Accuracy of Photo-Optical Timber Measurement Using a Stereo Camera Technology

doi: 10.5552/crojfe.2024.2268

volume: 45, issue:

pp: 10

- Author(s):

-

- Tomczak Karol

- Mederski Piotr S.

- Naskrent Bartłomiej

- Tomczak Arkadiusz

- Article category:

- Original scientific paper

- Keywords:

- wood measurement, stacked wood, forestry digitalisation, automatic measurement

Abstract

HTML

Harvested timber requires efficient and accurate measurements for timber trade. Recently, the amount of timber that is harvested for industrial purposes is growing and methods for roundwood measurements are under constant development. Some of these solutions are with certification confirming its accuracy, some of them are proposed for general use without certification. The aim of this paper was to select the best and most useful electronic solution for timber volume masurement and calculation, and to recommend the most effective and accurate solution for future timber trade. Three photo-optical systems were tested: LogStackPro, iFovea and Timbeter. Each system was used to measure 71 stacks of pine and oak roundwood, which amounted to 3481.15 cubic meter stacked. Timber volumes obtained from the manual measurements were used as reference. Volumes obtained from the photo-optical systems were larger in comparison with the volume from manual measurements, by 3.37, 8.07 and 9.08%, in LogStackPro, iFovea and Timbeter, respectively. It was concluded from the tested systems that, currently, the most recommended solution for timber measurement will be LogStack Pro, which also presented, in most cases, the smallest deviations from the volume obtained in manual measurements.

Accuracy of Photo-Optical Timber Measurement Using a Stereo Camera Technology

Karol Tomczak, Piotr S. Mederski, Bartłomiej Naskrent, Arkadiusz Tomczak

Abstract

Harvested timber requires efficient and accurate measurements for timber trade. Recently, the amount of timber that is harvested for industrial purposes is growing and methods for roundwood measurements are under constant development. Some of these solutions are with certification confirming its accuracy, some of them are proposed for general use without certification. The aim of this paper was to select the best and most useful electronic solution for timber volume masurement and calculation, and to recommend the most effective and accurate solution for future timber trade. Three photo-optical systems were tested: LogStackPro, iFovea and Timbeter. Each system was used to measure 71 stacks of pine and oak roundwood, which amounted to 3481.15 cubic meter stacked. Timber volumes obtained from the manual measurements were used as reference. Volumes obtained from the photo-optical systems were larger in comparison with the volume from manual measurements, by 3.37, 8.07 and 9.08%, in LogStackPro, iFovea and Timbeter, respectively. It was concluded from the tested systems that, currently, the most recommended solution for timber measurement will be LogStack Pro, which also presented, in most cases, the smallest deviations from the volume obtained in manual measurements.

Keywords: wood measurement, stacked wood, forestry digitalisation, automatic measurement

1. Introduction

Harvested timber requires measurement for trade purposes. According to FAO estimates, global roundwood production, including wood fuel (WF) and industrial roundwood (IR), totalled 3966 million cubic metres (WF 1945 million m3, IR 2021 million m3) in 2020 (FAO 2020). Compared to 2000, global timber production has therefore increased by approximately 24% (FAO 2000). In Poland, in 2020, roundwood timber and logs accounted for more than 60% of harvested wood, mainly prepared using cut-to-length technology (Mederski et al. 2022). Applications enabling the use of photo-optical (PO) methods in forestry are coming onto the market, and these can facilitate and speed up the measurement of stacked wood.

There are several photo-optical applications available on the market, including

iFovea Pro (SDP Digitale Produkte GmbH 2022)

LogStackPro (HD LogSystem)

Timbeter (Timbeter).

As a result of the processing, the application identifies the front of the stack and, depending on the selected measurement method, determines the diameter of the individual logs and their number, or the area of the whole stack based on its outline (polygon) and the reference marked on the stack. Both, the diameters of the individual logs and the stack shape (polygon) can be adjusted directly during stack processing or after the stack has been saved. Importantly, measurements can be performed without internet access. In case of software manufacturers who use external devices, the measurments are made by recording the video of the timber stack. Moreover, in case of Dralle and LogStackPro systems, the reference is defined as distance between centeres of two cameras located on the device. The only photo-optical stereoscopic (hereafter simply called stereoscopic) handheld device without a reference is LogStackPro, created by HD Silva. The sScale system, also based on a no-reference method, was created by Dralle, but in this case the device needs to operate on the roof of a car, and thus requires locations with good road systems alongside the timber stacks. Moreover, the Dralle sScale system is recommended for large stacks (Mederski et al. 2018). The LogStackPro and Dralle sScale photo-optical measurement systems both have certified accuracy.

The solutions proposed by manufacturers are quite universal; however, all ultimately require adaptation to the rules for measurement and conversion methods applied in each country. These methods are already used in countries such as Germany, Finland, Estonia, Japan and Brazil (HD LogSystem, SDP Digitale Produkte GmbH, Dralle, Timbeter, Trestima). In Poland, the use of photo-optical methods for wood measurement is recommended in case of natural disasters (State Forests – document no. 51/2019), and the Dralle measuring system was used in 2018 (Mederski et al. 2018) after a derecho windstorm that damaged ca. 8 million m3 of timber (Sanginés de Cárcer et al. 2021, Schweier et al. 2023). Currently, smartphone apps cannot be certified due to the lack of control over updates to the operating system of the device on which the photo-optical software is installed.

Several studies have been carried out on photo-optical measurement methods using smartphones (Boberg and Lilja 2016, Berendt et al. 2021, Cremer et al. 2021, Borz et al. 2022, Borz and Proto 2022), harvester built-in devices (Hohmann et al. 2017, Mederski et al. 2018), photogrammetry, 2D and 3D image processing (Janak 2007, Herbon et al. 2015, Acuna and Sosa 2019, Nuhlíček et al. 2020), and other appliances (Gutzeit et al. 2011). Photo-optical systems have been the subject of recent scientific research. Studies by Cremer et al. (2021) and Berendt et al. (2021) were focused on iFovea Pro and manual hardwood measurements. Borz et al. (2022) studied the potential of LiDAR for use in estimating log biometrics and compared the results with traditional methods of measuring logs using tape and a caliper in the sawmill environment. Kärhä et al. (2019) tested the Trestima Stack app in two different conditions – in large terminal yards and at smaller roadside landings – and reported the higher accuracy of photo-optical measurements in terminal yards, while manual measurement accuracy was similar in both locations. Available published studies on the photo-optical measurement of harvested wood using smartphones indicate the potential of this method as an alternative to traditional timber measurement. All smartphone applications based on photo-optical systems require a length reference, however, and no data are available concerning the use of a stereo camera technology that can be used for measurement without a reference. The stereo camera concept was used in studies carried out at storage sites and depots (Knyaz and Maksimov 2014), where the researchers applied a photogrammetric technique for measuring stack volumes at a timber depot, using a notebook computer and two synchronized digital Canon EOS 1100D cameras installed on an 800 mm baseline.

Electronic systems for timber measurement are particularly useful in large-scale operations. In Poland, the operations of the State Forests are suitable for the use of photo-optical measurements: the enterprise manages forests totalling over 7 million ha in area, with an annual harvest amounting to 40 million m3 of timber, of which over 90% is industrial timber (Statistical Yearbook of Forestry in Poland 2021). In the last decade, the State Forests have tested several measurement systems and applications, including Timbeter, iFovea Pro and sScale. These tests were carried out in order to recommend the best solution for use by the organization.

Manual wood measurement is reported to be one of the most time-consuming jobs of a forester during a working day (Grzywiński et al. 2019). According to Jodłowski et al. (2016), manual measurement of raw wood takes more than 0.19 min/m3, while photo-optical applications take about 0.10 min/m3. Manual measurement takes from 5 to 8 minutes longer than PO methods. Similar results for time consumption in timber measurements were reported by Borz and Proto (2022). According to Kärhä et al. (2019), measurement with a mobile photo-optical app was faster by 3.1 s/m3 than a conventional stacked wood measurement method.

Studies on the accuracy of remote timber measurement systems usually compare the results obtained from a device/software with timber volumes measured manually (VMM). A VMM is only an approximation to the real volume (RV). The RV can be obtained by submerging the timber in water; however, this is a very time-consuming and expensive method. In the present research, it was assumed that values close to the real timber volume could be obtained for a large number of timber stacks, which were measured in practice for purposes of trade in the forestry sector. The hypothesis was that manual measurements are subject to errors, but some of them will lead to overestimates and others to underestimates so that eventually a large number of stacks will give results statistically close to the real volume. The aim of this study was to select the best and most useful electronic solution for timber volume measurement and calculation and to recommend the most effective and accurate solution for future use in the timber trade. Therefore, different systems were compared: one based on stereo camera technology without a length reference, and two smartphone applications requiring a reference. All selected methods were compared with the results obtained from manual measurements.

2. Materials and Methods

2.1 Study Design

The study was carried out from November 2020 to May 2021 at the Forest Experimental Station, Poznan University of Life Sciences. During the study, 71 stacks of pine (48) and oak (23) roundwood were measured. The total cubic meter stacked (CMS) volume of the measured wood was 3481.15 m3 (Table 1). Each stack was measured by the standard method used for timber trading in the local market, and by three photo-optical methods: LogStackPro (stereo camera technology), iFovea Pro (smartphone app), and Timbeter (smartphone app). All logs in measured stacks had the same length – 250 cm and had similar quality, which enabled them to be classified into the same assortment group (Fig. 1). All measurements were taken by 4 foresters, who have been trained by the software manufacturers. All stacks were measured under similar weather conditions. If there were any errors in the measurement, e.g., stitching of the image, the measurement was repeated so the final result was based only on correct trials. Next, based on the volume, each stack was assigned to one of the following size classes (CMS in m3): 1) 0–10; 2) >10–20; 3) >20–40; 4) >40–60; 5) >60–80; 6) >80–100; 7) >100–150; 8) >150 (Table 2).

Fig. 1 Example of pile measured during study (photo: K. Tomczak)

Table 1 Number and volume of manually measured wood stacks, by species

|

Wood species |

Number of stacks |

Cubic meter stacked (CMS), m3 |

Average volume per stack, m3 |

|

Pine |

48 |

3096.25 |

64.51 |

|

Oak |

23 |

384.90 |

16.73 |

|

Total |

71 |

3481.15 |

49.03 |

Table 2 Number of manually measured wood stacks and all volume measurements in stack size classes

|

Volume class |

Wood stack volume m3 |

Number of measured pine stack |

Number of measured oak stack |

Number of measured stacks |

Number of all volume measurements |

|

1 |

0–10 |

0 |

3 |

3 |

12 |

|

2 |

>10–20 |

10 |

16 |

26 |

104 |

|

3 |

>20–40 |

13 |

4 |

17 |

68 |

|

4 |

>60–80 |

8 |

0 |

8 |

32 |

|

5 |

>80–100 |

11 |

0 |

12 |

48 |

|

6 |

>100–150 |

3 |

0 |

4 |

16 |

|

7 |

>150 |

3 |

0 |

3 |

12 |

2.2 Determination of Stack Volumes

2.2.1 Manual Measurements

Manual measurements were made according to the standards laid down for volume calculation and measurement of stacked timber for trading purposes (the State Forests, Poland; document no. 51/2019). To estimate the volume of a wood stack, the log length, average width, and height were measured according to the following guidelines:

Log length

The length of a stack was considered to be the nominal length of the logs stacked in it. The length was determined to the nearest 1 cm.

Average width

The width of the stack was measured parallel to the lower edge of the stack face, at its widest point, to the nearest 1 cm.

Average height

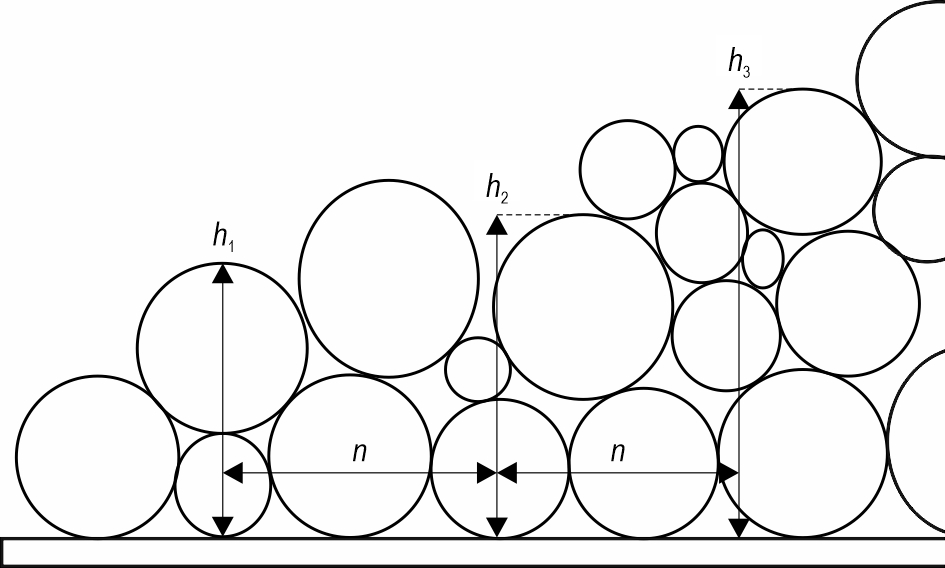

The height of the stack was measured perpendicularly from the bottom edge of the stack to the top edge, to the nearest 1 cm. The height of the stack was determined as the arithmetic mean of at least four measurements of the front side of the stack. The measuring points were evenly spaced along the width of the stack and permanently marked with paint. The distances between measurements (n) were not greater than 1 m (for stacks up to 10 m wide) and 2 m (for stacks wider than 10 m). The first height measurement was made at the left end of the stack, in a place where there were at least two logs on top of each other. The last height measurement was made in a place where there were at least two logs on top of each other (Fig. 2).

Fig. 2 Standards for measuring timber stacks: points of height measurement and determination of the top edge of a pile. If the measurement fall between two logs (h2), the height for the lower adjacent log was taken

2.2.2 Photo-Optical Measurements

To test photo-optical measurement methods, two smartphone apps and one stereo camera technology were used. A Samsung Galaxy Tab Active 3 tablet was used for wood measurements performed with the two Android applications (iFovea and Timbeter). For measurements with LogStackPro, a Mobile Demand tablet was used. This is a device with a Linux operating system, designed by HD LogSystem, with two integrated stereoscopic cameras. In the case of mobile apps, measurements were made by taking photographs of the front of the wood stacks; if there was more than one photograph, the app would combine them into one image (panorama picture) (Fig. 3). In the case of LogStackPro, the wood stacks were measured by recording a video of the front of the log stacks. As a reference for the mobile apps, the width of the log stack was measured manually, using a measuring tape with 1 cm accuracy. In the LogStackPro system, the reference was the constant distance between the stereo cameras. Each measurement was performed at a distance of approximately 2–4 metres from the wood stack, in accordance with the instructions. In the next step, post-processing editing of the detected contour was carried out (Table 3).

Table 3 Hardware and software used for photo-optical measurements

|

App/System name |

Device |

System requirements |

App/System version |

Reference |

|

LogStackPro |

Mobile Demand |

External system |

– |

No reference on the stack |

|

iFovea Pro |

Samsung Galaxy Tab Active 3 |

Android 7.0 or better |

2.5.7 |

Wide of stack |

|

Timbeter |

Samsung Galaxy Tab Active 3 |

iOS 12.0 or better |

3.0 |

75% of stack width |

Fig. 3 Devices used for LogStackPro (a) and mobile apps (b)

Finally, the best digital measuring system was selected based on mathematical criteria: the best solution was considered to be the one that gave a mean timber volume closest to the mean volume obtained from manual measurements. The second criterion was standard deviation between the volume obtained by electronic measurement and the volume measured manually.

2.3 Statistical Analysis

To verify the distribution of the data, the Shapiro–Wilk test was performed. The data did not meet the requirements of normality, which led to the rejection of the normal distribution hypothesis. To compare data obtained from the analysed methods of measurement, the non-parametric Mann–Whitney U-test was performed. Statistical analysis was performed at the significance level α = 0.05. The program Statistica 13.1 (TIBCO Software Inc., Palo Alto, CA, USA) and the R package (RCore Team 2022) were used for the calculations and for visualization.

3. Results

The average photo-optically measured volume of the stacks was approximately 49 m3 CMS, while the average result obtained by the manual method was 46.6 m3. The largest wood stack volume measured manually was approximately 221 m3, and the smallest was 8 m3. The most comparable results were obtained by LogStackPro, which gave a volume only 3.4% higher. The mean volumes as measured by iFovea Pro and Timbeter were quite similar; compared with the manual measurements, they were 8% and 9% higher (Table 4). The highest differences between photo-optical measurements of the examined software were noticed between LogStackPro and Timbeter, and then between LogStackPro and iFovea Pro. Meanwhile the differences in obtained CMS volume between iFovea Pro and Timbeter were below 1% (Table 5). In the case of pine wood, the average volume obtained by the manual method was 61.3 m3. The highest measurement accuracy was achieved by LogStackPro (3.5%), while the differences for iFovea Pro and Timbeter were around 8.0% and 9.0%, respectively. For oak wood, LogStackPro again gave the most accurate results (2.7%); the difference for both Timbeter and iFovea was 6.6% (Fig. 4). Based on the Mann–Whitney U-test, there were no statistically significant differences between the examined methods, either for all measured stacks or for specific wood species.

Table 4 Comparison of volumes obtained by photo-optical and manual measurement for all timber stacks

|

Method |

Mean |

N |

Standard deviation |

Min |

Max |

Median |

Differences in cubic meter stacked volume, % |

|

Manual |

46.64 |

71 |

45.10 |

8.00 |

221.20 |

25.03 |

– |

|

Log Stack Pro |

48.21 |

71 |

46.37 |

8.08 |

214.78 |

27.51 |

+3.37 |

|

iFovea Pro |

50.40 |

71 |

49.40 |

8.23 |

231.10 |

26.55 |

+8.07 |

|

Timbeter |

50.87 |

71 |

49.53 |

7.49 |

235.74 |

28.23 |

+9.08 |

|

Mean |

49.03 |

284 |

47.42 |

7.49 |

235.74 |

27.13 |

– |

Table 5 Differences in average volume (CMS) of measured stacks between photo-optical methods of measurements, %

|

LogStackPro |

iFovea Pro |

Timbeter |

|

|

LogStackPro |

x |

–4.34 |

–5.22 |

|

iFoveaPro |

+4.54 |

x |

–0.92 |

|

Timbeter |

+5.51 |

+0.93 |

x |

|

in bold – base value |

|||

Fig. 4 Range of accuracy obtained by photo-optical and manual measurement with respect to species. Whiskers correspond to minimum and maximum values, boxes represent the 1st and 3rd quartile values, midlines indicate the median

When different size classes of wood stacks were considered, the most accurate method of photo-optical measurement was LogStackPro. The results obtained with the mobile apps show Timbeter to be more accurate for only two classes of stack volumes, 10–20 m3 and 100–150 m3, while iFovea was more accurate in most of the classes (Table 6). In the case of pine wood (where the smallest stacks were assigned to the 10–20 m3 class), iFovea Pro made more accurate measurements than Timbeter in every class except for 100–150 m3 and 10–20 m3 (Table 7). The findings for oak wood were similar to those for pine wood, although the measurements included wood stacks from only three size classes. The Fovea app achieved greater accuracy only in the case of the 10–20 m3 class. Statistically significant differences were found only in the case of 80–100 m3 pine wood stacks measured using iFovea Pro and the manual method (Table 8).

Table 6 Differences in volumes obtained with photo-optical methods – all compared with volumes obtained by manual method (defined as 100%); pine and oak – indicate that the volume obtained by photo-optical method was higher or lower, respectively, than the volume obtained by manual measurement. All values in %

|

Method |

Size class |

||||||

|

0–10 |

>10–20 |

>20–40 |

>60–80 |

>80–100 |

>100–150 |

>150 |

|

|

Log Stack Pro |

+3.60 |

–0.13 |

+4.15 |

+2.83 |

+6.14 |

+3.19 |

+1.03 |

|

iFovea Pro |

+8.09 |

+6.50 |

+3.97 |

+4.22 |

+10.27 |

+15.68 |

+4.52 |

|

Timbeter |

+14.21 |

+3.92 |

+9.81 |

+1.72 |

+10.87 |

+13.09 |

+5.93 |

Table 7 Differences in cubic meter stacked volumes obtained by photo-optical measurement methods compared with manual method for pine wood stacks in different size classes

|

Method |

Size class |

Mean |

Standard deviation |

Differences in cubic meter stacked volume, % |

|

Manual |

>10–20 |

13.81 |

2.55 |

– |

|

Log Stack Pro |

13.53 |

3.58 |

–2.09 |

|

|

iFovea Pro |

14.57 |

3.16 |

+5.49 |

|

|

Timbeter |

14.55 |

2.60 |

+5.34 |

|

|

Manual |

>20–40 |

28.91 |

5.71 |

– |

|

Log Stack Pro |

29.93 |

5.91 |

+3.53 |

|

|

iFovea Pro |

29.96 |

5.87 |

+3.64 |

|

|

Timbeter |

31.53 |

6.64 |

+9.07 |

|

|

Manual |

>60–80 |

66.01 |

4.23 |

– |

|

Log Stack Pro |

67.88 |

6.33 |

+2.83 |

|

|

iFovea Pro |

70.75 |

6.73 |

+7.17 |

|

|

Timbeter |

71.96 |

8.51 |

+9.02 |

|

|

Manual |

>80–100 |

85.99 |

7.17 |

– |

|

Log Stack Pro |

91.27 |

6.03 |

+6.14 |

|

|

iFovea Pro |

94.82 |

11.04 |

+10.27 |

|

|

Timbeter |

95.34 |

12.25 |

+10.87 |

|

|

Manual |

>100–150 |

129.20 |

26.61 |

– |

|

Log Stack Pro |

133.32 |

28.13 |

+3.19 |

|

|

iFovea Pro |

149.46 |

36.44 |

+15.68 |

|

|

Timbeter |

146.11 |

33.81 |

+13.09 |

|

|

Manual |

>150 |

188.54 |

30.62 |

– |

|

Log Stack Pro |

190.49 |

26.44 |

+1.03 |

|

|

iFovea Pro |

197.06 |

35.41 |

+4.52 |

|

|

Timbeter |

199.72 |

35.28 |

+5.93 |

Table 8 Differences in values obtained by photo-optical measurement methods compared with manual method for oak wood stacks in different size classes

|

Method |

Size class |

Mean |

Standard deviation |

Differences in cubic meter stacked volume, % |

|

Manual |

0–10 |

9.15 |

1.00 |

– |

|

Log Stack Pro |

9.48 |

1.34 |

+3.60 |

|

|

iFovea Pro |

9.89 |

1.59 |

+8.09 |

|

|

Timbeter |

10.45 |

2.85 |

+14.21 |

|

|

Manual |

>10–20 |

14.81 |

2.85 |

– |

|

Log Stack Pro |

14.96 |

3.35 |

+1.01 |

|

|

iFovea Pro |

15.86 |

3.65 |

+7.09 |

|

|

Timbeter |

15.27 |

4.24 |

+3.08 |

|

|

Manual |

>20–40 |

26.43 |

5.07 |

– |

|

Log Stack Pro |

28.11 |

4.81 |

+6.35 |

|

|

iFovea Pro |

27.79 |

6.76 |

+5.14 |

|

|

Timbeter |

29.72 |

4.77 |

+12.43 |

4. Discussion

4.1 Photo-Optical Measurements

Most published studies provide only data on measurement accuracy between one selected app and a manual method (Kärhä et al. 2019, Berendt et al. 2021, Cremer et al. 2021) or present general information about photo-optical technology (Pachuta and Chojnacki 2018, Lepoglavec et al. 2019, Pásztory et al. 2019, Tomczak and Naskrent 2022). The range of wood volumes used in this study represents the typical distribution of CMS volumes of stacks of roundwood of the examined species. The higher proportion of pine roundwood in the study was a consequence of the proportion of that species in the total timber harvest in the experimental area. Overall, 14,054,000 m3 of industrial conifer roundwood and 4,288,000 m3 of hardwood roundwood were harvested in Poland in 2020 (Statistical Yearbook of Forestry in Poland 2021). Similar studies concerning the accuracy of photo-optical wood measurements in real forest conditions have been carried out by other authors (Herbon et al. 2015, Kärhä et al. 2019, Berendt et al. 2021, Cremer et al. 2021).

Almost all of the average photo-optical results for timber volume obtained in the present study were higher than the volumes obtained from manual measurements. In this study, the LogStackPro measurement system achieved the best accuracy (+3.4%); the CMS volume results from the mobile apps were approximately +8.0% (iFovea Pro) and +9.0% (Timbeter) higher than VMM. Measurements of stacked oak timber were more accurate than measurements of stacked pine timber. In the case of oak timber, the measurements performed using the mobile apps had similar accuracy. However, the pine timber measurements obtained with iFovea Pro had better accuracy than those of Timbeter. The reason for this difference may be the smaller range of stack volume classes in the case of oak. The results of this study are not in very good agreement with those of Berendt et al. (2021), who examined the accuracy of broadleaved wood measurements performed using only the iFovea Pro mobile app. That study found average deviations between –5.21% and +0.53% when oak timber volumes were measured using iFovea Pro, while in our study the deviations ranged between +5.14% and +8.09%.

The results obtained using stereo camera (LogStackPro) measurement technology exhibited the best accuracy in every analysed stack volume class. The volumes obtained with the mobile apps were higher than those given by LogStackPro. Moreover, the results obtained from the two apps within the same volume classes were not similar. In most volume classes the iFovea Pro app provided better accuracy than Timbeter. No statistically significant differences were observed between the manually and photo-optically measured timber volumes, or between the photo-optical methods.

From a statistical point of view, the results show that there is no difference between the compared photo-optical methods for timber measurement. However, from a practical point of view, every cubic metre by which the measured volume falls below the actual volume represents a loss to the forest owner. This has also been pointed out by other authors (Pásztory et al. 2019, Berendt et al. 2021). The mean price of 1 m3 of timber in Poland in 2021 was approximately 47 EUR (1 EUR = 4.81 PLN according to data from the National Bank of Poland as at 5 October 2022). Therefore, an error of ±1% in calculating wood volume results in a gain or loss to the forest owner of 4.7 EUR per 1 m3. In the case of photo-optical measurements, manufacturers claim that an experienced worker can repeat the measurement with an accuracy of ±3–5%. However, no scientific studies have yet been conducted to confirm the effect of experience on measurement repeatability.

Another very important element of the measurement procedure that affects its accuracy is the length reference. Depending on the application used, length references from 1 m up to the full width of the wood stack are recommended. In this study, measurements made with the iFovea Pro application, for which the reference segment covered the full stack width, were found to be more accurate than those of the Timbeter application, where the length of the reference segment was 75% of the stack width. This may suggest that the size of the reference segment can affect the accuracy of the measurement. However, this hypothesis needs to be confirmed by investigating the effect of reference segment size on measurement accuracy within a single application.

4.2 Study Limitations

Despite their good accuracy, photo-optical measurement methods may also be subject to limitations. Smartphone photo-optical applications place limits on the size of stacks that can be measured; for iFovea Pro the maximum width is 30 m and the maximum height approximately 4.5 m. Timbeter does not define such limits. If the width of the stack exceeds the app's maximum measurement value, it is advisable to divide it into several separate sections and to measure each section separately. Another limitation of the measurements may be excessive light. If there is too much light in the field, it is recommended to shade the camera using one's hand, although this is not a very convenient or effective solution. Problems with measurement can also occur if the stack is situated near the logging site and a strong wind causes standing trees in the background to sway, or when the timber stack covers less than 60% of the photograph. A very important aspect of correct photo-optical measurement is the quality of wood stacking. Stacks should be piled as evenly as possible to avoid errors during image recording. In addition, photo-optical measurement requires a high degree of accuracy on the part of the person using the device. The user should carry out the measurement according to the manufacturer's guidelines and must determine the reference length very accurately. It is also important to walk alongside the stack parallel to it, maintaining the same distance from the front of the stack. Failure to observe the principles of correct measurement may result in incorrect stitching of the series of photographs and can lead to a distorted final orthophotomosaic image, on the basis of which the final stack volume result is calculated. Photo-optical measurements using length references can also be subject to errors associated with reference determination. The reference must first be determined on the stack to an accuracy of 1 cm. It should then be plotted on the orthophotomosaic in the post-production screen. Any deviation from the starting value of the reference results in an erroneous volume result for the respective stack. Similar errors can also occur during manual measurement, which has a relatively low repeatability. Meanwhile, many application manufacturers claim that photo-optical measurements can be performed with an accuracy of ±3%. However, only LogStackPro and Dralle have certified accuracy. Therefore, for the time being, the best photo-optical solution seems to be the one that does not require the user to take additional measurements at the front of the stack.

4.3 Study Perspectives

Looking to the future, considering the development of technology in the mobile device market, which will favour the introduction of digital techniques in forestry, an interesting solution for the measurement of stacked timber may be the use of LiDAR. This is already being used on devices with the iOS system; for example, for measurements related to forest inventory (Balzter et al. 2007, Magnussen et al. 2018, Pyörälä et al. 2019, Gollob et al. 2021, Xu et al. 2021) and single log volume (Borz et al. 2022, Borz and Proto 2022).

5. Conclusions

As technology advances, the devices and applications used in forestry can provide increasingly accurate measurement data. According to the results of this study, it can be concluded that, at present, the use of stereo camera technology (LogStackPro) is the most promising and accurate solution to replace the manual measurement of timber volumes for trade purposes. However, from a statistical point of view, the differences between all of the tested methods of stacked timber measurement were not significant. From a practical point of view, every cubic metre by which the measured volume falls below the actual volume (manually measured) represents a loss to the forest owner. The length reference solution seems not to help very much in avoiding errors in photo-optical wood measurements. LogStackPro gives good accuracy of timber volume, it is easy to use even without length reference, and seems to be very practical in many aspects. A valuable element of the whole measurement process when using LogStackPro is the fact that, when activated, all data collection is taken in one go without stopping (creating a short film), rather than taking single pictures. Considering all results and practical issues, LogStackPro is a good candidate for future stack timber measurement and trade.

Acknowledgments

The authors of this study would like to thank: Wiesław Krzewina, Tadeusz Gałan, Maciej Piotrowski, Agata Rutkowska, Marek Dziel, Piotr Koprowski, Paweł Kukulski, Marek Knobel, Tadeusz Skitek, Jędrzej Dziel, and Konrad Różycki, for measuring stacks and for participating in data collection.

6. References

Acuna, M., Sosa, A., 2019: Automated volumetric measurements of truckloads through multi-view photogrammetry and 3D reconstruction software. Croatian Journal of Forest Engineering 40(1): 151–162.

Balzter, H., Rowland, C., Saich, P., 2007: Forest canopy height and carbon estimation at Monks Wood National Nature Reserve, UK, using dual-wavelength SAR interferometry. Remote Sensing of Environment 108(3): 224–239. https://doi.org/10.1016/j.rse.2006.11.014

Berendt, F., Wolfgramm, F., Cremer, T., 2021: Reliability of photo-optical measurements of log stack gross volume. Silva Fennica 55(3): 10555. https://doi.org/10.14214/sf.10555

Boberg, A., Lilja, J., 2016: Precision vid travmätning av rundvirke med en fotoinventeringsteknik applicerat i smarta telefoner. Kandidatarbete n i skogsvetenskap. Swedish University of Agricultural Sciences. Uppsala, 33 p.

Borz, S.A., Magaly, J., Toaza, M., Forkuo, G.O., Marcu, M.V., 2022: Potential of Measure App in Estimating Log Biometrics : A Comparison with Potential of Measure App in Estimating Log Biometrics : A Comparison with Conventional Log Measurement. Forests 13(7): 1028. https://doi.org/10.3390/f13071028

Borz, S.A., Proto, A.R., 2022: Application and accuracy of smart technologies for measurements of roundwood: Evaluation of time consumption and efficiency. Computers and Electronics in Agriculture 197: 106990. https://doi.org/10.1016/j.compag.2022.106990

Cremer, T., Berendt, F., Diez, F. de M., Wolfgramm, F., Blasko, L., 2021: Accuracy of Photo-Optical Measurement of Wood Piles. Environmental Sciences Proceedings 3(1): 90. https://doi.org/10.3390/iecf2020-08192

Dietz, H.U., Urbanke, B., 2009: Harvestervermessung-Hochmechanisierte Holzernte braucht verlässliche Produktionsdaten. KWF. Fachzeitung Für Waldarbeit Und Forsttechnik, 11. Dralle. Available online: https://www.dralle.dk/ (accessed 5 August 2022).

FAO, 2000: Global Forest Resources Assessment 2000 (FRA 2000), Food and Agricultural Organization of the United Nations.

FAO, 2020: Global Forest Resources Assessment 2020 (FRA 2020), Food and Agricultural Organization of the United Nations. In Global Forest Resources Assessment 2020. https://doi.org/10.406i0/ca8753en

Gollob, C., Ritter, T., Kraßnitzer, R., Tockner, A., Nothdurft, A., 2021: Measurement of Forest Inventory Parameters with Apple iPad Pro and Integrated LiDAR Technology. Remote Sensing 13(16): 3129. https://doi.org/10.3390/rs13163129

Grzywiński, W., Tomczak, A., Jelonek, T., Burzyńska-Jędrzejczak, G., Naskrent, B., 2019: Annual structure and actual worktime at the forester and deputy forester workstations. Sylwan 163(5): 355–364. https://doi.org/10.26202/sylwan.2018157

Gutzeit, E., Ohl, S., Voskamp, J., Kuijper, A., Urban, B., 2011: Automatic Wood Log Segmentation Using Graph Cuts. In P. Richard & J. Braz (Eds.), Computer Vision, Imaging and Computer Graphics. Theory and Applications: 96–109. https://doi.org/10.1007/978-3-642-25382-9_7

Herbon, C., Tonnies, K.-D., Otte, B., Stock, B., 2015: Mobile 3D wood pile surveying. 14th IAPR International Conference on Machine Vision Applications (MVA), 422–425. https://doi.org/10.1109/MVA.2015.7153101

Hohmann, F., Ligocki, A., Frerichs, L., 2017: Harvester measuring system for trunk volume determination: Comparison with the real trunk volume and applicability in the forest industry. Bulletin of the Transilvania University of Brasov, Series II: Forestry, Wood Industry, Agricultural Food Engineering 10(59): 27–34.

Janak, K., 2007: Differences in roundwood measurements using electronic 2D and 3D systems and standard manual method. Drvna Industrija 58(3): 127–133.

Jodłowski, K., Moskalik, T., Tomusiak, R., Sarzyński, W., 2016: The use of photo-optical systems for measurement of stacked wood. Proceedings of the 49th FORMEC Symposium, September 4–7, Warsaw, Poland, 306.

Kärhä, K., Nurmela, S., Karvonen, H., Kivinen, V.P., Melkas, T., Nieminen, M., 2019: Estimating the accuracy and time consumption of a mobile machine vision application in measuring timber stacks. Computers and Electronics in Agriculture 158: 167–182. https://doi.org/10.1016/j.compag.2019.01.040

Knyaz, V.A., Maksimov, A.A., 2014: Photogrammetric technique for timber stack volume contol. International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences – ISPRS Archives XL-3: 157–162. https://doi.org/10.5194/isprsarchives-XL-3-157-2014

Lepoglavec, K., Landekić, M., Kanižaj, M., Nevečerel, H., Šporčić, M., 2019: Mobilne aplikacije – korisna inovacija u šumarstvu? Nova mehanizacija šumarstva 40(1): 79–89. https://doi.org/10.5552/nms.2019.8

LogStackPro. Available online: https://www.hdlogsystems.com/ (accessed 5 August 2022).

Magnussen, S., Nord-Larsen, T., Riis-Nielsen, T., 2018: Lidar supported estimators of wood volume and aboveground biomass from the Danish national forest inventory (2012–2016). Remote Sensing of Environment 211: 146–153. https://doi.org/10.1016/j.rse.2018.04.015

Mederski, P.S., Bembenek, M., Karaszewski, Z., Brunka, B., 2018: Accuracy of timber volume measurements using a harvester and a photo-optical system in post-wind- throw stands. Presentation, FEC 2018, Rotorua, New Zealand, 16–19, 1–15 p.

Mederski, P.S., Borz, S.A., Đuka, A., Lazdiņš, A., 2021: Challenges in Forestry and Forest Engineering. Croatian Journal of Forest Engineering 42(1): 117–134. https://doi.org/10.5552/crojfe.2021.838

Mederski, P.S., Karaszewski, Z., Rosińska, M., Bembenek, M., 2016: Dynamics of harvester fleet change in Poland and factors determining machine occurrence. Sylwan 160(10): 795–804.

Mederski, P.S., Schweier, J., Đuka, A., Tsioras, P., Bont, L.G., Bembenek, M., 2022: Mechanised Harvesting of Broadleaved Tree Species in Europe. Current Forestry Reports 8(1): 1–19. https://doi.org/10.1007/s40725-021-00154-7

Nuhlíček, O., Slavík, M., Dvořák, J., 2020: 2D photogrammetry as a forwarder load measurement technique. Forests 11(9): 962. https://doi.org/10.3390/f11090962

Order No. 51/2019 of the Director General of the State Forests dated 30 September 2019 on the introduction of technical conditions in the turnover of wood raw material in the State Forests in Poland (mark: ZM.800.8.2019).

Pachuta, A., Chojnacki, J., 2018: Photo-optical timber stack measurment. Technika Rolnicza Ogrodnicza Leśna (2): 14–16.

Pásztory, Z., Heinzmann, B., Barbu, M.C., 2019: Comparison of Different Stack Measuring Methods. Siberian Forest Journal 3: 5–13. https://doi.org/10.15372/sjfs20190301

Pásztory, Z., Polgár, R., 2016: Photo Analytical Method for Solid Wood Content Determination of Wood Stacks. Journal of Advanced Agricultural Technologies 3(1): 54–57. https://doi.org/10.18178/joaat.3.1.54-57

Pyörälä, J., Saarinen, N., Kankare, V., Coops, N.C., Liang, X., Wang, Y., Holopainen, M., Hyyppä, J., Vastaranta, M., 2019: Variability of wood properties using airborne and terrestrial laser scanning. Remote Sensing of Environment 235: 111474. https://doi.org/10.1016/j.rse.2019.111474

R Core Team, 2021: R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria.

Sanginés de Cárcer, P., Mederski, P.S., Magagnotti, N., Spinelli, R., Engler, B., Seidl, R., Eriksson, A., Eggers, J., Bont, L.G., Schweier, J., 2021: The management response to wind disturbances in European forests. Current Forestry Reports 7(4):167–180. https://doi.org/10.1007/s40725-021-00144-9

Schweier, J., Bont, L.G., Mederski, P.S., Eriksson, A., Spinelli, R., Engler, B., Eggers, J., Magagnotti, N., Tolosana, E., Purfürst, T., Sanginés de Cárcer, P., Olschewski, R., Ferretti, M., 2022: Impacts of large windthrows on forest management – An assessment of European Experiences. For. Pol. Econ., (In Press).

SDP Digitale Produkte GmbH., 2022: iFOVEA Pro. Available online: https://fovea.eu/ifovea_pro_woodpile_mea- surement?language=en (accessed 5 August 2022).

Statistics Poland. Statistical Yearbook of Forestry in Poland, 2021.

Timbeter, 2022: Available online: https://timbeter.com (accessed 5 August 2022).

Tomczak, K., Naskrent, B., 2022: Photo-optical measurement of wood. In Biblioteczka Leśniczego (I, Vol. 412). Poland, Wydawnictwo Świat.

Trestima, 2022: Available online: https://www.trestima.com/w/en/ (accessed 5 August 2022).

Xu, D., Wang, H., Xu, W., Luan, Z., Xu, X., 2021: LiDAR Applications to Estimate Forest Biomass at Individual Tree Scale : Opportunities, Challenges and Future Perspectives. Forests 12(5): 550. https://doi.org/10.3390/f12050550

© 2023 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Karol Tomczak*

e-mail: karol.tomczak@pit.lukasiewicz.gov.pl

Łukasiewicz Research Network

Poznań Institute of Technology

Center of Wood Technology

Winiarska 1,

60-654 Poznań

and

University of Life Sciences

Faculty of Forestry and Wood Technology

Department of Forest Utilisation

Wojska Polskiego 71A,

60-625 Poznań

POLAND

Prof. Piotr Mederski, PhD

e-mail: piotr.mederski@up.poznan.pl

Bartłomiej Naskrent, PhD

e-mail:bartlomiej.naskrent@up.poznan.pl

Assoc. Prof. Arkadiusz Tomczak, PhD

e-mail: arkadiusz.tomczak@up.poznan.pl

University of Life Sciences

Faculty of Forestry and Wood Technology

Department of Forest Utilisation

Wojska Polskiego 71A,

60-625 Poznań

POLAND

* Corresponding author

Received: December 28, 2022

Accepted: February 21, 2023

Original scientific paper