Incorporating Simulators into a Training Curriculum for Forestry Equipment Operators: A Literature Review

doi: 10.5552/crojfe.2024.2142

volume: 45, issue:

pp: 15

- Author(s):

-

- Burk Erin

- Han Han-Sup

- Smidt Mathew F.

- Fox Bruce

- Article category:

- Subject review

- Keywords:

- simulator-based training, operator training, forest harvesting machines, logging operations, workforce

Abstract

HTML

Forestry equipment simulators offer opportunities for new operators to become familiar with operating logging machines as well as a promising solution to the high costs of training forestry equipment operators. Current literature lacks a synthesis on how best to train forestry equipment operators using simulators. The goal of this review was to identify effective ways to incorporate forestry equipment simulators into an equipment operator training curriculum. We analyzed a total of 14 independent studies in which construction and forestry equipment operators were trained on simulators and engaged in discussions with nine professionals in the field of heavy equipment operator training. In this review, traditional machine training and simulator training practices are introduced. Then, four key aspects of skill acquisition for forestry equipment operators are identified. Information collected from peer-reviewed literature and discussions with industry experts are used to consider how each aspect of skill acquisition is addressed in both traditional training using real machines and simulator-based training. Drawing on these sources, benefits and drawbacks of traditional machine training and simulator-based training for forestry equipment operators are synthesized and discussed. Finally, a model for an integrated and adaptive training curriculum that incorporates principles and technologies from both traditional machine training and simulator training is presented.

Incorporating Simulators into a Training Curriculum for Forestry Equipment Operators: A Literature Review

Erin Burk, Han-Sup Han, Mathew Smidt, Bruce Fox

Abstract

Forestry equipment simulators offer opportunities for new operators to become familiar with operating logging machines as well as a promising solution to the high costs of training forestry equipment operators. Current literature lacks a synthesis on how best to train forestry equipment operators using simulators. The goal of this review was to identify effective ways to incorporate forestry equipment simulators into an equipment operator training curriculum. We analyzed a total of 14 independent studies in which construction and forestry equipment operators were trained on simulators and engaged in discussions with nine professionals in the field of heavy equipment operator training. In this review, traditional machine training and simulator training practices are introduced. Then, four key aspects of skill acquisition for forestry equipment operators are identified. Information collected from peer-reviewed literature and discussions with industry experts are used to consider how each aspect of skill acquisition is addressed in both traditional training using real machines and simulator-based training. Drawing on these sources, benefits and drawbacks of traditional machine training and simulator-based training for forestry equipment operators are synthesized and discussed. Finally, a model for an integrated and adaptive training curriculum that incorporates principles and technologies from both traditional machine training and simulator training is presented.

Keywords: simulator-based training, operator training, forest harvesting machines, logging operations, workforce

1. Introduction

Since the mechanization of forestry operations in the 1960s, forestry equipment operators have learned the skills required for their job mainly through hands-on training using a real machine in the forest (LaPointe and Robert 2000). While access to logging equipment is essential to properly train equipment operators, new developments in simulator technology enable inexperienced operators to virtually learn and practice operating forestry equipment. Forestry equipment simulators offer a cost-effective and safe method for students to learn about the basics of operating forestry machines (Ovaskainen 2005). They promise to alleviate some of the problems associated with traditional machine training by reducing wear and tear on real equipment and lowering opportunity costs associated with removing equipment from production for training purposes (LaPointe and Robert 2000). While simulated training is growing in popularity, there is no synthesis available regarding the current state of knowledge on the use of simulators for training new forestry equipment operators.

A »forestry equipment operator« uses logging machines to fell, extract, process, and load trees onto logging trucks. A typical training program for forestry equipment operators familiarizes students with a wide range of mechanized forestry equipment used in common harvesting methods. For the remainder of this review, the terms »equipment« and »machine« or »machinery« will refer to a heavy, mechanized apparatus that contains a cab in which a person, or »operator«, sits inside to control the machine functions. When discussing forestry equipment, this might be a feller-buncher, skidder, processor, log loader, forwarder, or harvester. When discussing construction equipment, this might be heavy equipment such as an excavator, forklift, wheel loader, bulldozer, or grader. The terms »simulator« and »simulated« will refer to a computer-based simulation of the machine in question, complete with a set of similar controls and a visual replica of what the operator sees from inside the cab of the machine. The terms »operator«, »trainee« and »student« refer to inexperienced heavy equipment operators that are learning how to operate machinery. We will use »traditional machine training«, »traditional training« and »machine training« interchangeably in reference to training that occurs in a real machine, while the terms »simulated training« and »simulator training« will refer to training that occurs on a simulated machine. Finally, the term »training environment« will refer to the simulated and/or machine training site, separate from the jobsite, where trainees first learn how to operate equipment. »Working environment« on the other hand, refers to the jobsite where operators use their skills to contribute to production.

The goal of this literature review was to synthesize the current state of knowledge on the use of simulators for training new forestry equipment operators and identify effective ways to incorporate forestry equipment simulators into a training curriculum. We analyzed a total of 14 independent studies in which construction and forestry equipment operators were trained on simulators for a minimum of thirty minutes and a maximum of forty hours. Seven of these studies took place in the United States (Bhalerao et al. 2019, Hildreth and Gehrig 2009, Hildreth and Heggestad 2010, Hildreth and Stec 2009, So et al. 2013, So et al. 2016, Su et al. 2013). Three studies were conducted in Eastern Canada (Freedman 2004, LaPointe and Robert 2000, Yates 2000), two took place in Brazil (Lopes et al. 2008, 2010), and two were condected in Europe (Hoss 2001, Ranta 2009). Participants for nine of these studies included college-aged students. Participants of two studies were forestry or construction workers, and the remaining two studies did not list the demographics of their participants. These studies were chosen because they measured operator performance variables to evaluate the effectiveness of simulator-based training. Research topics ranged from the effectiveness of simulator training compared to machine training, to the effectiveness of specific practice strategies used on the simulator. We also engaged in discussions with professionals in the field of heavy equipment operator training including one researcher, three heavy equipment training professionals, and six representatives from simulator manufacturers. We spoke with one researcher, located in Finland, who has a background in simulator-based training for forestry equipment operators to request access to additional sources that were hard to locate (such as conference proceedings), as well as to verify we had considered all aspects of the subject in question. Our discussions with one construction training facility coordinator, one former logging business owner, and two forestry operations managers, all located in the western US, revealed insights into how both traditional and simulator-based training typically occur, as well as the benefits and drawbacks of both training types. We also met with six representatives from different manufacturers located in the US, Canada, Finland and Sweden that offer forestry equipment simulators to gain a better understanding of how these simulators are designed, what features they offer, and how they enable effective learning. One of the representatives we spoke with was also the construction training facility coordinator.

In this review, we first introduce the concepts of traditional and simulated training for forestry equipment operators. Then, we introduce four aspects of skill acquisition that we identified as important to training new forestry equipment operators. Experimental and observational studies, as well as information gleaned from industry professionals, are presented in the following sections; traditional and simulated training environments are considered with respect to facilitating each important aspect of skill acquisition. In the discussion section, we synthesize benefits and drawbacks of traditional and simulator training. We then draw conclusions about how to best to incorporate simulator training into a forestry equipment operator training program.

2. Traditional and Simulated Training for Forestry Equipment Operators

To better understand how traditional training works, we spoke with one former wildfire mitigation business owner and cable logging crew member with over 20 years of experience in the industry (Edwards, R., Ecological Restoration Institute, Arizona, USA, personal communication) and two current forestry equipment trainers and forest operations managers with a combined 15 years of experience in these positions (Green, P. and Mattioda, M., Miller Timber, Oregon, USA, personal communication). For the purposes of this review, we used their description of common practices for new equipment operator training. In a smaller company where machine availability is limited, training typically involves a 1:1 student to trainer ratio, is very informal, and occurs at the end of the day or between contracts when there are no big pushes for production. A student is typically asked to watch an experienced operator for several hours before being allowed into the cab of a machine. In a larger company that has more machines available for training, training is more formal. Initial training on practical skills typically involves a 3:1, 2:1, or 1:1 student to trainer ratio. Some core components of this initial practical training period include a »safety briefing«, in which new operator(s) cover a variety of safety topics that may include local safety regulations, the safety manual of the machine they learn to operate, and required personal protective equipment (PPE); a »machine walk-around«, in which the trainer shows the new operator(s) the parts of the machine and its safety features; a »controls orientation«, in which the trainer shows the new operator(s) how to turn the machine on and off and how to operate different parts of the machine; and a series of »practice exercises« designed to assist the new operators in committing their new motor skills to muscle memory and instill safe and efficient operating habits. Once the experienced trainer feels that the new operator(s) are proficient in safely operating the machine at a basic level (usually after about two weeks of training), they eventually move the new operator to a field scenario, in which the trainee joins the harvest system in the respective machine.

Getting a new operator up to a productive operating level (i.e., when the operator is producing enough material that the product is worth more than the cost of operating the equipment) varies depending on the harvesting system and the forest type (Ovaskainen, H., Metsäteho Oy, Uusimma, Finland, personal communication). For example, a new operator learning how to harvest tree-length material from a eucalyptus plantation in Brazil will not reach a productive operating level in the same amount of time as a new operator learning how to extract log-length material from a conifer forest in Finland. This typically takes anywhere from four to twelve months (Calabrese 2000, Pagnussat et al. 2021, Pürfurst 2010, Richardson and Makkonen 1994, Wenhold et al. 2020). For a very talented operator who has full access to a machine and trainer, this could take as little as three months (Mattioda, M., Miller Timber, Oregon, USA, personal communication). Though the time it takes a new operator to reach a productive operating level varies widely based on localized variables, training a new forestry equipment operator in any scenario requires a significant investment of time, money, and infrastructure.

Simulated learning is not a new idea. Flight simulators, for instance, have been in use since 1929 to teach safe and effective operating techniques to new pilots (Meyers et al. 2018). Driving simulators are also widely used in several countries as a safe, cost-effective alternative to traditional driver training (Martín de los Reyes et al. 2019). While there are some similarities between simulated training for forestry equipment operators and simulated training for pilots, the equipment, tasks, and operating environment are all different in flight than in forest operations. Similarly, the equipment, tasks, and environment are more complex in forestry than in driving. For this reason, we do not include a comprehensive review of lessons learned from simulator-based pilot or driver training studies. Instead, we focus on lessons learned from forestry and construction industries as working in these industries involves efficiently operating complex heavy equipment in a variable environment to achieve high rates of productivity.

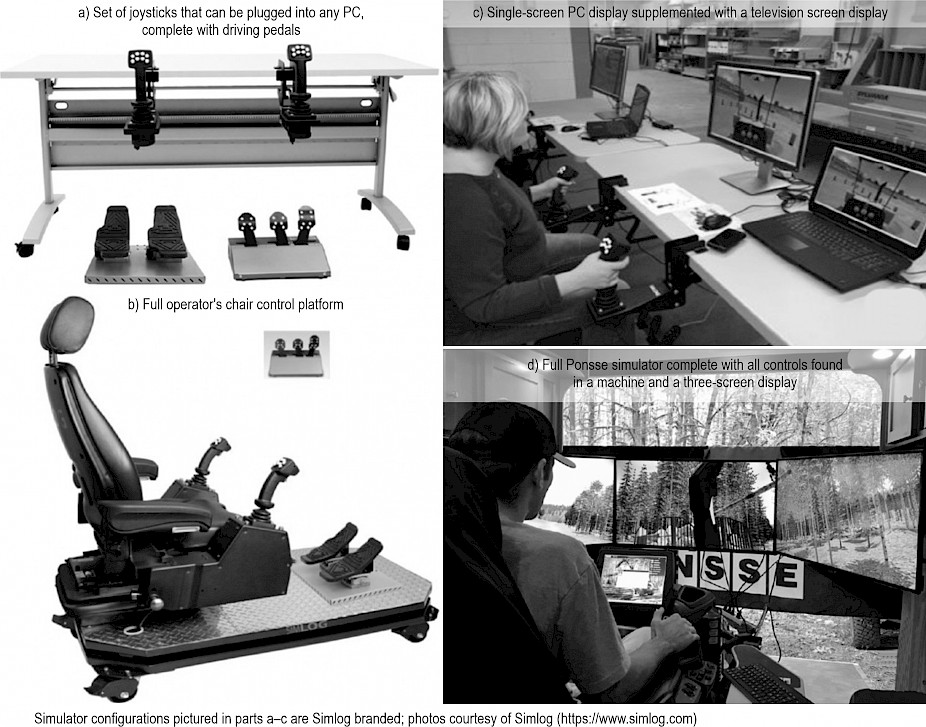

Forestry equipment simulators incorporate software and hardware to provide visual and physical replicas of the forestry equipment operating environment. Simulators typically consist of a set of controls attached to a computer with one or more screens (Fig. 1). The computer contains a simulation software that virtually places the user in the cab of a forestry machine. The user can manipulate the controls to »operate« the simulated machinery in a virtual environment portrayed on the screen(s).

Fig. 1 Multiple simulator control and display configurations

There are a variety of control systems on the market ranging from a set of joysticks that can be plugged into any PC (Fig. 1a) to a full operator's chair (Fig. 1b), complete with all the controls found in a machine. A simple joystick set lacks many of the controls essential to operating a forest machine such as the on/off switch, parking brake, and driving pedals. While it is typical of the full operator chair to closely resemble all controls found in the cab of a real machine, it is not located in a real cab, so the space surrounding the chair itself still differs notably from that of a machine. One relatively new development in heavy equipment simulation technology is a motion feedback feature that simulates the vibrations and responses to driving forces that an operator will feel in a machine in the forest. Simulators that do not have this motion feedback feature do not provide users with the physical sensation of driving a real machine through the woods and therefore do not closely resemble the real operating environment.

Forestry equipment simulators feature a variety of visual displays ranging from PC-based displays featuring a single screen (Fig. 1c) to Virtual Reality (VR) plug-ins. PC-based displays are two-dimensional (2D) representations of an environment often displayed on one or more computer or television screens (Fig. 1d). Though these displays are inexpensive, the mapping of a three-dimensional (3D) environment onto a two-dimensional (2D) display can interfere with the user's depth perception. Additionally, the size of the screen(s) limits the user's field of vision. In VR displays, the users wear VR goggles that allow them to see their environment in three dimensions and 360 degrees. Though VR simulators offer highly realistic displays, individuals who are not used to operating in a VR environment often become motion sick within 15 minutes or less of using the equipment, limiting their effective practice time (Jurvanen, J., Ponsse Oyj, Vieremä, Finland, personal communication). The issue of motion sickness in VR applications is widely studied, and there is currently no solution to the unpleasant symptoms invoked among users (Duzmanska et al. 2018). In both PC-based and VR displays, realistic graphics can enhance a user's learning experience.

Manufacturers that currently offer forestry simulators include Simlog, Komatsu, John Deere, CAT, Tigercat, and Ponsse. Each of these companies offer forwarder and harvester simulators for cut-to-length harvest systems. Simlog and Tigercat also offer wheel-loader simulators that can be used to train log loader operators. John Deere is the only company that currently offers a line of simulated whole-tree/tree-length harvesting equipment including a feller-buncher, skidder, and shovel logger. Public colleges and technical schools around the world are beginning to use simulators in their forestry equipment operator training curriculum to familiarize students with simulated controls before they step into the cab of a real machine (Freedman, P., Simlog, personal communication). If used properly, simulators could effectively replace, or at least supplement, the »controls orientation« and »practice exercises« components of traditional training, as discussed in the previous section. Some private forestry contractors and heavy equipment training facilities are also using simulators to evaluate the efficiency of their experienced operators and refresh their operating skills (Green, P., Miller Timber, Oregon, USA; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication). An investigation of important aspects of skill acquisition for forestry equipment operators reveals how traditional machine training can be most effectively supplemented using simulators.

3. Understanding Skill Acquisition in Forestry Equipment Operator Training

In reviewing existing scientific literature and speaking with industry professionals, we identified four main aspects of skill acquisition important to training forestry equipment operators. First, the degree to which skills transfer from a training environment to the real world is associated with the fidelity of the training environment (Meyers et al. 2018); therefore, trainees require access to at least a minimally realistic learning environment to enable skill transfer to the real world. Second, providing trainees with quality instruction and an effective curriculum design provides efficient learning (Ranta 2009). Third, trainees need time to practice their skills for them to become automatic (Gellerstedt 2002, Pürfurst 2010). Finally, facilitating continued training for experienced operators can enable the continued mastery of their skills (Hildreth and Gehrig 2009) (Green, P., Miller Timber, Oregon, USA; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication).

3.1 High-Fidelity Training Environment

Effectively operating heavy equipment requires the coordinated use of multiple controls, such as joysticks, buttons, and foot pedals, simultaneously. The synchronized handling of such controls allows for the operator to drive and manipulate the machine to accomplish a task (Proctor et al. 2013). Thus, the effective and efficient operation of forestry equipment requires perceptual-motor coordination, defined by the American Psychological Association (2022) as, »the use of perceptually derived information (e.g., from vision, touch) in the control of ongoing movements«. Since the ultimate goal of training is to teach operators the skills they need to work in the forest, trainees must eventually transfer their learned skills from the training environment to the working environment. For the purposes of this review, we define skill transfer as the extent to which skills learned in the simulated training environment are effectively applied when operating a real machine on the jobsite.

In traditional machine training, new forestry operators typically train on the exact machine, or the exact model, that they will be operating on the jobsite (Pürfurst 2010, Wenhold et al. 2020), so it can be assumed that skill transfer is maximized. In simulated training, the degree to which skills transfer to the real world is tied to the fidelity of the simulated environment (Meyers et al. 2018). Here, fidelity is defined as the degree to which the simulated environment emulates the real working environment. The effect of fidelity on skill transfer has been widely studied in many fields, but conclusions are variable depending on study methods and definitions of what constitutes skill transfer (Healy and Wohldmann 2012). A recent literature review on fidelity and skill transfer in flight simulation (Meyers et al. 2018) has shown that high-fidelity flight simulators are preferred by industry professionals and are known to increase individuals' beliefs in their ability to perform. Low fidelity simulators, on the other hand, have been shown to reduce skill transfer in some studies, yet have no effect on skill transfer in others. Authors conclude that the amount of fidelity required for effective training is specific to the training objective, training tasks, and the student in question. This literature review revolved around flight simulation; conclusions may differ if similar experiments are done using forestry simulators. Traditional and simulated training environments are discussed with respect to facilitating each aspect of skill acquisition in the following sections.

3.2 Effective Instruction and Curriculum Design for New Equipment Operators

Over the last several decades, logging equipment has become increasingly mechanized (Conrad et al. 2018, Freedman 2001). As machine functions become more sophisticated, so do the controls; therefore, the barrier to entry for inexperienced individuals has risen. Without access to quality instruction and a well-designed curriculum, learning to operate today's complex machines would be inefficient (Ranta 2009). Factors that influence the effectiveness of the training period for forestry equipment operators include guidance resources, which we will call instruction, as well as learning methods, which we will call curriculum design (Ranta 2009). For the purposes of this review, we break down quality training into these two factors—instruction and curriculum design. The way instruction is given to new forestry equipment operators differs between traditional and machine training, as does the way in which a curriculum is designed, implemented, evaluated, and revised.

3.2.1 Instructional Methods Used in Traditional and Simulator Training

Bhalerao et al. (2017) tested the effect of hands-on exploration vs. audiovisual instruction on operator learning and performance using a simulated hydraulic excavator. Researchers found that, while individuals taught how to use the controls via audiovisual instruction were able to execute commands faster and with fewer errors, individuals who had hands-on practice expressed slightly higher levels of confidence. Participants' confidence levels were found to be related to their performance. Authors suggest that a balance of instructional orientation and hands-on exploration should be used in training equipment operators depending on the proportion of cognitive and perceptual components of the task.

In traditional machine training, an experienced trainer joins the students in the cab of a machine to show them the controls and guide them through exercises that help hone their new motor skills (Edwards, R., Ecological Restoration Institute, Arizona, USA; Green, P., Miller Timber, Oregon, USA, personal communication), employing both instructional orientation and hands-on exploration. In some jurisdictions (Finland, for instance), operator safety laws prohibit more than one person at a time in the cab, so the trainer will teach the new operator through a headset while watching his performance from outside of the machine (Ovaskainen, H., Metsäteho Oy, Uusimma, Finland, personal communication). In both cases, a new operator receives immediate and personalized feedback from the trainer as they practice.

We spoke with six simulator manufacturers that currently offer software for forestry equipment to gain a better understanding of the instruction available through the simulated training environment. In simulator training, students typically guide themselves through learning modules using the built-in features of forestry simulators (Freedman, P., Simlog, Québec, Canada; Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). A literature review by Marcano et al. (2019) names this form of self-guided learning through simulators »individual training« and identifies four major factors that enable individual training. If simulated software 1) captures expert knowledge, 2) offers standardized feedback and assessment benchmarks, 3) prioritizes operators' needs and suggestions, and 4) provides access to educational materials, the authors argue that individuals will be able to practice individual training. While this review focused on industrial operators (skilled workers who operate industrial machines as a part of the manufacturing process), the findings can be applied to forestry equipment operators, as both professions involve operating complex machinery. We used the factors identified above to guide our discussions with equipment manufacturers and, in the process, learned about some features and design considerations specific to forestry equipment simulators that enable individual training (Table 1). These features are presented below.

Table 1 Simulator features and design considerations of contemporary forestry equipment simulator brands that enable individual training

|

Factor that enables individual training (Marcano et al. 2019) |

Simulator Feature/ Design Consideration |

Ponsse |

Tigercat: In partnership with CMLabs |

CAT: In partnership with Simlog |

Simlog |

Komatsu: In partnership with Oryx |

John Deere: In partnership with CMLabs |

|

Captures expert knowledge |

Designed in collaboration with industry experts |

x |

x |

x |

x |

x |

x |

|

Standardized feedback and assessment benchmarks |

Performance scores based on, or easily comparable to, expert operators' performance |

x |

x |

x |

x |

x |

|

|

Offers performance report at completion of training module |

x |

x |

x |

x |

x |

||

|

Offers real-time feedback |

x |

x |

|||||

|

Motion platform for operator chair |

x |

x |

x |

x |

x |

||

|

Prioritizes operators' needs and suggestions |

Designed in collaboration with professional trainers |

x |

x |

x |

x |

x |

x |

|

Designed based on direct feedback from users |

x |

x |

x |

x |

x |

||

|

Access to educational materials |

Support portal/training guide |

x |

x |

x |

x |

x |

x |

|

Controls orientation module |

x |

x |

x |

||||

|

Operator guide |

x |

x |

x |

x |

Modules offered in current forestry simulators range from step-by-step tutorials for beginners to free-form exploration of a forest environment that imitates what an expert operator experiences on the job. Feedback is usually given at the end of each module through a »performance report« that tells the user how they performed (Freedman, P., Simlog, Québec, Canada; Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). Only one simulator brand did not feature a modular software design with built-in feedback (LeConte, C., John Deere, Iowa, USA, personal communication). All other companies confirmed that their performance scores are based on, or are easily comparable to, expert operators' performance. Each simulator brand varies regarding the specific performance evaluation metrics reported, but all include some basic feedback such as execution time, number of collisions, and number of trees or logs cut or moved. Many companies' simulators offer many more detailed metrics, such as logs cut or moved per hour, distance of boom movement relative to frame, and machine RPMs (Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Najjar, J., CMLabs, Québec, Canada, personal communication). Only two simulator manufacturers confirmed that their simulators provide real-time feedback as the user works through a module (Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Najjar, J., CMLabs, Québec, Canada, personal communication). If an operator's boom collides with a tree, for example, a pop-up screen reminds them of their running collision tally. All other simulators only provide written feedback after the module is complete (Freedman, P., Simlog, Québec, Canada; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication). Another form of feedback available in full simulator models of most brands is the motion feedback feature introduced earlier in this paper (Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). Two studies conducted in 2009 and 2010 found that training on full motion simulators, as compared to zero-motion simulators, produced lower operator anxiety levels and higher operator confidence levels, though there was no difference in operator performance between the two groups (Hildreth and Heggestad 2010, Hildreth and Stec 2009). These studies both involved training periods of less than 30 minutes on construction simulators and equipment; therefore, results may vary with longer training periods on forestry simulators and equipment.

Each simulator manufacturer confirmed that they collaborate with both industry experts and professional trainers to develop their software (Freedman, P., Simlog, Québec, Canada; Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; LeConte, C., John Deere, Iowa, USA; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). Four companies emphasized the importance of collecting feedback regarding the usability of their simulators directly from experienced and unexperienced operators (Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). Each company we spoke with confirmed that their simulators feature some kind of »support portal« and/or »training guide« where users can get help when troubleshooting problems and/or find recommendations for a training curriculum. Four of the six simulator brands we studied feature an »Operator Guide« where users can, at any time, refresh their memory on the function of each control (Freedman, P., Simlog, Québec, Canada and Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). Three simulators we studied featured a »Controls Orientation« module that walks new operators through the functions of the machine controls while the trainee practices using them (Freedman, P., Simlog, Québec, Canada; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication).

3.2.2 Curriculum Design Used in Traditional and Simulator Training

In traditional machine training, an instructor usually follows a rough curriculum that is subject to change based on the students' performance and needs (Edwards, R., Ecological Restoration Institute, Arizona USA; Preston, Green., Miller Timber, Oregon, USA, personal communication). In most simulator-based training, a modular learning curriculum comes built into the software (Freedman, P., Simlog, Québec, Canada; Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). Modular learning is the division of a curriculum into smaller units, called modules, that act as standalone lessons and can be taken in any order at any speed (French 2015). In motor skill learning, a modular system offers many benefits. Wolpert and Kawato (1998) argue that a modular system mirrors the world in which we learn, enables individuals to learn new motor skills without affecting other motor behaviors that may have been learned in other modules, and can provide students with the building blocks they need to apply their motor skills in a wide variety of situations. Below, we present two studies that made use of heavy equipment simulators' modular curriculum to explore how curriculum design affects operator learning.

In a study conducted by Su et al. (2013) 15 new equipment operators were exposed to a mixed training schedule (i.e., practice sessions were intentionally interrupted with different tasks), while another group of equal size were trained on a block schedule (i.e., succeeding practice sessions are completed without interruptions). Contrary to a prior study, which shows that mixed practice schedules improve cognitive and perceptual-motor skill learning (Magill and Hall 1990), the researchers found that the mixed-schedule training group did not outperform the blocked-schedule training group. They concluded that blocked vs. mixed training schedules do not seem to make a difference when the tasks require considerable cognitive effort. However, authors hypothesize the tasks required by the modules may have been sufficiently complex to require a similar amount of cognitive effort in both test groups.

In another study published during the same year, researchers trained participants on a simulated excavator using either part-or whole-task training (So et al. 2013). Part-task training consisted of exercises that taught one skill at a time, progressing in difficulty, while whole-task training consisted of practice with one exercise that was the same as the test task. Each group completed three phases of the study: training, immediate testing, and retention testing. While participants in both training groups showed no significant differences in performance immediately after their training sessions, participants who completed part-task training showed better retention and quicker progression in performance standards after a two-week retention period. Trainees were not asked to operate a real excavator during this experiment; therefore, it is unknown whether this trend would transfer to a working environment.

3.3 Time Required for Effective Training

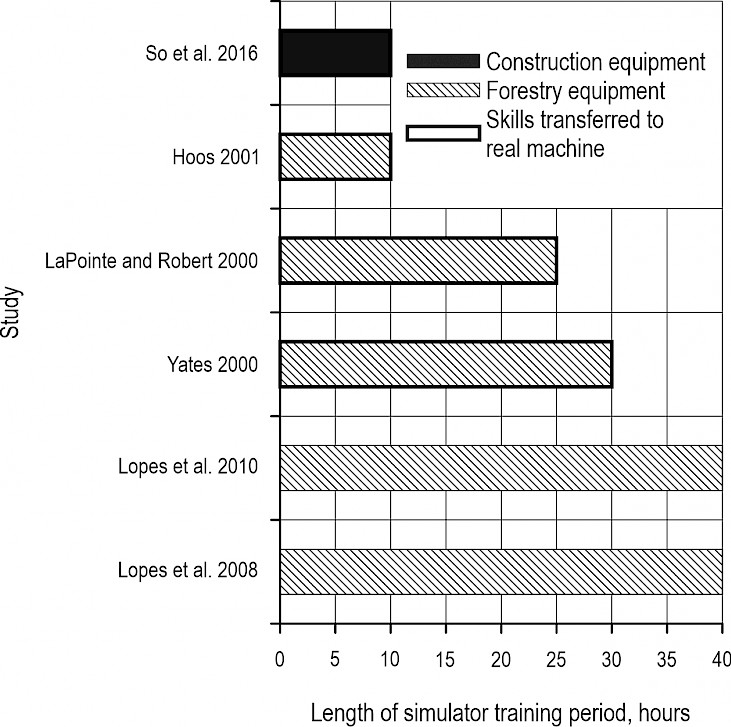

The working environment of a forest is highly variable, consisting of many dynamic factors that are different at every jobsite (Ranta 2009). In this inconstant environment, expert operators' skills are largely automated, requiring little cognitive effort to efficiently handle their machine in the forest (Gellerstedt 2002). Forestry equipment instructors and industry experts estimate it takes about five years for an operator to achieve full efficiency (Gellerstedt 2002); therefore, operators need time to practice with their machine to reach a point where their skills become automatic. In traditional training, a machine must be removed from production for trainees to practice. This can result in large opportunity costs as a contractor is not able to use the machine for timber production (Mattioda, M., Miller Timber, Oregon, USA, personal communication). In simulator-based training, all working machines can remain in production while trainees practice automating their new skills. The longer a student can effectively train on a simulator, the longer all machines can remain in production; therefore, opportunity cost for a contractor due to operator training will be minimized. The biggest concern that forestry equipment trainers have with simulated training is that it will not be as effective as machine training in producing skilled operators (Green, P. and Mattioda, M., Miller Timber, Oregon, USA; Jurvanen, J., Ponsse Oyj, Vieremä, Finland, personal communication). A handful of studies have evaluated the performance of forestry equipment operators after practicing on a simulator for a minimum of 10 hours and a maximum of 40 hours (Freedman 2004, Hoss 2001, LaPointe and Robert 2000, Lopes et al. 2008, Lopes et al. 2010, So et al. 2016, Yates 2000) (Fig. 2). Each study concluded that heavy equipment simulators are an effective training tool at all training intervals observed.

Fig. 2 Length of simulator training period in studies that involved training participants on simulated forestry and construction equipment. Studies in which participants transferred their skills to a real machine during or after the simulator training period are outlined in black

Two studies conducted in Brazil (Lopes et al. 2008, Lopes et al. 2010) evaluated the effectiveness of training harvester and forwarder operators for 40 hours on a simulator. In both studies, new equipment operators completed a series of pre-programmed simulator modules (Table 2) and were evaluated based on their performance in modules most representative of daily harvester and forwarder operation. Performance standards were set by researchers prior to the study, but the authors did not mention how these standards were decided upon. Trainees on both the harvester and forwarder significantly reduced their runtime, with biggest reductions at the beginning of their training period. There was also a significant increase in all other operator performance variables on both machines. All participants who trained on the harvester reached the satisfactory performance standards pre-determined by the authors within the 40-hour training period. On the forwarder, researchers observed that trainees had a harder time completing »Log Loading« and »Unloading« exercises because of the decreased visibility on the simulated machine. They concluded that the 14 hours of training on each of the »Log Loading« and »Unloading« exercises was not sufficient for trainees to reach satisfactory operator performance standards, and that trainees should spend more time on a simulator to practice these exercises. These studies did not evaluate how skills transferred to real equipment, so it is unknown how well students may have performed in the woods after training on the simulator.

Table 2 Time participants spent on each module in studies by Lopes et al. (2008, 2010). Names of modules were cross-referenced with Simlog's website, as the original figures are in Portuguese

|

Forwarder |

Harvester |

||

|

Module |

Hours |

Module |

Hours |

|

Grapple control 1 |

12 |

Harvester head functions |

2 |

|

Log loading 1 |

8 |

Controlling the movement of the harvester head |

6 |

|

Log loading 2 |

6 |

Simple felling |

8 |

|

Log unloading 1 |

8 |

Simple felling with cutting-to-length |

6 |

|

Log unloading 2 |

6 |

Simple felling and decking |

6 |

|

Total |

40 |

Multiple felling and decking |

4 |

|

Harvester as processor |

8 |

||

|

Total |

40 |

||

We found four studies that did quantify skill transfer from simulated to real forestry equipment after a simulator practice period. In an experimental study conducted at a forestry training center in Germany, one group of 16 individuals spent the first 10 hours training on a simulated harvester, then switched to training on a real harvester for the remaining 90 hours, while another group of 15 individuals spent all 100 hours training on a real harvester (Hoss 2001). After the first 20 hours of training, and again after 100 hours of training, all individuals were tested and evaluated. The group that spent the first 10 hours training on a simulator performed slightly worse during the first test, but after 100 hours of training, both training groups showed the same performance levels. The author concluded that the early stages of training can and should be completed using simulators so as to avoid unnecessary damage to machines and residual trees, as well as lower training costs. In another experimental study, Lapointe and Robert (2000) compared the productivity of 44 students who had received simulator training to 44 students who had not received simulator training on harvester in the woods. The authors found that the students who completed 25 1-hour sessions on the simulator harvested, on average, 23% more volume over the course of one year. An observational study completed in eastern Canada found that students who completed a minimum of 30 hours of simulated training prior to moving on to complete 30 hours of machine training harvested 100% more trees per hour during their first week on the real machine than expected (Yates 2000). The author of this report also claimed that students had »high praise« for their experience on the simulator, and that they would not have felt as comfortable or confident on the harvester without the simulated learning experience. In another observational study, 35 students completed four days of simulator training prior to completing four weeks of traditional machine training (Freedman 2004). The actual number of training hours was not reported, but students who completed the simulator training period showed a 50% increase in wood harvested, 30% increase in final productivity, and a 30% decrease in costs associated with equipment maintenance compared to those who did not receive simulator training. While these studies compared operator performance between groups who had and had not received simulator training, none directly observed the effect of simulated vs. traditional training on operator performance with equal practice time for both training types.

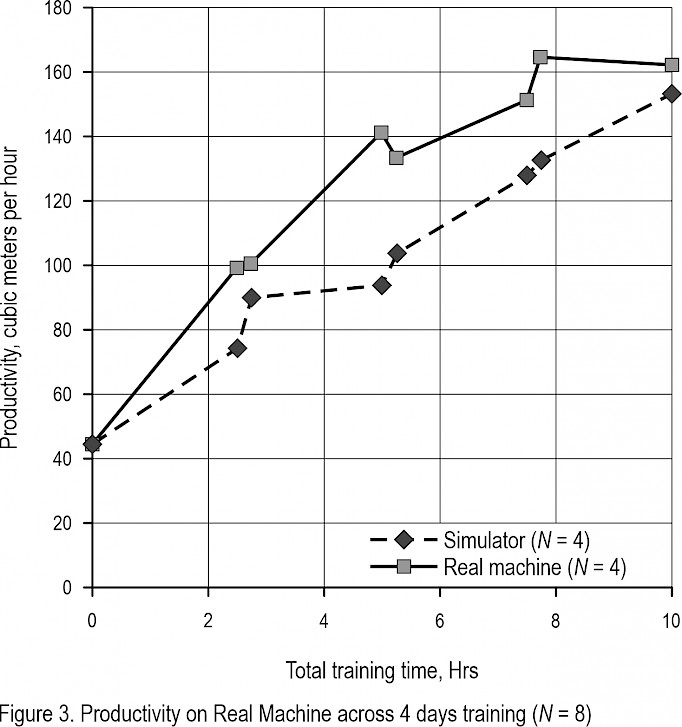

We found one experimental study that did directly compare the effectiveness of simulator training and machine training, as well as observed skill transfer; however, this study was completed using construction equipment, rather than forestry equipment. In 2016, So et al. trained one group of participants on real hydraulic excavators and one group on simulated excavators. Researchers evaluated the performance of simulator-trained and machine-trained groups at the beginning and end of each day of training throughout a four-day training period on a real excavator. After four days of training (a total of 10 hours of operating time), both groups reached a similar level of operator performance (Fig. 3). The simulator group was slower to learn the skills, but their learning curve was more consistent throughout the training period, and their performance caught up to the machine group by the end of the training period. Both groups showed similar overall improvements in performance on the machine, but the simulator group showed slight increases in performance overnight, while the machine group showed a slight dip in performance between their tests at the end of each training day and the beginning of the following day. This trend suggests that new operators may retain new skills more easily when trained on a simulator than when trained on a machine. Authors acknowledge that the intermittent time on a real excavator could have influenced outcomes by positively skewing simulator trainees' performance, but it is unclear if the short time spent in a machine affected retention rates in the simulator training group.

Fig. 3 Original figure published by So et al. (2016) showing the average learning curves of participants trained on simulated vs. real hydraulic excavators

3.4 Continued Training for Experienced Operators

In forestry equipment operation, the effectiveness of continued training has not been formally studied. However, two expert equipment operator trainers we spoke with mentioned they periodically ask expert operators to revisit their operating practices (Green, P., Miller Timber, Oregon, USA; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication). In doing so, the goal is to help the expert operator identify efficient operating practices and troubleshoot their own practices to achieve a higher level of operational efficiency, and therefore, productivity. Both trainers pointed to the simulator as an effective training tool for continued training, citing the unique feedback offered by simulators as the main reason they are used for this purpose.

We found one study that analyzed the effect of training experienced equipment operators on a simulator (Hildreth and Gehrig 2009). A total of fifteen participants, ten of which were inexperienced operators and five of which were experienced operators, trained on a Caterpillar Virtual Training System wheel loader simulator for 30 minutes. Researchers observed changes in operator performance as well as changes in operators' ability to identify factors influencing performance metrics. They found that, while new operators showed greater increases in performance and the ability to identify influencing factors, experienced operators also showed improvement after the training session. Though the training period in this study was short, these results suggest that simulator training is useful in coaching experienced operators to perform more efficiently.

4. Discussion and Conclusion

4.1 Benefits and Drawbacks of Traditional Machine Training

Traditional machine training theoretically maximizes perceptual-motor skill transfer between training and working environments for forestry equipment operators. As mentioned above, the machine that trainees use to learn skills is usually the same model they will use in the working environment (Pürfurst 2010, Wenhold et al. 2020), so skills learned at the training site are directly transferable to the jobsite. The low student-to-trainer ratios typical of machine training also maximize the amount of personalized and immediate feedback students receive while they familiarize themselves with the machine. Real-time feedback provided by trainers allows the students to receive instruction while simultaneously practicing hands-on exploration; each of these teaching strategies has been shown to facilitate effective learning in different ways (Bhalerao et al. 2017). Low student-to-trainer ratios also facilitate flexibility in the curriculum that allows a trainer to address individual students' needs (Blatchford 2012).

In the context of forestry equipment operation, a low student-to-trainer ratio does have some drawbacks. For instance, feedback provided by a single instructor is inherently biased. A single trainer can only observe a limited set of quantitative metrics in real time; there is no consensus on the new operators' performance and no report available on proficiency metrics. A low student-to-trainer ratio also requires more experienced operators to act as instructors than a high student-to-trainer ratio. Experienced operators are in high demand for logging contractors (Freedman 2001, Pagnussat et al. 2021, Vaughan et al. 2021), so pulling them out of production for training purposes might be difficult for logging contractors who have too few experienced employees.

Perhaps the most blatant drawback to traditional machine training is the high cost of training new forestry equipment operators. For a machine to be used for training purposes, it must be removed from production. While a machine is being used for training purposes, the cost of fuel, maintenance, and lubricant is not recuperated by production profits. Furthermore, the cost of any equipment damage that occurs during training cannot be offset by production profits. As discussed above, getting a new operator up to a productive operating level can take anywhere from four to 12 months. Removing a machine from production for this amount of time can result in large opportunity costs for a contractor (Mattioda, M., Miller Timber, Oregon, USA, personal communication). Additionally, the burning of fuel, disposal of dirty lubricants, and use of a site for training purposes all contribute to high levels of negative environmental impacts for traditional machine training.

4.2 Benefits and Drawbacks of Simulator-Based Training

The degree to which skills transfer from the training environment to the working environment is linked to the fidelity of the training environment (Meyers et al. 2018). Since the simulated environment is entirely separate from the working environment, it can be inferred that skills will not transfer as easily to the working environment as in traditional training. Intuition tells us that full simulators featuring realistic graphics, an operator's chair on a motion platform, and the full suite of machine controls will enable higher rates of skill transfer than desktop simulators featuring only a set of joysticks. However, flight simulation research concludes that the fidelity required for effective training is dependent on the training objective, tasks, and student (Meyers et al. 2018). It is unclear at what point higher simulator fidelity ceases to contribute to higher levels of skill transfer. No studies have been conducted regarding the effect of fidelity on skill transfer with forestry-specific equipment. More research is needed to study whether the degree of skill transfer in simulated training significantly differs from traditional machine training, and whether highly realistic forestry equipment simulators will promote higher levels of skill transfer than basic forestry simulators.

As the simulated environment is separate from the working environment, using simulators to train new forestry equipment operators allows all machines to remain in production during training. This eliminates the opportunity cost typically accrued during traditional training. Depending on the type and brand, a single simulator typically costs five to ten times less to purchase than a piece of forestry equipment, and software packages for multiple equipment types can be loaded onto the same hardware (Freedman, P., Simlog, Québec, Canada; Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada; LeConte, C., John Deere, Iowa, USA, personal communication). The virtual training environment also eliminates the potential for damage to equipment (LaPointe and Robert 2000) and to the training site while providing a safe learning environment (Ovaskainen 2005, Ranta 2009), which may further lower the cost of simulator-based training compared to traditional training. Moreover, since the simulator is powered by electricity and the training environment is virtual, the environmental impact of simulator-based training is lower than in traditional training. That being said, no studies have formally analyzed the cost, equipment and training site damages, or environmental impacts of simulated vs. traditional training.

Most forestry equipment simulators provide students with unbiased, quantitative feedback based on the expert knowledge of training and industry professionals (Freedman, P., Simlog, Québec, Canada; Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). The feedback individuals receive during simulator training, therefore, is more of a standardized consensus, rather than the opinion of a single individual. Automated feedback greatly reduces the need for an instructor's presence and allows for a higher trainer to student ratio. Increasing student-to-trainer ratios decreases the need for expert operators to act as trainers.

While a higher student-to-trainer ratio lowers the demand for expert operators, it also reduces students' access to immediate and personalized feedback. In most simulators, a »progress report« gives written feedback only after a module has been completed, which can make it hard for a trainee to know exactly what they could have done better in the moment. However, the pop-up screen feature offered by two simulator companies provides students with real-time feedback by showing a several running feedback metrics as students work through a module (Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Najjar, J., CMLabs, Québec, Canada, personal communication). Real-time feedback has been shown to improve comprehension of the learning subject (Marcano et al. 2019). This feature enables students to analyze their mistakes as they go, rather than obligating them to remember where mistakes were made. Reducing students' access to an instructor can also limit the instructional orientation component of training, leaving students to learn mostly through hands-on exploration. The »Operator Guide« feature in most simulators, however, enables students to teach themselves what function each control carries out. In this way, students can instruct themselves. Furthermore, the »Controls Orientation« module pre-programmed into some simulators (Freedman, P., Simlog, Québec, Canada; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada personal communication) walks students through the functions of the machine controls as they practice. This feature allows students to receive audiovisual instruction while practicing hands-on exploration simultaneously.

Using the built-in modules of a forestry simulator, an educational planner can write a block-schedule curriculum, where students must complete the same module numerous times before moving onto the next, or a mixed-schedule curriculum, where students are asked to complete a series of modules one after another. Research has shown both schedules to be equally effective in perceptual-motor skill learning for heavy equipment operators, though experts claim that more research is needed to better understand exactly what can be defined as repetition when tasks are complex, and how true repetition might affect operators' learning experience (Su et al. 2013). Similarly, an educational planner can implement part-task training, where students must complete modules in order of increasing difficulty and complexity, or whole-task training, where students are simply placed in the free-form exploration module and asked to work for several hours, using forestry simulator modules. While current research shows no difference in performance between part-task and whole-task training for heavy equipment operators, participants who partake in part-task training show better skill retention and quicker progression in performance standards following a period of non-training time (So et al. 2013). Modifying the curriculum to fit a block- or mixed-schedule, or to implement part- or whole-task training, would only require changing the order in which modules are completed and/or the number of times they are completed. Tracking any changes made to such a curriculum would be a matter of recording which module is completed when, and how many times. The built-in modular learning curriculum therefore makes it easier for educational planners to plan, monitor, manage, and evaluate their simulator-based training programs (Ranta 2009).

While modularization increases the efficiency of curriculum management systems, the rigid structure of each module allows little room to tailor the exercise to an individual's needs. If a student needs practice in a skill that is not well addressed by any of the pre-programmed modules, it may not be feasible for him to effectively practice the skill with direct feedback from the simulator. In this case, the student might still need one-on-one attention from an instructor to hone the skill he struggles with.

Studies have shown that forestry equipment operator trainees who practice on a simulator for 40 hours significantly improve their operational performance in the simulated environment (Lopes et al. 2008, Lopes et al. 2010). For forestry contractors, the main drawback of practicing on a simulator is that skills may not transfer as efficiently to the working environment (Green, P. and Mattioda, M., Miller Timber, Oregon, USA, personal communication); however, recent studies report that skill transfer does occur between simulated and real forest environments (Freedman 2004, Hoss 2001, Yates 2000). Results from these studies are limited in that their simulator training periods were relatively short (a maximum of 30 hours) compared to the time it takes for an operator to reach a profitable level of productivity (4–12 months), and none directly observed skill transfer from the simulator to the forest. The only study that compared the effectiveness of simulator training to machine training was completed using construction equipment (So et al. 2016). Operators trained on a real machine learned faster and achieved higher productivity rates than those trained on a simulator, though no statistical difference was found between the two groups. More research is needed to identify at what point forestry operators reach a learning »plateau« in the simulated environment, and whether this occurs at the same time as in the machine training environment. Further research is also needed to understand the effectiveness of simulated training compared to traditional training for forestry equipment operators. This type of study is both time and resource intensive, requiring collaboration between academia and industry, which is likely why it has not been done.

Even after operators graduate their training program and move to a jobsite, they can still benefit from simulator training (Hildreth and Gehrig 2009) (Green, P., Miller Timber, Oregon, USA; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication). Most forestry simulators report metrics that help an operator understand their operating efficiency and/or productivity (Freedman, P., Simlog, Québec, Canada; Hellstrandh, B., Oryx Simulations, Umeå, Sweden; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA; Najjar, J., CMLabs, Québec, Canada, personal communication). These metrics are difficult to quantitatively measure and report in the field, as they require tracking the machine through space or measuring product moved or processed over time. Using these quantitative metrics, experienced and even expert operators can see their operating habits through a new lens. The unique perspective offered in a simulated environment makes the simulator an effective tool for continued training (Green, P., Miller Timber, Oregon, USA; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication).

4.3 Developing an Integrated Training Curriculum for Forestry Equipment Operators

In reviewing pertinent literature and speaking with industry and training professionals, we found that the benefits and drawbacks of traditional machine training and simulator training complement each other (Table 3). We posit that an adaptive training curriculum which incorporates both traditional and simulator training practices will amplify the benefits of both training strategies while minimizing training costs and resource requirements, and remaining flexible enough to accommodate individual students' training needs. This approach involves an initial simulator training period, then shifts to a rotating schedule in which students alternate between simulator-based training and traditional machine training. This could be implemented either externally by a training school or internally by a logging contractor depending on available resources.

Table 3 Benefits and drawbacks of traditional training and simulator training for forestry equipment operators

|

Traditional Training |

Simulator Training |

|

Benefits |

Drawbacks |

|

Maximizes perceptual-motor skill transfer between training and working environments for forestry equipment operators |

Skills will not transfer as easily to the working environment |

|

Maximizes personalized and immediate feedback |

Reduced access to immediate and personalized feedback |

|

Facilitates flexibility in the curriculum that allows a trainer to address individual students' needs |

Rigid structure of each module allows little room to tailor exercises to an individual's needs |

|

Drawbacks |

Benefits |

|

Feedback provided by a single instructor is inherently biased |

Provides unbiased, quantitative feedback |

|

No consensus on operators' performance |

Standardized feedback based on a consensus of industry and training professionals |

|

No report available on proficiency metrics |

Performance report' after each module provides feedback on efficiency and productivity |

|

Requires more experienced operators, who are already in high demand, to act as instructors |

Reduces the need for expert operators to act as trainers |

|

Machine must be removed from production, resulting in opportunity costs |

Allows all machines to remain in production during training, eliminating opportunity costs |

|

Expensive |

More cost-effective |

|

Potential for equipment damage |

Eliminates the potential for equipment damage |

|

Potentially dangerous for new operators |

Increased operator safety |

|

High levels of negative environmental impacts |

Reduced negative environmental impacts |

|

Easier for an educational planner to plan, monitor, manage, and evaluate their program |

|

|

Skill transfer does occur between simulated and real forest environments |

|

|

Effective tool for continuing education |

Implementing an initial simulator training period prior to machine training allows students to gain initial operating skills through a pre-programmed, modular curriculum while receiving unbiased feedback from the simulator. Students can familiarize themselves with the machine controls in a virtual environment without worrying about causing equipment damage, harm to the training site, or injury to themselves. Once students have learned the basics, moving to a traditional training strategy allows them to receive more personalized feedback from an instructor. The instructor can offer guidance as to which skills the students need more practice in, and adjustments to each modular curriculum can be made accordingly. When students return to the simulator, they can adjust the timing and repetition of their practice modules as recommended by the trainer. This cycle can continue until students have reached the performance level required by the training institution. Given the benefits of using simulator-based training as a tool for continued training (Hildreth and Gehrig 2009) (Green, P., Miller Timber, Oregon, USA; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication), contractors would also benefit from sending their experienced operators back to the simulator every now and then. This would be especially beneficial when operators need to familiarize themselves with upgraded technologies that have been built into new equipment models. Once the operator has analyzed his or her operating habits in the simulated environment, perhaps transferring their new skills back to a traditional training environment, in the presence of an experienced instructor, can help the experienced operator apply their new awareness and techniques to the working environment.

A practice schedule that allows students to rotate through simulators and real equipment minimizes training costs without sacrificing the benefits of traditional machine training. Compared to a traditional training schedule, an integrated, rotating schedule reduces the cost of training while allowing more machines to remain in production. Scheduling an initial simulator training period will result in better initial operator performance when students transfer to a machine (Freedman 2004, Yates 2000) and integrating subsequent periods of simulator training may result in higher retention rates for learned skills (So et al. 2016). Scheduling practice time on a machine between simulator training sessions will ensure that students are able to easily transfer their new skill set to a working environment after completing the training program. Moreover, replacing several machine training hours with simulator training hours will lower the environmental impact of equipment operator training. Reduced use of fuel and lubricants will result in a reduction of harmful byproducts including carbon dioxide and dirty engine fluids.

An unexpected theme that we encountered when speaking with training and industry professionals is the preference to train students in pairs. Three industry professionals (one construction equipment trainer, one forestry equipment trainer, and one forestry simulator manufacturer) cited the ability for partners to watch the other operate the machine and/or simulator from a different perspective, as well as an element of support and competition within partnerships, as reasons why training in pairs is preferable to individual training (Green, P., Miller Timber, Oregon, USA; Jurvanen, J., Ponsse Oyj, Vieremä, Finland; Morris, R., Empire Cat Southwest, Arizona, USA, personal communication). Formally known as »cooperative learning«, shared learning opportunities in which students work in small groups has been shown to increase student achievement (Slavin et al. 2001). This strategy may be useful in the integrated training curriculum we propose here, though no studies have directly observed the effect of training partnerships in heavy equipment operator training programs.

While we can hypothesize about an optimum training schedule, more research is needed to determine the effectiveness of an integrated training schedule in comparison to traditional machine training and simulator training. Training programs for forestry equipment operators generally have limited access to training equipment due to the high cost of owning or renting equipment, limited access to experienced trainers due to the limited pool of expert operators (Freedman 2001, Pagnussat et al. 2021, Vaughan et al. 2021), and perhaps limited access to land for training purposes. The recommended training strategies presented in this article are to be applied based on the individual resource restrictions of each training institution. Specific training practices will also be based on the preferred operator performance outcomes of each training institution and should remain adaptive based on feedback from trainers and students in the program.

Acknowledgments

This study was funded by the Economic Development Administration, US Department of Commerce (Investment No.: 07 79 07629). We would like to thank Preston Green, Matt Mattioda, and Lee Miller of Miller Timber in Oregon, USA, as well as Ron Morris at Empire Cat Southwest in Arizona, USA for donating their time and allowing our team to observe their operator training practices. Our conversations with Paul Freedman at Simlog in Québec, Canada, Craig Yager at Komatsu in Georgia, USA and Bjorn Hellstrandh at Oryx Simulations in Sweden in partnership with Komatsu, Jussi Jurvanen at Ponsse in Finland, Joe Najjar at CMLabs in Québec, Canada in partnership with Tigercat, and Curtis LeConte at John Deere in Iowa, USA provided us invaluable insight into the design process and features available for current forestry simulators. We would also like to express our gratitude to Heikki Ovaskainen at Metsäteho Oy in Finland for providing several resources on simulator training that were difficult to find elsewhere, as well as his insight on factors affecting the effectiveness of simulator training for forestry equipment operators. Finally, we would like to thank Rich Edwards at the Ecological Restoration Institute in Arizona, USA for providing further insight into training for forestry equipment operators as well as edits to several drafts of this review.

5. References

American Psychological Association, 2022: Perceptual-motor coordination. Available online: https://dictionary.apa.org/perceptual-motor-coordination. (accessed 3 February 2022)

Bhalerao, B.N., Dunston, P.S., Proctor, R.W., 2017: Use of PC-based simulators to train basic control functions of a hydraulic excavator: audiovisual instruction contrasted with hands-on exploration. International Journal of Human–Computer Interaction 33(1): 66–74. https://doi.org/10.1080/10447318.2016.1232230

Blatchford, P., 2012: Three generations of research on class-size effects. In: Harris, K.R., Graham, S., Urdan, T., editors. Education Psychology Handbook. Vol. 2: Individual Differences and Cultural and Contextual Factors. Washington DC: American Psychological Association, 529–549 p.

Calabrese, D., 2000: Canadian Switches to Mechanized, Cut-to-Length. In: TimberLine Magazine. http://www.timberlinemag.com/articledatabase/view.asp?articleID=222 (accessed 22 Sept 2021).

Conrad, J.L., Greene, W.D., Hiesl, P., 2018: A review of changes in US logging businesses 1980s-present. Journal of Forestry 116(3): 291–303. https://doi.org/10.1093/jofore/fvx014

Duzmanska, N., Stojny, P., Strojny, A., 2018: Can simulator sickness be avoided? A review on temporal aspects of simulator sickness. Frontiers in psychology 9: 2132. https://doi.org/10.3389/fpsyg.2018.02132

Freedman, P., 2001: Something new: Personal training simulators for the professional logging contractor. Proceeding of the Council for Forest Engineering; 15–18 July, Snowshoe, West Virginia.

Freedman, P., 2004: Operator training with simulator-based help in Quebec. Simulator-based training of forest machine operators – A presentation; 18 November, Quebec, Canada.

French, S., 2015: The benefits and challenges of modular higher education curricula. Melbourne Centre for the Study of Higher Education. University of Australia, Melbourne.

Gellerstedt, S., 2002: Operation of the single-grip harvester: motor-sensory and cognitive work. International journal of forest engineering 13(2): 35–47. https://doi.org/10.1080/14942119.2002.10702461

Healy, A.F., Wohldmann, E.L., 2012: Specificity and transfer of learning. In: Ross, B., editor, Academic Press. Psychol Learn Motivation 57: 227–253. https://doi.org/10.1016/B978-0-12-394293-7.00006-6

Hildreth, J., Gehrig, B., 2009: Incorporating equipment simulators into a construction-education curriculum. American Society for Engineering Education; 2009 Annual Conference & Exposition Proceedings, 14–17 June, Austin, Texas, USA.

Hildreth, J., Heggestad, E.D., 2010: Effect of simulation training methods on operator anxiety and skill development. Proceedings from the 10th International Conference on Construction Applications of Virtual Reality (CONVR2010), 3–6 November, Sendai, Japan.

Hildreth, J.C., Stec, M., 2009: Effectiveness of simulation-based operator training. Proceedings from the 9th International Conference on Construction Applications of Virtual Reality (CONVR 2009), 5–6 November, Sydney, Australia.

Hoss, C., 2001: Harvester simulators as effective tools in education. Thinnings, a valuable forest management tool. – An international conference; September. Quebec, Canada.

LaPointe, J.F., Robert, J.M., 2000: Using VR for efficient training of forestry machine operators. Education and Information Technologies 5: 237–250. http://doi.org/10.1023/A:1012045305968

Lopes, E.D.S., Cruziniani, E., Araujo, A.J., Da Silva, P.C., 2008: Evaluation of harvester operator training using virtual reality simulators. Rev Árvore 32: 291–298. https://doi.org/10.1590/S0100-67622008000200012

Lopes, E.D.S, Oliveira, D.D., Da Silva, P.C., Chiqueto, A.L., 2010: Evaluation of operator's performance training with forwarder simulator. Ciência Florestal 20(1): 179–189.

Magill, R.A., Hall, K.G., 1990: A review of the contextual interference effect in motor skill acquisition. Human movement science 9(3–5): 241–289. https://doi.org/10.1016/0167-9457(90)90005-X

Marcano, L., Haugen, F.A., Sannerud, R., Komulainen, T., 2019: Review of simulator training practices for industrial operators: How can individual simulator training be enabled? Safety science 115: 414–424. https://doi.org/10.1016/j.ssci.2019.02.019

Martín, de los Reyes L.M., Jiménez-Meíjas, E., Martínez-Ruiz, V., Moreno-Roldán, E., Molina-Soberanes, D., Lardelli-Claret, P., 2019: Efficacy of training with driving simulators in improving safety in young novice or learner drivers: A systematic review. Transportation research part F: traffic psychology and behaviour 62: 58–65. https://doi.org/10.1016/j.trf.2018.12.006

Meyers, III P.L., Starr, A.W., Mullins, K., 2018: Flight simulator fidelity, training transfer, and the role of instructors in optimizing learning. International Journal of Aviation, Aeronautics, and Aerospace 5(1): 6. https://doi.org/10.15394/ijaa.2018.1203

Ovaskainen, H., 2005: Comparison of harvester work in forest and simulator environments. Silva fennica 39(1): 89–101. http://doi.org/10.14214/sf.398

Pagnussat, M.B., Lopes, E.D.S., Robert, R.C.G., 2021: Machine availability and productivity during timber harvester machine operator training. Canadian Journal of Forest Research 51(3): 433–438. h ttps://doi.org/10.1139/cjfr-2020-0164

Proctor, R.W., Dunston, P.S., So, J.C.Y., Lopez-Santamaria, B.N., Yamaguchi, M., Wang, X., 2013: Specificity of transfer in basic and applied perceptual-motor tasks. The American journal of psychology 126(4): 401–415. https://doi.org/10.5406/amerjpsyc.126.4.0401

Pürfurst, F.T., 2010: Learning curves of harvester operators. Croatian Journal of Forest Engineering 31(2): 89–97.

Ranta, P., 2009: Added values of forestry machine simulator based training. Proceedings from the International Conference on Multimedia and ICT Education, 22–24 April, Libson, Portugal.

Richardson, R., Makkonen, I., 1994: The performance of cut-to-length systems in eastern Canada. FERIC, Pointe-Claire. Tech. Rep. TR-109: 16.

Slavin, R.E., Hurley, E.A., Chamberlain, A.M., Cooperative learning in schools, 2001: In: Smelser, H.J., Baltes, B., editors. International Encyclopedia of the Social and Behavioral Sciences. New York City: Elsevier. 2756–2761 p.

So, J.C.Y., Macrowski, L.M., Dunston, P.S., Proctor, R.W., Goodney, J.E., 2016: Transfer of operator training from simulated to real hydraulic excavators. Proceedings from the 2016 Construction Research Congress, 31 May – 2 June, San Juan, Puerto Rico. http://dx.doi.org/10.1061/9780784479827.196

So, J.C.Y., Proctor, R.W., Dunston, P.S., Wang, X., 2013: Better retention of skill operating a simulated hydraulic excavator after part-task than whole-task training. Human factors 55(2): 449–460. https://doi.org/10.1177%2F0018720812454292

Su, X., Dunston, P.S., Proctor, R.W., Wang, X., 2013: Influence of training schedule on development of perceptual-motor control skills for construction equipment operators in a virtual training system. Automation in construction 35: 439–447. https://doi.org/10.1016/j.autcon.2013.05.029

Vaughan, D., Edgeley, C.M., Han, H-S., 2021: Forest contracting businesses in the southwest: Current profile and workforce training needs. Journal of Forestry 120(2):186–197. https://doi.org/10.1093/jofore/fvab060

Wenhold, R., Ackerman, P., Ackerman, S., Gagliardi, K., 2020: Skills development of mechanized softwood sawtimber cut-to-length harvester operators on the Highveld of South Africa. International Journal of Forest Engineering 31(1): 9–18. https://doi.org/10.1080/14942119.2019.1578561

Wolpert, D.M., Kawato, M., 1998: Multiple paired forward and inverse models for motor control. Neural Network 11(7–8): 1317–1329. https://doi.org/10.1016/s0893-6080(98)00066-5

Yates, B., 2000: High tech training of high-tech workforce in the forest industry. Canadian Woodlands Forum 81st Annual Meeting »Technologies for New Millennium Forestry«, Session 3B »Workforce development and issues«, 11–13 September, Kelowna, Canada.

© 2023 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Erin Burk, MSc *

e-mail: eeb297@nau.edu

Prof. Bruce Fox, PhD

e-mail: bruce.fox@nau.edu

Northern Arizona University

School of Forestry

200 E Pine Knoll Drive

86011, Flagstaff

Arizona

USA

Prof. Han-Sup Han, PhD

e-mail: han-sup.han@nau.edu

Northern Arizona University

Ecological Restoration Institute

200 E Pine Knoll Drive

86011, Flagstaff

Arizona

USA

Mathew Smidt, PhD

e-mail: mathew.smidt@usda.gov

US Forest Service

Southern Research Station

521 Devall Drive

36849, Auburn

Alabama

USA

* Corresponding author

Received: July 06, 2022

Accepted: November 21, 2023

Subject review