Use of Impact Penetrometer to Determine Changes in Soil Compactness After Entracon Sioux EH30 Timber Harvesting

doi: 10.5552/crojfe.2022.1054

volume: 43, issue:

pp: 13

- Author(s):

-

- Kormanek Mariusz

- Dvořák Jiri

- Article category:

- Original scientific paper

- Keywords:

- impact penetrometer, forest harvester, compactness, forest soil, operational trail

Abstract

HTML

Wood harvesting with the use of wheeled harvesters is now common in Polish and Czech forests. While moving in the forest, the wheels of these machines affect the forest soil and the extent of this impact is interesting. The paper presents the results of measurements of the changes that occur in the soil on the operational trails after the timber harvesting using the Entracon Sioux EH30 thinning harvester. The measurements were taken on fragments of three operational trails, in and between the ruts and at a distance of 1.0 m off the trail. An impact penetrometer was used to measure the penetration resistance, soil samples were collected to determine the bulk density and moisture content, and soil deformations on the trail were measured with a profile meter. Unit pressures exerted by harvester wheels on the ground were determined. It was shown that in the places where the harvester wheels pass, even of a small weight (5.73 tons, 8 wheels) and with unit pressures of the wheels on the ground <50 kPa, changes in soil parameters occurred. A statistically significant increase in penetration resistance in relation to the control occurred at a depth of up to 35 cm, while at a depth of up to 5 cm the increase was more than 2-fold. There was also a slight decrease in soil moisture content (up to 7.9%) and an increase (up to 8.4%) in bulk density in the ruts, while rut depths were small and reached 4 cm. As it was shown, the impact penetrometer, simple in design, which was assumed to be used for measurements, and which is not used in this type of research in forestry, despite its limitations, can be used to determine the compactness of the soil and its changes resulting from machine work.

Use of Impact Penetrometer to Determine Changes in Soil Compactness After Entracon Sioux EH30 Timber Harvesting

Mariusz Kormanek, Jiří Dvořák

Abstract

Wood harvesting with the use of wheeled harvesters is now common in Polish and Czech forests. While moving in the forest, the wheels of these machines affect the forest soil and the extent of this impact is interesting. The paper presents the results of measurements of the changes that occur in the soil on the operational trails after the timber harvesting using the Entracon Sioux EH30 thinning harvester. The measurements were taken on fragments of three operational trails, in and between the ruts and at a distance of 1.0 m off the trail. An impact penetrometer was used to measure the penetration resistance, soil samples were collected to determine the bulk density and moisture content, and soil deformations on the trail were measured with a profile meter. Unit pressures exerted by harvester wheels on the ground were determined. It was shown that in the places where the harvester wheels pass, even of a small weight (5.73 tons, 8 wheels) and with unit pressures of the wheels on the ground <50 kPa, changes in soil parameters occurred. A statistically significant increase in penetration resistance in relation to the control occurred at a depth of up to 35 cm, while at a depth of up to 5 cm the increase was more than 2-fold. There was also a slight decrease in soil moisture content (up to 7.9%) and an increase (up to 8.4%) in bulk density in the ruts, while rut depths were small and reached 4 cm. As it was shown, the impact penetrometer, simple in design, which was assumed to be used for measurements, and which is not used in this type of research in forestry, despite its limitations, can be used to determine the compactness of the soil and its changes resulting from machine work.

Keywords: impact penetrometer, forest harvester, compactness, forest soil, operational trail

1. Introduction

In 2018, 43,932 thousand m3 of net large timber was obtained in Poland, and this value has been constantly increasing over the years (in 1990 it was 17,617 thousand m3, in 2005 – 29,725 thousand m3, in 2010 – 33,568 thousand m3, and in 2015 – 38,327 thousand m3) (CSO 2018). Czechia produced 32.58 mil. m3 in 2019, 25.69 mil. m3 in 2018. The value has an increasing trend for incidental felling caused by bark beetles. The standard annual volume of timber logging is from 15 to 18 mil. m3 (in 1990 it was 13.33 mil. m3, in 2005 – 15.51 mil. m3, in 2010 – 16.74 mil. m3, and in 2015 – 16.16 mil. m3) (MZe 2001, MZe 2006, MZe 2020). Since timber harvesting is usually associated with activities dangerous to humans and difficult to perform, due to high physical loads, the contemporary mechanization of timber harvesting in Polish forests, similarly as in other countries of Eastern Europe, is carried out at a high mechanization level, especially harvesters and forwarders (Moskalik 2002, Moskalik et al. 2017). The first harvesters in Poland appeared in the late 1980s. In 2011, there were 351 harvesters operating in Poland, 365 in 2014, and 530 in 2015 (Mederski et al. 2016, Moskalik et al. 2017). This number of machines allows for estimating machine harvesting in Poland with the use of harvester and forwarder at about 20%, while data from the last two years in some locations indicate higher values exceeding 30% (Moskalik et al. 2017, Bodył 2019). In Czechia, the first cut machine was used in 1977 (Dvořák et al. 2011). The trend of CTL-method performed with/by harvester technology has been increasing since 2005. The share of annual production was 44% in 2019 (Dvořák et al. 2019, Dvořák et al. 2021).

Most of the damage that occurs in mechanized timber harvesting is observed in the soil in the immediate vicinity and directly on the skidding or operational trails (Matthies et al. 1995, Haas et al. 2015). Mixing of the top soil layer, its compaction and displacement in combination with rut compaction can have a negative environmental impact (Cambi et al. 2015, Haas et al. 2015, Solgi et al. 2019). Many authors indicate that soil degradation, as a result of machine harvesting, can significantly affect both the quality of growing trees and the deterioration of forest health (Ulrich et al. 2003, Murphy 2004, Ampoorter et al. 2007, Malík and Dvořák 2007). According to the literature, the resulting damage can affect the growth of trees up to 15 m on both sides of the skidding trail (Matthies et al 1995). Apart from abiotic factors, such as change of access to light, nutrients and water, this decrease is caused by factors related to soil physics, including compaction, i.e., excessive soil compactness caused by passing machines (Sack 2004, Blouin et al. 2008, Bejarano et al. 2010, Perez-Ramos et al. 2010, Alameda et al. 2012). This is because the compaction increases the volumetric density and reduces the size of free spaces, i.e., the porosity of the soil, which reduces air content and water permeability. The soil loses the possibility of infiltration and the storage of precipitation water is difficult, which causes rapid water run-off and soil erosion (Blouin et al. 2008, Bejorano et al. 2010, Jourgholami et al. 2018, Ring et al. 2021). Penetration resistance is the measure of soil compaction, and it is used in many areas of the economy such as civil engineering, agriculture and forestry (Kremer et al. 2007, Wang 2009, Picchio et al. 2011, Byun et al. 2016). Soil penetration resistance is defined as the resistance of the soil against the pressing of a standardized penetrometric cone into it. Measurement of soil penetration resistance, especially in inaccessible difficult forest conditions, is quite difficult (Harrick and Jones 2002, Kormanek and Lasota 2014, Kormanek and Gołąb 2021).

The penetration resistance depends primarily on the granulometric composition and soil moisture (ASAB 1998, Harrick and Jones 2002, Kees 2005, De Moraes 2014). The soil penetration resistance parameter can characterize the soil and its current state, as well as indicate what changes in the soil occurred under the influence of external factors (Kleibl et al. 2014, Cambi et al. 2016, Venanzi et al. 2019, Picchio et al. 2020, Venanzi et al. 2020). The penetration resistance measurement is carried out with penetrometers of different structures. Static cone penetrometers are most often used, and the cone is pressed into the soil by a constant force with a constant speed of penetration. This type of penetrometer developed by U.S. Army Corps of Engineers WES (Waterways Experiment Station) is widely used in agriculture, however, it has many limitations (Harrick and Jones 2002, Wang 2009). Usually, simple penetrometers are designed for a limited range of compactness, and instruments with manual drive equipped with electronic measuring sensors are relatively expensive and do not guarantee correct measurement. This involves a change in the speed of cone penetration in the soil, caused by the operator and the variable compactness of the soil layers. A way to eliminate this problem is to use, for example, a mechanical drive that causes the penetrometer cone to be introduced at a constant controlled speed (Minasny 2012, Sharifi and Mohsenimanesh 2012). The application of such solutions limits the costs of device manufacturing and measurements connected with the transport of the device, power supply, etc. (Harrick and Jones 2002). Separate solutions are dynamic penetrometers that have no problem with a constant speed of penetration of the cone in the soil, or with creating constant force acting on the cone. Penetrometers of this type transmit a certain constant amount of kinetic energy to the indenter so that it covers a certain distance in the soil. Currently available impact penetrometers usually contain something that falls into the soil from a certain height or where an element (usually a cone) is plunged into the soil by a suddenly striking element (Herrick and Jones 2002, Jones and Kunze 2004, Vangs et al. 2004, Vaz et al. 2011, Byun at al. 2016). Impact penetrometers are mainly used in civile engineering and in agriculture, and there are not many studies related to forestry. It would be interesting to establish whether the use of the impact penetrometer would allow determining the changes of compactness of soil caused by the passing machines in forest conditions.

The aim of the study was to determine the changes in soil compactness after the work with Entracon Sioux EH30 harvester. The penetration resistance was assumed to be determined with the use of a simple impact penetrometer made on the basis of the design proposed by Herrick and Jones (2002).

2. Materials and Methods

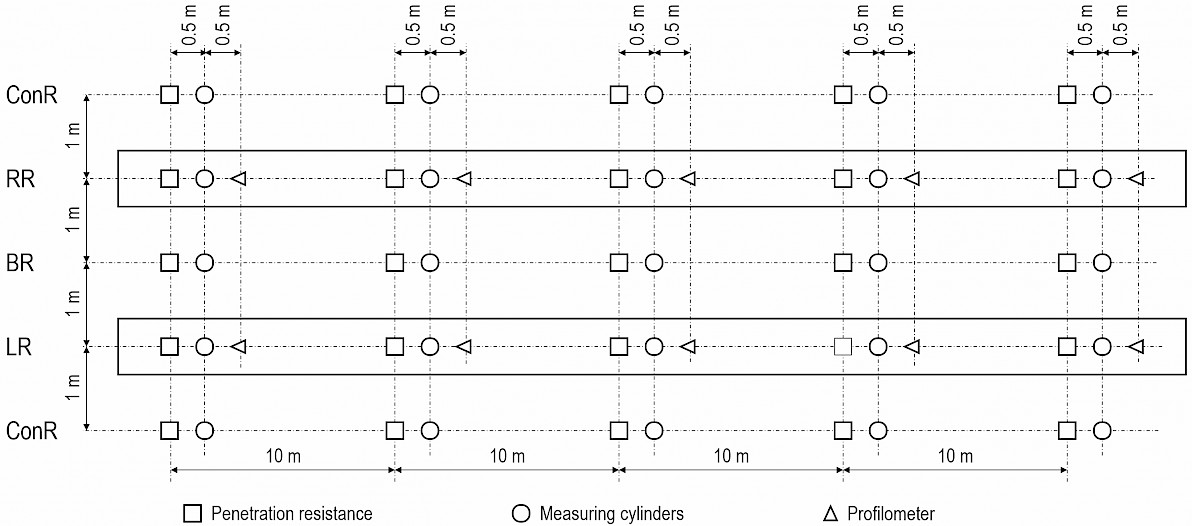

The measurements were made in Gołąb Forest District (51.488536, 21.876177), Puławy Forest Division, Regional Directorate of State Forests Lublin (Tab. 1). At the study site, the harvester made an early positive thinning and moved along 11 operating routes located every 20 meters, which were cut down in the course of the passage. Trees beyond the reach of the machine crane were cut down by a sawyer. A total of 190.49 m3 of timber was acquired on the surface, in the form of 1.5 meter long rolls. The timber harvesting was made with the Entracon Sioux EH30 thinning harvester from 1998, with the Keto Forest Eco head (Fig. 1, Table 2). After the work was carried out by the harvester, five measurements were taken with a penetrometer to a depth of 50 cm and five measuring cylinders (volume Vc – 250 cm3, height 7 cm, diameter 6.8 cm) from a depth of up to 10 cm were taken on fragments of three operational trails (OT1, OT2, OT3), as shown in Fig. 2, between the ruts (BR), in the left (LR) and right rut (RR) and at a distance of 1.0 m from the left (ContL) and right rut (ContR). The shape of the left (LR) and right (RR) rut was mapped using a bar profile meter. A total of 75 cylinders were collected (3 trails × 5 uptake sites × 5 replicates), and 75 penetrometer measurements were made (3 lanes × 5 uptake sites × 5 replicates) as shown in Fig. 2.

Table 1 Data on study site

|

Separation area |

8.3 ha |

|

Species composition |

100% Pinus sylvestris L., single Betula pendula Roth |

|

Stand, age |

Plantation, post-arable area, 44 years old |

|

Diameter at breast height, height, growing stock |

14 cm; 14 m; 212 m3∙ha-1 |

|

Forest habitat type, variant, |

Fresh coniferous forest FCF, fresh |

|

Area |

Flat, even, no growth or natural renewal. Single shrubs Juniperus communis L., and sparse Frangula alnus Mill. and Padus serotina (Ehrh.) Borkch in the undergrowth. Groundcover composed of abundant mosses |

|

Soil |

Arenosol with loose sand granulation |

Fig. 1 Entracon Sioux EH30 harvester at test site OT1 (photo by P. Sowa)

Table 2 Basic technical data of the harvester (Advertising materials 1998)

|

Specification |

Unit |

Value |

|

Harvester with crane Entracon Sioux EH30 |

||

|

Engine power (Kubota V3600) |

kW |

54.5 |

|

Weight with cabin/Maximum speed |

kg/km h-1 |

5450/22 |

|

Height/Width/Length/Clearance |

m |

2.7/1.8/7.2/0.56 |

|

Pressure in hydrostatic drive system |

MPa |

18 |

|

Hydraulic motor drive capacity 2 x MS 05 front/rear |

cm3 |

370/750 |

|

Unit pressure on the ground |

kPa |

43.2 |

|

Tires |

– |

400/60-15.5 14 PR |

|

Crane Mowi P30 |

||

|

Load capacity/Angle of column rotation/Max. crane reach |

kN/˚/m |

29/360/5.6 |

|

Harvester head Keto Forest Eco |

||

|

Cutting/Trimming diameter |

m |

0.30/0.34 |

|

Weight/Feed force/Feed speed |

kg/kN/ms-1 |

280/10/5 |

Fig. 2 Scheme of measurements performed on a single operational route

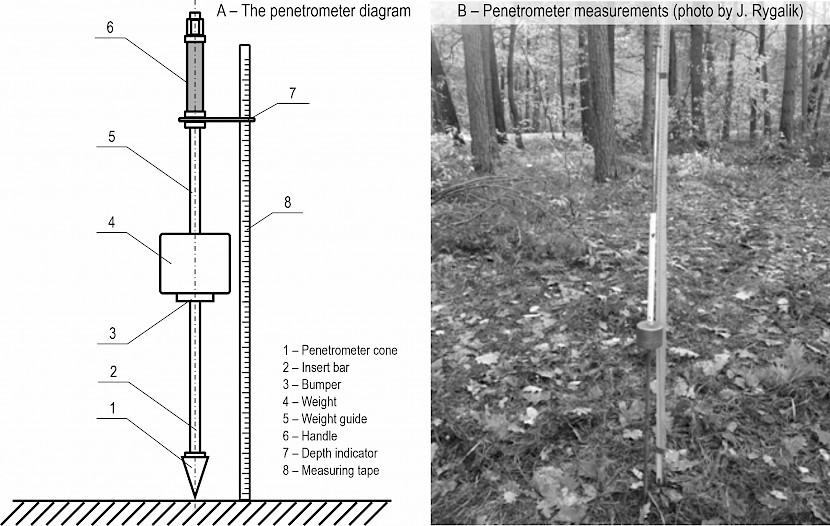

The penetration resistance PR was determined using a simple impact penetrometer (Fig. 3), made according to Harrick and Jones (2002). In this device, the recessing of cone 1, attached to the insert bar 2, is caused by a free-falling weight 4, after guide 5, which hits bumper 3. The measurement consists in repeatedly lifting weight 4 by hand and lowering it on guide 5, holding the penetrometer by the handle 6. During the gradual recessing of the cone in the soil, the distance between the ground level and the indicator 7 on the penetrometer was each time measured with a linear gauge 8 with ±1 mm. The penetrometer was equipped with a standardized cone with base diameter D=2.03 cm and opening angle α=30˚ (ASAE Standards 1998, Harrick and Jones 2002). The mass of the penetrometer without weight m’=4.5 kg, the weight m=2 kg and the height of weight falling H=0.4 m. Soil compactness determined by this type of penetrometer is the average compactness over the length of cone movement in the soil for successive weight falls.

Fig. 3 Conical impact penetrometer

The value of penetration resistance is influenced by the force of soil interaction with penetrometer indenter 1, the so-called soil resistance Rs, which causes the slowing down of penetrometer movement from the initial value resulting from the impact of falling weight 3 by bumper 6, to the speed equal to 0 m x s-1. Soil resistance Rs was calculated from equation (1) as the quotient of the work done by the soil Ws to stop the movement of the penetrometer and the distance Pd on which the penetrometer was moving (Harrick and Jones 2002). The work Ws was calculated as a conversion of the kinetic energy of the penetrometer Ek, which is transformed into the motion of the penetrometer when it moves in the soil as a result of a weight operation. The calculation assumes that all kinetic energy is transferred to the cone when weight 3 hits the bumper of penetrometer 6, and when the penetrometer stops in the soil, kinetic energy Ek=0 J.

(1)

(1)

Where:

Rs soil resistance, N

Ws soil work, J

Pd distance in the soil where the cone-ended penetrometer moves, m.

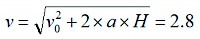

Knowing the distance H over which the weight m falls, the speed of the weight when it strikes the bumper was calculated (2). For the penetrometer used, with an initial speed of v0=0 m x s-1 and an acceleration a equal to acceleration of gravity g=9.81 m x s-1, the speed at the moment of hitting the bumper was calculated from equation (2) – Harrick and Jones (2002).

(2)

(2)

Where:

v final speed, m x s-1

v0 initial speed, m x s-1

a acceleration, equal to acceleration of gravity g, m x s-2

H height from which the weight falls, m.

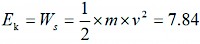

The kinetic energy at the initial speed v, and the mass of weight m=2 kg, was calculated according to equation (3) – Harrick and Jones (2002), while substituting the result to equation (1) at a known depth of penetration of the cone Pd after hitting the bumper, and taking into account the mass of the penetrometer without the weight m’, for which part of the kinetic energy is used, the soil resistance Rs (4) was calculated (Vanags et al. 2004, Sun et al. 2011). By dividing the soil resistance Rs by the cone base area A=3.24 cm2, with a diameter of 2.03 cm (0.8’’), the soil compactness penetration resistance PR (5) was calculated (Harrick and Jones 2002).

(3)

(3)

(4)

(4)

(5)

(5)

Where:

Ek kinetic energy of falling weight with a mass m, kg x m2 x s-2

m mass of weight, kg

m' mass of penetrometer without weight, kg

PR soil penetration resistance, Pa

A penetrometer cone base surface, m2.

The soil samples taken into the cylinders were used to determine the bulk density (6) and the soil moisture content by weight (7) (Myślińska 1998).

(6)

(6)

(7)

(7)

Where:

BD bulk density, kg x m-3

w moisture content by weight, kg x kg-1

ma cylinder weight after collection, kg

md cylinder weight after drying, kg

mc empty cylinder weight, kg

Vc cylinder volume, m-3.

The maximum depth of ruts after the machine passing through was determined on the basis of the rut profile made with a bar profile meter (distance between bars 2.5 cm) (30 measurements 2 ruts × 3 trails × 5 repetitions). After the calculation of the compactness at particular depths, the obtained values were averaged for particular routes (OT1; OT2; OT3) and measurement points (ContL; LR; BR; RR; ContR) at the assumed levels: p1: 0–5 cm; p2: 5.5–10 cm; p3: 10.5–15 cm; p4: 15.5–20 cm; p5: 20.5–25 cm; p6: 25.5–30 cm; p7: 30.5–35; p8: 35.5–40; p9: 40.5–45 cm; p10: 45.5–50 cm. The harvester characteristics were supplemented by determining the changes in the value of the average static unit pressure gp (8) that the machine wheels exert on the ground depending on the direction and degree of extension of the crane with head. The measurements were taken with the crane extending forward, along the axis and at an angle of 90° to the machine axis in three variants: min, max and half of the crane reach.

(8)

(8)

Where:

gp unit ground pressure, Pa

G vertical load, N

S tire-ground contact area, m2.

The vertical load G on the harvester wheels was determined in the field, using a hydraulic scale with a measuring range of up to 90 kN ± 0.5 kN, which was placed under the front and rear drive axle. The loads were converted to the center of the wheel on the basis of the machine wheels width and the place where the scale was set up. The surface S of the wheel influence on the ground was based on the dimensions of the tires, from equation (9) (McKyes 1995).

(9)

(9)

Where:

SA tire-ground contact area, m2

W tire width on harvester wheel, m

D harvester wheel diameter, m.

After checking the normality of the data and the homogeneity of variance using the analysis of variance taking into account the main effects, the mean values of penetration resistance, bulk density and moisture content were compared with respect to the site of measurement (ContL, LR, BR, RR, ContR) and with respect to the trail on which the measurements were made (OT1-3). This was followed by Fisher's least significant difference (LSD) test to distinguish homogeneous groups for the values of penetration resistance, bulk density and moisture content at particular depth levels, depending on the place of measurement. For illustrating the changes in the increase of penetration resistance in relation to the control with depth of measurement, a regression analysis was performed. The calculations were made using the Statistica 11 software (StatSoft 2006).

3. Results

Since the analysis of variance did not show (Tab. 3) any variation in the values of penetration resistance, bulk density and moisture content between the trails (OR1-3), the results were combined for further analyses without distinguishing between the routes.

Table 3 Analysis of variance of penetration resistance, bulk density and moisture content depending on trail and measurement site

|

Factor |

Differences significant at p<0.05 “*” and p<0.01 “**” |

|||||

|

Penetration resistance – PR, Pa |

Moisture content – w, kg x kg-1 |

Bulk density – BD, kg x m-3 |

||||

|

F |

p |

F |

p |

F |

p |

|

|

Operational trail |

2.80 |

0.061 |

0.231 |

0.794 |

0.19 |

0.824 |

|

Measurement point |

36.89 |

0.000** |

3.121 |

0.02* |

10.91 |

0.000** |

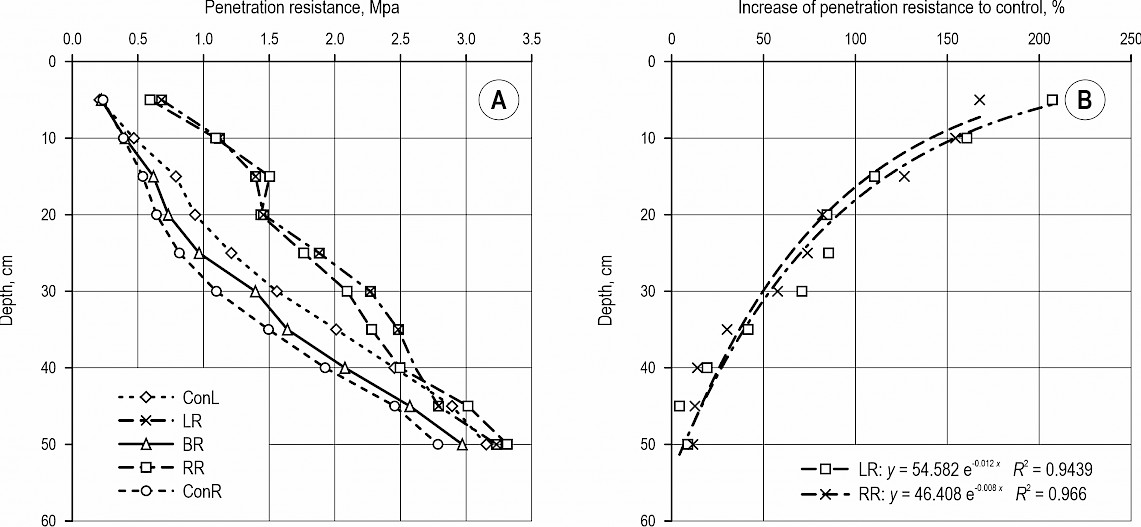

The compactness represented by PR at depth levels from p1 to p5, which corresponds to a depth of up to 25 cm, was higher in the ruts compared to the compactness next to and between ruts (Tab. 5, Fig. 4). This increase in relation to the control was particularly pronounced in the layer up to 15 cm, where for the right rut (RR) it had values from 110% to 207% and for the left LR from 126% to 168% (regression line for LR: F=97.21, p=0.000 and for RL: F=133.0, p=0.000). The differences in compactness were not visible above the depth of 35 cm (Tab. 4 and Fig. 4).

Table 4 Analysis of variance of compactness depending on depth

|

Level |

Depth, cm |

Compactness PR, MPa – Differences significant at p<0.05 “*” and p<0.01 “**” |

||||

|

ContL |

LR |

BR |

RR |

ContR |

||

|

p1** |

0.0–5 |

0.21±0.05a |

0.68±0.43c |

0.22±0.05a |

0.59±0.31b |

0.23±0.01a |

|

p2** |

5.5–10 |

0.47±0.15a |

1.23±0.65b |

0.40±0.22a |

1.09±0.50b |

0.39±0.06a |

|

p3** |

10.5–15 |

0.79±0.46a |

1.40±0.61b |

0.62±0.17a |

1.50±0.92b |

0.54±0.06a |

|

p4** |

15.5–20 |

0.94±0.39c |

1.46±1.02b |

0.73±0.23a |

1.44±0.54b |

0.64±0.07a |

|

p5** |

20.5–25 |

1.21±0.44c |

1.88±1.03b |

0.97±0.30a |

1.76±0.73b |

0.82±0.11a |

|

p6* |

25.5–30 |

1.56±0.56b |

2.27±0.63bc |

1.39±0.79ab |

2.09±1.31c |

1.10±0.19a |

|

p7* |

30.5–35 |

2.01±0.72b |

2.48±1.64ac |

1.64±0.48a |

2.28±0.75bc |

1.50±0.21a |

|

p8 |

35.5–40 |

2.45±0.58 |

2.61±0.81 |

2.08±0.52 |

2.50±0.69 |

1.93±0.20 |

|

p9 |

40.5–45 |

2.89±0.75 |

2.79±1.15 |

2.57±0.61 |

3.01±1.83 |

2.46±0.60 |

|

p10 |

45.5–50 |

3.15±0.78 |

3.23±1.24 |

2.97±1.07 |

3.31±1.63 |

2.79±0.46 |

|

Designations: ContL – to the left of the left rut, LR – left rut, BR – between ruts, RR – right rut, ContR – to the rightof the right rut, abcd – denote separate groups |

||||||

Moisture content by weight was relatively low during the study (Tab. 5). There was a slight but statistically significant decrease in the value of moisture in ruts in relation to the control (7.9% for LR and 3.0% for RR), and an increase in bulk density in relation to the control (8.4% for LR and 4.1% for RR). Static unit pressures exerted by the machine, regardless of the direction and degree of crane extension, were low and did not exceed 50 kPa in any of the measuring variants (Tab. 6). It should be noted that during the work of the machine, the pressures will be higher due to the additional weight coming from the processed load and forces resulting from the movement of the working elements of the machine and the load; however, despite this, the maximum depths of the ruts at the points where the machine passes on the operational trails were small and did not exceed 4 cm (Tab. 7, Fig.1).

Fig. 4 Soil penetration resistance depending on measurement location – A, increase of soil penetration resistance in ruts in relation to the control – B

Table 5 Moisture content by weight and bulk density for all analyzed trails depending on location of soil samples collection

|

Moisture content w, %% – Differences significant at p<0.05 |

||||

|

ContL |

LR |

BR |

RR |

ContR |

|

25.12±2.34a |

23.27±1.24b |

23.54±1.48a |

22.85±1.14b |

24.23±1.68a |

|

Bulk density BD (g x cm-3) – Differences significant at p<0.01 |

||||

|

1.20±0.03a |

1.23±0.07b |

1.23±0.04a |

1.29±0.06b |

1.19±0.01a |

Table 6 Unit pressures exerted by wheels on ground in different crane positions

|

Direction of extension |

Degree of crane extension |

Machine segment |

Unit pressure gp, kPa |

||

|

Left wheel |

Right wheel |

Average |

|||

|

Right side of machine 90° |

Min (folded) |

Front/ rear |

34.6/40.0 |

33.5/38.9 |

34.0/39.5 |

|

Half |

32.9/43.8 |

31.3/39.5 |

32.1/41.7 |

||

|

Max |

31.8/47.1 |

28.0/41.1 |

29.9/44.1 |

||

|

Forward of machine 0° |

Min (folded) |

Front/ rear |

35.1/38.9 |

||

|

Half |

33.5/41.1 |

||||

|

Max |

29.1/44.9 |

||||

Table 7 Maximum depth of ruts on particular routes

|

OT1 |

OT2 |

OT3 |

|||

|

LR |

RR |

LR |

RR |

LR |

RR |

|

3.92±0.30 |

2.48±0.17 |

3.28±0.33 |

3.66±0.43 |

3.24±0.40 |

3.52±0.66 |

|

Designations: OT1-3 – operational trails, ContL – to the left of the left rut, LR – left rut, BR – between ruts, RR – right rut, ContR – to the rightof the right rut, abcd – denote separate groups |

|||||

4. Discussion

As indicated by the measurement results (Tab. 3–5, Fig. 4), a single harvester passage affected the measured soil parameters. It may have had a significant impact in the case that, although the machine had a small weight (only 5.73 tons) and a wheeled chassis, which exerted low unit pressures on the ground (less than 50 kPa), many wheels (an 8-wheeled machine) passed one after another, causing multiple pressures (Kremer et al. 2007, Cudzik et al. 2010, Kormanek and Dvořák 2021). It is still a problem when designing forest machines to choose between a chassis with fewer wheels that exert higher unit pressure, and more wheels that exert lower unit pressure (Cambi at al. 2015). Compaction is affected by a lot of factors, not only by the methods of forest operations and technical parameters of harvesters (type of chassis, weight of machine, load and number of passes) but also by soil type, slope steepness and other, or by the applied surface protection, i.e by using logging residues, logging mats or sawdust mulch (Piccio et al. 2011, Majnounian and Jourgholami 2013, Pohořalý et al. 2014, Naghdi et al. 2017, Jourgoholami et al. 2018, Kormanek and Dvořák 2021, Ring et al. 2021). As indicated by the results, the significant increase in compactness represented by PR in the ruts in relation to the control reached the depth of 35 cm, while at the depth of up to 5 cm, the increase in compactness was more than 2 fold. This is in line with the literature that indicates that the impact on soils is highest to the depth 0–10 cm (Ampoorter et al. 2012), and forest soil is compacted to the depth of at least 45 cm, even when carrying out various technological measures (eg. leaving branches) (Hutchings et al. 2006). In research conducted by Varol at al. (2020), soil compaction values, caused by four-wheeled small-scale logging equipment attached to an ATV (all-terrain vehicle), increased three times higher at the depths of between 0 cm and 5 cm and four times between 15 cm and 40 cm than at the depth of 0 cm (top soil). The changes in the soil after the machine passed, although to a lesser extent, also reflected an increase in bulk density BD (up to 8.4%) and a decrease in moisture content by weight w (up to 7.9%) in relation to the control or the shallow ruts compacted (up to 4 cm). A similar increase in bulk density was reported by Majnourani and Jourgholami (2013) after the first ride of the Timberjack 450C skidder, and a rut depth of up to 50 mm for low soil moisture of 20–30% (Jourgholami and Majnounian 2011). These changes may be significant for the environment, since, as the literature indicates, an increase in soil compactness may affect the difficult growth of trees on the surface of operational routes as well as worse development of their root systems (Harrick and Jones 2002, Moreas et al. 2014). In turn, the passage of machines, depending on the type of chassis, may cause damage to the roots by crushing them, peeling them off the bark or breaking them (Kremer et al. 2007). A significant effect of excessive soil compactness caused by machines is also noted in case of forest renewal (Bartholomew and Williams 2010, Kormanek et al. 2015ab, Tadeusiewicz et al. 2017). Soil changes can be long lasting. Venanzi et al. (2019, 2020) indicate on the basis of research that the physical, chemical and biological soil features strongly impacted by harvesting operations last for at least 36 months, and in some cases they last up to 25 years (Sohrabi at al.2020). Also, as pointed out by Picchio et al. (2020), in any cases of changes in soil properties, it is worth noticing whether soil regeneration takes place, and if not, a reclamation process can be put in place to return the soil to the pre-harvest state. Therefore, the selection of the machine is so important, and this should be first of all justified by the type and size of the work to be carried out (type and size of the machine), but also by the conditions under which the work will be carried out (type of soil, terrain, meteorological conditions), which affects the type and characteristics of the chassis used (Kremer et al. 2007, Sakai et al. 2008, Visser and Stampfer 2015, Kulak et al. 2019, Kormanek and Dvořák 2021, Kormanek and Gołąb 2021). In the present research, the working conditions of the machine were undoubtedly favorable, and the occurrence of shallow ruts, apart from low unit pressures, could also be influenced by the rich fleece, i.e. moss and grain that made arenosol soil. The use of the Entracon Sioux EH30 harvester for thinning works in the present study was undoubtedly beneficial, and the impact on the forest environment, despite the recorded changes in the soil and on the surface of the area, was relatively small.

As is well known, measuring instruments such as the penetrometer, used to determine the soil changes that occur after the machine passes, are often complicated and expensive (Harrick and Jones 2002, Kees 2005). The measurements with static penetrometers without a drive require the use of force, which can be difficult with many measurements and with high soil compactness or on skeletal soils. Also keeping a constant speed of introducing a cone into the soil may pose a problem in manually operated static penetrometers. According to the standard, it is recommended that the soil penetration speed should be constant and should be about 3 cm x s-1, and as the literature indicates, a significant deviation from this value may influence the obtained measurement results (ASAE Standards 1998). The use of portable static penetrometers without this problem, e.g. with electric drive, is troublesome due to the need for power supply, which is particularly burdensome in difficult conditions, e.g. mountains, when making a large number of measurements implies the transport of usually heavy power supply battery. On the other hand, the drive of another type, e.g. hydraulic drive, which is most often made from the hydraulic system of an agricultural tractor, does not allow for the use of the device in the field, which the drive source cannot reach (Kees 2005). When using a portable hydraulic drive, problems related to devices with electric drive may occur. An alternative to these penetrometers is the use of an impact penetrometer presented in the paper (Harrick and Jones 2002, Kees 2005, Mohammadi et al. 2008). The use of this solution in soil sciences was presented for the first time by Parker and Jenny in 1945 (Vangas et al. 2004). It is a device of simple design and use and inexpensive in manufacturing (Vanags et al. 2004, Kees 2005). It is also a device with no problems with operation, change of force on the cone and speed stability, which is not dependent on the operator’s physical vigor. In this type of device, the operator has little influence on the measurement itself, since the penetration of the cone into the soil is dependent on the free fall of the weight. The measuring range of the device is relatively wide because it is possible to change the sensitivity of the device by selecting the weight and height of the weight fall and size of the cone. The wide measuring range allows the device to be used on a variety of soils, even skeletal soils, where the use of static instruments is not possible or is very limited. For many years, it was discussion in the literature how to calculate the compactness of soil defined by this type of device. There were doubts about the mathematical formulas used to calculate the measurement results and as to how these results relate to the values of the compactness determined by static devices, which would make it possible to compare the results obtained by different types of devices (Stolf at al. 2005, Sun et al. 2011, Vaz et al. 2011, Minasny 2012). It is also a problem that the obtained compactness result is an average value at the depth of the cone movement, and that it is impossible to record the compactness between successive points of the cone movement in simple devices of this type. The time of measuring with the device is also long due to the need to hit the bumper of the device many times, and it is even longer when taking measurements on more compact soil, because the movement of the cone to the assumed measuring depth is slower. The impact of the cone on the soil during the measurements is also doubtful (Kees 2005, Kormanek and Lasota 2014). Despite these problems, the presented measurement results indicate that it is possible to make measurements using this simple device and to determine the changes in compactness that occur in the soil as a result of the machine passing through. Completion of the penetrometer measurements with the analysis of the collected soil samples and the use of a bar profile meter made it possible to determine the basic characteristics of the harvester influence on the change of physical parameters of the soil and changes on the ground surface.

5. Conclusions

The single passage of the small Entracon Sioux EH30 thinning harvester, weighing 5.73 tons and less than 50 kPa of static ground unit pressures exerted by the machine wheels, resulted in relatively small changes in soil compactness represented by penetration resistance, moisture content, bulk density and ground deformation. Small ruts of up to 4 cm deep were formed in the place where the machine wheels passed, and compared to the control areas, there was a significant increase in soil penetration resistance at a depth of up to 35 cm, which at the soil surface (up to 5 cm) was over 2 times higher. There was also a slight decrease in moisture content to 7.9% and an increase in bulk density to 8.4% at a depth of up to 10 cm. The impact penetrometer applied in the research is a device of simple design and operation and also reliable. The weight of the device is relatively low, the range of operation is wide and the way the operator performs the measurement has a marginal impact on the results obtained. For a single fall of the weight, the device determines the mean compactness at the depth of the penetrometer cone, the time of taking the measurement. As it was shown, the impact penetrometer which was assumed to be used for measurements, and which has not been used in this type of research in forestry, despite its limitations, can be used to determine the compactness of the soil and its changes resulting from machine work.

Acknowledgments

The work was financed from the funds of the Ministry of Science and Higher Education allocated to the statutory activities of the University of Agriculture in Krakow and also supported by the Polish National Agency for Academic Exchange from Poland and Ministries of Education Youth and Sports from Czech Republic under the projects PPN/BCZ/2019/1/00013 (Poland) and 8J20PL062 (Czech Republic) »Analysis of the Impact of Harvester Technology on Forest Ecosystem Depending on Work Performance«, run by University of Agriculture in Krakow and Czech University of Life Sciences Prague.

Thank to eng. Andrzej Krzyżanowski who helped with data collection.

6. References

Advertising materials, 1998: Advertising materials of harwester Entracon Sioux EH30 https://entracon.cz/en/harvestory/ (accessed 01.06.2020).

Alameda, D., Anten, N.P.R., Villar, R., 2012: Soil compaction effects on growth and root traits of tobacco depend on light, water regime and mechanical stress. Soil and Tillage Research 120: 121–129. https://doi.org/10.1016/j.still.2011.11.013

Ampoorter, E., Goris, R., Cornelis, W.M., Verheyen, K., 2007: Impact of mechanized logging on compaction status of sandy forest soils. Forest Ecology and Management 241(1–3): 162–174. https://doi.org/10.1016/j.foreco.2007.01.019

Ampoorter, E., Schijver A.D, Nevel, L.V., Hermy, M., Verheyen, K., 2012: Impact of Mechanized Harvesting on Compaction of Sandy and Clayey Forest Soils: Results of a Meta-analysis. Annals of Forest Science 69(5): 533–542. https://doi.org/10.1007/s13595-012-0199-y

ASAE, 1998: Soil Cone Penetrometer. ASAE Standards, 820–821.

Bartholomew, P.W., Williams, R.D., 2010: Effects of soil bulk density and strength on seedling growth of annual ryegrass and tall fescue in controlled environment. Grass and Forage Science 65(3): 348–357. https://doi.org/10.1111/j.1365-2494.2010.00753.x

Bejarano, M.D., Villar, R., Murillo, A.M., Quero, J.L., 2012: Effects of soil compaction and light on growth of Quercus pyrenaica Willd. (Fagaceae) seedlings. Soil and Tillage Research 110(1): 108–114. https://doi.org/10.1016/j.still.2010.07.008

Blouin, V.M., Schmidt, M.G., Bulmer, C.E., Krzic, M., 2008: Effects of compaction and water content on lodgepole pine sidling growth. Forest Ecology and Management 255(7): 2444–2452. https://doi.org/10.1016/j.foreco.2008.01.008

Bodył, M., 2019: Rozmiar pozyskania maszynowego w Polsce. Drwal 3: 5–9.

Byun, Y.H., Hong, W.T., Lee, J.S., 2016: Application of dynamic and static cone penetrometer for characterization of railway substructure. Japanese Geotechnical Society Special Publication 46(2): 1628–1631. https://doi.org/10.3208/jgssp.KOR-39

Cambi, M., Certini, G., Neri, F., Marchi, E., 2015: The impact of heavy traffic on forest soils: a review. Forest Ecology and Management 338: 124–138. https://doi.org/10.1016/j.foreco.2014.11.022

CSO, 2019: Rocznik statystyczny leśnictwo w Polsce. Statistical Yearbook of Forestry Zakład Wydawnictw statystycznych. Warszawa. Statistics Poland ISSN 2657-3199, 1–57.

Cudzik, A., Białczyk, J., Czarnecki, J., Jamrozy, K., 2010: Traction properties of the wheel-turfy soil system. International Agrophysics 24(4): 343–350.

De Moraes, M.T., Da Silva, W.R., Zwirtes, A.L., Carlesso, R., 2014: Use of penetrometers in agriculture: a review. Eng. Agric. 34(1): 179–193. https://doi.org/10.1590/S0100-69162014000100019

Dvořák, J., Jankovský, M., Chytrý, M., Nuhlíček, O., Natov, P., Kormanek, M., Löwe, R., 2021: Operational Costs of Mid-Performance Forwarders in Czech Forest Bioeconomy. Forests 12(4): 435. https://doi.org/10.3390/f12040435

Dvořák, J., Chytrý, M., Natov, P., Jankovský, M., Beljan K., 2019: Long-term Costs Analysis of Mid-performance Harvesters in Czech Conditions. Austrian Journal of Forest Science 136(4): 351–372.

Dvořák, J., Bystrický, R., Hrib, M., Hošková, P., Jarkovská, M., Kováč, J., Krilek, J., Natov, P., Natovová, L., 2011: The Use of Harvester Technology in Production Forests. Kostelec nad Černými lesy: Lesnická Práce s.r.o., 1–156.

Haas, J., Schack-Kirchner, H., Lang F., 2015: Gleisbildung bei der Befahrung mit Forwardern. Forst & Technik 2: 20–24.

Herrick, J.E., Jones, T.L., 2002: A dynamic cone penetrometer for measuring soil penetration resistance. Soil Sci. Soc. Am. J. 66(7–8): 1320–1324. https://doi.org/10.2136/sssaj2002.1320

Hutchings, T., Moffat, A., French, C.J., 2006: Soil Compaction under Timber Harvesting Machinery: A Preminary Report on the Role of Brash Mats in its Prevention. Soil Use and Management 18(1): 34–38. https://doi.org/10.1111/j.1475-2743.2002.tb00047.x

Jones, D., Kunze, M., 2004: Guide to sampling soil compaction using hand- held soil penetrometers. Center for Environmental Management of Military Lands (CEMML), Colorado State University, 1–8.

Jourgholami, M., Khajavi, S., Labelle, E.R., 2018: Mulching and water diversion structures on skid trails: Response of soil physical properties six years after harvesting. Ecological Engineering 123: 1–9. https://doi.org/10.1016/j.ecoleng.2018.08.023

Jourgholami, M., Majnounian, B., 2011: Effects of wheeled cable skidder on rut formation in skid trail – a case study in Hyrcanian forest. Journal of Forestry Research 22(3): 465−469. https://doi.org/10.1007/s11676-011-0112-9

Kees, G., 2005: Hand-held electronic cone penetrometers for measuring soil strength. Tech. Rep. 0524–2837–MTDC. Missoula, MT: U.S. Department of Agriculture Forest Service, Missoula Technology and Development Center, 1–12.

Kleibl, M., Klvac, R., Lombardini, C., Porhaly, J., Spinelli, R., 2014: Soil compaction and recovery after mechanized final felling of Italian coastal Pine Plantations. Croat. J. For. Eng 35(1): 63–71.

Kormanek, M., Banach, J., Sowa, P., 2015a: Effect of soil bulk density on forest tree seedlings. Int. Agrophys. 29(1): 67–74. https://doi.org/10.1515/intag-2015-0003

Kormanek, M., Głąb, T., Banach, J., Szewczyk, G., 2015b: Effects of soil bulk density on sessile oak Quercus petraea Liebl. seedlings. Eur. J. Forest. Res. 134: 969–979. https://doi.org/10.1007/s10342-015-0902-2

Kormanek, M., Dvořák, J., 2021: Ground Pressure Changes Caused by MHT 8002HV Crawler Harvester Chassis. Croat. j. for. eng. 42(2): 201–211. https://doi.org/10.5552/crojfe.2021.844

Kormanek, M., Gołąb, J., 2021: Analysis of Surface Deformation and Physical and Mechanical Parameters of Soils on Selected Skid Trails in the Gorce National Park. Forests 12(6): 797. https://doi.org/10.3390/f12060797

Kormanek, M., Lasota, J., 2014: Soil compaction studies of selected forest habitats using the dynamic cone penetrometer. In: Trendy lesníckej a environmentálnej techniky a jej aplikácie vo výrobnom procese. TU Zvolen, 48–56.

Kremer, J., Matthies, D., Borchert, H., 2007: The impact of different carriages on soil and roots – wheels and tracks in comparison. »Meeting the Needs of Tomorrows' Forests: New Developments in Forest Engineering« AUSTRO 2007 & 40th International Symposium on Forestry Mechanisation (FORMEC'07), October 7–11, Wien–Heiligenkreuzl, Austria, 1–9.

Kulak, D., Stańczykiewicz, A., Szewczyk, G., 2019: Disturbance to outer soil layers depending on the season of timber harvesting. Baltic Forestry 25(2): 289–295.

Majnounian, B., Jourgholami, M., 2013: Effects of Rubber-Tired Cable Skidder on Soil Compaction in Hyrcanian Forest. Croat. j. for. eng. 34(1): 123–135.

Malík, V, Dvořák, J., 2007: Harvestorové technologie a vliv na lesní porosty. Folia forestalia Bohemica. Forestalia 5 (80): 84 p.

Matthies, D., Weixler, H., Guglhör, W., Löffler, H., 1995: Bodenuntersuchungen zu befahrungsbedingten Strukturveränderungen auf Waldstandorten in Bayern. – Abschlußbericht Kuratoriumsprojekt A30, Freising: 121 p.

McKyes, E., 1985: Soil cutting and tillage. Elsevier Science Publisher BV. 213 p.

Mederski, P.S., Karaszewski, Z., Rosińska, M., Bembenek, M., 2016: Dynamics of harvester fleet change in Poland & factors determining machine occurrence. Sylwan 160(10): 795–804.

Minasny, B., 2012: Contrasting soil penetration resistance values acquired from dynamic and motor-operated penetrometers. Geoderma 177–178: 57–62. https://doi.org/10.1016/j.geoderma.2012.01.026

Mohammadi, S.D., Nikoudel, M.R., Rahimi, H., Khamehchiyan, M., 2008: Application of Dynamic Cone Penetrometer (DCP) for determination of the engineering parameters of sandy soils. Engineering Geology 101(3): 195–203. https://doi.org/10.1016/j.enggeo.2008.05.006

Moskalik, T., 2002: Rozwoj technik i technologii maszynowego pozyskiwania drewna. Sylwan 146(10): 31–38.

Moskalik, T., Borz, S., Dvořák, J., Ferenčík, M., Glushkov, S., Muiste, P., Lazdiņš, A., Styranivsky, O., 2017: Timber Harvesting Methods in Eastern European Countries: a Review. Croat. j. for. eng. 38(2): 231–241.

Murphy, M., Firth, J.G., Skinner, M.F., 2004: Long-term impacts of forest harvesting related soil disturbance on log product yields and economic potential in a New Zealand forest. Silva Fen. 38(3): 279–289. https://doi.org/10.14214/sf.416

Myślińska, E., 1998: Laboratoryjna badania gruntów. PWN Warszawa, 278 p.

MZe, 2021: Zpráva o stavu lesa a lesního hospodářství České republiky v roce 2019. [Report on the State of Forests and Forestry in the Czech. Republic in the Year 2019]. Prague: Ministry of Agriculture of the Czech Republic, 124 p.

MZe, 2006: Zpráva o stavu lesa a lesního hospodářství České republiky v roce 2005. [Report on the State of Forests and Forestry in the Czech. Republic in the Year 2005]. Prague: Ministry of Agriculture of the Czech Republic, 135 p.

MZe, 2001: Zpráva o stavu lesa a lesního hospodářství České republiky v roce 2000. [Report on the State of Forests and Forestry in the Czech. Republic in the Year 2019]. Prague: Ministry of Agriculture of the Czech Republic, 124 p.

Naghdi, R., Solgi, A., Zenner E.K., Akbar, N., Salehi, A., Nikooy M., 2017: Compaction of Forest Soils with Heavy Logging Machinery. Silva Balcanica 18(1): 25–39.

Perez-Ramos, I.M., Gomez-Aparicio, L., Villar, R., Garcıa, L.V., Maranon, T., 2010: Seedling growth and morphology of three oak species along field resource gradients and seed-mass variation: a seedling-age-dependent response. J. Veg. Sci. 21(3): 419–437. https://doi.org/10.1111/j.1654-1103.2009.01165.x

Picchio, R., Mederski, P.S., Tavankar F., 2020: How and How Much, Do Harvesting Activities Affect Forest Soil, Regeneration and Stands? Current Forestry Reports 6(2): 115–128. https://doi.org/10.1007/s40725-020-00113-8

PN-EN ISO 14688 Standard 2018: Badania geotechniczne – Oznaczanie i klasyfikowanie gruntów – Część 2: Zasady klasyfikowania (Geotechnical research Soil identification and classification – Part 2: Classification rules), 1–12.

Pohořalý, J., Klvač, R., Kent, T., Kleibl, M., Coates, E., Horgan, B., 2014: Impact of Forest Biomass for Energy Harvesting on Soil Compaction – Irish Case Study. J. For. Sci. 60(12): 526–533. https://doi.org/10.17221/89/2014-JFS

Ring, E., M., Andersson, L., Hansson, G., Jansson, L., Högbom, 2021: Logging Mats and Logging Residue as Ground Protection during Forwarder Traffic along Till Hillslopes. Croat. j. for. eng. 42(3): 445–462. https://doi.org/10.5552/crojfe.2021.875

Sack, L., 2004: Responses of temperate woody seedlings to shade and drought: do trade-offs limit potential niche differentiation? Oikos 107(1): 110–127. https://doi.org/10.1111/j.0030-1299.2004.13184.x

Sakai, H., Nordfjell, T., Suedicani, K., Talbot, B., Bollehuus, E., 2008: Soil compaction on Forest soils from different kinds of tires and tracks and possibility of accurate estimate. Croat. j. for. eng. 29(1): 15–27.

Sharif, A., Mohsanimenesh, A., 2012: Soil mechnical resistance measurement by an unique multi – cone tips horizontal sensor. Int. Agrophys. 26(1): 61–64. https://doi.org/10.2478/v10247-012-0009-7

Stolf, R., Reichardt, K., Vaz, C.P.M., 2005: Response to »Comments on ‘Simultaneous Measurement of Soil Penetration Resistance and Water Content with a Combined Penetrometer–TDR Moisture Probe’ and ‘A Dynamic Cone Penetrometer for Measuring Soil Penetration Resistance’«. Soil Sci. Soc. Am. J. 69(3): 927–929. https://doi.org/10.2136/sssaj2005.0927

Solgi, A., Naghdi, R, Labelle, E.R., Behjou, F.K., Hemmati, V., 2019: Evaluation of Different Best Management Practices for Erosion Control on Machine Operating Trails. Croat. j. for. eng. 40(2): 319–326. https://doi.org/10.5552/crojfe.2019.532

Sohrabi, H., Jourgholami, M., Jafari, M., Shabanian, N., Venanzi, R., Tavankar, F., Picchio, R., 2021: Soil Recovery Assessment after Timber Harvesting Based on the Sustainable Forest Operation (SFO) Perspective in Iranian Temperate Forests. Sustainability 12(7): 2874. https://doi.org/10.3390/su12072874

StatSoft, 2006: Electronic Statistics Manual PL. Krakow. WEB: http://www.statsoft.pl/textbook/stathome.html (accessed 01.06.2020)

Sun, T., Cheng, Q., Schulze, L.P., Berg, A., Meng, F., Zeng, Q., Li, L., 2011: Energy- based comparison between a dynamic cone penetrometer and a motor-operated static cone penetrometer. Soil and Tillage Research 115–116: 105–109. https://doi.org/10.1016/j.still.2011.06.005

Tadeusiewicz, R., Tylek, P., Adamczyk, F., Kiełbasa, P., Jabłoński, M., Pawlik, P., Piłat, A., Walczyk, J., Szczepaniak, J., Juliszewski, T., Szaroleta, M., 2017: Automation of the Acorn Scarification Process as a Contribution to Sustainable Forest Management. Case Study: Common Oak. Sustainability 9(12): 2276. https://doi.org/10.3390/su9122276

Ulrich, R., Neruda, J., Valenta, J., 2003: Influence of chosen machine carriage systems on soil. Inżynieria Rolnicza 11(53): 229–235.

Vanags, Ch., Minasny, B., McBratney, A.B., 2004: The dynamic penetrometer for assessment of soil mechanical resistance. Super soil. Published on CDROM. Available online: http://www.regional.org.au/au/asssi/ (accessed 01.06.2020).

Varol, T., Emir, T., Akgul, M., Ozel, H.B., Acar, H.H., Cetin, M., 2020: Impacts of Small-Scale Mechanized Logging Equipment on Soil Compaction in Forests. J Soil Sci Plant Nutr 20(3): 953–963. https://doi.org/10.1007/s42729-020-00182-5

Venanzi, R., Picchio, R., Grigolato, S., Latterini F., 2019: Soil and forest regeneration after different extraction methods in coppice forests. Forest Ecology and Management 454(7): 117666 https://doi.org/10.1016/j.foreco.2019.117666

Venanzi, R., Picchio, R., Spinelli, R., Grigolato, S., 2020: Soil Disturbance and Recovery after Coppicing a Mediterranean Oak Stand: The Effects of Silviculture and Technology. Sustainability 12(10): 4074. https://doi.org/10.3390/su12104074

Vaz, C.M.P., Manieri, J.M., De Maria, I.C., Tuller, M., 2011: Modeling and correction of soil penetration resistance for varying soil water content. Geoderma 166(1): 92–101. https://doi.org/10.1016/j.geoderma.2011.07.016

Visser, R., Stampfer, K., 2015: Expanding Ground-based Harvesting onto Steep Terrain: A Review. Croat. j. for. eng. 36(2): 321–331.

Wong, J.I., 2009: Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and Design. Butterworth-Heinemann. 397 p.

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Author’s address:

Kormanek Mariusz, PhD

e-mail: rlkorma@cyf-kr.edu.pl

University of Agriculture in Kraków

Faculty of Forestry

Department of Forest Utilization, Engineering and Forest Techniques

Al. 29- listopada 46

31-423 Kraków

POLAND

Assist. prof. Jiří Dvořák, PhD

e-mail: dvorakj@fld.czu.cz

Czech University of Life Sciences Prague

Faculty of Forestry and Wood Sciences

Institute of Forest Use of Forest Engineering and Technology

Kamycka 1176

165 21 Prague 6 – Suchdol

CZECH REPUBLIC

Received: June 01, 2020

Accepted: August 02, 2021

Original scientific paper