Exposure to Occupational Noise: Machine Operators of Full Tree System in Brazil

doi: 10.5552/crojfe.2022.1437

volume: 43, issue:

pp: 13

- Author(s):

-

- Camargo Diego Aparecido

- Munis Rafaele Almeida

- Batistela Gislaine Cristina

- Simões Danilo

- Article category:

- Original scientific paper

- Keywords:

- ergonomics, Eucalyptus, forest operations, labor disorders, physical agent, wood harvesting

Abstract

HTML

Physical agent noise can be considered one of the main disturbances that compromise the occupational health of self-propelled forest machine operators. We evaluated whether occupational noise levels emitted by self-propelled forest machines employed in the full tree system are in accordance with both the National Institute for Occupational Safety and Health and ISO 1999:2013 standards, while also proposing mitigating measures aimed at protecting the operators hearing. Seventeen operators, who performed wood harvesting operations in Eucalyptus forests in Brazil, were analyzed. Noise levels were collected in a daily shift of eight hours as recommended by the Acoustics – Determination of occupational noise exposure - Engineering method for full-day measurements (ISO 9612:2009). The standards adopted for the evaluation were the exposure action value of 80 dBA and the exposure limit of 85 dBA based on the National Institute for Occupational Safety and Health – NIOSH and on Acoustics – Estimation of noise-induced hearing loss (ISO 1999:2013) Directive 2003/10/EC. The operators were arranged in homogeneous groups according to the Acoustics recommendation – Determination of occupational noise exposure - Engineering method for full-day measurements (ISO 9612:2009), classified by the operations of felling, skidding of tree bundles and bucking. The results showed that 17 self-propelled forest machines exceeded the exposure action value of 80 dBA, of which 10 machines exceeded the exposure limit of 85 dBA. It was concluded that the levels of occupational noise emitted by self-propelled forest machines used in the full tree system are higher than those recommended by both standards, National Institute for Occupational Safety and Health and ISO 1999:2013. Therefore, the allocation of self-propelled forest machines to homogeneous groups allows inferring mitigation actions that protect operators' hearing. The correct use of hearing protectors during the daily workday provides hearing protection for operators in mechanized wood harvesting. Adoption of actions such as maintenance of cabin seals and mechanical components, breaks for fatigue relief, reduction of daily working hours and rotation of operators in different self-propelled forest machines can mitigate the damage to the occupational health of operators.

Exposure to Occupational Noise: Machine Operators of Full Tree System in Brazil

Diego Aparecido Camargo, Rafaele Almeida Munis, Gislaine Cristina Batistela, Danilo Simões

Abstract

Physical agent noise can be considered one of the main disturbances that compromise the occupational health of self-propelled forest machine operators. We evaluated whether occupational noise levels emitted by self-propelled forest machines employed in the full tree system are in accordance with both the National Institute for Occupational Safety and Health and ISO 1999:2013 standards, while also proposing mitigating measures aimed at protecting the operators hearing. Seventeen operators, who performed wood harvesting operations in Eucalyptus forests in Brazil, were analyzed. Noise levels were collected in a daily shift of eight hours as recommended by the Acoustics – Determination of occupational noise exposure - Engineering method for full-day measurements (ISO 9612:2009). The standards adopted for the evaluation were the exposure action value of 80 dBA and the exposure limit of 85 dBA based on the National Institute for Occupational Safety and Health – NIOSH and on Acoustics – Estimation of noise-induced hearing loss (ISO 1999:2013) Directive 2003/10/EC. The operators were arranged in homogeneous groups according to the Acoustics recommendation – Determination of occupational noise exposure - Engineering method for full-day measurements (ISO 9612:2009), classified by the operations of felling, skidding of tree bundles and bucking. The results showed that 17 self-propelled forest machines exceeded the exposure action value of 80 dBA, of which 10 machines exceeded the exposure limit of 85 dBA. It was concluded that the levels of occupational noise emitted by self-propelled forest machines used in the full tree system are higher than those recommended by both standards, National Institute for Occupational Safety and Health and ISO 1999:2013. Therefore, the allocation of self-propelled forest machines to homogeneous groups allows inferring mitigation actions that protect operators' hearing. The correct use of hearing protectors during the daily workday provides hearing protection for operators in mechanized wood harvesting. Adoption of actions such as maintenance of cabin seals and mechanical components, breaks for fatigue relief, reduction of daily working hours and rotation of operators in different self-propelled forest machines can mitigate the damage to the occupational health of operators.

Keywords: ergonomics, Eucalyptus, forest operations, labor disorders, physical agent, wood harvesting

1. Introduction

Wood harvesting in the Eucalyptus forest planted in Brazil, in areas that allow mechanization, replaced operations that required physical overload for operators. However, the choice of mechanized wood-harvesting systems, composed of different self-propelled forest machines, resulted in other damages to the occupational health of operators, consequently impacting the effective productivity of forestry operations.

It should be noted that the mechanized harvesting of wood systems was developed and became part of the routine of forestry sector companies (Ajani 2011, Kärhä et al. 2018, Malinovski et al. 2015, Mologni et al. 2018, Norihiro et al. 2018, Tolosana et al. 2014). Given this, the selection of self-propelled forest machines must be guided by the edaphoclimatic characteristics of the planted forest, the efficiency and optimization of ecologically sustainable and socially acceptable operations and, above all, provision of working conditions favorable to operators (Lindroos et al. 2017, Marčeta et al. 2020, Mederski et al. 2021, Miyajima et al. 2020, Pandur et al. 2021, Spinelli and Marchi 2021).

Among the mechanized wood harvesting systems, the full tree system stands out. It is usually composed of the feller-buncher, grapple skidder and grapple processor (Gerasimov and Sokolov 2014, Jodłowski and Kalinowski 2018, Tolosana et al. 2018). This system aims to make the felling of trees and remove them to the margins of forest roads or intermediate yards, for later timber processing (Malinovski et al. 2008, Proto et al. 2020).

From the ergonomic point of view, the full tree system can be understood in a working environment with the presence of physical agents, such as occupational noise and, according to Yovi and Yamada (2019), characterized as an unhealthy working environment. According to Brown and Kamp (2017) and Guski et al. (2017), when operators are exposed to occupational noise for long periods at work, fatigue, decreased productivity, mood swings, lack of motivation and focus and sleep dysfunction occur. Besides that, Oishi and Schachat (2011), Guo et al. (2018) and Nyarubeli et al. (2018) point out that exposure to occupational noise results in temporary to permanent disturbances, such as noise-induced hearing loss, which causes acoustic trauma and inflammation of the ear canals.

From this standpoint, Landekić et al. (2019) and Routa et al. (2020) suggest the adoption of mechanisms to reduce the exposure of operators to the emitted noise levels, aiming to protect the health and safety of operators through decision making (Spinelli et al. 2020). The elimination, control of noise levels and implementation of preventive and predictive measures, are decisions that can be implemented based on analysis of data obtained in the field. (Naskrent et al. 2020, Potočnik and Poje 2017, Potočnik et al. 2009).

Albizu et al. (2013), Prell et al. (2020) and Soylemez and Mujdeci (2020) emphasize that the perception of risk is of vital importance for operators, as they do not perceive, in the short term, the consequences of exposure to occupational noise and therefore it is an important element in the detection and implementation of mitigation actions. Thus, noise levels emitted by self-propelled forest machines can expose operators to unhealthy conditions, justifying constant monitoring.

Due to this, it was evaluated whether the occupational noise levels emitted by self-propelled forest machines employed in the full tree system are in accordance with both the National Institute for Occupational Safety and Health and ISO 1999:2013 standards, while also proposing mitigation measures aimed at protecting the operators hearing.

2. Materials and Methods

2.1 Study Overview

The research and the respective informed consent form were previously approved by the Research Ethics Committee of Universidade Estadual Paulista »Júlio de Mesquita Filho« – Medical School - Botucatu Campus, according to the Opinion No. 3.492.969.

The data were collected under real operating conditions in forests planted with two species of Eucalyptus, located in Brazil. E. saligna’s average planting age was of 10.2 years ±2.68, with mean individual tree volume (MIV) of 0.52 ±0.13 m³ and spacing of 3.30x1.80 m. As for the planting of E. grandis, the average age was 8 years ±2.13 with MIV of 0.41 ±0.10 m³ and spacing of 3.30x1.80 m. The classification of slope classes was performed (Table 1) according to Viel et al. (2020).

Table 1 Characterization of the forest site

|

Species |

Study area |

Distribution of diameter classes cm |

Mean individual tree volume m³ |

Cutting age year |

Terrain slope % |

Classification of slope classes |

|

Eucalyptus saligna |

1 |

12–12.9 |

0.639 |

12 |

27 to 30 |

Severely undulated |

|

2 |

12–12.9 |

0.639 |

12 |

5 to 8 |

Mildly undulated |

|

|

3 |

7–7.9 |

0.360 |

8 |

10 to 15 |

Undulated |

|

|

4 |

12–12.9 |

0.608 |

13 |

5 to 8 |

Mildly undulated |

|

|

5 |

6–6.9 |

0.359 |

6 |

5 to 8 |

Mildly undulated |

|

|

Eucalyptus grandis |

6 |

6–6.9 |

0.373 |

7 |

5 to 8 |

Mildly undulated |

|

7 |

8–8.9 |

0.409 |

8 |

10 to 15 |

Undulated |

|

|

8 |

12–12.9 |

0.622 |

12 |

5 to 8 |

Mildly undulated |

|

|

9 |

8–8.9 |

0.425 |

8 |

5 to 8 |

Mildly undulated |

|

|

10 |

6–6.9 |

0.336 |

6 |

5 to 8 |

Mildly undulated |

|

|

11 |

5–5.9 |

0.342 |

6 |

5 to 8 |

Mildly undulated |

2.2 Mechanized Harvesting of Wood

The felling of trees was performed by feller-bunchers, which performed the felling of trees and accumulation of bundles for subsequent allocation on the soil. That said, four Tigercat feller-bunchers and one John Deere feller-buncher were considered, all with rigid track wheels and auger felling head. (Table 2).

As for the skidding of tree bundles, grapple skidders were used to perform the skidding of tree bundles from the interior of the stand to the margins of the forest road. Thus, four Tigercat grapple skidders with 6x6 pneumatic wheel systems were evaluated.

Finally, the log twisting comprised pruning and twisting the trees together and was performed by five John Deere grapple processors with a rigid track system, in addition to three grapple saws with a John Deere rigid treadmill track system.

Table 2 Self-propelled forest machines and accumulated number of hours of use

|

Self-propelled forest machines |

Identification |

Brand |

Model |

Accumulated hours of use, h |

|

|

Feller-buncher |

FB1 |

Tigercat |

L 870 C |

10,071 |

|

|

FB2 |

Tigercat |

L 870 C |

18,647 |

||

|

FB3 |

Tigercat |

L 870 C |

9,644 |

||

|

FB4 |

Tigercat |

L 870 C |

21,189 |

||

|

FB5 |

John Deere |

953 MH |

342 |

||

|

Grapple skidder |

GSk1 |

Tigercat |

635 D |

13,631 |

|

|

GSk2 |

Tigercat |

636 D |

12,892 |

||

|

GSk3 |

Tigercat |

637 D |

14,152 |

||

|

GSk4 |

Tigercat |

635 E |

8,359 |

||

|

Grapple processor |

GPR1 |

John Deere |

351 G |

21,303 |

|

|

GPR2 |

John Deere |

352 G |

21,333 |

||

|

GPR3 |

John Deere |

903 k |

8,927 |

||

|

GPR4 |

John Deere |

903 k |

8,875 |

||

|

GPR5 |

John Deere |

953 MH |

801 |

||

|

Grapple saw |

GS1 |

John Deere |

350 G |

13,644 |

|

|

GS2 |

John Deere |

909 k |

11,502 |

||

|

GS3 |

John Deere |

909 k |

7,767 |

Thus, 17 operators of self-propelled forest machines were considered, that is, one operator for each machine. The feller-buncher operators had an average age of 31.8 ±5.2 years, with an average professional experience in the felling of trees of 4.7 ±2.5 years. As for the grapple skidder operators, they had an average age of 41 ±8.9 years, with an average time of professional experience in the skidding of tree bundles of 4.9 ±4.3 years. In the log bucking, the grapple processor operators had an average age of 34 ±3.7 years and an average professional experience of 4.2 ±0.6 years. In the bucking of trees with the use of a grapple saw, the operators had an average age of 39.7 ±4.5 years and an average professional experience of 3.9 ±2.2 years.

2.3 Dosimetry Procedure

Daily journey of forestry operations was of eight hours. Due to the time spent on physiological needs and mechanical interruptions, dosimetry was paused. However, it took more than six hours for the daily individual collection.

Noise levels were collected through two integrating meters for personal use of the Instrutherm brand, models DOS-500 and DOS-600, which were attached to the operators' clothing, and the microphone was fixed at shoulder height as recommended by the Acoustics – Determination of occupational noise exposure -Engineering method (ISO 9612:2009).

Sound pressure level was measured in decibels (dB), every 60 seconds, with the adjustment of curve A to compensate for the decibel level. The range between 70 and 140 dBA was considered as a measuring range; in addition, noise levels above 115 dBA were also considered. The response circuit adopted was slow, given its employability in situations that cause oscillations of sound pressure level.

Noise levels were analyzed according to the guidelines established by the National Institute for Occupational Safety and Health – NIOSH purposes that deal with Occupational Noise Exposure (NIOSH 1998) and Acoustics – Estimation of noise-induced hearing loss (ISO 1999:2013). The reference criterion adopted as an exposure limit for a daily workload of eight hours was 85 dBA.

As for the exposure action value, which establishes the occupational noise exposure limit for preventive actions, half the dose was adopted as the exposure action value for the physical agent noise, defined as exposure to sound levels less than 80 dBA, according to Directive 2003/10/EC (EU 2003) and ISO 1999:2013. Based on Regulatory Standard N. 1733 – Annex N. 6 (Portugal 1981), the risk of hearing loss during work activity was estimated, considering the length of professional experience, aiming to protect operators’ hearing.

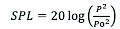

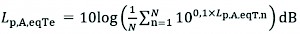

The sound pressure level, which represents an approximation of the noise captured through the human ear, was expressed through Eq. 1.

(1)

(1)

Where:

SPL sound pressure level

P mean square root of variations in instantaneous values of sound pressure

Po reference sound pressure that corresponds to audibility threshold.

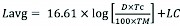

Due to the hearing damage produced by noise variation over time, the average levels of daily exposure to occupational noise (Eq. 2) were calculated in accordance with Wallas et al. (2019), for the dose increment factor of 5.

(2)

(2)

Where:

Lavg average levels of daily exposure to occupational noise

D daily noise dose projected for 8 hours

TC base level period of evaluation criteria (8 hours)

TM measurement time

LC base level of the criterion, equal to 85 dBA.

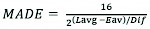

It was possible to determine the maximum allowable daily exposure according to the average levels of daily exposure to occupational noise, according to Eq. 3.

(3)

(3)

Where:

MADE maximum allowable daily exposure

EAV exposure action value, equal to 80 dBA

Dif dose increment factor, adopted as 5.

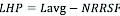

The mitigation levels of hearing protection devices were determined according to the Noise Reduction Rate Subject Fit using Eq. 4 according to Schulz (2011).

(4)

(4)

Where:

LHP estimated noise level that reaches worker's ear in dBA

NRRSF noise reduction rate subject fit.

2.4 Criterion for Defining Homogeneous Groups

Homogeneous groups were defined with the operators of self-propelled forest machines, which were exposed to occupational noise, as recommended by ISO 9612:2009. Homogeneous groups consist of the arrangement of more than one operator, grouped according to the function performed, characterized as:

Homogeneous Group 1 (HG1): composed of five self-propelled forest machines, therefore five operators operating feller-buncher;

Homogeneous Group 2 (HG2): formed by four self-propelled forest machines, consequently four operators operating grapple skidder;

Homogeneous Group 3 (HG3): established by five self-propelled forest machines, therefore five grapple processor operators;

Homogeneous Group 4 (HG4): consisting of three self-propelled forest machines, therefore three grapple saw operators.

Exposure to noise level for a daily journey of eight hours was dimensioned using the full-day measurement strategy, according to the guidelines of ISO 9612:2009.

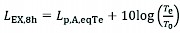

The daily occupational noise exposure level, with an effective working day duration, depended on the average levels of daily exposure to occupational noise (Eq. 5).

(5)

(5)

Where:

Lp,A,eqTe A-weighted equivalent continuous sound pressure level for Te

Lp,A,eqT,n A-weighted equivalent continuous sound pressure level of sample n

N total number of job samples.

The achievement of the daily occupational noise exposure level was estimated using Eq. 6.

(6)

(6)

Where:

LEX,8h A-weighted noise exposure level normalized to a nominal 8 h working day

Te effective duration of working day

T0 reference duration, (T0=8 h).

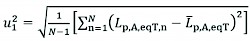

Therefore, to calculate the uncertainty of the average levels of daily exposure to occupational noise of the measured values, Eq. 7 was used.

(7)

(7)

Where:

u1 standard uncertainty of the average energy of several measurements of A-weighted equivalent continuous sound pressure level

arithmetic average of N job samples of A-weighted continuous equivalent sound pressure level

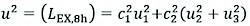

The combined standard uncertainty for the level of exposure to noise weighted in the daily working day was calculated using Eq. 8.

(8)

(8)

Where:

u combined standard uncertainty

c1 sensitivity coefficient associated with job noise level sampling

c2 sensitivity coefficient associated with measurement instrumentation

u2 standard uncertainty due to instrumentation

u3 standard uncertainty due to microphone position

Finally, to determine the (U) expanded uncertainty, Eq. 9 was applied.

(9)

(9)

2.5 Statistical Analysis

We sought to infer about each constituent element, derived from observation between homogeneous groups, considering the condition of statistical equality. In such manner, the conditions assumed in the arrangement of homogeneous groups were analyzed according to the hypothesis of equivalence of occupational noise levels emitted.

The assumptions of normality and homoscedasticity of the data were verified using the Lilliefors (Lilliefors 1969) and Bartlett tests (Bartlett 1937). As for the comparison of the Sound Pressure Level (SPL) response, the Friedman non-parametric ranks test (Friedman 1937) was applied, followed by post hoc analyses using the Nemenyi multiple comparison test (Nemenyi 1963), between the homogeneous groups and within each homogeneous group.

Statistical analyses were discussed at a 5% significance level and performed using software R version 3.5.2 (R development core team 2021).

3. Results

3.1 Occupational Noise Assessment

When analyzing the average levels of daily exposure to occupational noise for operators of self-propelled forest machines, it was found that two HG1 operators were exposed to the exposure limit of 85 dBA recommended by NIOSH (1998) and ISO 1999:2013 described in Table 3.

The FB1 operator was exposed to an average level of daily exposure to occupational noise of 4.4 dBA above the exposure limit, and for the computed maximum allowable daily exposure level, it would be 4 hours and 21 minutes. As for the FB2 operator, the average level of daily exposure to occupational noise was 1.9 dBA higher than the exposure limit, so the maximum allowable daily exposure for the assessed level would be 6 hours and 25 minutes.

Regarding HG2, the average level of daily exposure to occupational noise for the GSK1 operator was 4.5 dBA higher than the exposure limit and for the weighted level, the maximum allowable daily exposure would be 4 hours and 19 minutes. Regarding the GSK2 operator, the average level of daily exposure to occupational noise was 1.5 dBA above the exposure limit, with 6 hours and 30 minutes of maximum allowable daily exposure.

The GSK3 operator was exposed to an average level of daily exposure to occupational noise of 2.2 dBA above the one recommended by NIOSH (1998) and ISO 1999:2013, with 5 hours and 54 minutes of maximum allowable daily exposure. As for the GSK4 operator, he was exposed to 1.5 dBA above the average daily level of exposure to occupational noise, with a maximum allowable daily exposure of 6 hours and 30 minutes.

As to HG3, the GPR1 operator was exposed to the average levels of daily exposure to occupational noise plus 0.1 dBA, as recommended by NIOSH (1998) and ISO 1999:2013 for labor purposes, with 7 hours and 52 minutes of maximum allowable daily exposure for a daily journey. The GPR4 operator was exposed to 0.1 dBA above the exposure limit, with 7 hours and 52 minutes of maximum allowable daily exposure. As for the GPR5 operator, it presented an average level of daily exposure to occupational noise of 2.0 dBA above the exposure limit and 6 hours and 4 minutes of maximum allowable daily exposure.

In HG4, the GS2 operator presented an average level of daily exposure to occupational noise of 0.3 dBA above the exposure limit and 7 hours and 43 minutes of maximum allowable daily exposure. Therefore, the risk of hearing loss for coverage was estimated, according to Portuguese Standard number 1733 (1981), and determined based on the professional experience of the operators, when it was equal to or greater than 60 months. Only two operators had professional experience longer than the recommended period: GSK3 and GPR1.

Table 3 Average levels of daily exposure to occupational noise, maximum allowable daily exposure and protection level

|

Homogeneous groups |

Identification |

Lavg, dBA |

MADE, h |

LHP, dBA |

|

HG1 |

FB1 |

89.4 |

4h 21 |

72.4 |

|

FB2 |

86.9 |

6h 09 |

69.9 |

|

|

FB3 |

84.6 |

8h 29 |

67.6 |

|

|

FB4 |

84.8 |

8h 14 |

67.8 |

|

|

FB5 |

84.7 |

8h 23 |

67.7 |

|

|

HG2 |

GSK1 |

89.5 |

4h 19 |

72.5 |

|

GSK2 |

86.5 |

6h 30 |

69.5 |

|

|

GSK3 |

87.2 |

5h 54 |

70.2 |

|

|

GSK4 |

86.5 |

6h 30 |

69.5 |

|

|

HG3 |

GPR1 |

85.1 |

7h 52 |

68.1 |

|

GPR2 |

84.0 |

9h 11 |

67.0 |

|

|

GPR3 |

84.1 |

9h 02 |

67.1 |

|

|

GPR4 |

85.1 |

7h 52 |

68.1 |

|

|

GPR5 |

87.0 |

6h 04 |

70.0 |

|

|

HG4 |

GS1 |

84.8 |

8h 19 |

67.8 |

|

GS2 |

85.3 |

7h 43 |

68.3 |

|

|

GS3 |

84.4 |

8h 40 |

67.4 |

3.2 Comparison between Homogeneous Groups

In the homogeneous group HG1, operators were subject to a daily occupational noise exposure level of 86.5 dBA, with a minimum of 84.6 dBA and a maximum of 89.4 dBA and expanded uncertainty of 4.0 dBA, for a 95% unilateral confidence interval.

HG2 operators were exposed to a daily occupational noise exposure level of 87.6 dBA, with a minimum of 86.5 dBA and a maximum of 86.5 dBA, with an expanded uncertainty of 3.2 dBA, for a 95% unilateral confidence interval.

HG3 operators were exposed to a daily occupational noise exposure level of 85.2 dBA, with a minimum of 84.0 dBA and a maximum of 87.0 dBA, with an expanded uncertainty of 3.1 dBA, for a 95% unilateral confidence interval. In HG4, operators had a daily occupational noise exposure level of 84.9 dBA, with a minimum of 84.4 dBA and a maximum of 85.3 dBA, expanded uncertainty of 3.0 dBA, for a 95% unilateral confidence interval.

In this scenario, given the non-parametric spectrum of the data, the Friedman ranks test was applied, through which it was found that there was no evidence to reject the null hypothesis (p-value = 0.73), that is, there is no evidence that the medians of the sound pressure level are different between the homogeneous groups (Table 4).

Table 4 Comparative analysis between homogeneous groups of self-propelled forest machines

|

Homogeneous groups |

Median, dBA |

Amplitude, dBA |

|

HG1 |

80.19 |

12.80 |

|

HG2 |

83.95 |

16.95 |

|

HG3 |

78.04 |

10.36 |

|

HG4 |

76.63 |

13.43 |

3.3 Comparison of Constituents of Each Homogeneous Group

The conditions of normality of the data and homogeneity of the variances were not satisfied at the significance level of 5%, resulting from the applications of the Lilliefors and Bartlett tests. With the application of the Friedman test, it was possible to verify the differences that did not agree with the arrangement.

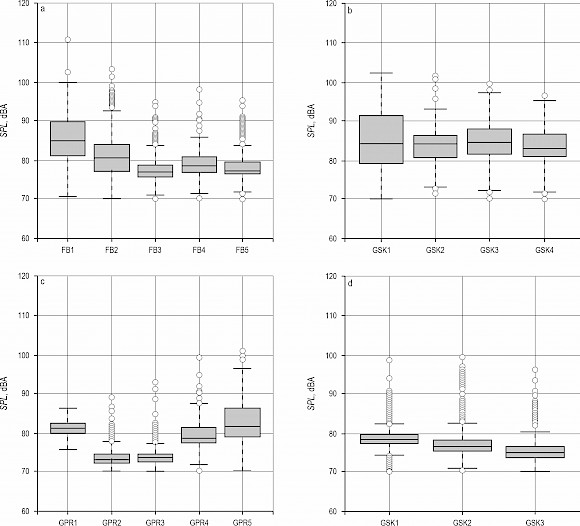

In view of the above, for HG1 and HG2, it was found that there was no evidence to reject the null hypothesis (p-value = 0.22 and p-value = 0.70, respectively), that is, it was not possible to demonstrate that sound pressure levels differed statistically between feller-bunchers (Fig. 1a) and grapple skidders (Fig. 1b). Similarly, the sound pressure level emitted by the grapple processor (Fig. 1c) did not show statistical differences (p-value = 0.05); in like manner, the grapple saw (Fig. 1d) did not show evidence that would lead to accepting the test hypothesis (p-value = 0.95).

Fig. 1 Comparative analysis of sound pressure level within homogeneous groups

4. Discussion

The occupational risks to the health of operators of self-propelled forest machines are a problem in the forestry sectors according to Souza et al. (2003), Suchomel et al. (2011) and Araújo et al. (2018). Noise analysis in mechanized harvesting of wood in the full tree system resulted in values higher than the exposure action value, that is, all operators were exposed to occupational noise levels above 80 dBA, according to Prince et al. (1997), Health and Safety Executive (2012) and Regulatory Standard No. 9 (Brasil 1978).

In this perspective, it is necessary to adopt personal protective equipment, since the 17 self-propelled forest machines presented average levels of daily exposure to occupational noise higher than the exposure action value. The correct use of the hearing protection insert allows attenuating up to 17 dB or up to 20 dB when using the circum-auricular. Furthermore, according to Aalmo et al. (2016), interruptions during the daily workday can therefore help mitigate the damage to the operators’ health.

In the tree felling, among the five feller-bunchers evaluated, the FB1 and FB2 had occupational noise levels higher than recommended by NIOSH (1998) and ISO 1999:2013. FB1 performed the operation in study area 2 (5 to 8%) with mildly undulated slope class and FB2 in study area 3 and 7 with undulated slope class (10 to 15%).

These two feller-bunchers operated on terrain with slopes above 5%, which according to Obi and Visser (2018) can impact the emission of noise levels. In addition, the felling effects exerted by these two machines were in the perpendicular direction, differing from the other three that operated in the horizontal direction. According to Souza et al. (2004), in slope situations, the machine's motor requires greater power. Therefore, according to Poje et al. (2015), the higher the power required by the engine, the higher the noise levels emitted.

The accumulated hours of use of FB1 showed an average difference of 1908 hours when compared to the other feller-bunchers, while for FB2 this difference was 6668 hours. In line with Iftime et al. (2020), when the useful life of the self-propelled forest machines approaches the limit, there is the occurrence of wear and tear of the mechanical constituents that, without carrying out periodic maintenance, result in variations in noise levels.

In the skidding of tree bundles by grapple skidders, the GSK1 (study area 1) was the only one that operated in severely undulated slope class (27 to 30%), while the GSK2 (study area 1), GSK3 (study area 1) and GSK4 (study area 1) operated in a condition of mildly undulated slope class (5 to 8%). However, even with the displacements in different slope conditions, all grapple skidders presented average levels of daily exposure to occupational noise with values higher than the exposure limit, corroborated by Poje et al. (2016).

As for the log bucking by grapple processor, the GPR1, GPR4 and GPR5 showed values above 85 dBA. GPR1 and GPR4 showed an average difference of 9055 and 8875 hours, respectively, when compared to the other grapple processors. According to Poje et al. (2015), it was observed that machine life is one of the limiting factors for the beneficial use of self-propelled machines for operators, when evaluating exposure to occupational noise. According to Bassoli et al. (2020), the economic life of the self-propelled forest machines that make up the full tree system is 4 years, approximately 34,000 accumulated hours of use, therefore, these grapple processors have approximately 26.5% of the total service life.

The GPR5 had the least amount of accumulated hours of use among the five grapple processors, but it was the only one that needed to move from the main road margin to the interior of the stand, which resulted in noise levels above the exposure limit. This fact can be corroborated by Poje et al. (2019) since, when there is a displacement of self-propelled forest machines in a planted forest, noise levels increase.

There was also no compliance in the bucking of trees by grapple saw, and GS2 presented a higher noise level than the recommended by NIOSH (1998) and ISO 1999:2013. The three grapple saws were from the same brand, but of different models, the GS2 showed an average difference of 531 accumulated hours. The operator performed the operation at the limit of the number of tree bundles, therefore, due to the grip area and, consequently, the number of trees per cycle, which according to Miyajima et al. (2020) causes the intensification of the mechanical force in the hydraulic arm of the machine, raised the noise levels emitted, in line with Borz et al. (2019), who points out that noise levels can increase depending on the rate of engine use.

In view of this, 58.88% of the operators evaluated, that is, the operators of FB1 and FB2 of HG1, the four operators of HG2, the operators of GPR1, GPR4 and GPR5 of HG3, in addition to the GS2 operator of HG4, were exposed to higher average levels of daily exposure to occupational noise than the exposure limit, and consequently the use of personal protective equipment to mitigate the occupational noise to which they were exposed is mandatory. When operators are exposed to periods greater than the maximum allowable daily exposure, without the use of personal protective equipment, a variety of disorders can occur, thus decreasing performance and, consequently, resulting in health impairment (Gallis 2013).

The mandatory use of personal protective equipment, according to Almeida-Agurto et al. (2011), allows the mitigation of occupational noise levels provided by hearing protectors. The adoption of the Noise Reduction Rate Subject Fit criterion allows the fulfillment of the eight-hour workday, without compromising the physical integrity of the operators (Dastpaak et al. 2019).

When operators are exposed to noise levels higher than the exposure limit recommended by NIOSH (1998) and ISO 1999:2013, with professional practice exceeding five years, their physical integrity may be affected (Portugal 1981). The risk of hearing loss for GSK3 conversation, for example, was 3%, resulting from the 144 month occupational exposure time, while the risk for GPR1 was 1% due to 60 months of exposure. Hearing impairment due to this type of exposure constitutes irreversible damage to the health of operators, which, according to Hayes et al. (2019), results in hearing loss, and suppresses the formation of nerve tissue, in addition to memory loss.

Supported by the individual analysis of the machines, also in the grouping of operators of self-propelled forest machines in homogeneous groups, the average levels of daily exposure to occupational noise were higher than recommended by NIOSH (1998) and ISO 1999:2013.

There were uncertainties resulting from sampling errors, instrumentation and false sources of emission in the four homogeneous groups (ISO 9612:2009). However, the HG1 uncertainty was 4.0 dBA, which is higher than that of the other homogeneous groups, which, therefore, was lower than that obtained by Poje et al. (2019) in a study with self-propelled forest machines, which determined an uncertainty of 5.3 dBA.

When establishing the comparison between the functions arranged in homogeneous groups, it was observed that they did not differ statistically, that is, no evidence was found that could contradict the assumption of equality of the sound pressure level emitted in the felling, dragging and bucking of logs.

It was found that, within each of the homogeneous groups HG1, HG2, HG3 and HG4, there were no statistical differences between the self-propelled forest machines. These results indicate the need for the implementation of mitigation actions, since through knowledge and anticipation of the behavior of sound emission sources in mechanized harvesting of wood systems, the performance of the forest manager puts health integrity and the well-being of all system operators in a beneficial perspective.

In view of the harmful potential of occupational noise to self-propelled forest machine operators, protection and control measures should be applied (Al-arja and Awadallah 2020, Straker and Mathiassen 2009) in accordance with the recommendations of the National Institute for Occupational Safety and Health – NIOSH (1998), aiming at health protection and integrity of operators.

5. Conclusions

For the analyzed conditions, the occupational noise levels emitted by self-propelled machines that make up the full tree system for harvesting planted forests are higher than the recommended by both the National Institute for Occupational Safety and Health and ISO 1999:2013 standards. The use of insert or circum-auricular hearing protectors lessens the damage caused to the operators' hearing.

The correct use of hearing protectors during the daily workday provides hearing protection for operators in mechanized wood harvesting.

Adoption of actions such as maintenance of cabin seals and mechanical components, breaks for fatigue relief, reduction of daily working hours and rotation of operators in the different self-propelled forest machines can contribute to mitigating the damage to the occupational health of operators.

Analysis of noise levels based on the allocation of self-propelled forest machines in homogeneous groups provides the inference of mitigation actions that protect the operators’ hearing.

Acknowledgments

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil (CAPES) – Finance Code 001.

6. References

Ajani, J., 2011: The global wood market, wood resource productivity and price trends:an examination with special attention to China. Environmental Conservation 38(1): 53–63. https://doi.org/10.1017/S0376892910000895

Aalmo, G.O., Magagnotti, N., Spinelli, R., 2016: Forest Workers and Steep Terrain Winching: the Impact of Environmental and Anthropometric Parameters on Performance. Croatian Journal of Forest Engineering 37(1): 97–105.

Al-arja, O.A., Awadallah, T.S., 2020: Assessment of occupational noise exposure in coffee grinding shops. Applied Acoustics 158: 1–11. https://doi.org/10.1016/j.apacoust.2019.107047

Albizu, P.M., Tolosana, E., Roman-Jordan, E., 2013: Safety and health in forest harvesting operations – Diagnosis and preventive actions – A review. Forest Systems 22(3): 392–400. http://dx.doi.org/10.5424/fs/2013223-02714

Almeida-Agurto, D., Gerges, S.N.Y., Arenas, J.P., 2011: MIRE-IL methodology applied to measuring the noise attenuation of earmuff hearing protectors. Applied Acoustics 72(7): 451–457. https://doi.org/10.1016/j.apacoust.2011.01.009

Araújo, B.M., Oliveira, G.C., Catunda, P.H., 2018: Avaliação ergonômica em atividade de supressão vegetal: uma revisão sistemática. Revista Agrária Acadêmica 1(3): 92–105. https://doi.org/10.32406/v1n32018/92-105/agrariacad

Bartlett, M.S., 1937: Properties of sufficiency and statistical tests. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 160(901): 268–282. https://doi.org/10.1098/rspa.1937.0109

Bassoli, H.M., Batistela, G.C., Fenner, P.T., Simões, D., 2020: Custo anual uniforme equivalente de máquinas de colheita de madeira: uma abordagem estocástica. Pesquisa Florestal Brasileira 40: 1–10. https://doi.org/10.4336/2020.pfb.40e201902073

Borz, S.A., Talagai, N., Cheţa, M., Chiriloiu, D., Montoya, A.M.G., Vizuete, D.D.C., Marcu, M.V., 2019: Physical Strain, Exposure to Noise and Postural Assessment in Motor-Manual Felling of Willow Short Rotation Coppice: Results of a Preliminary Study. Croatian Journal of Forest Engineering 40(2): 377–388. https://doi.org/10.5552/crojfe.2019.550

Brasil 1978: Ministério do Trabalho. Norma Regulamentadora N. 9 – Avaliação e controle das exposições ocupacionais a agentes físicos, químicos e biológicos, Brasília.

Brown, A.L., Kamp, I.V., 2017: Review WHO Environmental Noise Guidelines for the European Region: A Systematic Review of Transport Noise Interventions and Their Impacts on Health. International Journal of Environmental Research and Public Health 14(8): 873. https://doi.org/10.3390/ijerph14080873

Dastpaak, H., Alimohammadi, I., Sameni, S.J., Abolghasemi, J., Vosoughi, S., 2019: Effects of earplug hearing protectors on the intelligibility of Persian words in noisy environments. Applied Acoustics 148: 19–22. https://doi.org/10.1016/j.apacoust.2018.11.017

EU 2003: Directive 2003/10/EC of the European Parliament and of the Council of 6 February 2003 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise). Official Journal of the European Communities, Brussels, Belgium.

Friedman, M., 1937: The Use of Ranks to Avoid the Assumption of Normality Implicit in the Analysis of Variance. Journal of the American Statistical Association 32(200): 675–701. https://doi.org/10.1080/01621459.1937.10503522

Gallis, C., 2013: Increasing Productivity and Controlling of Work Fatigue in Forest Operations by Using Prescribed Active Pauses: a Selective Review. Croatian Journal of Forest Engineering 34(1): 103–112.

Gerasimov, Y., Sokolov, A., 2014: Ergonomic evaluation and comparison of wood harvesting systems in Northwest Russia. Applied Ergonomics 45(2) Part B: 318–338. https://doi.org/10.1016/j.apergo.2013.04.018

Guo, H., Ding, E., Sheng, R., Cheng, J., CaI, W., Guo, J., Wang, N., Zhang, H., Zhu, B., 2018: Genetic variation in KCNQ4 gene is associated with susceptibility to noise-induced hearing loss in a Chinese population. Environmental Toxicology and Pharmacology 63: 55–59. https://doi.org/10.1016/j.etap.2018.08.009

Guski, R., Schreckenberg, D., Schuemer, R., 2017: Review WHO Environmental Noise Guidelines for the European Region: A Systematic Review on Environmental Noise and Annoyance. International Journal of Environmental Research and Public Health 14(12): 1539. https://doi.org/10.3390/ijerph14121539

Hayes, S.H., Manohar, S., Majumdar, A., Allman, B.L., Salvi, R., 2019: Noise-induced hearing loss alters hippocampal glucocorticoid receptor expression in rats. Hearing Research 379: 43–51. https://doi.org/10.1016/j.heares.2019.04.013

Health and Safety Executive: Noise at work – A brief guide to controlling the risks, This is a web-friendly version of leaflet INDG362(rev2), published 11/12. Available online: https://www.hse.gov.uk/pubns/indg362.htm (accessed 08 October 2021).

Iftime, M., Dumitrascu, A., Dumitrascu, D., Ciobanu, V.D, 2020: An investigation on major physical hazard exposures and health effects of forestry vehicle operators performing wood logging processes. International Journal of Industrial Ergonomics 80: 103041. https://doi.org/10.1016/j.ergon.2020.103041

ISO 9612: 2009: Acoustics – Determination of occupational noise exposure – Engineering method. ISO, Geneva, Switzerland.

ISO 1999: 2013: Acoustics – Estimation of noise-induced hearing loss. ISO, Geneva, Switzerland.

Jodłowski, K., Kalinowski, M., 2018: Current possibilities of mechanized logging in mountain areas. Forest Research Papers 79(4): 365–375. http://dx.doi.org/10.2478/frp-2018-0037

Kärhä, K., Poikela, A., Palander, T., 2018: Productivity and Costs of Harwarder Systems in Industrial Roundwood Thinnings. Croatian Journal of Forest Engineering 39(1): 23–33.

Landekić, M., Katuša, S., Mijoč, D., Šporčić, M., 2019: Assessment and Comparison of Machine Operators’ Working Posture in Forest Thinning. South-east European forestry 10(1): 29–37. https://doi.org/10.15177/seefor.19-02

Lilliefors, H.W., 1969: On the Kolmogorov–Smirnov test for the exponential distribution with mean unknown. Journal of the American Statistical Association 64(325): 387–389. http://dx.doi.org/10.1080/01621459.1969.10500983

Lindroos, O., Hera, P.L., Häggström, C., 2017: Drivers of Advances in Mechanized Timber Harvesting – a Selective Review of Technological Innovation. Croatian Journal of Forest Engineering 38(2): 243–258.

Marčeta, D., Petković, V., Ljubojević, D., Potočnik, I., 2020: Harvesting System Suitability as Decision Support in Selection Cutting Forest Management in Northwest Bosnia and Herzegovina. Croatian Journal of Forest Engineering 41(2): 251–265. https://doi.org/10.5552/crojfe.2020.744

MalinovskI, R.A., Fenner, P.T., Schack-Kirchner, H., Malinovski, J.R., Malinovski, R.A., 2008: Otimização da distância de extração de madeira com forwarder. Scientia Forestalis 36(79): 171–179.

Malinovski, R.A., Malinovski J.R., Nutto L., Sanches N.S., 2015: Safety and Training in Harvesting. In Tropical Forestry Handbook, 1nd ed.; Köhl M., Pancel L., Eds., Springer: Heidelberg, Berlin, 31 p. https://doi.org/10.1007/978-3-642-41554-8_186-1

Mederski, P.S., Borz, S.A., Duka, A., Lazdiņs, A., 2021: Challenges in Forestry and Forest Engineering – Case Studies from Four Countries in East Europe. Croatian Journal of Forest Engineering 42(1): 117–134. https://doi.org/10.5552/crojfe.2021.838

Miyajima, R.H., Fenner, P.T., Batistela, G.C., Simões, D., 2020: Technical-Economic Analysis of Grapple Saw: A Stochastic Approach. Croatian Journal of Forest Engineering 41(2): 219–229. https://doi.org/10.5552/crojfe.2020.681

Mologni, O., Dyson, P., Amishev, D., Proto, A.R., Zimbalatti, G., Cavalli, R., Grigolato, S., 2018: Tensile Force Monitoring on Large Winch-Assist Forwarders Operating in British Columbia. Croatian Journal of Forest Engineering 39(2): 193–204.

Naskrent, B., Grzywiński, W., Łukowski, A., Polowy, K., 2020: Influence of Cutting Attachment on Noise Level Emitted by Brush Cutter during Tending of Young Forests. Croatian Journal of Forest Engineering 41(1): 129–135. https://doi.org/10.5552/crojfe.2020.657

National Institute for Occupational Safety and Health – NIOSH 1998: Criteria for a Recommended Standard – Occupational Noise Exposure, Cincinnati.

Nemenyi, P.B., 1963: Distribution-free Multiple Comparisons, Ph.D. thesis, Princeton University, Princeton, NJ.

Norihiro, J., Ackerman, P., Spong, B.D., Längin, D., 2018: Productivity Model for Cut-to-Length Harvester Operation in South African Eucalyptus Pulpwood Plantations. Croatian Journal of Forest Engineering 39(1): 1–13.

Nyarubeli, I.P., Tungu, A.M., Bratveit, M., Sunde, E., Kayumba, A.V., Moen, B.E., 2018: Variability and Determinants of Occupational Noise Exposure Among Iron and Steel Factory Workers in Tanzania. Annals of Work Exposures and Health 62(9): 1109–1122. https://doi.org/10.1093/annweh/wxy071

Obi, O.F., Visser, R., 2018: Including Exogenous Factors in the Evaluation of Harvesting Crew Technical Efficiency using a Multi-Step Data Envelopment Analysis Procedure. Croatian Journal of Forest Engineering 39(2): 153–162.

Oishi, N., Schacht, J., 2011: Emerging treatments for noise-induced hearing loss. Expert Opinion on Emerging Drugs 16(2): 235–245. https://doi.org/10.1517/14728214.2011.552427

Pandur, Z., Šušnjar, M., Bačić, M., 2021: Battery Technology – Use in Forestry. Croatian Journal of Forest Engineering 42(1): 135–148. https://doi.org/10.5552/crojfe.2021.798

Poje, A., Grigolato, S., Potočnik, I., 2019: Operator Exposure to Noise and Whole-Body Vibration in a Fully Mechanised CTL Forest Harvesting System in Karst Terrain. Croatian Journal of Forest Engineering 40(1): 139–150.

Poje, A., Spinelli, R., Magagnotti, N., Mihelič, M., 2015: Exposure to noise in wood chipping operations under the conditions of agro-forestry. International Journal of Industrial Ergonomics 50: 151–157. https://doi.org/10.1016/j.ergon.2015.08.006

Poje, A., Potočnik, I., Danilović, M., Antonić, S., 2016: A Case Study of the Impact of Skidding Distance on Tractor Operator Exposure to Noise. Baltic Forestry 22(2): 357–364.

Portugal 1981: Instituto Português da Qualidade. NP-1733 Anexo 6, Estimativa da exposição ao ruído durante o exercício de uma actividade profissional com vista à protecção da audição, Lisboa.

Potočnik, I., Pentek, T., Poje, A., 2009: Severity Analysis of Accidents in Forest Operations. Croatian Journal of Forest Engineering 30(2): 171–184.

Potočnik, I., Poje, A., 2017: Forestry Ergonomics and Occupational Safety in High Ranking Scientific Journals from 2005–2016. Croatian Journal of Forest Engineering 38(2): 291–310.

Prell, C.G.L., Hackett, T.A., Ramachandran, R., 2020: Noise-induced hearing loss and its prevention: current issues in mammalian hearing. Current Opinion in Physiology 18: 32–36. https://doi.org/10.1016/j.cophys.2020.07.004

Prince, M.M., Stayner, L.T., Smith, R.J., Gilbert, S.J., 1997: A re-examination of risk estimates from the NIOSH Occupational Noise and Hearing Survey (ONHS). The Journal of the Acoustical society of America 101(2): 950–963. https://doi.org/10.1121/1.418053

Proto, A.R., Sperandio, G., Costa, C., Maesano, M., Antonucci, F., Macrì, G., Mugnozza, G.S., Zimbalatti, G.A., 2020: Three-Step Neural Network Artificial Intelligence Modeling Approach for Time, Productivity and Costs Prediction: A Case Study in Italian Forestry. Croatian Journal of Forest Engineering 41(1): 35–47. https://doi.org/10.5552/crojfe.2020.611

R development core team, 2021. R: A language and environment for statistical computing. reference index version 3.3.3. R Foundation for Statistical Computing, Vienna, Austria.

Routa, J., Nuutinen, Y., Asikainen, A., 2020: Productivity in Mechanizing Early Tending in Spruce Seedling Stands. Croatian Journal of Forest Engineering 41(1): 1–11. https://doi.org/10.5552/crojfe.2020.619

Schulz, T., 2011: Individual fit-testing of earplugs: A review of uses. Noise and Health 13(51): 152–162. http://doi:10.4103/1463-1741.77216

Souza, L.H., Fernandes, H.C., Vitória, E.L., 2003: Avaliação do nível de ruído causado por diferentes conjuntos mecanizados. Revista Brasileira de Saúde Ocupacional 28(105/106): 21–30. http://dx.doi.org/10.1590/S0303-76572003000100003

Souza, L.H., Vieira, L.B., Fernandes, H.C., Lima, J.S.S., 2004: Noise levels emitidos por uma recolhedora-trilhadora de feijão. Engenharia Agrícola 24(3): 745–749. https://doi.org/10.1590/S0100-69162004000300027

Soylemez, E., Mujdeci, B., 2020: Dual-task performance and vestibular functions in individuals with noise induced hearing loss. American Journal of Otolaryngology 41(6): 102665. https://doi.org/10.1016/j.amjoto.2020.102665

Spinelli, R., Magagnotti, N., Labelle, E.R., 2020: The Effect of New Silvicultural Trends on the Mental Workload of Harvester Operators. Croatian Journal of Forest Engineering 41(2): 177–190. https://doi.org/10.5552/crojfe.2020.747

Spinelli, R., Marchi, E., 2021: Trends and Perspectives in the Design of Mobile Wood Chippers. Croatian Journal of Forest Engineering 42(1): 25–38. https://doi.org/10.5552/crojfe.2021.787

Straker, L., Mathiassen, S.E., 2009: Increased physical work loads in modern work – a necessity for better health and performance? Ergonomics 52(10): 1215–1225. https://doi.org/10.1080/00140130903039101

Suchomel, J., Belanová, K., Štollmann, V., 2011: Analysis of Occupational Diseases Occurring in Forestry and Wood Processing Industry in Slovakia. Drvna Industrija 62(3): 219–228. https://doi.org/10.5552/drind.2011.1104

Tolosana, E., Laina, R., Ambrosio, Y., Martín, M., 2014: Residual biomass recovery from fully-mechanized delayed thinnings on Spanish Pinus spp. Plantations. Biomass and Bioenergy 71: 98–105. https://doi.org/10.1016/j.biombioe.2014.10.022

Tolosana, E., Spinelli, R., Aminti, G., Laina, R., López-Vicens, I., 2018: Productivity, Efficiency and Environmental Effects of Whole-Tree Harvesting in Spanish Coppice Stands Using a Drive-to-Tree Disc Saw Feller-Buncher. Croatian Journal of Forest Engineering 39(2): 163–172.

Viel, J.A., Rosa, K.K., Mendes Junior, C.W., 2020: Avaliação da Acurácia Vertical dos Modelos Digitais de Elevação SRTM, ALOS World 3D e ASTER GDEM: Um Estudo de Caso no Vale dos Vinhedos, RS – Brasil. Revista Brasileira de Geografia Física 13(5): 2255–2268.

Wallas, A.E., Eriksson, C., Bonamy, A.E., Gruzieva, O., Kull, I., Ögren, M., Pyko, A., Sjöström, M., Pershagen, G., 2019: Traffic noise and other determinants of blood pressure in adolescence. International Journal of Hygiene and Environmental Health 222(5): 824–830. https://doi.org/10.1016/j.ijheh.2019.04.012

Yovi, E.Y., Yamada, Y., 2019: Addressing Occupational Ergonomics Issues in Indonesian Forestry: Laborers, Operators, or Equivalent Workers. Croatian Journal of Forest Engineering 40(2): 351–363. https://doi.org/10.5552/crojfe.2019.558

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors’ addresses:

Diego Aparecido Camargo, MSc

e-mail: diegocamargoflorestal@gmail.com

Rafaele Almeida Munis, MSc

e-mail: rafaele.munis@gmail.com

Prof. Danilo Simões, PhD *

e-mail: danilo.simoes@unesp.br

São Paulo State University (Unesp)

School of Agriculture, Botucatu

3780, Universitária Avenue

Botucatu 18610-034

BRAZIL

Prof. Gislaine Cristina Batistela, PhD

e-mail: gislaine.batistela@unesp.br

São Paulo State University (Unesp)

Campus of Itapeva

519, Geraldo Alckmin Street

Itapeva 18409-010

BRAZIL

* Corresponding author

Received: January 28, 2021

Accepted: October 16, 2021

Original scientific paper