaires, direct observation, desk studies, field studies and descriptive statistical analysis. A total of 234 participants responded to the main research questionnaire, which resulted in data analysis of significant questions related to the use of personal protective equipment (PPE) and possible causes of accidents. Key findings included a need for more information relating to the effect of regulations in individual countries and chainsaw accident and fatality statistics within Asia. A requirement for further research into the suitability of PPE used in Asia was identified. Inadequate training was seen as a primary factor causing accidents in Asia, while in Europe, it was due to chainsaw operators taking shortcuts. Inadequate workplace supervision and a lack of uniform and affordable training provision were common issues identified within both regions. Field tests carried out in accordance with the International/European chainsaw (ICC/ECC) qualification standards of the »non-profit« Awarding Body Association (ABA) International were successful in demonstrating the benefits of uniform training to participants in Europe and Asia. Overall, the study raises awareness of the fatal consequences of risk-taking behaviour to work safety, requiring a better understanding of the problem from a social psychology perspective. It identifies the self-employed or temporary worker groups as high-risk categories in both regions, with younger workers seen to be more at risk of injury in Asia and older workers more at risk in Europe. The findings demonstrate that, while there are differences between the two regions (at least within the participating countries), it is essential to provide quality education and raise skills by training and promotion of supervision in order to prevent chainsaw accidents. This can lead to the development of the building blocks of a holistic approach to safety in forestry work, which, as shown in this paper, can result in a decrease in the occurrence of accidents.

Keywords: work safety, forestry, accidents, chainsaw, PPE, OSH, training, loggers, arborists

1. Introduction

Chainsaw operations remain inherently dangerous activities (Robb and Cocking 2014). This is supported by numerous studies. For example, the chainsaw is the most common machine used for cutting and has been documented as the cause of most fatalities in Indonesia (Yovi and Yamada 2019). Portable (hand-held) mechanical chainsaws are commonly used by professionals in the forestry sector. Forestry continues to be one of the most hazardous industrial sectors in most countries (ILO 1998) and is one of the most dangerous work sectors (FAO 2020). This paper addresses the forestry sector, which includes occupations such as loggers and arborists using chainsaws at work. Its main objective is to help improve education and increase awareness of chainsaw operator safety issues in both Asian and European countries. Safety information is well documented in Europe but this does not appear to be the case in Asia. In today’s global economy with increased mobility of forestry workers, sharing of knowledge and lessons already learned in work safety between different regions, at the least, can positively improve forestry safety.

In Europe, the effects of storm damage on forests have been reported to lead to an increase of 10% in logger fatalities (Klun and Medved 2007) while dealing with the after-effects. Chainsaw operators involved in treework are exposed to numerous hazards and associated risks such as those encountered during the clearance of windblown trees (Robb and Cocking 2014), whereby the uncontrolled movement of timber under extreme tension forces can lead to serious or fatal impact injury. For example, extreme tension forces are commonly encountered while felling trees such as rubber (Hevea sp.) trees found in Asia and larch (Larix sp.) trees in Europe. This is usually due to the effects of phototropism and/or thigmotropism, which can present a danger to chainsaw operators as the tree stem can violently and suddenly split and delaminate during the felling operation. Similar dangers can be found in the Asian tropical forests which exhibit plank buttresses, for example mangrove (Xylocarpus sp.), whereas the adaptations are here likely biomechanical and/or thigmomorphogenetic responses to tension and compression forces (Srikanth et al. 2015) rather than phototropic.

Additionally, harvesting of windfall (windblown, damaged and uprooted trees) are regarded as high-risk activities alongside tree climbing and forest fire-fighting (ILO 1998). On a macro-level, chainsaw operations in early thinnings in temperate European forests differ from selective logging practices in tropical Asian forests but both jobs include hazards that can lead to serious personal injury (FAO 2020). Occupational safety and health (OSH) is one of three key areas recognised by the Food and Agriculture Organisation of the United Nations (FAO), and accordingly, the forestry industry must provide better work safety. For example, most forest workers can still be found not wearing the compulsory safety equipment and ignoring safety rules and thus, accident rates are fairly high (Melemez 2015). It has already become increasingly difficult to attract young people to a sector known for its physically demanding work, modest salaries and poor safety record (FAO 2020). According to the ILO (1998), safety and health measures in forestry can be viewed at three levels: national, enterprise and worksite. While taking into consideration national measures, this paper combines the forestry enterprise and worksite into local workplace factors. In order to effectively compare and analyse chainsaw operator safety in the workplace, the following four key objectives were identified:

Þ OSH Regulations - how is the forestry sector regulated (objective 1)

Þ Chainsaw accidents - what are the primary causes (objective 2)

Þ Personal protective equipment (PPE) - its use and suitability (objective 3)

Þ Chainsaw training - level of provision and satisfaction (objective 4).

Many other factors can contribute to a broader understanding of Asian and European forestry work safety conditions but are outside the scope of this paper. For example, chainsaw operator exposure to: Lyme disease commonly carried by ticks in Europe or Dengue fever carried by mosquitoes in south east Asia; northern European sub-zero weather conditions (hypothermic environment) as opposed to Asian hot and humid conditions (hyperthermic environment); presence of wildlife hazards such as European bears in comparison to wild elephants, tigers and snakes found in Thailand or the various timber characteristics of tropical and temperate tree species, topography, etc.

2. Materials and Methods

2.1 OSH Regulations

The main sources of information reviewed and analysed relating to objective 1 (OSH regulations) were obtained via an extensive literature review of regulatory and other legislative materials. These included key sources such as the International Organization for Standardization (ISO), European Union law and the International Labour Organisation (ILO). In collecting data for research on OSH legislation, we focused our attention on the member states of two large groupings in Europe and Asia, the European Union (EU) and the Association of Southeast Asian Nations (ASEAN). Information on EU legislation was obtained from the official server for access to legal documents – EUR Lex. Unlike the EU, ASEAN does not have a common policy in the field of safety and health at work, and therefore an overview of individual member states in the framework of national legislation was carried out. In this case, the main sources of information were the ILO and the responsible authorities in each country. ASEAN country specific information was identified and listed in the following order: country name, authorities responsible for OSH, basic legislation and regulations relating to forestry – if provided in English. The ISO was the basic source of information on international standards.

2.2 Accidents, PPE and Training

The main sources of information relating to objectives 2 (accidents), 3 (PPE) and 4 (training) included the design and circulation of a targeted chainsaw research questionnaire. For data protection reasons, the questionnaire did not require identification of responders nor any information that could be sensitive. The responses were securely controlled and only distributed between the paper authors for analysis. To facilitate potential responders from both Asia and Europe, this questionnaire was designed as an easily accessible online google form available in Thai, Chinese, English and Czech. Participants were asked to provide the following information: occupation; country; age; gender; employment status and any additional comments. The main aim here was to identify the influence of various aspects of the respondent’s profiles, such as employment status, on their attitude and potential behaviour towards risk. As shown by the UK Health and Safety Executive (HSE), during the related research studies (HSE 2017), drivers of risk-taking behaviour include cultural, business and demographic factors. Once respondent’s profiles were provided, they were asked to complete two key questions with an opportunity to add additional comments. Question 1 (Fig. 1a) was focused on PPE issues and question 2 (Fig. 1b) was aimed at key safety issues related to accidents and training.

Fig. 1 Research questionnaire

Survey questions on PPE were selected due to its importance as part of measures aimed at preventing operator injury and associated anecdotal information suggesting either non-use or misuse of PPE in practice. Accident questions were chosen following a literature review of the most common incidents involving chainsaws. The idea was that data analysis would help to identify common chainsaw safety issues found in Asia (i.e. Cambodia, Thailand, China, etc) and Europe (i.e. Germany, UK, Czech Republic etc) as well as trends more specific to each region. Fig. 1b contained questions related to causes of accidents but also included training. The idea here was to find out what the respondents considered was the most important cause of accidents by ranking the key questions in order of importance. The respondent’s data was analysed and complemented by desk studies of relevant scientific literature, various sector specific documents, and personal observations/interviews and own findings from previous activities, for example, the European Commission supported the Evaluation and Implementation of Chainsaw Operator Certification (EAIOCOC) project (Robb 2011). Additionally, two of the paper authors with extensive practical experience in chainsaw use participated in chainsaw operator’s field testing exercises in the Czech Republic during 2019 and in Thailand during 2020 (Fig. 2). This enabled first-hand comparisons to be made of uniform training provided in Asia and Europe, including opportunities to undertake personal interviews with participants. For example, chainsaw techniques for safely dealing with trees under excessive tension, as highlighted in the introduction, were successfully practiced during the European and Asian field tests, and the benefits were clearly understood as confirmed by the numerous positive responses received from the participants.

Fig. 2 Field testing of chainsaw training standards in Thailand 2020 (two of the paper authors can be seen in the front row, 3rd and 4th from the right)

2.3 Statistical Analyses

A comparison of the means of the Asian and European responses was made to determine and summarise statistically significant differences between the two groups, if any, by using descriptive statistics. The distribution and comparison of data distributions was useful in understanding the value of questionnaire responses. Data evaluation involved the use of MS Excel tools for descriptive analysis, such as the measures of frequency in group responses, i.e. central tendency of the data, and the application of the F-test of equality of variances between the two groups. This was based on the null hypothesis that two normal populations representing the response groups had similar variance. Where a statistical significance was found between Asian and European responses, the null hypothesis was rejected.

3. Results

3.1 OSH Regulations

EU activities in the field of OSH are stipulated in Article 153 of the Treaty on the Functioning of the European Union (EU 2012). Within the European Commission, the Directorate-General for Employment, Social Affairs and Inclusion deals with the OSH. At the European Parliament level, this topic belongs to the Committee on Employment and Social Affairs, and at the Council of the European Union level, it belongs to the Council of Employment, Social Policy, Health and Consumer Affairs. OSH is also the subject of activities of two agencies of the EU: European Agency for Safety and Health at Work and European Foundation for the Improvement of Living and Working Conditions. In the EU, the basic requirements for OSH are formulated in the Council Directive 89/391/EEC – Measures to encourage improvements in the safety and health of workers at work (EEC 1989). This framework directive is supplemented by individual directives that address specific health and safety issues. For example, in accordance with the work equipment directive 2009/104/EC (EC 2009) and machinery directive 2006/42/EC (EC 2006). The ABA-ICC/ECC qualification standards (ABA 2012) used in the field tests met the provision of training in and information on the safe use of chainsaws and PPE as required by the regulations.

Numerous directives have been reviewed while the most important follow-up directives/regulations references and titles were collated (Table 1). Generally, regulations are enforced at a national level.

Table 1 OSH regulatory framework-EU (28 countries)

|

Directive |

Function |

|

2009/104/EC |

The minimum safety and health requirements for the use of work equipment by workers at work |

|

89/656/EEC |

The minimum health and safety requirements for the use by workers of personal protective equipment at the workplace |

|

2003/10/EC |

The minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise) |

|

2002/44/EC |

The minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (vibration) |

|

98/24/EC |

The protection of the health and safety of workers from the risks related to chemical agents at work |

|

89/654/EEC |

The minimum safety and health requirements for the workplace |

|

2006/42/EC |

Machinery safety |

Other legally binding OSH documents are the labour standards of the ILO, which relate to the EU and ASEAN nations. The tripartite agency ILO brings together governments, employers and workers of 187 member states. Recognising the global magnitude of occupational injuries, diseases and deaths, and the need for further action to reduce them, in 2006, ILO introduced the International Labour Standard for the Promotional Framework for Occupational Safety and Health Convention (ILO 2006), which has currently been ratified by 57 countries around the world. Another tool that the ILO uses to improve OSH in forestry are codes of practice. These codes set out practical guidelines for public authorities, employers, workers and enterprises; however, they are not legally binding documents. Both the Forest Stewardship Council (FSC) and the Program for the Endorsement of Forest Certification (PEFC) refer to ILO documents related to OSH in forestry within their own voluntary forest management standards. Additionally, a number of other ISO standards apply specifically to portable chainsaw safety requirements such as ISO 6535:2015 Portable chain-saws – Chain brake performance (ISO 2015). This standard specifies methods for measuring the braking time and release force of manually operated chain brakes on portable hand-held chainsaws - a critical safety device.

Based on numerous directives, the EU has a comprehensive OSH system of enforceable regulations and standards associated with ISO for the benefit of chainsaw operator safety. Information is less readily available in relation to the ASEAN nations, as previously stated. An example of the various national structures is the framework within the Philippines which is led by the Department of Labor and Employment – Occupational Safety and Health Centre and Bureau of Working Conditions. Here, the labor code (Presidential Decree No. 442-1974) mentions OSH in book four (GOVPH 1974). At this point, the labor code emphasizes the need to develop and implement training programs to increase the number and competence of personnel in the field of occupational safety and industrial health and also emphasizes the importance of research for developing innovative methods, techniques and approaches for dealing with occupational safety and health problems. The OSH standards deal with logging operations in Rule 1420. Among other things, they also mention the use and maintenance of the chainsaw. Similar types of OSH structures and functions were found within other ASEAN nations (Table 2). ISO standards are also applicable.

Table 2 OSH regulatory framework - Asia (ASEAN)

|

Nation |

OSH responsibilities |

|

Brunei Darussalam |

Ministry of Health - Labor Dept. Workplace Safety and Health Order 2009 (No. S 44) |

|

Cambodia |

Ministry of Labor and Vocational Training - Dept. Of Occupational Health and Safety. Royal Kram CS/RKM/ 0397/01 - Labor Law, Code du travail du Cambodge |

|

Indonesia |

Ministry for Manpower and Transmigration and Ministry of Health. Law No. 1-1970 on Occupational Safety, Regulation-No. PER-01-MEN/1981 on the obligatory report on occupational diseases. Ministerial Regulation No. PER-01/MEN/1978 on safety and health in tree felling and log transportation |

|

Laos |

Ministry of Labor and Social Welfare, Ministry of Health. Labor Law 2013 (No. 43/NA), Law on Hygiene, Disease Prevention and Health Promotion-2001 |

|

Malaysia |

Ministry of Human Resources - Dept. of Occupational Safety and Health, Ministry of Health. OSH Act 1994 (No. 514). Based on the above act, the Dept. of Occupational Safety and Health of the Ministry of Human Resources Malaysia created the Guidelines for Safety and Health in Logging Operations |

|

Myanmar |

Ministry of Health and Ministry of Labor - Factories and General Labor Laws Inspection Dept. OSH Law, 2019 (Law No 8-2019) |

|

Singapore |

Ministry of Manpower. Workplace Safety and Health Act (No. 7-2006) |

|

Thailand |

Ministry of Labor - Dept. of Labor Protection and Welfare. Safety, Occupational Hygiene and Workplace Environment Act B.E. 2554-2011 |

|

Vietnam |

Ministry of Labor - Dept. of Work Safety. Law on OSH ( No. 84/2015/QH13), Labor Code (10/2012/QH13), Circular 04/2014/TTBLDTBXH measures for the wearing of PPE, Circular 27/2013/TTBLDTBXH regulating OSH training |

3.2 Accidents, PPE and Training

3.2.1 Overview

Injuries, diseases and deaths are associated with different sorts of costs. First, there are direct costs, such as healthcare costs. Next, there are costs associated with productivity and output losses. In addition, there are costs associated with the impact on human well-being, that is, the impact on people’s lives and health (EU-OSHA 2019). It is well known that in forestry work most fatal accidents are caused by falling trees and parts of trees (Lindroos and Burstrom 2010, Robb and Cocking 2014), and many other fatal and non-fatal accidents are the result of operators’ injury due to contact with the chainsaw and/or the occurrence of slips, trips and falls. Fatalities due to incorrect methods of dealing with hung-up trees have been reported in the UK (HSE 2003). This type of tree felling fatality was also demonstrated by the FAO (1993/4), in Finland for example, where two-thirds of fatal accidents in forest work were caused by hung-up trees that workers had tried to bring down with inappropriate work methods. It is well known that the self-employed sector in forestry is particularly vulnerable to the consequences of fatal accidents. Robb and Cocking (2014) also found a number of issues related to the self-employed sector. For example, Slovakian self-employed operators suffered serious injury twenty-two times more often than employed operators. In Spain, 80% of chainsaw operators were self-employed and paid on piecework, which encouraged short cuts due to the pressure of achieving targets. Also, many operations were performed without the use of PPE. The statistics of fatal accidents is generally the most accurate of all accidents because they involve a certain degree of publicity and have to be officially published (Thelin 2002). Further, the chainsaw hazard cycle (Robb and Cocking 2014) identifies numerous areas where European accidents occur due to bad practice on the part of the chainsaw operator, such as being in a dangerous position at the time of the accident; this was also pointed out by Melemez (2015).

An earlier Swedish study reported that more than half of the accidents were due to either the victim or a fellow worker not following generally known rules or recommendations (Thelin 2002). Many accidents have been recorded due to either inadequate PPE or training. The UK HSE states that most accidents are due to short cuts and ignoring safety guidance (Robb and Cocking 2014). Melemez (2015) pointed out that, in relation to forestry fatalities in Turkey, other important sub-factors were the organisational factors of unsuitable selection of workers and insufficient training of workers. The consequences of accidents are also a significant item in the national accounts (Klun and Medved 2007) and of course, human or personal and social costs are not so easily quantifiable.

From an Asian perspective, typically, logging operations are seasonal, with high labour intensity. As pointed out by Wang et al. (2003) in relation to logging accidents because of poor management, workers’ low level of education, and lack of resources, safety is often neglected in many Chinese logging operations and others throughout Asia. Logging injuries in the Jilin Province of China showed both similarities and differences in comparison to injury studies conducted in other parts of the world. Differences in observed injury patterns between Jilin and other developed countries may be explained by variation in logging operations, injury reporting methods, seasonal environmental differences, use of personal protective equipment, and/or general societal differences, such as proportion of the population that owns and operates motor vehicles, age of the workforce, and opportunities for new types of employment (Wang et al. 2003).

The average estimated incidence rate of fatal accidents per 100,000 forestry workers in the EU has been collated and summarised (Fig. 3). Accident incidence rates are often a better indicator of performance since they take into account numbers of workers (ILO 2009). When interpreting this data obtained from EU statistics (Eurostat 2020), due to various limitations, caution should be applied, especially related to the number of forestry workers actually employed, as further research is necessary before a more accurate estimate can be obtained (ILO 2009). However, as described by Klun and Medved (2007), a comparison of fatality rates is a useful indicator of whether the work safety is satisfactory.

Fig. 3 Average fatal incidence rate forestry and logging EU-28 (2008–2018)

EU statistics for the forestry and logging sector is collated from all member states across the region via a nomenclature of economic activities (NACE) code. Forestry and logging are classified under code A2, which includes chainsaw operations. Following analysis, a significant difference can be observed on either side of the average EU fatality rate, as shown in Fig. 3. It would be useful to get more detailed data on what influence migration, climate, topography or national systems, etc. have on the difference observed.

Information on forestry accidents in Asia on a regional scale is unavailable. However, according to a study of fatalities across the whole of China (Wang et al. 2003), the total number of logging fatalities appears to have been identified, at least for the year 1991. Further research (Kaakkurivaara and Stampfer 2018) provides additional forestry fatality information for Thailand (2011–2012) and Malaysia-Sarawak 1973 till 1984 based on an average rate for the years presented. An estimate for Japan (Garland 2018) was also included in the data analysed. Therefore, a basic comparison for some Asian countries has been estimated against the available EU-28 (pre-Brexit) average total figures for the period 2010–2017. This may help provide a useful basis for future regional investigations. The estimated 2018 logging fatality rate was 202 in Asia and 111 in Europe. The figure for Asia is likely an underestimate due to the lack of available information from a number of countries.

3.2.2 Data Analysis

The research questionnaire (Fig. 1) received 234 responses from participants in 19 different countries. The questionnaire was targeted at the forestry sector and made available online between November 2019 and February 2020 for ease of completion. The questions were designed to encompass the four objectives outlined above. The percentage distribution of responses was fairly evenly distributed between 51% for Asia and 45% for Europe with 4% attributed to other regions. Although the survey was deliberately kept very specific to the subject of chainsaw operations, primarily affecting loggers and arborists, together they accounted for approximately one third of the responses received. Sector training and education represented another third and the final third of respondents came from safety supervision, OSH and various management roles. The gender balance was predominantly male, which accounted for 81% of the total of responses received. The largest proportion of female responses of 16% was from Asia with only 3% from Europe. 86% of all respondents were between the age of 21–50yrs. Nearly half of the respondents were in full-time employment. 30% were self-employed, while the remainder included retired loggers, volunteer workers, etc.

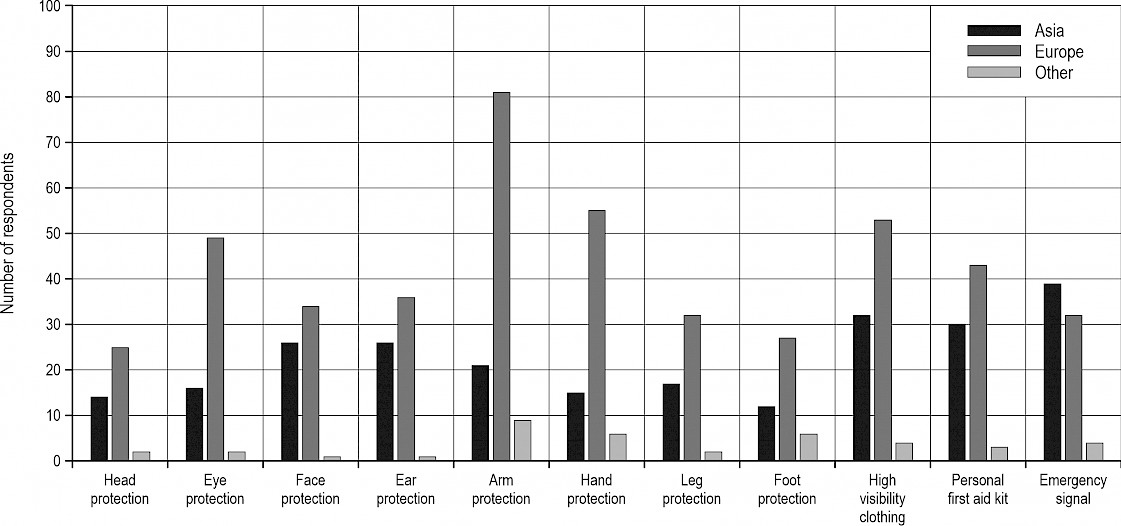

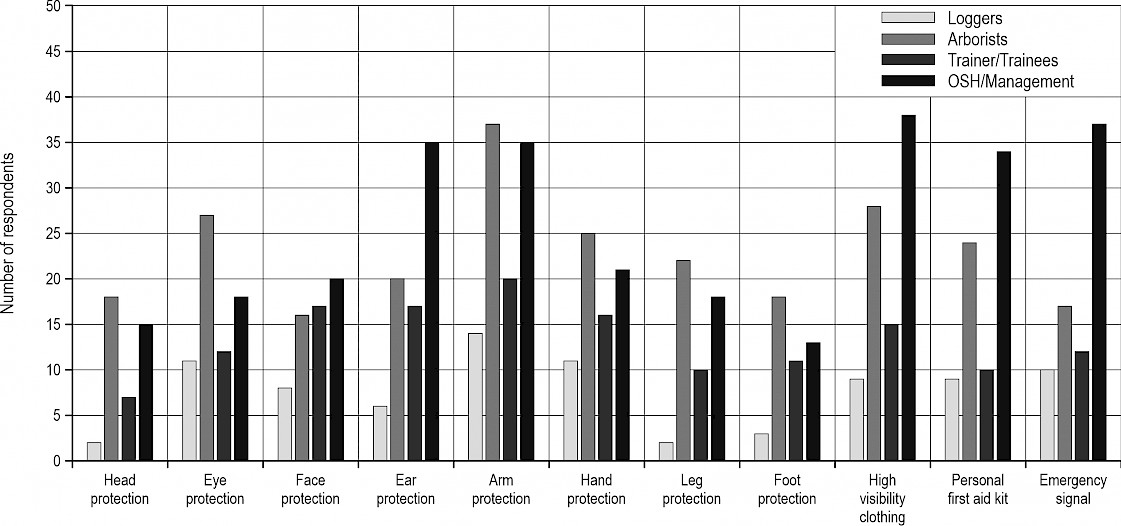

Most forest workers can still be found not wearing the compulsory safety equipment and ignoring safety rules and thus, accident rates are fairly high (Melemez 2015). The lack of use of PPE and non-conformance with safety guidance for various reasons, along with small numbers of individuals on forestry sites, have been reported in Asia and Europe. Overall, the responses to question 1 highlighted the main items of PPE least used by chainsaw operators. A regional comparison was made for the data received. The results were then compared against the overall results reflecting the regional preferences for the least used PPE from the list provided (Fig. 4).

Fig. 4 Least used PPE by region

By applying descriptive analysis, a comparison of the means of the Asian and European responses was made to determine and summarise if there was any significant difference between two sample groups (Table 3).

Table 3 Data analysis results: Research question 1

|

Europe |

Asia |

||

|

Mean |

42.45 |

Mean |

22.54 |

|

Standard Error |

4.92 |

Standard Error |

2.62 |

|

Median |

36 |

Median |

21 |

|

Mode |

32 |

Mode |

26 |

|

Standard Deviation |

16.34 |

Standard Deviation |

8.69 |

|

Sample Variance |

267.27 |

Sample Variance |

75.67 |

|

Kurtosis |

2.06 |

Kurtosis |

–0.69 |

|

Skewness |

1.35 |

Skewness |

0.57 |

|

Range |

56 |

Range |

27 |

|

Minimum |

25 |

Minimum |

12 |

|

Maximum |

81 |

Maximum |

39 |

|

Sum |

467 |

Sum |

248 |

|

Count |

11 |

Count |

11 |

|

Confidence level, 95.0% |

10.98 |

Confidence level, 95.0% |

5.84 |

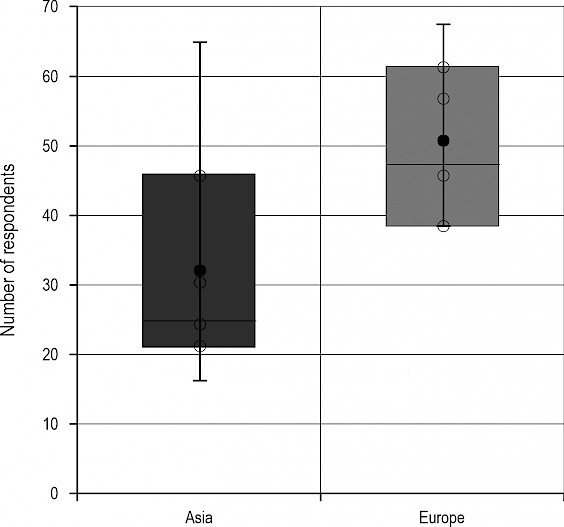

The central tendency of the data for Asia is given by a mean of 22.54, whereas for Europe it is 42.45, the difference being due to the frequency of responses received. It is interesting to note that the frequency of responses for both groups positively ranged between 12 and 81, and the total of responses received to this question was n=715. The higher standard deviation for Europe highlights the wider spread in responses of this group, which is reflected in the sum figure and the response variance seen when compared with Asia (Fig. 5).

Fig. 5 Measures of variance: Research question 1

This was further confirmed by a test for the null hypothesis that the two sample populations have similar variance by using the F-test of equality of variances; otherwise, the alternative hypothesis that the two sample populations have different variance applies. The F value was higher than the critical value confirming there was a statistical significance between the two sample groups therefore rejecting the null hypothesis in this case. This is further substantiated by a very low P value as seen in Table 4.

Table 4 F-test result: Research question 1

|

F-Test two-sample for variances |

||

|

Europe |

Asia |

|

|

Mean |

42.45 |

22.54 |

|

Variance |

267.27 |

75.67 |

|

Observations |

11 |

11 |

|

df |

10 |

10 |

|

F |

3.53 |

– |

|

P (F<=f) one-tail |

0.02 |

– |

|

F critical one-tail |

2.97 |

– |

Further analysis of the responses received identified the ranking of least used PPE by occupation. For ease of comparison, the seven sub-categories were distributed into four groups, namely: loggers; arborists; trainers/trainees and OSH/management (Fig. 6).

Fig. 6 Least used PPE by occupation

Many of the respondents also provided an explanation briefly outlining their opinion on what PPE was least used during chainsaw operations. These were categorised into five types of responses with 59% of the respondents stating PPE that was rarely used as not being necessary or legally required, in their opinion. The EC OSH communication (Com 2004) reported that the only available empirical study on the motivation of employers as regards health and safety at work was carried out in the United Kingdom. It leads to the conclusion that complying with the legal regulations is the most important reason for the employer to take new measures (80% of employers). Other results included stress factors such as heat stress exacerbated by wearing PPE or unsuitability of PPE to the working and environmental conditions.

In Europe, PPE is regulated under what is known as the PPE Directive (EU 2016). Generally, there seemed to be an acceptance of PPE as the norm in Europe but this was apparently not the case in Asia, especially relating to the unsuitability of certain types of PPE due to climatic conditions and associated stress factors for the chainsaw operator. For example, chainsaw operators who had to wear heavy chainsaw boots/trousers in very hot and dry conditions lost motivation, which led to high levels of fatigue, heat stress and an increased risk of having an accident. These were factors experienced by the paper authors first-hand while participating in chainsaw activities in Thailand in early 2020 and wearing standard European approved PPE. The chainsaw operator’s perception of risk plays a key role in many decisions around the use and suitability of PPE. Their behaviour, e.g. by taking more risks, annuls the benefits of the safety improvement (Klen 1997) relating to the use of PPE. This is a phenomenon known as »risk compensation«. Klen (1997) found that 90% of the test persons noted that the use of personal protectors enhanced the feeling of safety. Nearly half of the loggers reported that their work behaviour changed when they wore personal protectors; they became more careless, faster, bolder, and they anticipated less dangers.

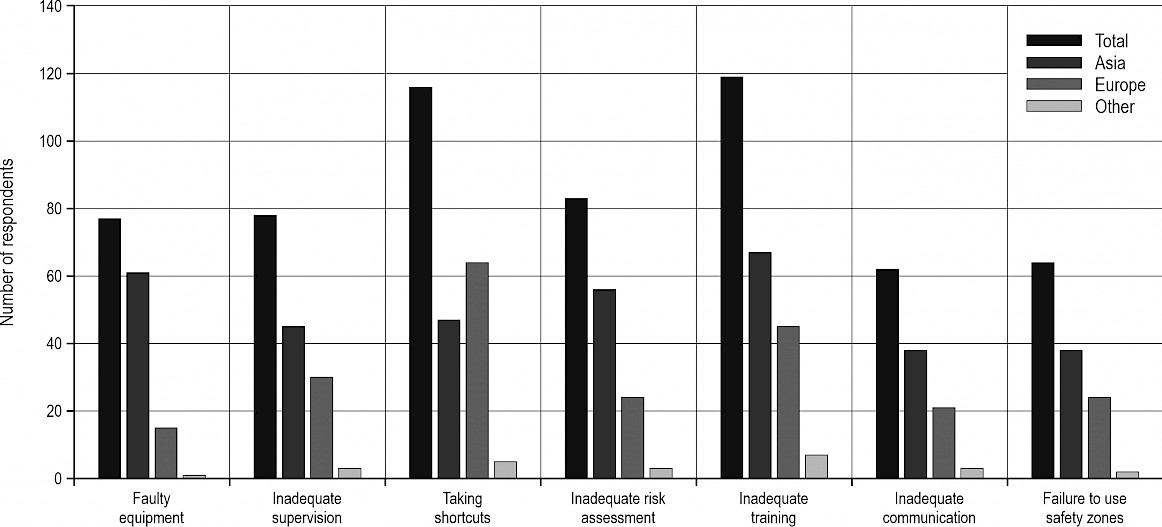

Fig. 7 Regional comparison on causes of chainsaw accidents

Data received from research question 2 reveals some divergence of opinions between Asia and Europe on the ranking of causes of accidents suffered by chainsaw operators (Fig. 7). Inadequate training (highest in Asia) and taking shortcuts (highest in Europe) were regarded as the most important causes overall. Inadequate risk assessment/emergency planning was another major contributory cause. In Europe, risk assessments are regulated by regional legislation but this does not appear to be the case in Asia. In Europe during the 1990s, a major innovation in the legislation consisted in the introduction of systematic risk assessments (Com 2004). Prior to this, it was a matter for individual employers. Since 1989, when the Framework Directive 89/391 was passed into law, employers have had a legal duty to carry out risk assessments at the workplace (Boix and Vogel 1999). The lack of planning and lone working were also raised as issues during the field tests. The remaining data relates to the other issues (responses from regions outside of Asia or Europe).

Table 5 Data analysis results: Research question 2

|

Europe |

Asia |

||

|

Mean |

31.85 |

Mean |

50.28 |

|

Standard Error |

6.42 |

Standard Error |

4.27 |

|

Median |

24 |

Median |

47 |

|

Mode |

24 |

Mode |

38 |

|

Standard Deviation |

17 |

Standard Deviation |

11.3 |

|

Sample Variance |

289.14 |

Sample Variance |

127.9 |

|

Kurtosis |

1.29 |

Kurtosis |

–1.44 |

|

Skewness |

1.34 |

Skewness |

0.35 |

|

Range |

49 |

Range |

29 |

|

Minimum |

15 |

Minimum |

38 |

|

Maximum |

64 |

Maximum |

67 |

|

Sum |

223 |

Sum |

352 |

|

Count |

7 |

Count |

7 |

|

Confidence level, 95.0% |

15.72 |

Confidence level, 95.0% |

10.45 |

The central tendency of the data for Asia in Table 5 is provided by a mean figure of 50.28, whereas for Europe it is 31.85, the difference being due to the frequency of responses received. It is interesting to note that this time the frequency of responses for both groups positively ranged between 15 and 67, while the total of responses received to this question was n=575. The standard deviation did not differ as greatly as before but a wider variance can still be found in the European responses when compared with Asia (Fig. 8).

Fig. 8 Measures of variance: Research question 2

The figures for kurtosis and skewness show that the response values for Asia are closer to the sample mean and, when compared to Europe, the responses are overall more uniform. This can also be seen for the values of both mean and median, which are closer for Asia indicating that the distribution of the data is more symmetrical. Overall, the number of responses to research question 2 from Asia were greater than to question 1. This appears to indicate that the cause of chainsaw accidents held more importance than the use of PPE to Asian respondents. Although the European values expressed a wider distribution of responses to some questions, there appears to be no great difference in statistical significance between the groups in this question. This was confirmed by applying the F-test of equality of variances (Table 6).

Table 6 F-test result: Research question 2

|

F-Test two-sample for variances |

||

|

Europe |

Asia |

|

|

Mean |

31.85 |

50.28 |

|

Variance |

289.14 |

127.9 |

|

Observations |

7 |

7 |

|

df |

6 |

6 |

|

F |

2.26 |

|

|

P (F<=f) one-tail |

0.17 |

|

|

F Critical one-tail |

4.28 |

|

The F value was lower than the critical value, confirming that there was no statistical significance between the two sample groups. Therefore, this time the null hypothesis was accepted.

It is clear from the results of the questionnaire and comments received that respondents rated inadequate training as the biggest cause of chainsaw accidents. The question is why? Regulatory requirements, where they exist, generally require that employers should ensure that employees are adequately trained particularly in high-risk activities such as chainsaw operations. In some countries, accident insurance organisations also require evidence of compliance. Training systems for chainsaw operators at national levels in Europe, although they may vary in content and delivery or quality, appear to be well established in comparison to Asia. This may be one reason why the demand for training seems to be higher in Asia. The ABA European chainsaw standards (ECS), also known as (ICS), became the first ever state-of-the-art international chainsaw standards in use from 2012. One of the paper authors presides over ABA and was very familiar with the standards; therefore he ensured consistency during the implementation of the training activities as part of the field test studies. The chainsaw schemes are known as the European Chainsaw Certificate (ECC) and International Chainsaw Certificate (ICC) outside of Europe (Robb 2020), respectively. Overall, responses received were very positive and confirmed that quality training was relevant and beneficial in raising participant’s safety awareness in chainsaw operations. These field tests confirmed that, at least in the sample of participants attending the training (over 30), that chainsaw operators were not averse to training, indeed it indicated that just the opposite was the case, where training opportunities existed. For example, statements provided during field interviews included the following typical comment from one logger »… thanks to training provided, the quality of work and safety is rising and that’s very good for our job....«.

For safety knowledge and safety performance, highly engaging training was considerably more effective than less engaging training (Burke et al. 2011). Although minimum chainsaw qualification safety standards, such as those used in the field tests (Table 7), can be assessed as part of the competence of a chainsaw operator, to be effective in a long run, this needs to be aligned with highly engaging training followed by periodic refresher training and re-assessment of chainsaw operators’ skills, to ensure that »skills fade« has not become an issue. For example, forestry harvester operators may only operate a chainsaw periodically to deal with trees beyond the capabilities of the harvester. If the harvester operator has not used the chainsaw for a considerable period of time, his level of ability can decrease, increasing the corresponding level of his exposure to risk of injury. A recent study in Romania highlights the need for highly engaging local training from an employee’s perspective. In a significant percentage of 36%, the employees think that the training courses were little useful or even useless (Georgescu and Gliga 2020).The same study also identified the lack of funds as the main barrier for professional training.

Table 7 Chainsaw qualification safety standards (ABA 2012)

|

ABA RECORD OF ASSESSMENT (ROA): Assessment Criteria ICC/ECC1 |

Feedback comments to candidate and Result √/x |

|||||

|

CHAINSAW MAINTENANCE and CROSS-CUTTING: Recommended max guide bar size 15” (38cm) Max.Time Allowed – 1hr |

||||||

|

1. (unit 1) SELECT and WEAR PERSONAL PROTECTIVE EQUIPMENT |

||||||

|

Candidate to wear appropriate PPE, and show photo ID: |

|

CANDIDATE: |

||||

|

1. Chainsaw safety trousers |

C |

|||||

|

2. Chainsaw safety boots |

C |

TIME |

Start: |

Stop: |

Total: |

|

|

3. Safety helmet |

C |

|||||

|

4. Eye and Ear protection (airline use/exclusion zone) |

C |

|||||

|

5. Gloves appropriate to task |

||||||

|

6. Non-snag outer clothing |

||||||

|

7. Personal First Aid Kit - on person (+ Team Kit as appropriate) |

C |

|||||

|

8. Whistle/Mobile/Radio (according to national standards) |

C |

|||||

|

2. COMPLETE A WORKPLACE RISK ASSESSMENT and EMERGENCY PLANNING PROCEDURES |

||||||

|

Candidate to identify hazards and risks: |

||||||

|

1. RISK ASSESSMENT-walk site (state min.3 site H/R and min.3 task H/R) |

||||||

|

2. METHOD STATEMENT – verbal (state for task and 1st aid scenario) |

||||||

|

3. EMERGENCY PLANNING – verbal (state min. 8 key requirements) |

C |

|||||

|

3. UNDERTAKE CHAINSAW MAINTENANCE (chainsaw OFF) |

||||||

|

A) Candidate to identify and check function of safety features: |

||||||

|

1. Chain brake |

C |

|||||

|

2. Anti-vibration mounts |

C |

|||||

|

3. Safety chain |

||||||

|

4. Throttle lock |

C |

|||||

|

5. Exhaust away from the operator |

C |

|||||

|

6. Chain catcher |

C |

|||||

|

7. Legal symbols: Head/eyes/ears |

||||||

|

8. Right hand guard |

C |

|||||

|

9. Left hand guard |

C |

|||||

|

10. Chain/Bar cover |

C |

|||||

|

11. Functional clearly marked on/off switch |

C |

|||||

4. Discussion

4.1 OSH Regulations

Information about chainsaw operator safety and regulations in Asia requires more research. For example, the regulatory structure affecting chainsaw operators in Europe is clearly very comprehensive and, to a certain extent, effective. The situation in Asia appears to be less clear. In one example, 50% of the questionnaire respondents felt that PPE was not a legal requirement. It has been shown that one of the most important motivating reasons for chainsaw operators to »stick to the rules« is the threat of enforcement, due to non-compliance with legislation. As pointed out by Takala et al. (2013), legal and enforcement measures that support companies and organizations need to be supplemented with economic justification and convincing arguments to reduce corner-cutting in risk management, etc. As previously identified, legal and enforcement measures are normally undertaken at the national/state level but supplemented by regional (EU/ASEAN) and international (ILO) OSH guidance, where applicable. Additionally, the EU regulatory framework provides a mechanism that supports a more uniform approach to enforcement between member states at a European level. Yet, as pointed out by EU-OSHA (2020), the fact that there is no clear OSH regulatory framework to protect foresters and manage OSH, particularly for the self-employed, highlights challenges still to be addressed. As this paper has found, information is less readily available in relation to the ASEAN nations, and without the benefits of a uniform regulatory framework or regional cooperation, the challenges to be addressed here are likely more formidable than those at the European level.

4.2 Accidents, PPE and Training

4.2.1 Accidents

In general, the estimation of accident numbers is a function of the definition used for workers, work, accident severity and the accident database used (Lindroos and Burstrom 2010). This means, for example, that data relating to chainsaw accidents may be classified as different categories or one category of workers, or types of work, depending upon national statistical collection, interpretation and recording systems. It is therefore recommended that member states be encouraged to classify injuries in a standardised manner that supports the future determination of the causes of accidents and of the effectiveness of interventions aimed at reducing them (EU-OSH 2015). For example, the lack of transparency and the wholly inaccurate occupational accident and ill health reporting in the sector, particularly for the self-employed (EU-OSHA 2020), are challenges that need to be addressed.

Finland generally has a flatter topography than Romania and a highly mechanised forestry sector but it also has a well-developed safety culture referred to as the »Finish approach« worthy of further investigation particularly as, according to Fig. 3, the Finish fatality rate in forestry is the lowest in Europe. According to the FAO (1993/4), this approach has been successful in promoting health and safety via a comprehensive combination of the following measures: training, legislation, advice, motivation, cooperation, incentives, product development and when necessary enforcement. Further, in relation to the frequency of fatal accidents suffered by professional loggers, Klun and Medved (2007) pointed out that the best safety record has been achieved in Scandinavia (Sweden and Finland), particularly Finland, covered by the analysis, mentioned above, as part of this paper.

Questionnaire responses highlighted a number of important areas. It was interesting to note that responses of Asian females were five times more frequent than those of European females. This could be due to a larger female population employed in the Asian forestry sector or other factors such as historical or cultural development of forestry in Asia compared with Europe; this requires further research. In terms of regional demographics, it would be beneficial to investigate further the underlying causes in the differences between the age of workers injured in both regions. Associated factors may include, for example, chainsaw operations that are seasonal or temporary, low paid work, lack of education or training of workers, etc. Indeed, this paper has found that inadequate training was rated as the number one factor causing accidents to chainsaw operators (Fig. 7). This is further substantiated by an ILO study of labour conditions within the Indonesian forestry sector. According to the Labour Force data, 99.9% of males and 99.1% of females engaged in the forestry sector had never attended any form of training (ILO 2010). This is supported by Yovi and Yamada (2019) who recommended the following topics for the training: handling emergency conditions and safe work practices. According to a European Commission report (Com 2004), high-risk workers are also found among the young workers, the ones on temporary contracts and those with low qualifications. From the data analysis of research question 2, there was little significant difference in the distribution of responses between European and Asia respondents, indicating that in relation to causes of accidents, as seen in Fig. 7, with the exception of faulty equipment (an issue more specific to Asia), both regions were closely aligned in their opinions.

4.2.2 PPE

Suitability of PPE was raised as an issue and investigated by two of the paper authors during field tests. They used the same PPE during tree felling activities in Czech Republic and in Thailand. Although suitable for use in Czech Republic, this was not the case in Thailand, where heat stress became a serious issue affecting safety performance even during a cooler period of the year. The scope of further research could be to use smart technology with PPE and investigate options for the use of lighter materials/new designs by manufacturers. Personal behaviour was also commonly reported to be under the influence of others or a result of safety investigations. Chainsaw operator’s behaviour can be influenced by others in the workplace as seen by research responses provided under the category personal experience. This is known as social psychology and merits further research due to its importance in the overall safety culture. For example, when field test participants undertaking training were asked how they behaved in the presence of a supervisor on work sites, most commented that they »stuck to the rules more« or »were more careful«. Interviews conducted during the field tests confirmed that some respondents followed the safety regulations, including wearing PPE, only after an accident had occurred so as to comply with a forthcoming safety investigation. It is also apparent from both European and Asian responses that there appears to be agreement that the most important PPE item is the chainsaw helmet for the protection of the head. A lack of suitable awareness or knowledge about PPE is a factor in chainsaw operator’s decision making around the use of PPE. From the data analysis, the large difference in the distribution of responses between European and Asia respondents confirms that they give different significance to various types of PPE, which primarily reflects climatic and cultural influences. For example, as seen in Fig. 4, the difference in the use of hand and arm protection between the two regions is very pronounced.

4.2.3 Training

Economic obstacles to training provision are factors raised by questionnaire respondents in this paper that should be addressed. In one study, it was found that companies still approach safety expenditure as a necessary element of compliance; they are hence reluctant to invest in safety and health beyond the bare minimum as they feel it would erode their bottom line and reduce their competitiveness (Takala et al. 2013). It is clear that injury or fatality of a chainsaw operator can lead to very expensive direct and indirect costs such as insurance, medical and legal costs. As pointed out by Takala et al. (2013), these include training replacement employees, lost productivity and costs associated with lower employee morale and absenteeism (2013).

Field tests conducted during the study included a total of 16 days training with the use of the uniform ABA qualification safety standards implemented in both European and Asian conditions. Training covered the first two levels of the ABA standards for tree felling, but due to a number of restrictions, did not cover the advanced levels such as storm damaged techniques. Nonetheless, it was useful for the purposes of the study. Independent assessment of the training meant that the trainers worked hard to make sure the participants met the minimum required standard for the test. The impact and benefits of raising awareness and skills proficiency of the participants was noticeable and very positive. It was clear that all participants were keen to improve their knowledge and skills. It was also clear from the study findings that opportunities for this type of training appeared to be more available in Europe than Asia. Yet, according to EU-OSHA (2020), the challenges to be addressed are the lack of a prevention culture (foresters tend to give low priority to OSH over other competing issues), as well as poor skills and training deficit, particularly in OSH. Any proposal dealing with these challenges should begin by addressing the parts of the sector most at risk, which includes the above factors, thus creating a generic relationship of safety improvement measures (Table 8).

Table 8 Summary of chainsaw operator safety risks and recommended improvement measures

|

Generic measures for improving the safety of chainsaw operators in Asia and Europe |

||

|

Those most at risk |

Risk factors |

Mitigation/Safety culture measures |

|

Self-employed temporary/seasonal workers young/old workers workers on piecework rates workers with low or no qualifications |

Poor or no contracts |

Enforcement of minimum national/international standards |

|

Insufficient or no site supervision |

Dedicated role(s) established |

|

|

Lack of adequate mentoring/teamwork |

Support and communication mechanisms adopted |

|

|

Low education and knowledge |

Provision of additional support and opportunities |

|

|

Inadequate or no training |

Regular provision of quality »awareness raising« training appropriate to the level of chainsaw activity/risk |

|

|

Lack of suitable PPE/equipment |

Provision of appropriate equipment |

|

|

Risk-taking behaviour |

»Zero tolerance« approach, accountability and increased personal responsibility |

|

|

Inadequate risk assessing/emergency planning |

Enforcement of minimum national/international standards and accountability |

|

|

Lone working |

»Zero tolerance« approach and accountability |

|

|

Poor accident reporting |

Ease of access, collection and uniform system of reporting |

|

5. Conclusions

Even with the onset of new technologies, such as battery powered chainsaws, as pointed out by EU-OSHA (2020), chainsaw use will continue to be the most important risk in forestry for some time. As shown by Klun and Medved (2007), the number of fatalities is an important indicator of mastering the risks and shows the effectiveness as well as integrity of measures taken by individual countries in their attempts to provide for safety in forestry work. Uniformity of national/regional injury classification and reporting systems, such as separation of professional from non-professional users, would enhance accuracy and reliability of the data therefore yielding greater benefits through knowledge that can be applied with the aim of reducing accidents to chainsaw operators. Better enforcement and accident reporting measures at a local or company level is a key factor for accident deterrence particularly in the case of high-risk workers, such as the self-employed.

The analysis of logging fatality data for Europe (Fig. 3) and evaluation of other studies from Asia clearly demonstrate that there are lessons to be learned and shared from the success of the »Finish approach« in improving the forestry safety culture. A broader implementation of the combination of key measures demonstrated by this approach, such as training (in chainsaw safety at all levels) and cooperation (including supervision in the workplace), which have contributed to a significant reduction of forestry accidents in Finland, should be adopted. Since the research findings in this study indicate that logging fatality rates in Asia are likely to be far higher than those in Europe, further cooperation and research investigations between the regions is recommended, such as between ministries of labour, national statistics offices and OSH bodies because in the absence of more conclusive evidence, such inference currently remains speculative.

As recommended by EU-OSHA (2020), the forestry sector needs to improve the prevention culture and apply more holistic approaches to safety and health, which are necessary to achieve improvements in areas such as the stubborn long-standing risks of accidents from chainsaw use. This recommendation, supported by the findings of this paper, means that it can equally apply to countries in Asia and Europe. A recommendation for safety improvement measures has also been proposed (Table 8). To be effective, this must include supporting instruments, such as motivational tools, incentives, mechanisms for cooperation and sharing of information, etc. Additionally, FAO (2020) states that OSH is one of the key areas that the forestry industry must improve, alongside its reputation. To achieve this and reduce accidents, a successful forestry safety culture has been demonstrated to be effective. This includes employers or self-employed who may or may not be »on the front line« addressing as follows:

Þ applying effective local enforcement, support and monitoring measures (e.g., for risk-taking behaviour, etc),

Þ ensuring high quality and engaging cyclic (hazard/risk) »awareness raising« training, which includes independent assessment of high-risk activities and adequate refresher training,

Þ ensuring the use of appropriate and suitable PPE, including emergency aids,

Þ providing additional support (mentoring/supervision, etc) for high-risk groups including fostering good teamwork, personal responsibility and communication.

Acknowledgments

The authors would like to thank: Dr Allen Lim for translation of the research questionnaire into Chinese language; Dr Iván Ciudad-Valls and the Erasmus + »Ester« project team for providing statistical data; ABA International for providing support during the field tests.

6. References

ABA, 2012: Chainsaw qualification safety standards. Awarding Body Association International. Brno. ABA-ICC/ECC1 1 p.

ABA, 2012: ECC European Chainsaw Project. Available online: https://www.aba-skills.com/projects/eaiococ-icc-ecc/ (Accessed 31 June 2021)

Boix, P., Vogel, L., 1999: Risk Assessment at the Workplace: A Guide for Union Action. European Trade Union Technical Bureau for Health and Safety (TUTB), 8 p.

Burke, M., Salvador, R., Smith-Crowe, K., Chan Serafin, S., Smith, A., Sonesh S., 2011: The dread factor: How hazards and safety training influence learning and performance. Journal of Applied Psychology 96(1): 46–70. https://doi.org/10.1037/a0021838

Com, 2004: Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of Regions. European Commission document no. 52004DC0062, 4 p.

EC, 2006: Council Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC, Official Journal L 157, 9.6.2006, 24–86.

EC, 2009: Council Directive 2009/104/EC of the European Parliament and of the Council of 16 September 2009 concerning the minimum safety and health requirements for the use of work equipment by workers at work (second individual Directive within the meaning of Article 16(1) of Directive 89/391/EEC). Official Journal L 260, 3.10.2009, 5–19.

EEC, 1989: Council Directive 89/391/EEC — measures to improve the safety and health of workers at work. Official Journal L 393, 30.12.1989, 1–12.

EU, 2012: Consolidated version of the Treaty on the Functioning of the European Union. Official Journal C 326, 26/10/2012 1–390.

EU, 2016: Regulation (EU) 2016/425 — personal protective equipment. Official Journal L 81, 31.03.2016, 51–98.

EU-OSH, 2015: Evaluation of the Practical Implementation of the EU Occupational Safety and Health (OSH) Directives in EU Member States. European Commission project no. A031983, 65 p.

EU-OSHA, 2019: The value of occupational safety and health and the societal costs of work-related injuries and diseases. European Agency for Safety and Health at Work, 5 p.

EU-OSHA, 2020: Review on the future of Agriculture and Occupational Safety and Health – Report. European Agency for Safety and Health at Work, 9–45.

Eurostat, 2020: European statistics. European Commission web site. Available at: https://ec.europa.eu/eurostat/web/main/home. (Accessed 31 June 2020)

FAO, 1993/4: Forest worker safety and health in Finland. Unasylva – No. 175: 44. Available at: https://www.fao.org/3/v1500e/v1500e00.htm. (Accessed 21 June 2020)

FAO, 2020: Occupational safety and health in forest harvesting and silviculture – A compendium for practitioners and instructors. Forestry Working Paper No. 14. Rome, FAO, 16–40. https://doi.org/10.4060/ca8773en

Garland, J., 2018: Accident reporting and analysis in forestry: guidance on increasing the safety of forest work. Forestry Working Paper No. 2. Rome, FAO, 7 p.

Georgescu, M.A., Gliga, C., 2020: Continuous Vocational Training for Sustainable Work Practices in Forestry. Procedia Manufacturing 46: 299–307. https://doi.org/10.1016/j.promfg.2020.03.044

GOVPH, 1974: Presidential Decree No. 442-1974-Labor Code of the Philippines. Department of Labor and Employment, Republic of the Philippines. Official Gazette, 162–165 p.

Health and Safety Executive, UK, 2003: Tree Work Accidents (INDG 278). Suffolk: HSE, 1–12.

Health and Safety Executive, UK, 2017: Summary Report: Agriculture Sector – Farmers and Agricultural Workers‘ Safety and Attitudes to Risk’ Research. London: HSE, 1–11.

ILO, 1998: Safety and health in forestry work: An ILO code of practice. ILO Publications, Geneva, 8–96.

ILO, 2006: International Labor Standard for the Promotional Framework for Occupational Safety and Health Convention. Available at: https://www.ilo.org/dyn/normlex/en/f?p=NORMLEXPUB:12100:0::NO::P12100_ILO_CODE:C187 (Accessed 21 June 2020)

ILO, 2010: Labour Condition in Forestry Indonesia. ILO Publications, Geneva, 1–12.

ISO, 2015: 6535:2015 Portable chain-saws — Chain brake performance. International Organisation for Standardization, 4th Ed, 1–4.

Kaakkurivaara, N., Stampfer, K., 2018: Assessment for Improvement: Harvesting Operations in Small-Scale Forest on Thai Steep Terrain. Small-scale Forestry 17: 259–276. https://doi.org/10.1007/s11842-017-9386-x

Klen, T., 1997: Personal protectors and working behaviour of loggers. Safety Science Volume 25(1–3): 89–103. https://doi.org/10.1016/S0925-7535(97)00036-2

Klun, K., Medved, M., 2007: Fatal accidents in forestry in some European countries. Croatian Journal of Forest Engineering 28(1): 55–62.

Lindroos, O., Burstrom, L., 2010: Accident rates and types among self-employed private forest owners. Accident Analysis and Prevention 42(6): 1729–1735. https://doi.org/10.1016/j.aap.2010.04.013

Melemez, K., 2015: Risk factor analysis of fatal forest harvesting accidents: A case study in Turkey. Safety Science 79: 369–378. https://doi.org/10.1016/j.ssci.2015.07.004

Robb, W., 2011: A brief review of national training provision and development of international training standards-European Commission project report. Available online: https://ec.europa.eu/programmes/erasmus-plus/project-result-content/aab72262-dc1e-4a36-a4b8-f133214584b5/ICS%20and%20Mapping%20Report%20No.1.pdf (Accessed 25 June 2020)

Robb, W., 2020: International Occupational Standards: European Chainsaw Standards. Mendel University in Brno, 32 p.

Robb, W., Cocking, J., 2014: Review of European chainsaw fatalities, accidents and trends. Arboricultural Journal: The International Journal of Urban Forestry 36(2): 103–126. https://doi.org/10.1080/03071375.2014.913944

Srikanth, S., Kaihekulani, S., Lum, Y., Chen, Z., 2015: Mangrove root: adaptations and ecological importance. Trees: Structure and Function 30: 451–465. https://doi.org/10.1007/s00468-015-1233-0

Takala, J., Hamalainen, P., Saarela, K.L., Gan, S.K., Loke, Y., Manickam, K., Tan, W.J., Heng, P., Lim, G. K., Lim, S.Y.E., Gan, S.L., 2013: Global Estimates of the Burden of Injury and Illness at Work in 2012. Journal of Occupational and Environmental Hygiene 11(5): 326–337. https://doi.org/10.1080/15459624.2013.863131

Thelin, A., 2002: Fatalities in Farming and Forestry: An examination of the registry information used in the Swedish national statistics, 1988–1997. Journal of Agricultural Safety and Health 8(3): 289–295. https://doi.org/10.13031/2013.9053)@2002

Wang, J., Bellb, J.L., Grushecky, S.T., 2003: Logging injuries for a 10-year period in Jilin Province of the People’s Republic of China. Journal of Safety Research 34(3): 273–279. https://doi.org/10.1016/S0022-4375(03)00024-0

Yovi, E., Yamada, Y., 2019: Addressing Occupational Ergonomics Issues in Indonesian Forestry: Laborers, Operators, or Equivalent Workers. Croatian Journal of Forest Engineering 40(2): 351–363. https://doi.org/10.5552/crojfe.2019.558

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors’ addresses:

William Robb, BSc *

e-mail: william.robb@mendelu.cz

Ing. Tomáš Zemánek, PhD

e-mail: tomas.zemanek@mendelu.cz

Mendel University in Brno

Faculty of Forestry and Wood Technology

Department of Engineering

Zemědělská 3

613 00, Brno

CZECH REPUBLIC

Assist. Prof. Nopparat Kaakkurivaara, PhD

e-mail: ffornrm@ku.ac.th

Kasetsart University

Faculty of Forestry

Department of Forest Engineering

50 Ngamwongwan Rd, Ladyao

Chatuchak, Bangkok

THAILAND

* Corresponding author

Received: February 21, 2021

Accepted: January 4, 2022

Original scientific paper