Effects of Boom-Tip Control and a Rotating Cabin on Loading Efficiency of a Forwarder: A Pilot Study

doi: 10.5552/crojfe.2024.2179

volume: 45, issue:

pp: 14

- Author(s):

-

- Hartsch Florian

- Schönauer Marian

- Pohle Christopher

- Breinig Lorenz

- Wagner Thilo

- Jaeger Dirk

- Article category:

- Original scientific paper

- Keywords:

- Forest work science, time study, mechanized harvesting, cut-to-length, forest operations, forwarding

Abstract

HTML

Climate change and associated heat waves and droughts are causing enormous amounts of damaged wood in Central Europe. To face these challenges, mechanized timber harvesting systems consisting of single-grip-harvesters and forwarders are commonly employed due to their high productivity and work safety. Despite the advantages of these work systems, the operation of advanced forestry machines requires lengthy training and entails high levels of mental strain for machine operators. In recent years, operator assistance systems have been installed in forest machines with the intention of reducing mental workload of machine operators, thereby improving productivity. However, knowledge of the actual effect of operator assistance systems on productivity is still lacking.

The present case study surveyed the effect of two recently released operator assitance features, Intelligent Boom Control (»IBC«) and a rotating cabin (»RC«), on productivity during loading cycles, by means of a time study. Therefore, IBC and RC were tested in different loading settings using a forwarder, John Deere 1210G. Three loading angles were tested (55°, 90° and 125° azimuthal and counterclockwise to the machine axis) in combination with five loading distances (4 m, 5.5 m, 7 m, 8.5 m, and 10 m distance from the crane pillar). The 15 loading positions were sampled using four variants (I: IBC off RC off, II: RC on IBC off, III: IBC on RC off, IV: IBC on RC on), capturing 10 replications for each position and variant, resulting in 600 loading cycles in total.

When the operator was not supported by any system, mean time consumption per loading cycle amounted to 20.6 ± 0.114 sec. The utilization of IBC resulted in a significant reduction in time consumption of 2 seconds per loading cycle. Moreover, further time savings were observed when IBC was engaged in combination with a rotating cabin, leading to a mean time consumption of 17.8 ± 0.114 sec (or 14% improvement) per loading cycle. Although the lowest time consumption was observed when IBC and RC were engaged, the use of RC alone did not show any significant time improvements.

Since loading activities occupy approximately 50% of the total cycle time in timber forwarding, potential time savings within this work element are crucial for further improvements of work productivity. This pilot case study quantified the time savings when IBC and RC were engaged during loading in an experimental setting. The results can be used as a basis for further investigations dealing with factors influencing the productivity of highly mechanized timber harvesting systems.

Effects of Boom-Tip Control and a Rotating Cabin on Loading Efficiency of a Forwarder: A Pilot Study

Florian Hartsch, Marian Schönauer, Christopher Pohle, Lorenz Breinig, Thilo Wagner, Dirk Jaeger

Abstract

Climate change and associated heat waves and droughts are causing enormous amounts of damaged wood in Central Europe. To face these challenges, mechanized timber harvesting systems consisting of single-grip-harvesters and forwarders are commonly employed due to their high productivity and work safety. Despite the advantages of these work systems, the operation of advanced forestry machines requires lengthy training and entails high levels of mental strain for machine operators. In recent years, operator assistance systems have been installed in forest machines with the intention of reducing mental workload of machine operators, thereby improving productivity. However, knowledge of the actual effect of operator assistance systems on productivity is still lacking.

The present case study surveyed the effect of two recently released operator assitance features, Intelligent Boom Control (»IBC«) and a rotating cabin (»RC«), on productivity during loading cycles, by means of a time study. Therefore, IBC and RC were tested in different loading settings using a forwarder, John Deere 1210G. Three loading angles were tested (55°, 90° and 125° azimuthal and counterclockwise to the machine axis) in combination with five loading distances (4 m, 5.5 m, 7 m, 8.5 m, and 10 m distance from the crane pillar). The 15 loading positions were sampled using four variants (I: IBC off RC off, II: RC on IBC off, III: IBC on RC off, IV: IBC on RC on), capturing 10 replications for each position and variant, resulting in 600 loading cycles in total.

When the operator was not supported by any system, mean time consumption per loading cycle amounted to 20.6 ± 0.114 sec. The utilization of IBC resulted in a significant reduction in time consumption of 2 seconds per loading cycle. Moreover, further time savings were observed when IBC was engaged in combination with a rotating cabin, leading to a mean time consumption of 17.8 ± 0.114 sec (or 14% improvement) per loading cycle. Although the lowest time consumption was observed when IBC and RC were engaged, the use of RC alone did not show any significant time improvements.

Since loading activities occupy approximately 50% of the total cycle time in timber forwarding, potential time savings within this work element are crucial for further improvements of work productivity. This pilot case study quantified the time savings when IBC and RC were engaged during loading in an experimental setting. The results can be used as a basis for further investigations dealing with factors influencing the productivity of highly mechanized timber harvesting systems.

Keywords: Forest work science, time study, mechanized harvesting, cut-to-length, forest operations, forwarding

1. Introduction

Central European forests are currently strongly affected by bark beetle calamities as a result of extreme drought in recent years (BMEL 2021 a). At the moment, salvage logging makes up around 75% of the total annual harvest in Germany (Destatis 2021). Extensive logistics challenges burden the German forest industry (BMEL 2021 b). Due to high occupational risks, damaged stands are often no longer entered by motormanual loggers, even though motormanual logging still plays an important role in German forestry (KWF 2010, BaySF 2022). Highly mechanized harvesting systems are extensively used due to both high system productivity and high occupational safety (Dvorak et al. 2008, Axelsson 2013). In Germany, around 50% of the total volume of timber is processed in a highly mechanized way (BaySF 2022, Labelle et al. 2017, Karjalainen et al. 2001), and probably even more at the time of publication of this study (Hoffmann and Jaeger 2021), with harvesters felling and processing the timber, and forwarders extracting it to the landing.

The productivity of such cut-to-length (CTL) systems is influenced by a variety of parameters, especially operator-related (Tervo et al. 2010, Palmroth 2011, Purfürst and Lindroos 2011, Manner 2021), stand and timber characteristics (Manner et al. 2013, Acuna and Kellogg 2009, Gingras and Favreau 2005, Bodelschwingh 2006, Eriksson and Lindroos 2014, Belisario et al. 2022), terrain-related factors (Proto et al. 2018, Bodelschwingh 2006, Eriksson and Lindroos 2014, Ghaffarian et al. 2007, Strandgard et al. 2015, Tiernan et al. 2004), technical parameters (Proto et al. 2018, Eriksson and Lindroos 2014, Tiernan et al. 2004), and general organizational aspects (Zimbalatti and Proto 2010). In this context, improvement potential in work processes can be observed during collaboration of harvester and forwarder work, e.g. depositing of processed timber along the machine operating trail for effective forwarding (Väätäinen et al. 2006). Therefore, detailed examination of single work elements and practices is suggested, and is currently the subject of scientific research (Hartsch et al. 2022, Hildt et al. 2020). Several studies revealed that the influence of individual operator performance on the productivity of such CTL systems is highly significant (Purfürst 2010, Purfürst and Erler 2010, Purfürst and Lindroos 2011). Consequently, operator support systems in both scientific research and forest machine development has experienced increased focus (Lindroos et al. 2017, Manner et al. 2017, Manner et al. 2019).

Assisting operators with technical support is a common and established but still evolving practice in the automotive industry (Bengler et al. 2014, Ziebinski et al. 2017, Köller and Hensel 2019, Kryzanowski 2021). Operator assistance, GNSS and digitalization have also been playing a role in forestry for several years (Zimbelman and Keefe 2018, Müller et al. 2019, Picchio et al. 2020, Latterini et al. 2022), as work tasks in modern timber harvesting systems require great mental strain (Grzywinski et al. 2008). Operator assistance increases safety, overview and efficiency and therefore reduces mental strain as well (Bendel 2021). Based on previous studies, operator assistance can be divided into six levels of automation: from driving without assistance to full automation with machine learning (Lindroos et al. 2017). In the forestry sector, operator assistance and automation processes are of increasing importance (Visser and Obi 2021). Already in the early 2000s, surveillance of machine operating areas was tested in forestry applications (Bombosch et al. 2003), and has since seen steady development (Lindroos et al. 2015, Öhman et al. 2008). Today, operator assistance in forestry focuses not only on logistics planning and optimization (John Deere 2022a, Pellegrini et al. 2013, Contreras et al. 2016) or the application of sensor technology (Picchio et al. 2019), but also on crane work and cabins, as individual operator performance, mental workload and human-centered optimization approaches of operations moves steadily into focus (Spinelli et al. 2020, Szewczyk et al. 2020, Holzinger et al. 2022).

To ensure higher productivity and better ergonomics, different machine manufacturers developed boom-tip control systems (John Deere 2021, Ponsse 2022, Komatsu Forest 2022). Such crane controls simplify the operation of the boom. While using Intelligent Boom Control (»IBC«, manufactured by John Deere company), control inputs are simplified by automatically controlling the extension (Manner et al. 2019). Studies revealed that the application of IBC can improve productivity (Manner et al. 2019) and decrease training extent for less experienced operators (Manner et al. 2017). In addition, a rotating cabin (»RC«) is considered state-of-the-art technology in modern CTL-systems. The rotation of the cabin is realized automatically by a motor, but can be deactivated if necessary (Paakkunainen 2015). Even if IBC and RC seem to improve operational efficiency, these systems have not been widely accepted, so far.

The effect of the application of operator assistance on the productivity of highly mechanized harvesting systems is the subject of the current research, where the loading element is of particular interest (Manner et al. 2017, Manner et al. 2019, Zemanek and Filo 2022). One loading cycle is defined as the time duration from a pre-defined boom position in the load space until the deposition of the log in the load space. Since the loading element occupies nearly 50% of the entire extraction time in forwarding cycles (Ghaffarian et al. 2007), and with the goal to identify improvement potential in terms of loading conditions in forwarding operations, the objective of this study was to analyze the ability of intelligent cranes and rotating cabins to reduce time consumption of loading cycles. The following research questions were addressed in this study:

How does the use of IBC and RC affect time consumption of forwarder loading cycles?

Are there any interactions between the use of IBC and RC and different loading settings?

Can areas of the loading cycle, where time savings due to IBC and RC peak, be identified?

In this study, 600 loading cycles were captured by means of a time study in an experimental setting, comprising of three loading angles and five loading distances. Time consumption per loading cycle was compared between the variants IBC (on/off), in combination with RC (on/off).

2. Materials and Methods

2.1 Machine and Operator

The time study was conducted with an eight-wheel John Deere 1210G forwarder (Fig. 1). The machine was equipped with a double telescopic crane, Intelligent Boom Control (IBC), and a rotating cabin (Table 1).

Fig. 1 John Deere Forwarder 1210 G used in the study

Table 1 Technical details of the crane used in the study (John Deere 2016)

|

unit |

||

|

Manufacturer |

John Deere |

|

|

Model |

CF7 |

|

|

Max. boom range |

m |

10 |

|

Gross lifting torque |

kNm |

125 |

|

Swing torque |

kNm |

32 |

|

Swing angle |

° |

380 |

|

Opening width (grapple) |

m |

1.82 |

|

Gripping area (grapple) |

m² |

0.95 |

The operator selected for the study was a forest machine operator instructor (male, 54 years old, 12 years experience in operating forwarders) at the Forest Education Center of the Northrhine-Westfalian state forest service.

2.2 Study, Settings and Variants

To ensure a precise analysis of the loading work element in interaction with the operator assistance systems tested, it was decided to conduct a time study focussing on measurements of time consumption per loading cycle. The key methodology steps were similar to a previous case study on the loading work element (Hartsch et al. 2022), but were adapted to achieve the specific objectives of this study.

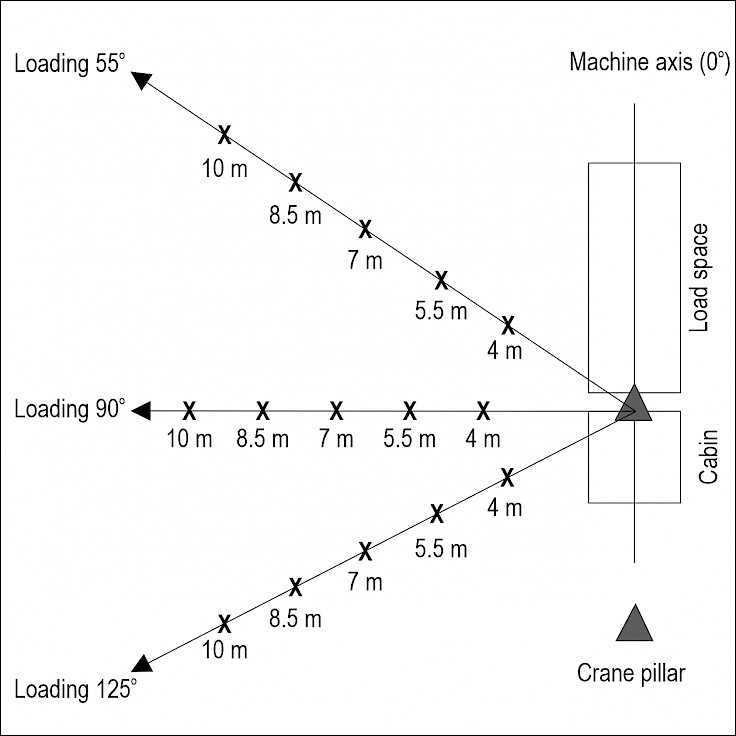

During the study, the forwarder was operated on flat terrain from a fixed position. In total, 15 different loading positions (settings) were defined in a typical working range. These included three loading angles (55°, 90° and 125° azimuthal and counterclockwise to the machine axis). For each loading angle, five loading distances to the crane pillar were set (4 m, 5.5 m, 7 m, 8.5 m, 10 m) (Fig. 2). At each of the 15 different loading settings, four treatments (Table 2) were applied. To clearly illustrate the interaction of the different combinations of operator assistance systems (variants) and time consumption per loading cycle, letters »T« (true) and »F« (false) were used to show whether the systems were activated or deactivated during the measured loading cycles. For each loading position and variant, 10 loading cycles were captured (i.e. 600 loading cycles in total). Consistency of visibility of the loading positions was ensured by repeatedly marking the positions on the ground using spray paint.

Fig. 2 15 different loading settings with John Deere Forwarder 1210 G, indicated by black »x«

Table 2 Different test variants applied with each of 15 different loading settings

|

Test Variant |

IBC |

Rotating Cabin |

|

I |

Deactivated (F) |

Deactivated (F) |

|

II |

Deactivated (F) |

Activated (T) |

|

III |

Activated (T) |

Deactivated (F) |

|

IV |

Activated (T) |

Activated (T) |

Loading angles and loading distances to the crane pillar were determined using a compass and a measuring tape. It was assumed that loading a grapple full of logs would have led to an increased variance and error rate of time consumption per loading cycle as operators in practice, depending on the concentration grade of logs along the skidtrail, need to merge the logs to fully use the capacity of the grapple (Väätäinen et al. 2006). Therefore, and as the study intended to focus on the loading work element, it was decided to load only one 3 m log per cycle. At each loading position, the log (length = 3 m, mid-diameter = 0.28 m) was positioned perpedicularly (90°) to the machine axis. The middle of the log was marked by spray paint to designate the gripping position on the log to avoid bias caused by varied gripping position between loading cycles. One loading cycle included the duration from a predefined boom position in the load space until the deposition of the log in the load space (Fig. 3). A stopwatch (accurate to hundreths of a second) was used to measure loading cycles, which started when the boom movement for loading the log was started and stopped by the operator. After time measurements were taken, the operator was instructed to reposition the log either in the same loading position (if 10 repetitions were not reached for the setting yet) or in the next one, and to prepare the boom for the next loading cycle. Footage of all loading cycles was captured to allow for subsequent analysis and verification.

Fig. 3 Forwarder at start (left) and end (right) of loading cycle

2.3 Statistical Analysis

Data were available for 600 loading cycles in total. The data were analyzed using the free software language R (version 4.0.5, R Core Team 2020), interfaced with RStudio (version 1.4.1103, RStudio, PBC, Boston, MA, USA). The response variable »time consumption per loading cycle« TCL was fitted using a »full« linear model, including all available variables: loading distance, loading angle, as well as IBC and RC as dummy variables and potential interactions between. The independent variables were treated as factors due to distance-specific patterns of time consumption per loading cycle (Hartsch et al. 2022). Homoscedasticity of TCL across groups according to levels of the independent variables, as well as the interaction of IBC and RC, was tested for and confirmed by Levene's tests. Normal distribution of the residuals was tested and confirmed by means of a Shapiro-Wilk test. Least-squares means were estimated using the package {emmeans} (Lenth et al. 2019). Pairwise comparisons were conducted between each setting and treatment {package: multComp} (Hothorn et al. 2008) using Tukey´s HSD post-hoc test. Visualization (graphing) was performed using {package: ggplot2} (Kassambara et al. 2020). The significance level for all tests was set at α = 0.05, and least-squares means were caluculated with their standard error (SE) and confidence limits for a 95%-interval.

3. Results

3.1 Overall Time Consumption per Variant and Setting

The time study revealed an average time consumption per loading cycle (TCL) of 19.5 ± 0.11 seconds across all settings tested. Mean TCL per setting and variant ranged between a minimum of 14.6 ± 0.935 seconds, observed when loading was carried out from a distance of 4 m and at a loading angle of 55°, with IBC and RC activated, to a maximum of 22.3 ± 1.477 seconds, when loading was done at 10 m, under 55°, with RC activated, but IBC deactivated.

To test for statistically significant differences of TCL between the settings and variants, a linear model was chosen, integrating the independent variables IBC and RC, as well as loading distance and loading angle. All predictors were found to be highly significant, with loading distance having the highest explanatory power in the regression (Supplementary information A1). The application of both systems (IBC and rotating cabin) resulted in time savings per loading cycle. The use of IBC resulted in a mean decrease of TCL of 1.9 seconds (IBC: on, TCL = 18.6 ± 0.0803 sec.; off, TCL = 20.5 ± 0.0803 sec.). With RC activated, TCL was reduced by 0.9 seconds (Rotation: on, TCL = 19.1 ± 0.0803; off, TCL = 20.0 ± 0.0803).

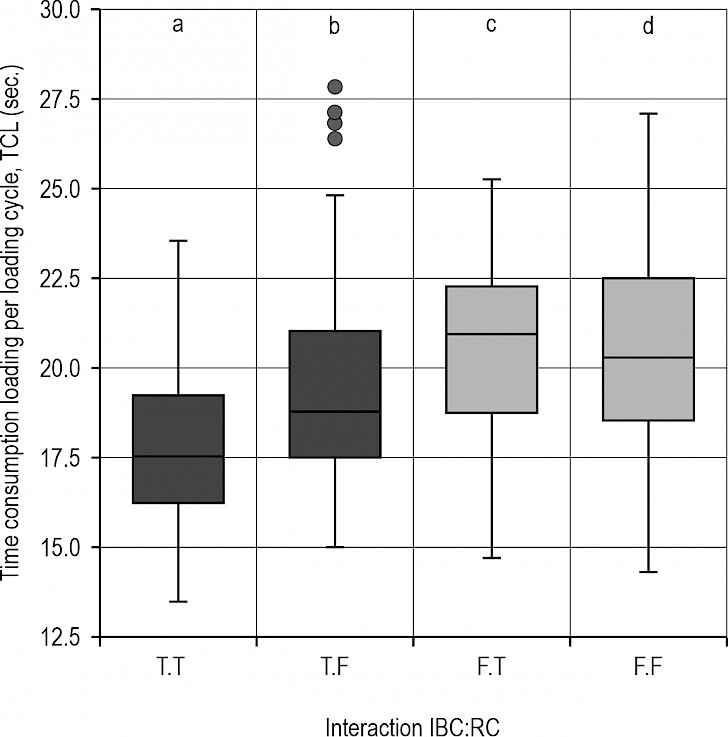

A significant interaction could be observed between the factors IBC and RC (Supplementary information A1). This resulted in specific distributions of time consumption per loading cycle (Fig. 4). Lowest TCL was observed when the machine was operated with IBC and RC activated, averaging 17.8 ± 0.114 sec per loading cycle. With IBC activated and RC deactivated (T.F, Fig. 4), TCL was greater by 1.7 seconds. Significantly higher values of TCL were observed when the crane movement was not supported by IBC, with 20.4 ± 0.114 sec and 20.6 ± 0.114 sec when RC was activated and deactivated, respectively. An influence of RC on TCL could not be confirmed when IBC was deactivated during loading.

Fig. 4 Time consumption per loading cycle (TCL) of a John Deere Forwarder 1210 G. The »interaction« (»T« = true, on; »F« = false, off) refers to the use of the operator assistance system »Intelligent Boom Control« (IBC in dark grey fill) and rotating cabin (RC in light grey fill). Small caps indicate significant differences

3.2 Interactions Between Variants and Loading Conditions

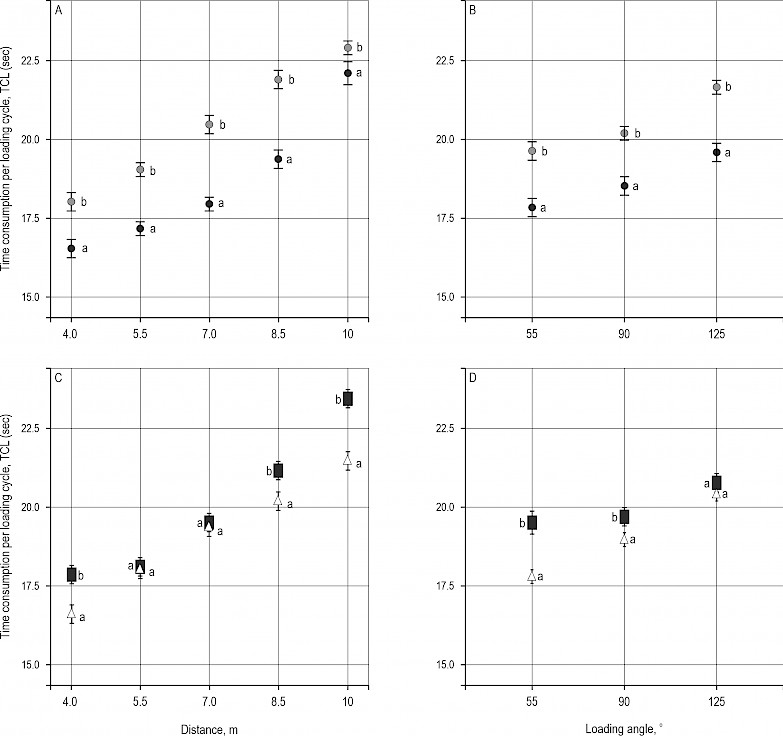

The differences in TCL between the combination of variants (i.e. IBC:RC) were reflected on the levels of loading distance and loading angle. The overall difference in TCL caused by the utilization of IBC was 1.9 seconds. The analysis showed that the effect of IBC on time consumption per loading cycle was more profound in loading distances between 5.5 m and 8.5 m, as compared to the short or long loading distances of 4.0 and 10.0 m (Fig. 5 A). At a loading distance of 10 m, differences between TCL per variant were low, with 0.9 sec (Fig.5 A). Across the tested loading angles, IBC was able to uniformly reduce TCL (Fig. 5 B). Contradicting patterns occurred within the variant RC (Fig. 5 C and D). When a rotation of the cabin was activated, TCL was reduced by 0.9 sec. This value was driven through differences occurring in short and long loading distances. When loading was done at 10 m and RC was activated, TCL decreased by 2.1 sec (Fig. 5 C), compared to the fixed cabin. Differences in TCL caused by RC generally decreased with increasing loading angle, as shown in Fig. 5 D.

Fig. 5 Time consumption per loading cycle (TCL) at different loading angles (n=50) and loading distances (n=30). »Intelligent Boom Control« (IBC) was either activated (dark grey points) or deactivated (light grey points) (A, B). The rotating cabin (RC) was either activated (triangles), or deactivated (squares) (C, D), resulting in 600 loading cycles in total

3.3 Time Consumption per Test Variant

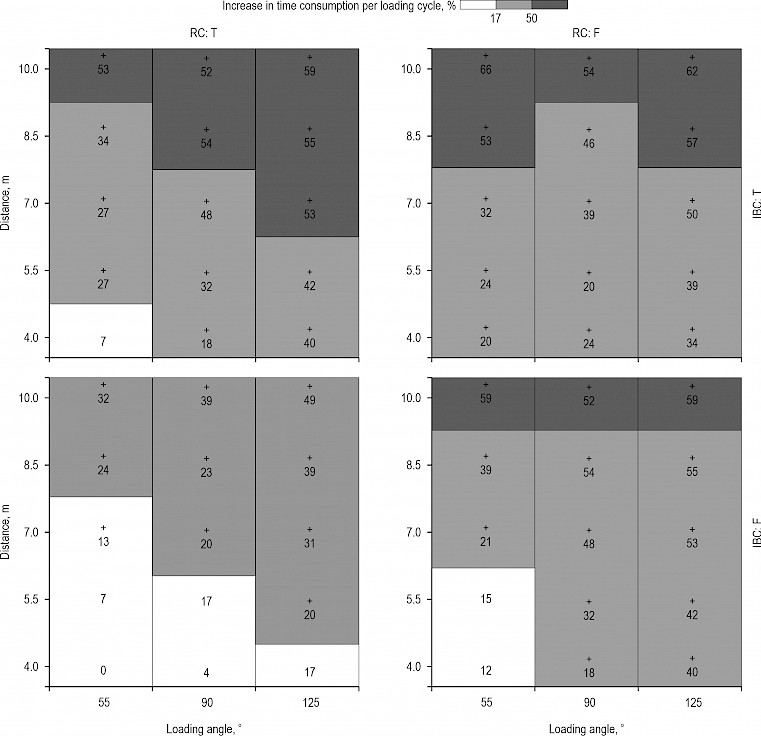

Tukey´s HSD post-hoc test was used to identify the settings resulting in significantly higher values of TCL in relation to the reference setting, i.e. the setting with the lowest TCL. Fig.6 illustrates that the lowest mean TCL was observed when loading was done from the shortest distance and smallest angle, and with both IBC and RC activated. Within this combination of activated systems, several settings of loading distance and loading angle resulted in similar loading efficiency. In general, short loading distance and small loading angles led to lower TCL. Without support of IBC, increases of TCL ranged from between +7% and +66% compared to the reference setting (Fig. 6), with the highest increases occurring at longer loading distances. During loading with IBC activated and RC deactivated, relatively low values of TCL occurred at short loading distances and at a loading angle of 55°, yet high values occurred at the longest loading distance resulting in a maximum increase in TCL of up to +75%.

Fig. 6 Relative increase in time consumption per loading cycle (TCL) in relation to the reference setting (14.6 ± 0.935 sec.), using »Intelligent Boom Control« (IBC) and/or cabin rotation (RC) (»T«=true; »F«=false). »+« indicates significant differences according to a Tukey HSD post-hoc test

4. Discussion

4.1 Limitations of Study Setup

Overall, the study setup with the possibility to observe standardized loading sequences was suitable to highlight the effect of IBC and RC on time consumption of forwarder loading cycles. Since the loading element occupies nearly 50% of the total extraction time in forwarder work (Ghaffarian et al. 2007), the results may be of importance for practitioners. The isolation of the loading work element allowed for clear measurment of the influence of the chosen operator assistance systems on TCL of forwarders.

The study design was set up to avoid bias caused by terrain- and stand-specific conditions. However, the stationary loading setup was not able to show how e.g. obstacles or terrain related aspects could affect the ability of operator assistance systems to reduce TCL. Other studies revealed that especially boom-tip control systems can save up to 5.2% of productive machine time in forwarding operations (Manner et al. 2019). Results of the present study revealed 10% time savings for the use of IBC. The potential impact of IBC in combination with RC (14% time savings compared to the reference setting) is likely to be less profound in practice, as this study only took the loading element into account. This corresponds to the results of Manner et al. (2019) in which time savings less than the results of this study were found. Studies revealed that the use of RC is able simplify the orientation of forest machine operators in forest stands (Paakkunainen 2015).

Loading distances were adapted to the maximum crane reach. In practice, the positioning of the machine is crucial in loading efficiency (Holzfeind et al. 2018), but also strongly depends on stand- and site-specific charactersitics (Proto 2018). Therefore, the study design could only provide limited insight into the influence of operator assistance systems on TCL through the tested loading distances and angles, as the full variety of potential machine surroundings could not be displayed.

The gripping position at the log was pre-defined and marked using spray paint. In practice, machine operators tend to grip the logs slightly offset from the the middle to facilitate the placement in the load space. Video analysis of the loading cycles showed that this led to few corrections of the gripping position, due to the predefinition of the gripping point, which also increased loading time consumption. Furthermore, no statement can be made on the extent to which the use of both tested systems could influence TCL when using logs longer than 3 m.

Due to limited time, it was not possible to consider loading from both sides of the forwarder. Psychology studies show that machines are operated according to the individual preferences of their operators (Olson and Sarter 2009). It can be assumed that forest machine operators also have individual preferences that could influence the productivity per loading side.

Due to time and financial constraints, it was decided to work with only one forest machine operator. Therefore, it was important to recruit an experienced operator in order to avoid any bias in observations due to insufficient experience. Homogenity of variance of the test settings allows for comparison of the sub-samples. The increasing levels in productivity are similar to those measured by Manner et al. (2019). Therefore, it can be assumed that in this study, the effect of operator experience was minimized and that the observed patterns are transferable to other operators, at least to some extent. It was not the objective of this study to conduct an operator comparison, but to analyze standardized loading cycles under the influence of activation or deactivation of IBC and RC, in as detailed a manner as possible. Therefore, it is important to refrain from generalizing the results, as productivity differences between machine operators can be very large (Ovaskainen et al. 2004).

4.2 Ability of IBC and RC to Reduce Time Consumption per Loading Cycle

Results showed that TCL varied depending on the loading angle and loading distance, but according to the test variant applied. TCL ranged from between a minimum of 14.6 ± 0.935 sec, observed when loading at a distance of 4 m and under a loading angle of 55°, with IBC and RC activated, to a maximum of 22.3 ± 1.477 sec.

In a previous study on the loading element itself, the authors did not find a significant difference in TCL between short and long loading distances from the machine, with the relationship between TCL and loading distance behaving non-linearly, with the lowest TCL at medium distances of 4–5 m (Hartsch et al. 2022). The results of the present study revealed an increased TCL with increased loading distance.

The low variance in TCL could indicate that the machine operator had a high level of experience. In this context, it is important to mention that IBC has a different effect on experienced and beginner machine operators (Manner et al. 2017).

Taking a closer look at the test variants applied, results revealed that the use of the rotating cabin alone had no significant influence on TCL. The situation was different when the RC was deactivated and IBC was activated – TCL was significantly reduced. And when IBC and RC were both activated, TCL was further reduced to 17.8 seconds per loading cycle, which could be related to the generally improved work environment.

It is possible that due to the high level of experience of the machine operator, the potential benefit for productivity of this assistance system was not fully recognizable. Although manufacturers also advertise increased productivity with RC (John Deere 2022 b), this could not be confirmed in the present study, at least with regard to the loading work element. Perhaps a more likely benefit of RC lies in improved operator ergonomics. A positive influence of RC on the posture or movement of the upper body is very likely. Rapid upper limb assessment (RULA) could be an adequate method to investigate strains of the upper muscoskeletal system (Cremasco et al. 2019).

When IBC was activated, TCL was reduced from 20.6 ± 0.114 sec (both systems deactivated) to 18.6 ± 0.0803 sec. It can be assumed that in real-world scenarios the effect of IBC on the whole forwarding cycle would be less profound, since the results of the present study only consider the loading work element. This is also confirmed by other studies (Manner et al. 2019). Machine operators also reported that cognitive load is greatly reduced when using IBC (Bläsing and Bornewasser 2021). Other studies showed that IBC is not only suitable for reducing TCL, but also to reduce damage to the machine caused by crane work (Zemanek and Filo 2022).

A further reduction of TCL to 17.8 ± 0.114 sec was possible, when in addition to IBC, RC was activated. Although a professional machine operator was tested and therefore a low level of variance in time consumption during loading was assumed, TCL could be strongly reduced, depending on the setting applied. It is possible that by using IBC and RC together, the machine operator was able to focus more on the execution of crane work. Based on the results, visibility of the logs could also be crucial in reducing TCL. With RC activated, the field of view was automatically centered to the work area, allowing the operator to focus more on the loading element itself.

In general, the use of IBC and RC had a considerable influence on TCL, depending on the setting applied and interactions between IBC and RC. Apparent synergistic effects between the use of RC and IBC together should also be mentioned here, which may represent a kind of optimum variant based on the results. TCL could be reduced from 20.6 ± 0.114 sec (both systems deactivated) to 17.8 ± 0.114 sec (both systems activated).

4.3 Interactions Between Variants and Loading Conditions

Results revealed that when IBC was activated, TCL could be significantly reduced. However, this effect was strongest between 5.5 and 8.5 m loading distance, compared to loading from a close (4 m) or a far (10 m) distance. TCL could be reduced for all tested loading angles with IBC activated, with the potential for maximum time savings per loading cycle being highest at 125° loading angle.

When loading at the 125° angle, the operator needed to adjust his body posture in the cabin to be able to observe the grapple. Due to the change in posture, it is conceivable that the simplified coordination stemming from the help of the IBC system enabled more purposeful crane movements and thus had a positive influence on loading efficiency. Manner et al. (2017) also reported easier crane operation by using IBC.

For short (4 m) and longer (10 m) loading distances, RC seemed to have a positive effect on time consumption per loading cycle. Taking loading angle into account, a reduction in TCL, with rotating cab activated, occurred at the 55° loading angle. However, loading positions of the other angles (55° and 90°) were slightly negatively affected by RC. This could be related to the visibility of the logs. The forest machine operator reported that in some loading positions, the log was briefly hidden from the machine operator's view due to the design of the cabin. Video recordings from the machine operator's point of view for additional in-depth analyses could support this observation.

In general, the use of IBC and RC lead to interactions at certain loading distances and loading angles. However, the effect of the tested systems varied depending on the loading setting. In a nutshell, a reduction in TCL was seen with IBC under all loading distances and angles, but especially at medium loading distances (5.5 – 8.5 m) and »unproductive« loading angles (125°). RC showed advantages especially at the 55° loading angle.

4.4 Time Consumption per Test Variant

When IBC was deactivated, TCL increased between +7 and +66% compared to the reference variant, depending on the loading angle and distance. Although the maximum increase occurred with IBC activated (+75% compared to the reference variant), it can be stated that the overall increase in time consumption with larger loading angles and distances is lower when using IBC. Results showed that IBC could be the decisive factor for a possible reduction in the time requirement. However, significant increases in TCL (up to +17%) also occurred when IBC was activated and the RC was deactivated. The use of IBC seemed to lead to improved focus on the work task. By eliminating the extension joystick function, the forest machine operator can concentrate more on the loading process. Studies revealed that cognitive demands and task complexity can affect human performance and workload (Layer et al. 2009, Bläsing and Bornewasser 2021).

Compared to the reference setting, the smallest increase in TCL was observed at the 55° loading angle. Short loading distances also seemed to be advantageous. The results confirm the findings by a previous study (Hartsch et al. 2022), where shorter loading distances as well as small loading angles were highlighted as optimal loading settings.

Based on the results of this study, it can be concluded that it is less the RC that appears to be characteristic for an improvement in loading productivity, but rather the use of IBC. In this context, the effect of IBC seems to be stronger at different loading angles and distances (see 4.3). However, the most productive loading areas are quite close to the machine. The study has demonstrated the importance of the preliminary work of the harvester for the subsequent forwarder, as also shown by, for example, Manner et al. (2013) and Väätäinen et al. (2006). Especially in thinnings, the demand on log placement increases. If these are positioned close to the machine operating trail, the work is made easier for the forwarder operator due to reduced loading distances resulting in shorter loading cycles.

Overall, future research should aim to investigate more factors that affect forwarder productivity. In forest engineering, it is fundamentally difficult to create laboratory conditions. The goal of the present study was to create as controlled loading conditions as possible to be able to investigate how operator assistance systems could impact time consumption of forwarder loading cycles. However, since the loading element alone is not sufficient for a comprehensive assessment of a forwarder productivity, future studies could include more complex aspects affecting forwarder productivity, such as obstacles in the loading area or further operator comparisons. The study does not claim to be exhaustive, but it does give some indications as to how further studies could be structured. In addition to already existing studies, the effectiveness of IBC during training of machine operators should be further examined, as well as technical advancements of the systems and their effect on the productivity of the loading process.

5. Conclusions

To summarize, the results have shown three key findings:

In total, the use of IBC was able to significantly reduce TCL. In combination with IBC, the use of RC lead to a further reduction in TCL.

When using IBC, TCL was reduced over all tested loading distances and angles. This effect became more pronounced when IBC was activated at medium loading distances (5.5 – 8.5 m) and at the 125° loading angle. The use of RC reduced TCL, especially at short (4 m) and long (10 m) loading distances, as well as at the 55° loading angle.

Productive loading »areas«, showing the highest potential for time savings during loading cycles were found to consist of shorter loading distances and small loading angles, which can be supported extensively by using operator assistance systems. This shows the importance of appropriate positioning of the forwarder before loading.

The methods applied as well as the different variants and settings are suitable for performing an in-depth-analysis of the loading work element. However, the transferability to real-world scenarios is limited, since other work elements and factors also influence TCL.

Due to the importance of highly mechanized timber harvesting systems in world forestry, a detailed analysis of further performance determining factors is suggested. The analysis of factors influencing forwarder productivity, differentiated by work elements, can contribute to increased productivity of forest machines and therefore a reduction of harvesting costs. Although softwood stands are deeply affected by drought and bark beetle infestations in central Europe, highly mechanized harvesting systems will continue to be state-of-the-art technology, as many areas are reforested with other coniferous species, such as larch or Douglas fir. Even in younger hardwood stands, harvesters and forwarders are increasingly used.

The study cannot fully represent real-world conditions since other performance determining factors and work elements were not considered. However, the goal of this study was to analyze the influence of selected operator assistance systems on the loading work element itself, in as much detail as possible. Since the loading element is one of the most important in forwarding operations, the results can contribute to a better understanding of performance determining factors in highly mechanized harvesting systems and provide a basis for further investigations.

Acknowledgments

The authors would like to thank the Forest Education Center, Center for Forest and Timber Industry, State Enterprise Forestry and Timber Northrhine Westfalia, for the provision of a forwarder. In particular, thanks go to the forest machine operator trainer Michael Schulte.

Funding

The research was funded within the framework of the EU-project AVATAR under the umbrella of ERA-NET Cofound ForestValue by Fachagentur Nachwachsende Rohstoffe e.V. (FNR). ForestValue has received funding from the European Union´s Horizon 2020 research and innovation programme under grant agreement No. 773324.

Appendix A

Table A1 Analysis of Variance Table

|

Df |

Sum Sq |

Mean Sq |

F value |

Pr(>F) |

|

|

Distance |

4 |

2049.76 |

512.44 |

265.11 |

7.21e-126 |

|

IBC |

1 |

513.10 |

513.10 |

265.45 |

7.79e-49 |

|

Angle |

2 |

383.94 |

191.97 |

99.31 |

1.87e-37 |

|

RC |

1 |

125.46 |

125.46 |

64.91 |

5.06e-15 |

|

Distance:IBC |

4 |

55.57 |

13.89 |

7.19 |

1.21e-05 |

|

Distance:Angle |

8 |

64.63 |

8.08 |

4.18 |

7.20e-05 |

|

IBC:Angle |

2 |

7.46 |

3.73 |

1.93 |

1.46e-01 |

|

Distance:RC |

4 |

81.88 |

20.47 |

10.59 |

2.88e-08 |

|

IBC:RC |

1 |

77.32 |

77.32 |

40.00 |

5.33e-10 |

|

Angle:RC |

2 |

49.42 |

24.71 |

12.78 |

3.76e-06 |

|

Distance:IBC:Angle |

8 |

64.29 |

8.04 |

4.16 |

7.72e-05 |

|

Distance:IBC:RC |

4 |

12.63 |

3.16 |

1.63 |

1.64e-01 |

|

Distance:Angle:RC |

8 |

31.71 |

3.96 |

2.05 |

3.89e-02 |

|

IBC:Angle:RC |

2 |

25.08 |

12.54 |

6.49 |

1.64e-03 |

|

Distance:IBC:Angle:RC |

8 |

33.35 |

4.17 |

2.16 |

2.93e-02 |

|

Residuals |

540 |

1043.80 |

1.93 |

NA |

NA |

6. References

Acuna, M.A., Kellogg, L.D., 2009: Evaluation of Alternative Cut‐to‐Length Harvesting Technology for Native Forest Thinning in Aus‐tralia. International Journal of Forest Engineering 20(2): 19–27. https://doi.org/10.1080/14942119.2009.10702579

Axelsson, S., 2013: The Mechanization of Logging Operations in Sweden and its Effect on Occupational Safety and Health. International Journal of Forest Engineering 9(2): 25–31. https://doi.org/10.1080/08435243.1998.10702715

Bayerische Staatsforsten (BaySF), 2022: Maschinen.

Belisario, A.V., Fiedler, N.C., de Assis do Carmo, F.C., Moreira, G.L., 2021: Influence of Log Length on the Productivity of Wood Harvesting and Transportation. Floresta 52(1): 17–24. https://doi.org/10.5380/rf.v52i1.73246

Bendel, O., 2021: Definition: Fahrerassistenzsystem: Gabler Wirtschaftslexikon. Springer Fachmedien, Wiesbaden, Germany.

Bengler, K., Dietmayer, K., Färber, B., Maurer, M., Stiller, C., Winner, H., 2014: Three Decades of Driver Assistance Systems: Review and Future Perspectives. IEEE Intelligent Transportation Systems Magazine 6(4): 6–22. https://doi.org/10.1109/MITS.2014.2336271

Bläsing, D., Bornewasser, M., 2021: Influence of Increasing Task Complexity and Use of Informal Assistance Systems on Mental Workload. Brain Sciences 11(1): 102. https://doi.org/10.3390/brainsci11010102

Bodelschwingh, E.v.: Analyse der Rundholzlogistik in der Deutschen Forst‐ und Holzwirtschaft—Ansätze für ein Übergreifendes Supply Chain Management. Technische Universität München, Lehrstuhl für Forstliche Arbeitswissenschaft und Angewandte Informatik, Freising. PhD-Thesis. 214 p.

Bombosch, F., Bobey, K., Brekerbohm, L., Burdick, R., Sohns, D., Dreeke, R., 2003: Harvester lernen sehen. Forst und Technik 5: 14–19.

Bundesministerium für Ernährung und Landwirtschaft (BMEL), 2021a: Ergebnisse der Waldzustandserhebung 2020. Publisher: Bundesministerium für Ernährung und Landwirtschaft (BMEL), Referat 515 – Nachhaltige Waldbewirtschaftung, Holzmarkt, Bonn, Germany, 72 p.

Bundesministerium für Ernährung und Landwirtschaft (BMEL), 2021b: Waldbericht der Bundesregierung 2021. Publisher: Bundesministerium für Ernährung und Landwirtschaft (BMEL), Referat 513 – Nationale Waldpolitik, Jagd, Kompetenzzentrum Wald und Holz, Bonn, Germany, 84 p.

Contreras, M.A., Parrott, D.L., Chung, W., 2016: Designing Skid-Trail Networks to Reduce Skidding Cost and Soil Disturbance for Ground-Based Timber Harvesting Operations. Forest Science 62(1): 48–58. https://doi.org/10.5849/forsci.14-146

Cremasco, M.M., Giustetto, A., Caffaro, F., Colantoni, A., Cavallo, E., Grigolato, S., 2019: Risk Assessment for Muscoskeletal Disorders in Forestry: A Comparison between RULA and REBA in the Manual Feeding of a Wood-Chipper. International Journal of Environmental Research and Public Health 16(5): 793. https://doi.org/10.3390/ijerph16050793

Dvorak, J., Malkowsky, Z., Macku, J., 2008: Influence of Human Factor on the Time of Work Stages of Harvesters and Crane‐Equipped Forwarders. Journal of Forest Science 54(1): 24–30.

Eriksson, M., Lindroos, O., 2014: Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow‐up datasets. International Journal of Forest Engineering 25(3): 179–200. http://dx.doi.org/10.1080/14942119.2014.974309

Ghaffarian, M.R., Stampfer, K., Sessions, J., 2007: Forwarding Productivity in Southern Austria. Croatian Journal of Forest Engineering 28(2): 169–175.

Gingras, J.F., Favreau, J., 2005: Effect of Log Length and Number of Products on the Productivity of Cut‐to‐Length Harvesting in the Boreal Forest. Advantage 6(10): 1–8.

Grzywinski, W., Tomczak, A., Jelonek, T., Wandycz, A., 2008: Assessment of Multifunction Machines Operators´ Workload during Mechanized Timber Harvesting. In: Integrované Ťažbovo-Dopravné Technológie – Integrated Logging Technology. Publisher: Technická Univerzita vo Zvolene, Lesnícka Fakulta, 55–61 p.

Hartsch, F., Schönauer, M., Breinig, L., Jaeger, D., 2022: Influence of Loading Distance, Loading Angle and Log Orientation on Time Consumption of Forwarder Loading Cycles: A Pilot Case Study. Forests 2022 13(3): 384. http://dx.doi.org/10.3390/ f13030384

Hildt, E., Leszczuk, A., Mac Donagh, P., Schlichter, T., 2020: Time Consumption Analysis of Forwarder Activities in Thinning. Croatian Journal of Forest Engineering 41(1): 13–24. http://dx.doi.org/10.5552/crojfe.2020.615

Hoffmann, S., Jaeger, D., 2021: Insights on motor-manual tree felling in Germany, recent developments to ensure efficient operations in singletree selection harvest. European Journal of Forest Engineering 7(1): 39–44. https://doi.org/10.33904/ejfe.953226

Holzinger, A., Saranti, A., Angerschmid, A., Retzlaff, C.O., Gronauer, A., Pejakovic, A., Medel-Jimenez, F., Krexner, T., Gollob, C., Stampfer, K., 2022: Digital Transformation in Smart Farm and Forest Operations Needs Human-Centered AI: Challenges and Future Directions. Sensors 22(8): 3043. http://dx.doi.org/10.3390/s22083043

Holzfeind, T., Stampfer, K., Holzleitner, F., 2018: Productivity, setup time and costs of a winch-assisted forwarder. Journal of Forest Research 23(2): 1–8. http://dx.doi.org/10.1080/13416979.2018.1483131

Hothorn, T., Bretz, F., Westfall, P., 2008: Simultaneous Inference in General Parametric Models. Biometrical Journal 50(3): 346–363. https://doi.org/10.1002/bimj.200810425

John Deere, 2016: 1110G / 1210G / 1510 G. More than a machine. Product data sheet. Finland, 6 p.

John Deere, 2021: Neue Version der IBC führt Funktionen zur Fahrerassistenz ein.

John Deere, 2022a: Timbermatic Karten.

John Deere, 2022b: 910 G Rückezug.

Karjalainen, T., Zimmer, B., Berg, S., Welling, J., Schwaiger, H., Finer, L., Cortijo, P., 2001: Energy, Carbon and Other Material Flows in the Life Cycle Assessment of Forestry and Forest Products: Achievements of the Working Group 1 of the COST Action E9. Publisher: European Forest Institute, Joensuu, Finland. Discussion Paper 10: 43 p.

Kassambara, A., 2020: ggpubr: 'ggplot2' Based Publication Ready Plots.

Komatsu Forest, 2022: Komatsu Smart Crane. Einfacher, ergonomischer und produktiver.

Köller, K., Hensel, O., 2019: Verfahrenstechnik in der Pflanzenproduktion. Publisher: Eugen Ulmer, Stuttgart, Germany.

Kryzanowski, T., 2021: Fahrerlose Holz-LKW in Kanada. Forst & Technik, 10, 8.

Kuratorium für Waldarbeit und Forsttechnik, e.V. (KWF), 2010: Lastenheft Harvestervermessung. KWF-Bericht Nr. 41/2010.

Labelle, E.R., Bergen, M., Windisch, J., 2017: The effect of quality bucking and automatic bucking on harvesting productivity and product recovery in a pine-dominated stand. European Journal of Forest Research 136(4): 639–652. http://dx.doi.org/10.1007/s10342- 017-1061-4

Latterini, F., Stefanoni, W., Venanzi, R., Tocci, D., Picchio, R., 2022: GIS-AHP Approach in Forest Logging Planning to Apply Sustainable Forest Operations. Forests 2022(13): 484. http://dx.doi.org/10.3390/f130304

Layer, J.K., Karwowski, W., Furr, A., 2009: The effect of cognitive demands and perceived quality of work life on human performance in manufacturing environments. International Journal of Industrial Ergonomics 39(2): 413-421. http://dx.doi.org/10.1016/j.ergon.2008.10.015

Lenth, R.V., Buerkner, P., Herve, M., Love, J., Riebl, H., Singmann, H., 2019: emmeans: Estimated Marginal Means aka Least-Squares Means.

Lindroos, O., Ringdahl, O., La Hera, P., Hohnloser, P., Hellström, T., 2015: Estimating the Position of the Harvester Head – a Key Step towards the Precision Forestry of the Future? Croatian Journal of Forest Engineering 36(2): 147–164.

Lindroos, O., La Hera, P., Häggström, C., 2017: Drivers of Advances in Mechanized Timber Harvesting – a Selective Review of Technological Innovation. Croatian Journal of Forest Engineering 38(2): 243–258.

Manner, J., Nordfjell, T., Lindroos, O., 2013: Effects of the number of assortments and log concentration on time consumption of forwarding. Silva Fennica 47(4): 1–19. https://doi.org/10.14214/sf.1030

Manner, J., 2021: What is (not) an operator effect in forest work science? Silva Fennica 55(1): 1–4. https://doi.org/10.14214/sf.10542

Manner, J., Gelin, O., Mörk, A., Englund, M., 2017: Forwarder crane's boom tip control system and beginner-level operators. Silva Fennica 51(2): article id 1717. http://dx.doi.org/10.14214/sf.1717

Manner, J., Mörk, A., Englund, M., 2019: Comparing forwarder boom‐control systems based on an automatically recorded follow‐up dataset. Silva Fennica 53(2): 1–15. http://dx.doi.org/10.14214/sf.10161

Müller, F., Jaeger, D., Hanewinkel, M., 2019: Digitization in wood supply—A review on how Industry 4.0 will change the forest value chain. Computers and Electronics in Agriculture 162: 206–218. https://doi.org/10.17632/3pjs44k794.1

Öhman, M., Miettinen, M., Kannas, K., Jutila, J., Visala, A., Forsman, P., 2008: Tree Measurement and Simultaneous Localization and Mapping System for Forest Harvesters. Field and Service Robotics book series Star 42: 369–378. https://doi.org/10.1007/978-3-540-75404-6_35

Olson, W.A., Sarter, N.B., 2000: Automation Management Strategies: Pilot Preferences and Operational Experiences. International Journal of Aviation Psychology 10(4): 327–341. https://doi.org/10.1207/S15327108IJAP1004_2

Ovaskainen, H., Uusitalo, J., Väätäinen, K., 2004: Characteristics and Significance of a Harvester Operators' Working Technique in Thinnings. International Journal of Forest Engineering 15(2): 67–77. https://doi.org/10.1080/14942119.2004.10702498

Paakkunainen, M., 2015: Ergonomics and productivity improvements through machine automation. In: Forest engineering: making a positive contribution. Abstracts and Proceedings of the 48th Symposium on Forest Mechanization, Linz, Austria, 5–8 p.

Palmroth, L., 2011: Performance Monitoring and Operator Assistance Systems in Mobile Machines. Ph.D. Thesis. Publisher: Tampere University of Technology, Tampere, Finland.

Pellegrini, M., Ackerman, P., Cavalli, R., 2013: On-board computing in forest machinery as a tool to improve skidding operations in South African softwood sawtimber operations. Southern Forests 75(2): 89–96. https://doi.org/10.2989/20702620.2013.785107

Picchio, R., Proto, A.R., Civitarese, V., Di Marzio, N., Latterini, F., 2019: Recent Contributions of Some Fields of the Electronics in Development of Forest Operations Technologies. Electronics 8(12): 1465. https://doi.org/10.3390/electronics8121465

Picchio R., Latterini F., Mederski P.S., Tocci D., Venanzi R., Stefanoni W., Pari L., 2020: Applications of GIS-Based Software to Improve the Sustainability of a Forwarding Operation in Central Italy. Sustainability 12(14): 5716. https://doi.org/10.3390/su12145716.49

Ponsse, 2022: Neue Produkte von Ponsse für eine verantwortungsbewusste Forstwirtschaft.

Proto, A.R., Macri, G., Visser, R., Harrill, H., Russo, D., Zimbalatti, G., 2018: A Case Study on the Productivity of Forwarder Extraction in Small‐Scale Southern Italian Forests. Small‐Scale Forestry 17(2): 1–17. https://doi.org/10.1007/s11842‐017‐9376‐z

Purfürst, T., 2010: Learning Curves of Harvester Operators. Croatian Journal of Forest Engineering 31(2): 89–97.

Purfürst, T., Lindroos, O., 2011: The Correlation between Long‐Term Productivity and Short‐Term Performance Ratings of Harvester Operators. Croatian Journal of Forest Engineering 32(2): 509–519.

Purfürst, T., Erler, J., 2011: The Human Influence on Productivity in Harvester Operations. International Journal of Forest Engineering 22(2): 15–22. https://doi.org/10.1080/14942119.2011.10702606

R Core Team, 2020. R: A Language and Environment for Statistical Computing. Vienna, Austria: The R Foundation for Statistical Computing.

Spinelli, R., Magagnotti, N., Labelle, E.R., 2020: The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators. Croatian Journal of Forest Engineering 41(2): 1–13. https://doi.org/10.5552/crojfe.2020.747

Statistisches Bundesamt (Destatis), 2021: Land- und Forstwirtschaft, Fischerei. Forstwirtschaftliche Bodennutzung -Holzeinschlagsstatistik-. Fachserie 3 Reihe 3.3.1. Publisher: Statistisches Bundesamt, Germany, 51 p.

Strandgard, M., Mitchell, R., Acuna, M., 2015: Impact of Slope on Forwarder Load Size and Productivity. In: Proceedings of the 48th FORMEC Symposium, Linz, Austria, December, 101–105 p.

Szewczyk, G., Spinelli, R., Magagnotti, N., Tylek, P., Sowa, J.M., Rudy, P., Gaj-Gielarowiec, D., 2020. The mental workload of harvester operators working in steep terrain conditions. Silva Fennica 54(3): article id 10355. https://doi.org/10.14214/sf.10355

Tervo, K., Palmroth, L., Koivo, H.N., 2010: Skill Evaluation of Human Operators in Partly Automated Mobile Working Machines. IEEE Transactions on Automation Science and Engineering 7(1): 133–142. https://doi.org/10.1109/TASE.2009.2025364

Tiernan, D., Zeleke, G., Owende, P.M.O., Kanali, C.L., Lyons, J., Ward, S.M., 2004: Effect of Working Conditions on Forwarder Productivity in Cut‐to‐length Timber Harvesting on Sensitive Forest Sites in Ireland. Biosystems Engineering 87(2): 167–177. https://doi.org/10.1016/j.biosystemseng.2003.11.009

Väätäinen, K., Ala‐Fossi, A., Nuutinen, Y., Röser, D., 2006: The Effect of Single Grip Harvester´s Log Bunching on Forwarder Efficiency. Baltic Forestry 12(1): 64–69. https://doi.org/10.17221/10/2017‐JFS

Visser, R., Obi, O.F., 2021: Automation and Robotics in Forest Harvesting Operations: Identifying Near-Term Opportunities. Croatian Journal of Forest Engineering 42(1): 13–24. https://doi.org/10.5552/crojfe.2021.739

Zemanek, T., Filo, P., 2022: Influence of Intelligent Boom Control in Forwarders on Performance of Operators. Croatian Journal of Forest Engineering 43(1): 47–64. https://doi.org/10.5552/crojfe.2022.965

Ziebinski, A., Cupek, R., Grzechca, D., Chruszczyk, L., 2017: Review of advanced driver assistance systems (ADAS). AIP Conference Proceedings 1906(1): 120002. https://doi.org/10.1063/1.5012394

Zimbalatti, G., Proto, A.R., 2010: Productivity of Forwarders in South Italy. In: Proceedings of the 44th FORMEC Symposium, Padova, Italy, 11–14 July.

Zimbelman, E.G., Keefe, R.F., 2018: Real-time positioning in logging: Effects of forest stand characteristics, topography, and line-of-sight obstructions on GNSS-RF transponder accuracy and radio signal propagation. PLoS ONE 13(1): e0191017. https://doi.org/10.1371/journal.pone.0191017

© 2023 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Florian Hartsch, MSc *

e-mail: florian.hartsch@uni-goettingen.de

Marian Schönauer, PhD

e-mail: marian.schoenauer@uni-goettingen.de

Christopher Pohle, MSc

e-mail: christopher.pohle@uni-goettingen.de

Lorenz Breinig, PhD

e-mail: lorenz.breinig@uni-goettingen.de

Prof. Dirk Jaeger, PhD

e-mail: dirk.jaeger@uni-goettingen.de

University of Göttingen

Faculty of Forest Sciences and Forest Ecology

Department of Forest Work Science and Engineering

Büsgenweg 4

37077 Göttingen

GERMANY

Thilo Wagner, MSc

e-mail: thilo.wagner@wald-und-holz.nrw.de

State Enterprise for Forestry and Timber Northrhine-Westfalia

Center for Forest and Timber Industry

Team Forest Education Center

Alter Holzweg 93

59755 Arnsberg

GERMANY

* Corresponding author

Received: August 15, 2022

Accepted: December 09, 2022

Original scientific paper