Mechanical Feeding of Grapple Yarders: Productivity, Flexibility and Time Use Efficiency

doi: https://doi.org/10.5552/crojfe.2025.3425

volume: 46, issue: 2

- Author(s):

-

- Visser Rien

- Howden Angus

- Spinelli Raffaele

- Article category:

- Original scientific paper

- Keywords:

- cable, steep terrain, loader, excavator, time study

Abstract

HTML

Excavator-based shovelling machines can be used on steep terrain to improve the safety and productivity of cable yarder extraction. Shovelling felled timber across to a yarding corridor limits the number of line-shifts required, and feeding the grapple carriage reduces cycle time and increases average payload. The study determined the productivity, utilization and time use of four excavator-based shovelling machines feeding a cable yarder operation using a grapple motorized carriage at four different sites in New Zealand’s South Island. The four machines were owned and operated by four different contractors, but they all worked on end-of-rotation radiata pine clearcuts. Productivity varied from approximately 25 to 100 m3 per hour, including waiting time for the grapple carriage to return, but excluding all other delays. Piece size had the strongest impact on productivity. Mean utilization was 61%. 20% of shovel worksite time was spent engaging with productive work other than feeding the grapple, such as felling, shovelling or tidying up the cutover.

Mechanical Feeding of Grapple Yarders: Productivity, Flexibility and Time Use Efficiency

Rien Visser, Angus Howden, Raffaele Spinelli

https://doi.org/10.5552/crojfe.2025.3425

Abstract

Excavator-based shovelling machines can be used on steep terrain to improve the safety and productivity of cable yarder extraction. Shovelling felled timber across to a yarding corridor limits the number of line-shifts required, and feeding the grapple carriage reduces cycle time and increases average payload. The study determined the productivity, utilization and time use of four excavator-based shovelling machines feeding a cable yarder operation using a grapple motorized carriage at four different sites in New Zealand's South Island. The four machines were owned and operated by four different contractors, but they all worked on end-of-rotation radiata pine clearcuts. Productivity varied from approximately 25 to 100 m3 per hour, including waiting time for the grapple carriage to return, but excluding all other delays. Piece size had the strongest impact on productivity. Mean utilization was 61%. 20% of shovel worksite time was spent engaging with productive work other than feeding the grapple, such as felling, shovelling or tidying up the cutover.

Keywords: cable, steep terrain, loader, excavator, time study

1. Introduction

Two main drivers of progress in forest harvesting technology are work safety and the need to cope with increasingly steep terrain (Spinelli et al. 2019). Logging has gained a dubious reputation as one of the most dangerous jobs in peacetime, with four times the fatality rates of other occupations in the agricultural sector (Klun and Medved 2007). For that reason, work safety agencies worldwide have applied increasing pressure onto all stakeholders to improve safety in forestry. Measures include enforcing the use of personal protective equipment and promoting ad-hoc training (MacKay et al. 1996, Magagnotti et al. 2021). However significant, the effectiveness of safety training alone is not as definitive as hoped for (Bell and Grusheky 2006). Manual forestry work remains a high-risk occupation and accounts for most of the fatal accidents (Albizu et al. 2013). Mechanizing forestry work remains the only resolutive measure, whose effectiveness has been demonstrated over and again (Axelsson 1998, Bell 2002, Bonauto et al. 2019). This is especially true on steep slopes where mechanization challenges include not only machine stability but also environmental performance (Visser et al. 2014).

At the same time, economic and demographic growth have caused a dramatic expansion of agriculture and urban development, which are occupying all the best sites (Nauhelhal et al. 2012). Forestry cannot compete economically, and it is being pushed to less favorable terrain. Countless cities in Europe – from Berlin to Ravenna – teach us that it is easier to drain a swamp than flatten a mountain, and therefore the main challenge confronting foresters across the globe is steep terrain. From North America (Bennet 2016) to Europe (Spinelli et al. 2017) logging crews are tackling stands that have been planted on the lower value steep terrain or were passed over in the past because they were considered too steep for cost-effective exploitation with conventional ground-based equipment.

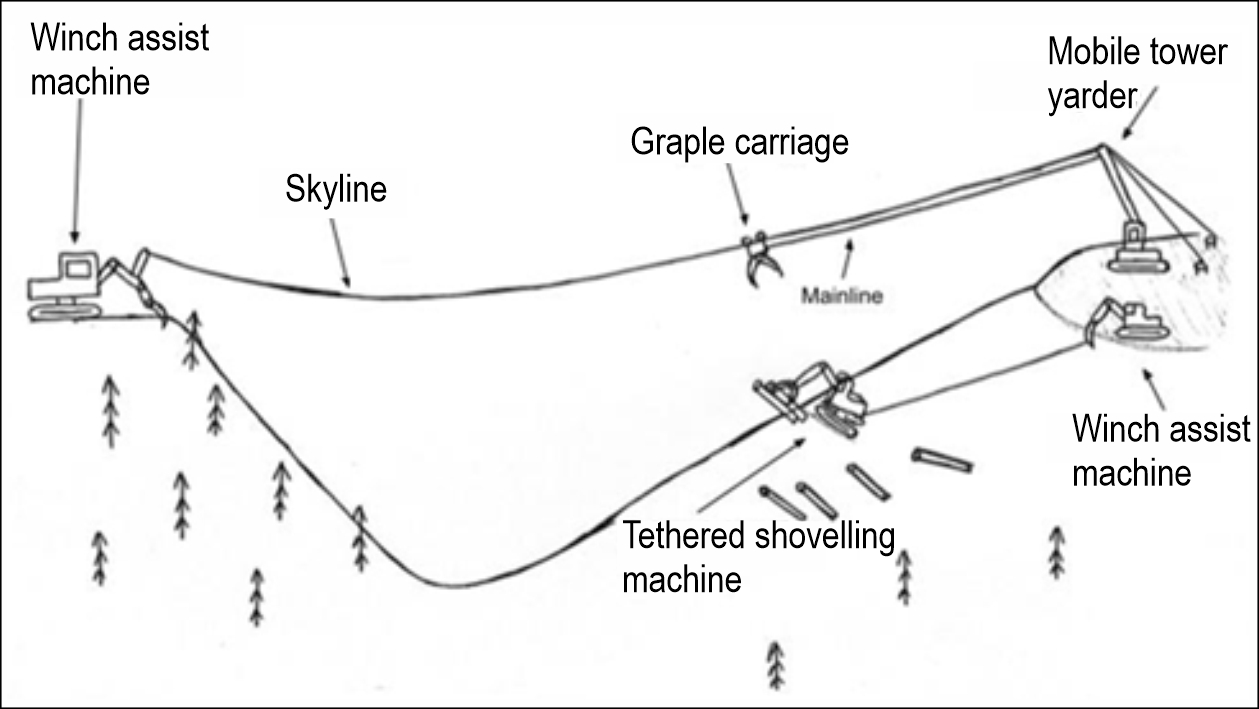

While cable yarding is a long-proven technology for harvesting on steep terrain, the application of grapple yarding systems, either mechanical or motorized, allows for higher levels of mechanization (Studier and Binkley 1974). Grapple yarders were very popular in the past for tackling old-growth forests, whose large trees could be turned into ideal single-piece loads, easy to grab even for the clumsy mechanical grapples of the time (De Souza 1983). In contrast, secondary or plantation forests offer smaller trees that cannot form a suitable payload if taken singularly and require accumulation. Hence there was a general shift to using choker slings that have remained dominant until recently (Helton 1985). The issue with choker slings is that they must be fastened manually by one or more workers (»choker-setters« or »breaker-outs«) sited on the cutover – a task that is uncomfortable, tiresome and very hazardous. The alternative is to use a machine to prepare the loads and feed them to the yarder grapple, so that the operators tasked with such job may sit comfortably inside a certified safety cab (Chung et al. 2023, Engelbrecht et al. 2017) (Fig. 1). Today, winch-assist technology makes it possible to introduce such machines to steep terrain, for safe and effective operation (Visser and Stampfer 2015). As a matter of fact, more and more loggers are now adopting the new work system, whereby a suitably equipped machine is tasked with preparing the loads and feeding them to the yarder grapple, in order to boost productivity and remove labour from hazardous workplaces (Harril et al. 2019). Since the system is relatively new, there is very little quantitative information on its performance and efficiency.

Fig. 1 Typical grapple feeding system

Therefore, the goal of this study was to observe a representative sample of commercial operations where grapple feeding is routinely applied and collect quantitative information on the productivity and efficiency of grapple feeding work. That information can then be used to assess the pros and cons of the new technique, to develop guidelines for its effective deployment and to address future research aimed at refining the knowledge thus obtained, given the preliminary character that is inevitable for all initial system developments.

2. Materials and Methods

Four observational studies were conducted at four different pine plantations in New Zealand's South Island. The main characteristics of the four sites and of the machines used at each site are shown in Table 1. Different contractors were engaged at the different sites, but they were all highly professional and relied on experienced crews.

The machines used at each site are also described in Table 1. Two were powerful purpose-built feller-bunchers that were self-levelling and winch-assisted, and two were excavator-based loaders working under easier terrain conditions.

Therefore, one may distinguish between two technical levels: operations 1 and 2, where dedicated self-levelling winch-assisted machines were tasked with feeding a motorized grapple carriage and worked on considerably steep terrain (>50% slope gradient); and operations 3 and 4, where excavator-based loaders without leveling platform nor winch assistance were tasked with feeding the mechanical carriages of smaller yarders and worked on somewhat easier terrain (<50% slope gradient).

Table 1 Description of test sites

|

Site |

1 |

2 |

3 |

4 |

|

Herbert forest |

Geraldine |

Pidgeon valley |

Golden downs |

|

|

Nearest town |

Oamaru |

Timaru |

Nelson |

Tapawera |

|

Species |

P. radiata |

P. radiata |

P. radiata |

P. radiata |

|

Mean stem size, m3 |

0.5 |

3.5 |

1.3 |

2.0 |

|

Slope gradient, % |

57 |

51 |

42 |

45 |

|

Extraction distance, m |

250 |

126 |

175 |

190 |

|

Extraction direction |

Uphill |

Uphill |

Uphill |

Uphill |

|

Yarder make |

Madill |

Madill |

Madill |

Madill |

|

Yarder model |

171 |

171 |

124 |

124 |

|

Grapple carriage type |

Motorized |

Motorized |

Mechanical |

Mechanical |

|

Feeding unit type |

Feller-buncher |

Feller-buncher |

Excavator |

Excavator |

|

Feeding unit make |

Tigercat |

Tigercat |

Hitachi |

Sumitomo |

|

Feeding unit model |

855E |

LS855E |

ZX290 |

SH220 |

|

Feeding unit mass, t |

30 |

30 |

29 |

23 |

|

Feeding unit power, kW |

212 |

212 |

130 |

112 |

|

Winch-Assisted |

Yes |

Yes |

No |

No |

|

Observations |

149 |

339 |

134 |

43 |

|

Observation days |

3 |

3 |

2 |

1 |

Mechanized directional felling was applied to all worksites. All harvests were planned end-of-rotation clearcuts. Work data collection lasted 9 days for a total of 43 hours or 665 complete cycles. For each cycle, researchers measured time consumption and estimated load size.

Fig. 2 Tigercat LS855E feeding a stem to Falcon 1750 at Site # 2 (Geraldine)

Load size was estimated through a piece count. The stem volume per site was obtained from the processor operator, since the machine was regularly calibrated and kept a log of daily production that included total volume and number of stems (Visser and Spinelli 2023). Estimates were validated by cross-checking with the company inventory information. The number of pieces extracted with each cycle was recorded and categorized as either »stem« or »top«. When harvesting NZ pine, most trees break during the felling process at a height of approximately two-thirds of the total height (Fraser et al. 1997). The lower portion (»stem«) would represent 85% of the tree volume and the upper one (»top«) the remaining 15%: those proportions were used to estimate load size.

Cycle time was recorded manually with a stopwatch (Magagnotti et al. 2013). The feeding cycle was broken down into the following functional steps, which were timed separately: bunching, feeding and waiting. Bunching consisted in reaching out for the stems and tops and moving them under the skyline to form a bunch. That step often required covering up to 50 m, which would be done according to the »shovelling« technique (Hemphill 1986); feeding consisted in lifting the bunch and presenting it to the yarder grapple, which would grab it and pull it to the landing pad; waiting was the time spent under the skyline with a bunch at the ready, before the yarder grapple would come and claim it. Furthermore, the researcher would separately record all the time the feeding machine was engaged with other productive work, not directly related to feeding the grapple (e.g. felling, tidying up the cutover, etc.). Delays were also recorded separately and categorized as operational, mechanical or personal (Spinelli and Visser 2008).

First, the data was checked for outliers and other blatant errors. In particular all datapoints that were 2 times the interquartile range below the lower quartile or above the upper quartile were considered suspected outliers and inspected: if the inspection could not find a reasonable explanation why the datapoint was so far off the cloud, then the datapoint would be removed. Then descriptive statistics were extracted, with the goal of finding solid indicators for centrality and variability. Those are the main qualities used for assessing the value and reliability of the general benchmarks we wanted to obtain. The statistical significance of any difference found between the different test sites or machine types was tested with non-parametric techniques that are robust against violations of the normality assumption, such as the Kruskal-Wallis test. The significance threshold was set at α<0.05. Regression analysis was also used, with the main purpose of testing the general relationship between cycle time, load size and extraction distance – the latter represented by the observation sequence, as the grapple started picking the loads closest to the landing and progressed outwards in the direction of the tailhold.

The study included a subjective element, consisting in direct interviews to the harvest planner, crew boss or shovelling machine operator, designed to obtain further insights on the benefits and limitations of detaching a separate machine to feed the yarder grapple. Survey questions were the same or followed the same rationale as those used by Pedofsky and Visser (2019) for their survey of winch assisted skidder users.

3. Results

The daily production data shows the dramatic effect of piece size on machine productivity (Table 2). While mean cycle time ranged from 104 to 233 s, mean productivity ranged from 23 to 114 m3/PMH and the smallest piece size systematically corresponded to the longest cycle time and the lowest productivity. At site #1, the machine negotiating the smallest piece size took a longer time than all the others in order to accumulate an average three-pieces load, and yet could not match the load size achieved at the other sites, felling far behind in terms of productivity. The table also shows a very clear trend for load size, which contained an average three pieces for very small stems (0.5 m3), about two pieces for large stems (~2 m3) and only one piece for very large stems (>3 m3) that were close to reaching the payload capacity of the yarder.

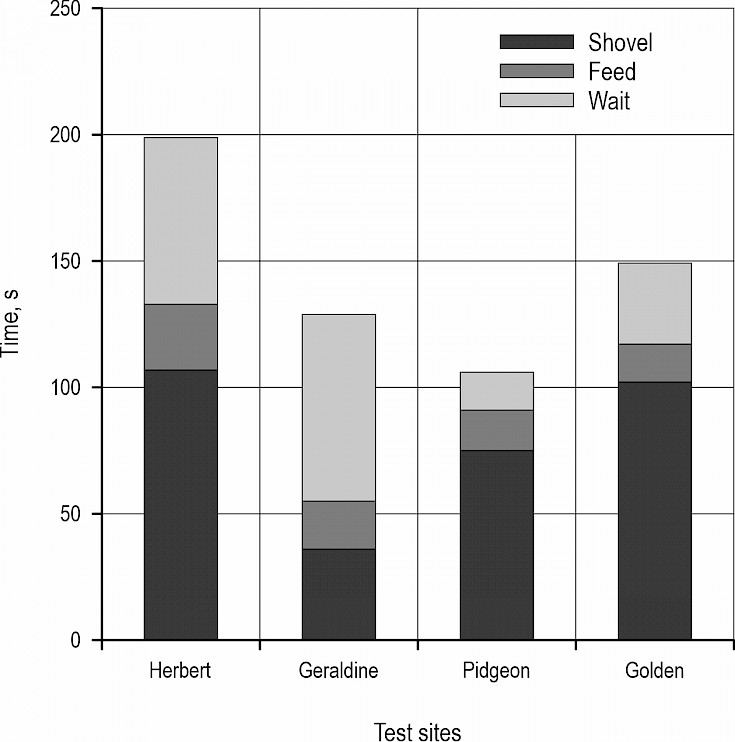

The elemental time study provided further insights into the factors affecting work performance. Accumulating a load (shovelling) was the fastest where stem size was the largest (Geraldine), and the longest where stem size was the lowest (Herbert) (Fig. 3). The figure also indicates that the task of feeding a load to the grapple took approximately the same time, regardless of bunch size or machine type – which was confirmed by regression analysis. Apparently, once a load had been formed, the time to pass it onto the yarder grapple was relatively constant.

As a typical interaction delay, waiting time would depend on the difference between the cycle times of the feeding unit and of the yarder. Fig. 3 suggests that such difference was largest at sites #1 and #2, which could be explained by the yarder at site #1 spanning the longest distance (hence a long yarding cycle), while at site #2 the feeding cycle was the shortest. Overall, mean waiting time represented 39% of the feeding cycle and ranged from 13% at site #3 and 54% at site #2.

Table 2 Results: cycles, pieces, volumes, time consumption and productivity

|

Site |

Day |

Cycles |

Pieces |

m3 |

Pieces cycle-1 |

m3 piece-1 |

m3 cycle-1 |

Cycle time, s |

Piece h-1 |

m3 h-1 |

|

Herbert |

1 |

51 |

102 |

51 |

2.0 |

0.50 |

1.00 |

157 |

46 |

23 |

|

Herbert |

2 |

56 |

168 |

84 |

3.0 |

0.50 |

1.50 |

233 |

46 |

23 |

|

Herbert |

3 |

42 |

126 |

63 |

3.0 |

0.50 |

1.50 |

204 |

53 |

27 |

|

Geraldine |

1 |

131 |

130 |

455 |

1.0 |

3.50 |

3.47 |

110 |

33 |

114 |

|

Geraldine |

2 |

150 |

149 |

522 |

1.0 |

3.50 |

3.48 |

132 |

27 |

95 |

|

Geraldine |

3 |

58 |

59 |

207 |

1.0 |

3.50 |

3.56 |

121 |

30 |

106 |

|

Pidgeon |

1 |

39 |

93 |

121 |

2.4 |

1.30 |

3.10 |

112 |

77 |

100 |

|

Pidgeon |

2 |

95 |

176 |

229 |

1.9 |

1.30 |

2.41 |

104 |

64 |

83 |

|

Golden |

1 |

43 |

91 |

181 |

2.1 |

1.99 |

4.21 |

146 |

52 |

104 |

|

Notes: m3 – solid volume over bark; h – hours of feeding machine work, including waiting time but excluding all other delays |

||||||||||

Fig. 3 Mean cycle time by task and site

Table 3 reports the average duration of all elemental times, as well as the 5th and 95th percentiles, taken as the actual range of variation after removing the effect of erratic datapoints. The table also shows what values are statistically different from each other, according to the Kruskall-Wallis non-parametric test.

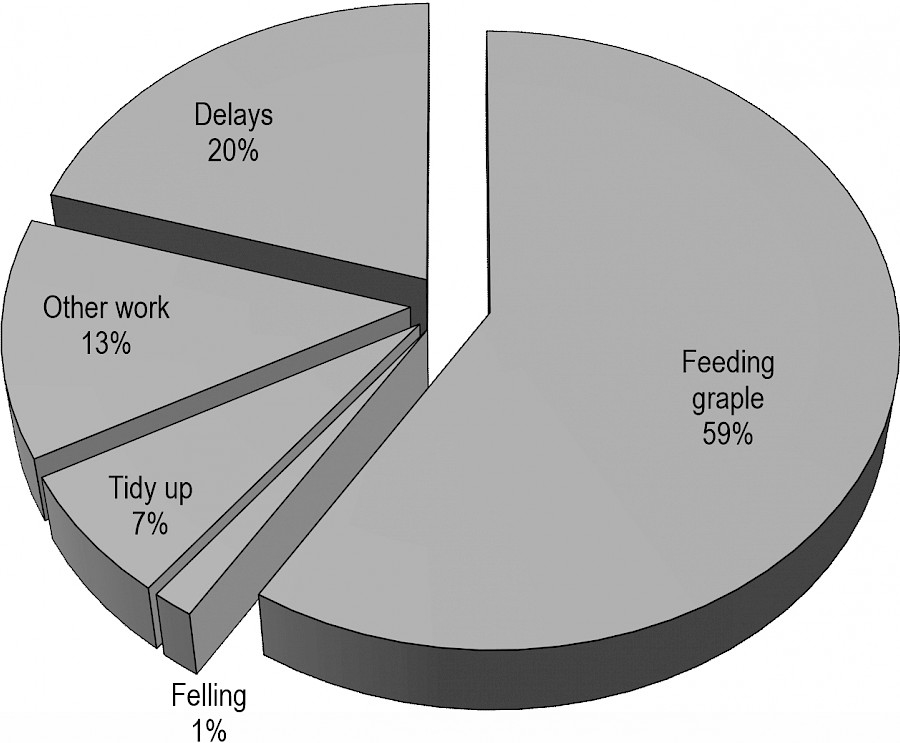

All the machines deployed to feed the yarder grapple were quite versatile and were used accordingly. As a general average, feeding the yarder grapple took approximately 60% of total worksite time (Fig. 4). That 60% included waiting for the grapple to show up, which represented 40% of grapple feeding time, or 23% of total worksite time. Other productive work represented an additional 20% of worksite time and consisted most often of felling and tidying up the cutover. Delays accounted for 20% of worksite time, excluding grapple feeding waiting time. If that was also included, then delay time expanded to 43% and utilization reduced to 57%.

Table 3 Results of elemental time study

|

Site |

1 |

2 |

3 |

4 |

|||||||||||||

|

Site |

Herbert |

Geraldine |

Pidgeon |

Golden |

|||||||||||||

|

Metrics |

Mean |

Median |

5th |

95th |

Mean |

Median |

5th |

95th |

Mean |

Median |

5th |

95th |

Mean |

Median |

5th |

95th |

|

|

Shovel, s |

107a |

99 |

38 |

193 |

36 b |

27 |

12 |

115 |

75 a |

77 |

31 |

116 |

102 a |

108 |

35 |

161 |

|

|

Feed, s |

26 a |

23 |

14 |

47 |

19 b |

18 |

10 |

31 |

16 c |

15 |

8 |

28 |

15 c |

14 |

9 |

26 |

|

|

Wait, s |

66 a |

67 |

0 |

163 |

74 b |

74 |

29 |

114 |

15 c |

8 |

0 |

52 |

32 d |

30 |

0 |

87 |

|

|

Cycle, s |

198 a |

196 |

94 |

298 |

122 b |

125 |

44 |

165 |

106 c |

99 |

66 |

160 |

146 d |

148 |

87 |

198 |

|

|

Load size pieces |

2.6 a |

2.4 |

2.0 |

3.0 |

1.0 b |

1.1 |

0.5 |

2.0 |

2.0 a |

2.0 |

1.0 |

3.0 |

2.1 a |

2.0 |

2.0 |

3.0 |

|

|

Load size m3 |

1.3 a |

1.3 |

1.0 |

1.5 |

3.5 b |

3.4 |

1.6 |

7.0 |

2.6 c |

2.5 |

1.3 |

3.9 |

4.2 d |

4.1 |

3.9 |

5.9 |

|

|

Notes: 5th – Fifth percentile; 95th – Ninety-fifth percentile; m3 – solid volume over bark; different superscript letters attached to the mean values on the same row indicate that the differences between the means were found statistically significant at the 5% level by the Kruskal-Wallis non-parametric comparison test |

|||||||||||||||||

Fig. 4 Time use breakdown of grapple feeding machines (general average). Notes: approximately 40% of the »Feeding grapple« time is represented by waiting for the grapple to show up

Table 4 reports the same values for each site and day, in order to allow a better appreciation of local and temporal variability. The same table also indicates the proportion of cycles where waiting time was experienced, with the purpose of detecting system unbalance. Depending on the site and day, between 50% and 90% of the feeding cycles contained a »waiting« element, suggesting that the feeding unit had excess capacity and could keep the more expensive yarder going, instead of waiting itself. The mechanisms of interaction are potentially more complex and mutual waiting is not impossible, especially in poorly synchronized operations. Therefore, our inference is just suggestive and would require validation through a parallel time study of both machines. Visual observation during the study indicated that the main bottleneck in all operations was the processor sitting at the landing, which was often unable to clear the stems away from the yarder before the next turn showed up. As a result, the yarder had to wait until the processor had at least moved the stems away before releasing its load and sending the grapple back to the loading site, where the feeding unit also stood waiting.

Table 4 Proportion of cycles with waiting time, other work, delays and utilization

|

Site |

Day |

Total cycles |

Cycles w/ Wait |

% Cycles w/ Wait |

Grapple work h |

Grapple wait h |

Other work h |

Delays h |

Util % |

Other work % |

|

|

Herbert |

1 |

51 |

47 |

92 |

1.30 |

0.92 |

0.00 |

0.07 |

57 |

0 |

|

|

Herbert |

2 |

56 |

49 |

88 |

2.29 |

1.33 |

0.00 |

0.25 |

59 |

0 |

|

|

Herbert |

3 |

42 |

25 |

60 |

1.89 |

0.48 |

1.21 |

1.32 |

63 |

39 |

|

|

Geraldine |

1 |

131 |

128 |

98 |

1.70 |

2.30 |

1.16 |

0.27 |

53 |

41 |

|

|

Geraldine |

2 |

150 |

142 |

95 |

2.21 |

3.29 |

1.30 |

0.75 |

46 |

37 |

|

|

Geraldine |

3 |

58 |

37 |

64 |

1.20 |

0.75 |

2.23 |

0.27 |

77 |

65 |

|

|

Pidgeon |

1 |

39 |

21 |

54 |

1.09 |

0.11 |

1.18 |

0.75 |

73 |

52 |

|

|

Pidgeon |

2 |

95 |

56 |

59 |

2.31 |

0.44 |

1.84 |

1.86 |

64 |

44 |

|

|

Golden |

1 |

43 |

29 |

67 |

1.36 |

0.38 |

1.99 |

1.44 |

65 |

59 |

|

|

All |

665 |

534 |

80 |

15.35 |

10.00 |

10.91 |

6.98 |

61 |

42 |

||

|

Notes: Total Cycles – number of grapple feeding cycles recorded for that day and that site; Cycles w/ Wait – number of grapple feeding cycles where waiting time was recorded; Other work – productive work other than grapple feeding (e.g. felling, tidying up etc.); Delays – non-work time other than waiting (e.g. breakdowns, personal delays etc.); Utilization – work time / (work time + delays) expressed a percent value |

|||||||||||

Ten professionals responded to the survey questions, including all the four machine operators observed at the four study sites, and their foremen. Their answers provided valuable insights on the reasons for using a separate machine to feed the yarder grapple and of its perceived advantages. Examples mentioned where a grapple would struggle to perform included: obstructed field of vision (back faces and gullies), small tree size and excessive load scatter. Grapple feeding under those conditions prevented the need to using slings and thus removed the risky and tiresome task of choker-setting (WorkSafe BC 1992, Howard 1991). Second, they believed that grapple feeding resulted in a marked increase in yarder productivity, which some respondents estimated at about 100 t of additional extraction per day. Third, respondents stressed that once on the cutover, the loader was also used to tidy up the work site, resulting in a cleaner slope that would be easier to replant and less prone to slash mobilization. Finally, the use of an excavator-based shovel machine allowed covering flatter areas and back faces without building new roads and landings, which would result in significant savings. Concerning work conditions, respondents generally agreed on 30° being the maximum slope gradient for unassisted feeding units, 45° for winch-assisted ones. Maximum viable distance was estimated to 500 m, based on the cable capacity of the assisting winch. However, even if winch capacity was extended, working on longer distances would result in a severe decrease of yarder productivity and might not be profitable. Of course, those are informed but subjective statements and cannot be taken as scientific evidence until validated by suitable studies.

4. Discussion

Grapple feeding adds complexity to an already complex chain of tasks where interdependence can cause significant delays. Therefore, one of the main concerns is checking whether its inclusion will further decrease system stability and increase vulnerability to interaction delays. Both the time study and the interviews suggest that it may not be the case. The majority of the grapple feeding cycles included a sizable waiting component, suggesting that the feeding unit had excess capacity to prevent lengthy yarder delays. One cannot exclude a certain lack of synchronicity, but the fact that none of the interview respondents mentioned the additional risk for interaction delays eventually introduced by the feeding machine is a good indicator that it is not generally the case. In fact, the feeding machine may act as a productivity stabilizer: it may occasionally fall behind on very short hauls where the yarder is most productive, but it will boost yarder productivity on longer hauls, effectively counterbalancing the impact of extraction distance.

A certain overcapacity of the feeding machine is likely desirable as it will prevent operational yarder delays, which are the least desirable, since the yarder is the most expensive piece of equipment on site. As the feeding machine is a versatile piece of equipment, it can also be used for other ancillary tasks if the yarder falls behind, for example it can shovel the easiest segments directly to the landing and/or a logging road where ground-based equipment can pull it to the landing. As a whole, the feeding machines in our study spent 20% of their worksite time performing tasks other than feeding, such as felling or tidying up the cutover from scattered tops and slash. In New Zealand, a new law (National Environmental Standard for Commercial Forestry) requires the removal of larger woody debris (i.e. »tops«) from erosion prone areas (Parker and Henare 2023). In those cases, a shovel must be introduced to the cutover to bunch residues and feed them to the grapple, so it would make sense to use it all along and facilitate the extraction of commercial stems. At the same time, the capacity to perform multiple tasks allows the feeding unit to achieve good utilization levels, as demonstrated in our study. In this study two of the machines used for feeding the grapple were actually the same feller-bunchers previously used to fell the trees (Site #1 and Site #2). Therefore, the level of versatility of the feeding unit depends on machine type. A feller-buncher is more expensive, but it is also more versatile, and it might be a better option if frequent task changes are required. Furthermore, using the feller-buncher for feeding the grapple allows increasing its utilization, thus lowering capital cost.

Cost is certainly an important issue. Adding a machine to shovel stems towards the yarding corridor can add 1200 USD to the daily cost of the operation and, if winch-assist is also required, then the amount will swell to over 2000 USD per day (Forme 2023). This study was not designed to provide a conclusive answer to the question of improved cost-effectiveness, but the few references available on the subject indicate it may be the case (Evanson and Amishev 2009, Acuna et al. 2011, Chung et al. 2023). Further corroboration can be obtained from the work of Engelbrecht et al. (2017), which shows how grapple feeding is a generalized practice in the Malaysian forest plantations. In fact, none of the respondents to the interviews even questioned the profitability of grapple feeding, taking for granted that it was the way to go. Of course, that sample is biased because it consists exclusively of operators who do resort to grapple feeding, but they would have complained about poor profitability if they thought grapple feeding was unprofitable and was forced upon them by some additional consideration, other than cost effectiveness.

Profitability did not appear to be the most important driver: all respondents seemed to consider grapple feeding more as an enabler than as a cost saver. Deploying a shovel to bunch and feed stems to the yarder grapple allows dispensing with choker-setters and chasers, thus solving cogent labor safety and recruitment issues (Evanson 2014).

Future research could address the effect of shovelling distance on shovel production and line shift frequency or - even better - explore the interaction between shovelling distance and yarding distance in order to develop effective operational guidelines. Yarding corridors tend to fan out from a central pivot represented by the tower sitting at the landing. Therefore, the distance between adjacent lines will become longer the further one moves away from the yarder. As a consequence, shovelling distance should also become longer moving down towards the tailhold, which subsumes a self-compensating mechanism where the shovel will need to cover longer distances when the yarder will also need to cover longer distances, thus giving the shovel enough lead time to accomplish its job before the carriage returns. A future study could aim at developing guidelines for optimizing such system, as well as to organize a better controlled experiment to conclusively determine the cost-effectiveness of grapple feeding under varying work conditions.

5. Conclusions

Grapple yarding offers an effective solution to fully mechanized steep terrain wood extraction. Its application is greatly facilitated by stationing a machine at the loading site on the cutover, for preparing the loads and feeding them to yarder grapple. Such machine must be versatile and productive, with some overcapacity, so that the yarder does not need to sit waiting. On slopes steeper than 30° that machine should be winch-assisted. If the yarder is stalled for some reason, the feeding machine can be used for other tasks, such as felling, shovelling and tidying up the cutover.

Acknowledgments

Support was received from the University of Canterbury – Christchurch, New Zealand, through the Erskine Programme.

6. References

Acuna, M., Skinnell, J., Evanson, T., Mitchell, R., 2011: Bunching with a self-levelling feller-buncher on steep terrain for efficient yarder extraction. Croatian Journal of Forest Engineering 32(2): 521–531.

Albizu, P., Tolosana-Esteban, E., Roman-Jordan, E., 2013: Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. Forest Systems 22(3): 392–400. https://doi.org/10.5424/fs/2013223-02714

Axelsson, S., 1998: The mechanization of logging operations in Sweden and its effect on occupational safety and health. Journal of Forest Engineering 9(2): 25–31. https://doi.org/10.1080/08435243.1998.10702715

Bell, J., Grushecky, S., 2006: Evaluating the effectiveness of a logger safety training program. Journal of Safety Research 37(1): 53–61. https://doi.org/10.1016/j.jsr.2005.10.019

Bennet, N., 2016: Timber supply crunch drives loggers to more dangerous terrain. Business Vancouver 2016/1. https://www.biv.com/article/2016/1/timber-supply-crunch-drives-loggers-more-dangerous

Bonauto, D.K., Wuellner, S.E., Marcum, J.L., Adams, D.A., 2019: Injury rate comparisons for nonmechanized and mechanized logging operations, Washington State, 2005–2014. Journal of Agromedicine 24(2): 205–214. https://doi.org/10.1080/1059924X.2019.1566106

Chung, W., Morrissette, B., Green, P., Garrelts, B., Leshchinsky, B., Belart, F., Sessions, J., Wimer, J., Garland, J., 2022: Effects of pre-bunching trees with a tethered feller-buncher on cable logging productivity and costs: a case study in southern Oregon. Forest Science 68(3): 325–333. https://doi.org/10.1093/forsci/fxac008

De Souza, A., 1983: A study of production and ergonomic factors in grapple yarding operations using an electronic data logger system. PhD Thesis, University of British Columbia, Vancouver, Canada, 231 p.

Engelbrecht, R., McEwan, A., Spinelli, R., 2017: A robust productivity model for grapple yarding in fast-growing tree plantations. Forests 8(10): 396. https://doi.org/10.3390/f8100396

Evanson, T., 2014: Alpine grapple carriage - from prototype to production. Harvesting Technical Note HTN06-09, Future Forests Research Ltd: Rotorua, New Zealand, 6 p.

Evanson, T., Amishev, D., 2009: A New Method for Bunching Trees on Steep Terrain . Rotorua: Future Forests Research.

Forme, 2023: Informe Harvesting 2023. Forme Consulting, Tawa, Wellington, NZ.

Harrill, H., Visser, R., Raymond, K., 2019: New Zealand cable logging 2008–2018: a period of change. Current Forestry Reports 5(3): 1–10. https://doi.org/10.1007/s40725-019-00092-5

Helton, J., 1985: A comparison of grapple yarding and choker yarding in British Columbia. Master Thesis. University of New Brunswick, Fredericton, Canada, 88 p.

Hemphill, D., 1986: Shovel Logging. New Zealand: Logging Industry Research Association 8(1): 1–4.

Howard, A., 1991: Production equations for grapple yarding in Coastal British Columbia. Western Journal of Applied Forestry 6(1): 7–10. https://doi.org/10.1093/wjaf/6.1.7

Klun, J., Medved, M., 2007: Fatal accidents in forestry in some European countries. Croatian Journal of Forest Engineering 28(1): 55–62.

MacKay, D., Ellefson, P., Blinn, C., 1996: Registration, certification and licensing – creating better timber harvesters. Journal of Forestry 94(7): 27–31.

Magagnotti, N., Kanzian, C., Schulmeyer, F., Spinelli, R., 2013: A new guide for work studies in forestry. International Journal of Forest Engineering 24(3): 249–253. https://doi.org/10.1080/14942119.2013.856613

Magagnotti, N., Smidt, M., Spinelli, R., 2021: Trainee's reactions to logger training course characteristics: data from 300 courses held in Italy. International Journal of Forest Engineering 32(1): 67–76. https://doi.org/10.1080/14942119.2021.1848165

Nahuelhual, L., Carmona, A., Lara, A., Echeverría, C., González, M., 2012: Land-cover change to forest plantations: Proximate causes and implications for the landscape in south-central Chile. Landscape and Urban Planning 107(1): 12–20. https://doi.org/10.1016/j.landurbplan.2012.04.006

Parker, D., Henare, P., 2023: Updated forestry regulations increase council controls and require large slash removal. Retrieved from Beehive.govt.nz: https://www.beehive.govt.nz/release/updated-forestry-regulations-increase-council-controls-and-require-large-slash-removal

Pedofsky, M., Visser, R., 2019: Assessment of Winch-Assist Skidder Case Study in Gisborne, New Zealand. Christchurch: University of Canterbury, 30 p.

Spinelli, R., Visser, R., 2008: Analyzing and estimating delays in harvester operations. International Journal of Forest Engineering 19(1): 36–41. https://doi.org/10.1080/14942119.2008.10702558

Spinelli, R., Visser, R., Riond, C., Magagnotti, N., 2017: A survey of logging contract rates in the southern European Alps. Small-scale Forestry 16: 179–193. https://doi.org/10.1007/s11842-016-9350-1

Spinelli, R., Visser, R., Han, H.S., 2019: A decade of forest engineering: achievements and future directions. Forests 10(9): 724. https://doi.org/10.3390/f10090724

Studier, D., Binkley, V., 1974: Cable Logging Systems. Division of Timber Management, USDA Forest Service, Portland, OR, USA, 190 p.

Visser, R., Stampfer, K., 2015: Expanding ground-based harvesting onto steep terrain: a review. Croatian Journal of Forest Engineering 36(2): 321–331.

Visser, R., Raymond, K., Harrill, H., 2014: Mechanising steep terrain harvesting operations. New Zealand Journal of Forestry 59(3): 3–8.

Visser, R., Spinelli, R., 2023: Benefits and limitations of winch-assist technology for skidding operations. Forests 14(2): 296. https://doi.org/10.3390/f14020296

WorkSafe BC, 1992: Grapple yarder and supersnorkel handbook. Richmond, Canada, 196 p.

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Prof. Rien M. Visser, PhD

e-mail: rien.visser@canterbury.ac.nz

Angus Howden, MSc

University of Canterbury, Christchurch, New Zealand

Faculty of Engineering

School of Forestry

Private Bag 4800

8140 Christchurch

NEW ZEALAND

Raffaele Spinelli, PhD *

e-mail: raffaele.spinelli@ibe.cnr.it

National Research Council (CNR)

Institute of Bio-Economy (IBE)

Via Madonna del Piano 10

I-50019 Sesto Fiorentino (FI)

ITALY

* Corresponding author

Received: July 28, 2024

Accepted: October 08, 2024

Original scientific paper

11