Time Consumption of Timber Harvesting and Forwarding from Pine Thinning Stands in Terrain with Linear Unevenness

doi: https://doi.org/10.5552/crojfe.2025.3081

volume: 46, issue: 2

pp: 15

- Author(s):

-

- Szewczyk Grzegorz

- Podlaski Rafał

- Kulak Dariusz

- Leszczynski Krzysztof

- Stańczykiewicz Arkadiusz

- Tylek Paweł

- Article category:

- Original scientific paper

- Keywords:

- forest utilization, method of soil preparation for planting, harvester, forwarder, forest trailer, effectiveness

Abstract

HTML

Terrain roughness and local unevenness are included in the classifications of technological accessibility of stands, which are the starting point for functional classifications. The aim of research was to determine the impact exerted on the time consumption of timber harvesting and forwarding by linear terrain unevenness remaining after soil preparation for planting in the form of trenches and ridges with a depth ranging from 0.2 m to 0.6 m. The research was conducted in pine stands where early thinning was being carried out applying harvesters, forwarders and agricultural tractors with forestry trailers. The share of main work time and complementary work time for harvesters amounted to approx. 50%, of which delimbing and bucking accounted for 35%, and tree felling for 15%. The times of forwarding and unloaded journeys amounted to 28% for forwarders and were shorter by approx. 17% as compared to forest trailers. The share of loading and unloading times amounted to approx. 50%. Higher moving time was noted in the case of harvesting in stands with deeper linear unevenness of the terrain and when machines ran on skid trails perpendicular to unevenness. In the Eco Wood land accessibility classification applied in forest practice, we propose the use of a new factor, linear unevenness of terrain.

Time Consumption of Timber Harvesting and Forwarding from Pine Thinning Stands in Terrain with Linear Unevenness

Grzegorz Szewczyk, Rafał Podlaski, Dariusz Kulak, Krzysztof Leszczyński, Arkadiusz Stańczykiewicz, Paweł Tylek

https://doi.org/10.5552/crojfe.2025.3081

Abstract

Terrain roughness and local unevenness are included in the classifications of technological accessibility of stands, which are the starting point for functional classifications. The aim of research was to determine the impact exerted on the time consumption of timber harvesting and forwarding by linear terrain unevenness remaining after soil preparation for planting in the form of trenches and ridges with a depth ranging from 0.2 m to 0.6 m. The research was conducted in pine stands where early thinning was being carried out applying harvesters, forwarders and agricultural tractors with forestry trailers. The share of main work time and complementary work time for harvesters amounted to approx. 50%, of which delimbing and bucking accounted for 35%, and tree felling for 15%. The times of forwarding and unloaded journeys amounted to 28% for forwarders and were shorter by approx. 17% as compared to forest trailers. The share of loading and unloading times amounted to approx. 50%. Higher moving time was noted in the case of harvesting in stands with deeper linear unevenness of the terrain and when machines ran on skid trails perpendicular to unevenness. In the Eco Wood land accessibility classification applied in forest practice, we propose the use of a new factor, linear unevenness of terrain.

Keywords: forest utilization, method of soil preparation for planting, harvester, forwarder, forest trailer, effectiveness

1. Introduction

The machine harvesting model has had a long history. The first harvesters appeared in North America and Europe over half a century ago (Moskalik 2004, Nordfjeld et al. 2010). Although harvesters are normally used in one-storey felling and thinning of coniferous stands, these machines have already been used successfully in stands of various structures, deciduous and mountain ones (Heinimann 1999, Moskalik and Stampfer 2003, Frutig et al. 2007, Szewczyk and Kulak 2013, Szewczyk 2014a, Szewczyk 2014b, Garland et al. 2019, Kormanek and Dvořák 2022, Mederski et al. 2022). The number of harvesters in Poland has increased several times since 2000 and currently amounts to approx. 600 (Mederski et al. 2016, Bodył 2019). Similar tendencies are visible in most European countries (Moskalik et al. 2017). The operation of these machines requires access to tree stands by means of skid trails. Their course, especially in older stands, considers their structure and local terrain conditions (Ghaffariyan 2014). Although the principles of providing access to forest areas and performing treatments in thinning stands are well documented (Dvořák et al. 2011, Zasady 2020), their implementation encounters many barriers in practice. These include the lack of skid trails, underestimated standards of tree felling times that lower the labor costs, undercapitalization of forest enterprises that perform thinning operations and the related lack of appropriate harvesters. Due to the probable increase in personal labor costs and the gradual, increasing availability of machines, mechanical timber harvesting in Poland will probably exceed 50% of the total timber harvest in the closest future (2–3 years), because, according to Bodył (2019, 2022), in just three years in the last five years, the share of timber harvested with harvester-forwarder sets in Poland increased from 37% to 46% at the expense of motor-manual logging.

Scots pine (Pinus sylvestris L.) is common in most countries with the temperate climate and is of great economic importance (Jaworski 2011). It is a key species of most European forest stands in terms of area and volume resources. The tending of pine stands is particularly important in their middle age classes, in thinnings. Its goal is primarily to protect the most valuable components of the stand, to improve its quality and sanitary condition, to intensify the thickness increase of the supported trees and to improve stability (Burschel and Huss 1997). The area of thinning treatments in the state forests in Poland has increased in the last 10 years by approx. 10%, i.e. 40,000 ha (Anon. 2022). This increase is caused by intensive afforestation carried out since the 1950s and the transition of successive forest generations to the group of middle-aged stands. In thinning stands, approx. 15,822,000 m3 of large timber are obtained, including mainly medium-sized assortments important for timber industry. Due to its economic and ergonomic advantages, the model of mechanized timber harvesting, promoted in the State Forests, has its particular justification in thinning stands.

In thinning stands, the performance of work related to timber harvesting is particularly difficult, especially within the stand, during the operations of harvesting and forwarding the wood to the skid trail. This is influenced by both the spatial structure of such stands, as well as by small tree dimensions and volumes (Kärhä et al. 2004, Szewczyk et al. 2014, Stańczykiewicz et al. 2023). For this reason, among other things, it is in middle-aged stands that the greatest difficulties occur in agreeing on the appropriate levels of time standards used in harvesting procedures concerning the performance of services in the State Forests (Szewczyk 2014a, Szewczyk et al. 2014).

The terrain slope and the load-bearing capacity of the ground are factors often indicated as important determinants of achieving the appropriate effectiveness of timber harvesting and forwarding (Visser et al. 2014, Visser and Berkett 2015, Visser and Stampfer 2015, Jodłowski and Kalinowski 2018, Cavalli and Amishev 2019, Kormanek and Dvořák 2021). Ground unevenness: large stones, stumps of fallen trees or local depressions can also affect the time-consumption of the work (Pentek et al. 2008, Đuka et al. 2017). Such impediments are classified as roughness or local unevenness. The main problem of timber harvesting in stands of younger age classes are linear unevenness of various depths, trenches and ridges of various depths, created during the preparation of the soil for planting. In such an area, the time-consumption of machine travel may depend on the type of device and the location of skid trails, perpendicular or parallel to the linear unevenness, and thus to the rows of trees. The main aim of our research was to determine the influence of the depth and the arrangement of linear terrain unevenness on the harvesting time consumption and forwarding time consumption of harvested timber. Therefore, we hypothesized that the harvesting time consumptions based on harvesters and forwarding time consumptions using forwarders achieved in stands with linear unevenness up to 0.2 m, 0.2–0.4 m and 0.4–0.6 m in depth, and achieved by moving along and across linear unevenness, differed significantly from each other.

We conducted the research in pine stands where early thinning was being performed using the model of mechanical timber harvesting and forwarding.

2. Materials and Methods

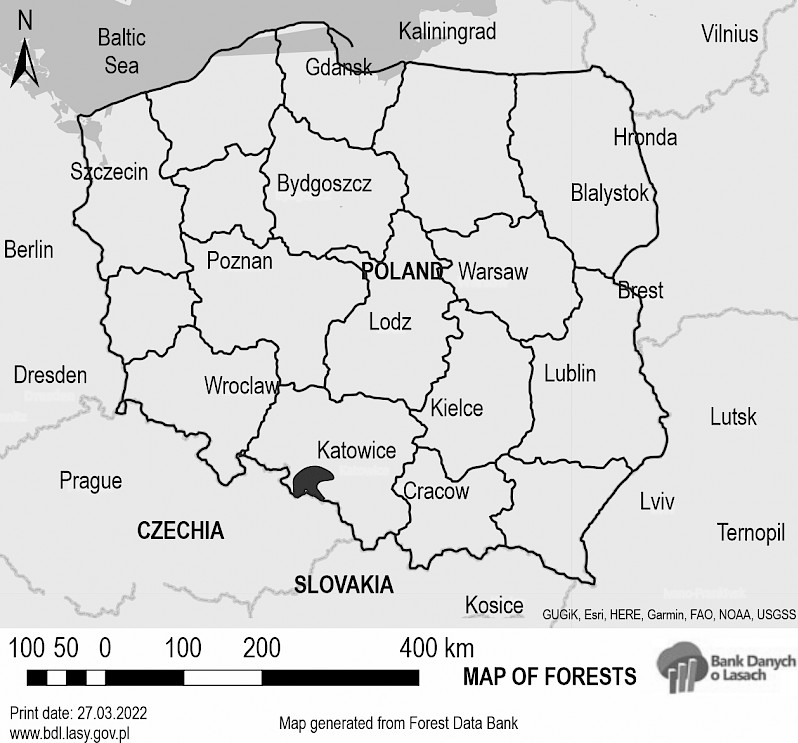

The research was conducted in southern Poland, in the Rudy Raciborskie Forest District, which is part of the Regional Directorate of State Forests in Katowice (Fig. 1).

Fig. 1 Location of research plots, Rudy Raciborskie Forest District (50°16' N, 18°21' E), Poland

In 1992, a large fire damage occurred in the analyzed area. In the Rudy Raciborskie Forest District, the fire covered an area of 4480 ha. In the post-fire areas, during their afforestation in the years 1993–1997, standard methods of soil preparation were applied with the use of a plow, i.e. plowing either ground strips or the entire surface. As a result, the area was prepared for planting e.g. in the form of trenches and ridges with the depth of 0.4–0.6 m, and with a distance between them of approx. 1.5 m. Part of the surface was left without mechanical soil preparation and was either artificially regenerated or self-seeding was used.

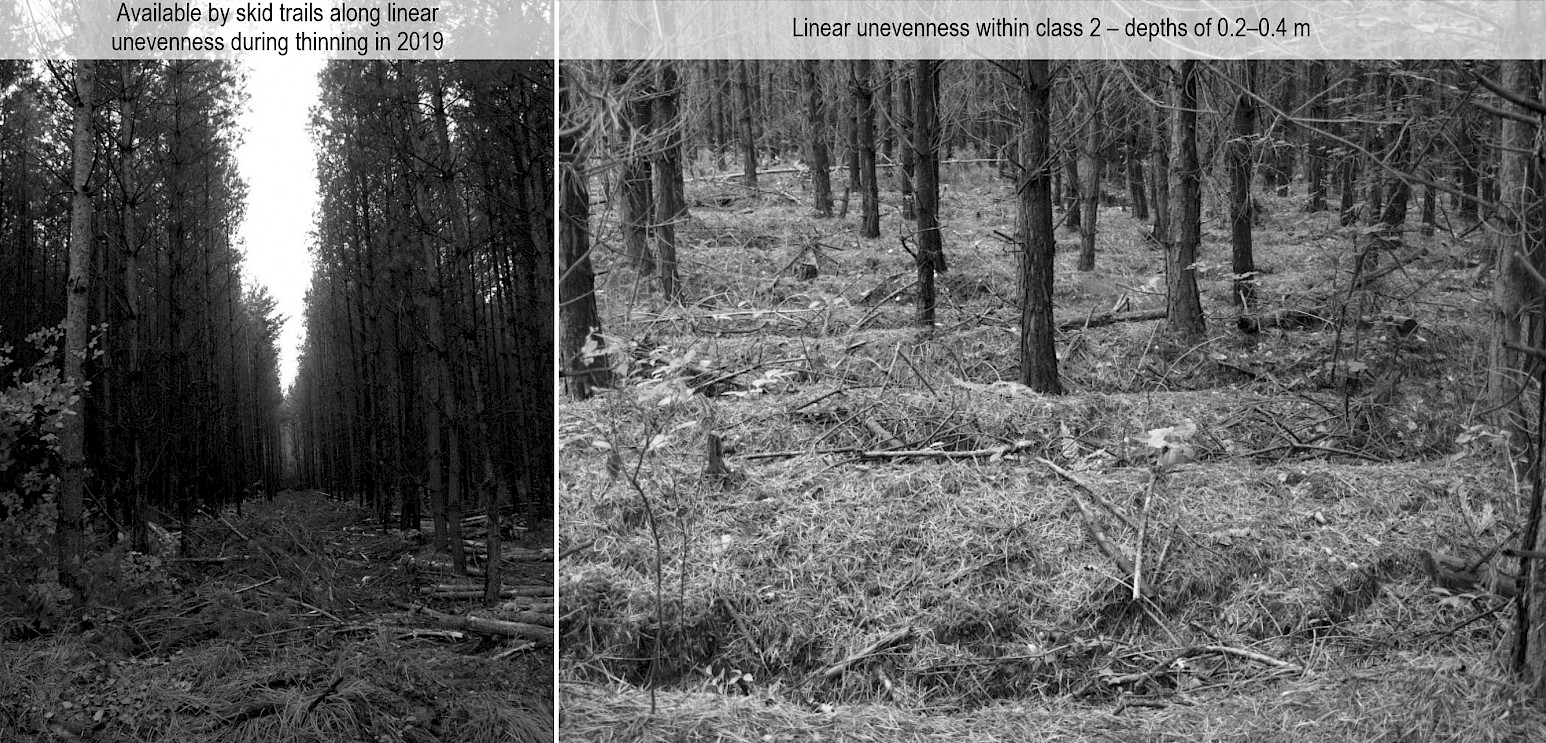

Field work was carried out in those forest divisions where linear unevenness of various depths occurred:

class 1 up to 0.2 m

class 2 0.2–0.4 m

class 3 0.4–0.6 m.

Within class 1, stands without any terrain obstacles, from natural regeneration (0 nr) and from planting (0 para) were additionally included.

In the species composition of the examined stands with a volume of approx. 70 m3/ha, the prevailing species was pine (60–80%), aged 25 to 27 years, with an average diameter at breast height (DBH) of 12 cm and an average tree height of 13 m. In those parts of stands that were uniform as to their structure and species composition, we established 38 research plots. Within the research plots, the State Forests employees designated the trees to be removed in accordance with the principles of selective crown thinning based on Shädelin's method (Zasady 2012). The size of the study area in which each technology variant was tested depended on the number of trees designated for removal (felling by harvester). Based on previous experience (Szewczyk et al. 2016, Szewczyk and Sowa 2017, Leszczyński et al. 2021), we determined that the number per research plot had to be in the range of 80–100 trees. For the timber harvested from such a number of trees, observations were made of forwarding by forwarders and tractors with forest trailers.

We analyzed the time-consumption of the processes of mechanized timber harvesting in the cut-to-length (CTL) method, with tree felling and production of 2.5 m long assortments as well as timber forwarding. The forest stands in which the research was carried out had not been previously accessible by skid trails. In the stands where linear unevenness were visible, the skid trails spaced approx. 10–20 m apart were designed to be perpendicular and parallel to the rows of trees (linear unevenness) (Fig. 2).

The study was conducted in May–July during rain-free weather or with short but not intense rainfalls. In selected stands growing in flat terrain with equal bearing capacity and soil compaction (CI 2.02–2.32 MPa) (Kulak et al. 2020), such weather conditions did not affect the effectiveness of the technologies analyzed. Classic harvesters as well as felling and delimbing device (stroke head) built on the chassis of construction machine were selected for the study. In order to ensure that the results achieved by the machine operators are comparable, stands with the largest possible area were selected for the study, so that on sample plots with linear unevenness in all three classes it was possible to apply the technologies side by side, but in separate working plots, as follows:

with class 1 and 2 unevenness: SAMPO, VIMEK, FAO-FAR harvesters, and VIMEK forwarder and two forwarding units with FAO-FAR trailers,

with class 3 unevenness: SAMPO, VIMEK, PONSSE harvesters and PONSSE forwarder.

The analyses were carried out considering the traction capabilities of individual machines. Table 1 characterizes the most important parameters of the tested machines and summarizes the variants of the experiment. Due to the attractive purchase prices on the Polish market (also secondary market) and the availability of professional service, all the logging machines and units (farm tractor with forestry trailer) observed in the study, are among the most widely used by Polish contractors carrying out early thinning in pine stands.

All harvesters, forwarders and mid-range forwarding units worked in the sample plots moving on skid trails located both parallel and perpendicular to the class 1 and class 2 linear unevenness, while in the sample plots with class 3 linear unevenness, small harvesters worked only on parallel trails and mid-range harvesters and forwarders worked on trails parallel and perpendicular to the linear unevenness.

Fig. 2 Stands introduced in post-fire areas

Table 1 Technical parameters of machines and devices tested

|

Harvesters |

|||||||||

|

Model |

Range |

Power kW/rpm |

Ground clearance cm |

Width m |

Weight kg |

Crane |

Range m |

Head |

|

|

VIMEK 404 T5 |

Small |

44/2700 |

40 |

1.8/2.15 |

4100 |

MOVI 2046 |

4.6 |

KETO Forst Silver |

|

|

FAO-FAR 6840 construction machine |

Small |

57/2200 |

47 |

2.05 |

5760 |

FAO-FAR |

7.5 |

ARBRO 400S |

|

|

SAMPO HR46 |

Small |

124/2100 |

67 |

2.1/2.4 |

7450 |

KESLA 671H tilt |

7.1 |

KETO 51 Eco Supreme |

|

|

PONSSE Beaver |

Medium |

129/1600 |

67 |

2.65/2.93 |

14,900 |

PONSSE C2 |

10.0 |

H5 |

|

|

Forwarders/Forwarding units |

|||||||||

|

Model |

Class |

Power kW |

Ground clearance cm |

Width m |

Weight kg |

Load capacity kg |

Length m |

Crane |

Range m |

|

VIMEK 606 TT |

Small |

18 |

40 |

1.8 |

2960 |

3000 |

6.20 |

MOVI 2046 |

4.6 |

|

PONSSE Elk |

Medium |

129 |

67 |

2.69/2.99 |

15,900 |

13,000 |

9.15 |

PONSSE K70+ |

10.0 |

|

URSUS C-330 |

Small |

22 |

48 |

1.6 |

1880 |

– |

3.08 |

– |

– |

|

FAO-FAR 51 forest trailer |

– |

47 |

1.67 |

1700 |

5000 |

3.40 |

FAO-FAR 2241 |

4.6 |

|

|

DEUTZ DX 90 |

Medium |

65 |

56 |

2.3 |

4830 |

– |

4.36 |

– |

– |

|

FAO-FAR 842 forest trailer |

– |

52 |

1.97 |

2500 |

8000 |

4.40 |

FAO-FAR 3264 |

6.4 |

|

The tasks were carried out by experienced contractors, with work experience of 3–5 years at the workstations under research.

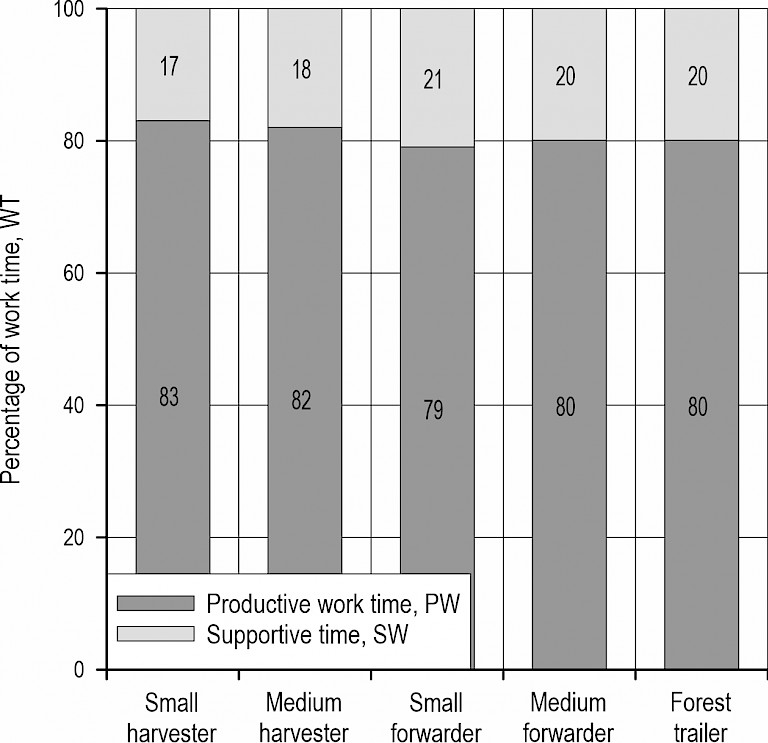

The time consumption of timber harvesting and forwarding at the analyzed workstations was determined for the repeated work cycles measured during the tests as productive time (PW). In further proceedings, supportive times (SW) were also considered and determined on the basis of analyses of the working day structure, therefore the final levels of time consumption were increased by 20% and as such represented the work time (WT) (Rickards et al. 1995).

The studies of duration of timber harvesting and forwarding were performed using Motorola's Workabout PRO microcomputers (Mississauga, Ontario, Canada) with TIMING 2® software to measure the times. The large size of the tasks required full digitization of the measurement data. The application designed for PDA devices (»handheld« computers) of Motorola Workabout PRO was developed using the Microsoft Compact Framework technology provided by the company, using the Visual Studio 2008 development environment in the C# language. Due to the rapid changes of the observed activities in work cycles at selected workstations, the measurement was verified by video time study analyses using the TIMER PRO PROFESSIONAL software for the analysis of film materials. Boundary points, precisely defining the beginning and end of each observed activity, were imposed on the film track.

Timber harvesting and forwarding observed on the research plots had a smooth course, there were no breaks related to possible repairs, maintenance activities or rest. The measurement of the forwarding time was carried out only within the research plots. Time studies were carried out with an accuracy of 1 second. The following boundary points of the activities observed within the work cycles were distinguished (Table 2).

Table 2 Characteristics of activities observed during logging and their boundary points

|

Time category |

Machine |

|||

|

Harvester |

Forwarder/Forwarding unit |

|||

|

Work time (WT) |

Productive work time (PW) |

Main work time (MW) |

Felling – from the beginning of setting the harvester head at the base of the tree trunk to the first movement of the trunk through the feeding rollers in the head |

Loading – from pointing the grapple towards the wood in the packet until the moment when the grapple is immobilized on the log placed on the loading box |

|

Processing – from the first movement of the trunk through the feeding rollers until the removal of the tree top, remaining after delimbing |

Forwarding – from the moment of moving from the place of loading to stopping the tractor at the place of the next loading of timber in the stand |

|||

|

Complementary work time (CW) |

Moving – from the moment of starting the machine after the removal of the top of the processed tree, moving to the next tree, until stopping the head before felling |

Travel – from the moment of starting the tractor with an unloaded trailer within the research plot until the moment when the tractor is in the place of the first loading |

||

|

Supportive work time (SW) |

Repair time (RT) Refuel time (RF) Maintenance time (MT) |

|||

The structure of the working day of the operators of individual machines was determined during the use of those machines in stands analogous to the examined ones, based on snapshot observations made in a five-minute interval (Szewczyk 2014b, Pszenny et al. 2019).

The total volume of timber harvested in a single work cycle was determined on the basis of the average volume of a log on each research plot and the number of harvested/forwarded rollers (Kulak et al. 2023). The average volume of rollers on each research plot was estimated on the basis of measuring the diameters over bark of 100 rollers and calculating the volume of each of them using the Huber formula.

A Generalized Additive Mixed Model (GAMM) was used to assess the effect of the machine used on the amount of time consumption. The Generalized Additive Mixed Model is used to fit generalized additive mixed models. It allows the modeling of complex relationships when there is a need to include both smooth functions of variability (as in generalized additive models, GAM) and random effects (as in mixed models). The variable large timber is treated as a fixed effect with a default smooth basis function (thin plate spline basis functions), while machine type and terrain conditions are random effects (Wood 2017).

Investigations of differences in the effectiveness of the machines in use were carried out for the time of the machines (harvester – moving, forwarder – forwarding). This category of machine operating time reflected the diversity of the terrain to the greatest extent. Analyses of the effect of terrain conditions on harvester moving time and forwarder skidding time were conducted using the Generalized Linear Model (GLM). The Generalized Linear Model is a class of statistical models that extends traditional linear regression models to allow prediction of dependent variables that do not have a normal distribution. GLMs are very flexible as they can handle different types of data and relationships, including dependent variables that take only positive values. A gamma distribution was used as the random component and a logarithmic function as the link function (Wood 2017).

The computational procedures were implemented in R using, among others, the mgcv library (Wood 2017, R Core Team 2023).

3. Results

Time sequences observed during full shifts were cleared by removing observations that had evidently been classified either wrongly or mistakenly (re-recorded sequences and those with a duration of up to 5 s). The dataset for analyzing the duration of specified activities comprized 3866 instances for studying time consumption and 2665 instances for examining moving and forwarding times, involving 2093 harvesters and 572 forwarders. The data collection spanned 225 hours. Fig. 3 presents the parameters of the estimated shift time structures at the analyzed workstations.

Fig. 3 Share of productive work time (PW) and supportive time (SW) at analyzed workstations, %

The largest share among the types of non-operational work time was constituted by service time (on average 9%). The percentage of repair time (RT), which reveals the reliability of machines and devices, was relatively low. The failure rate of the entire technologies amounted to approx. 8%. Both the technical condition of the machines used as well as their correct operation, which did not cause significant failures, were at a high level.

For the analyzed workstations, a total of 3295 work cycle time studies were performed with a total duration of almost 70 hours. The structure of the work time (WT) is presented in Table 3.

Table 3 Structure of productive time (PW) at analyzed workstations, %

|

Time category |

Type of machine |

||

|

Harvester |

Forwarder |

Forest trailer |

|

|

Main work time (MW) |

51 |

72 |

54 |

|

Complementary work time (CW) |

49 |

28 |

46 |

In the case of harvesters, we observed a comparable share of main work times (MW) and complementary work times (CW), with the share of approx. 50%, of which delimbing and bucking accounted for 35%, and felling for 15%. A large (almost 50%) share of moving times between successive trees being felled reflected the difficulties in accessing individual trees and the need for precise positioning of machines on the skid trail. Differences in the structure of work cycles of forwarding machines were clear. The times of forwarding and return journeys accounted for 28% in the case of forwarders, and were almost 38% shorter compared to tractors with forestry trailers. The share of loading and unloading times for both types of forwarding machines was over 60%.

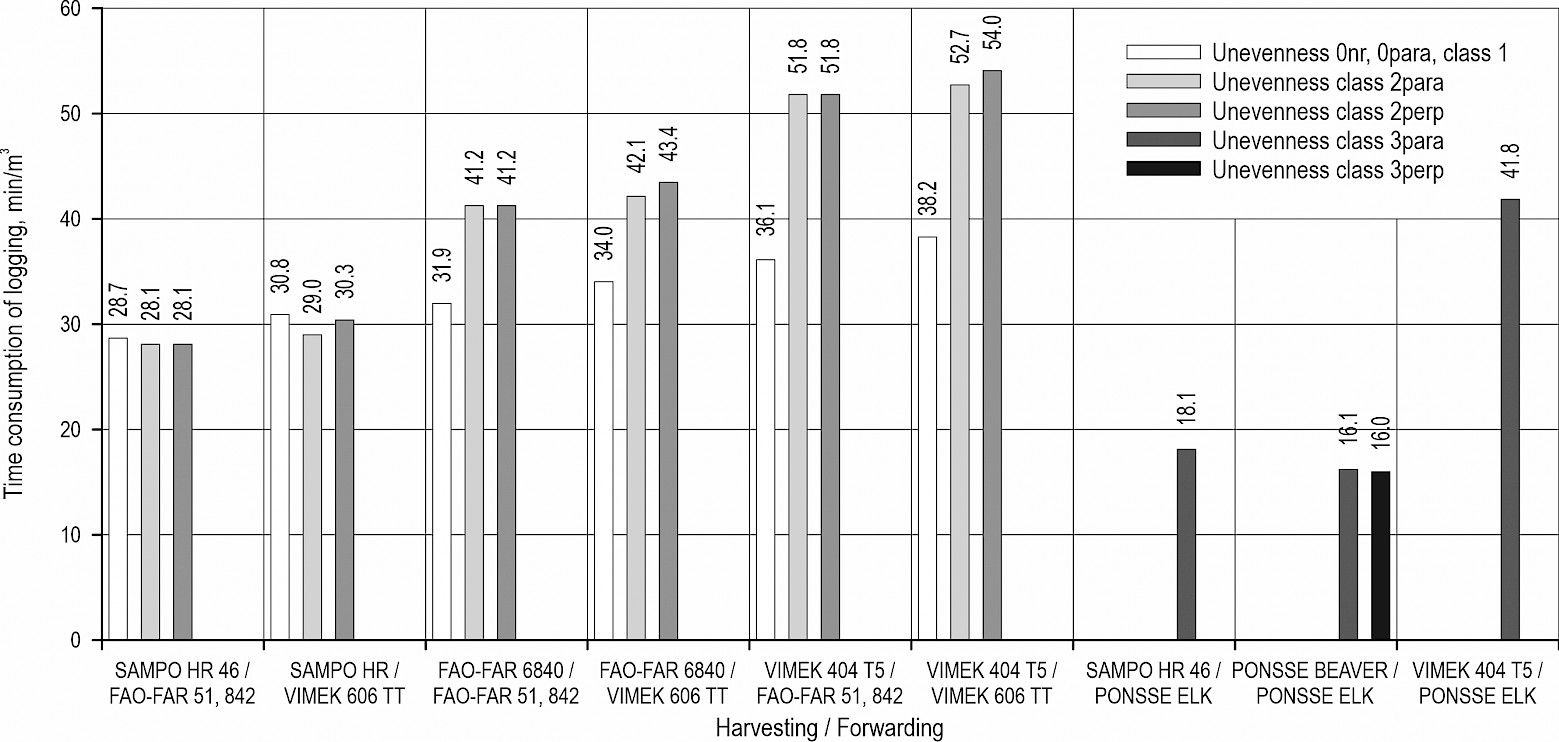

Fig. 4 presents the time consumption observed for the analyzed technologies in the linear unevenness classes distinguished.

Fig. 4 Time consumption of logging performed with the use of machines tested considering the layout of skid trails in relation to linear unevenness (0 – no obstacles, 1 – depths up to 0.2 m, 2 – depths of 0.2–0.4 m, 3 – depths of 0.4–0.6 m, nr – natural regeneration, para – parallel system of unevenness, perp – perpendicular system of unevenness)

In easier terrain (unevenness 1, 2), the most advantageous technological variant was the use of the SAMPO harvester in all stands and the FAO-FAR in stands without obstacles or with shallow unevenness, as well as forest trailers or the VIMEK forwarder. The time consumption of timber harvesting and forwarding in this case was approximately 30 min/m3 for each analyzed stand (Fig. 4). In the other technological variants, the time consumption was higher by several up to several dozen percent, especially in the case of harvesting in stands with deeper linear unevenness of terrain. In stands with linear unevenness of the third class of depth, the use of medium-sized machines was the most advantageous, although the use of the SAMPO harvester resulted in an increase in time consumption only by approx. 2 min/m3. However, due to the design parameters (wheelbase of only 2.74 m), this machine was tested only in a parallel system of linear unevenness, similar to the VIMEK harvester (wheelbase of only 2.10 m). Most likely, the difficulties in crossing very deep terrain unevenness caused by the relatively small clearance of the VIMEK harvester made this variant the most time-consuming.

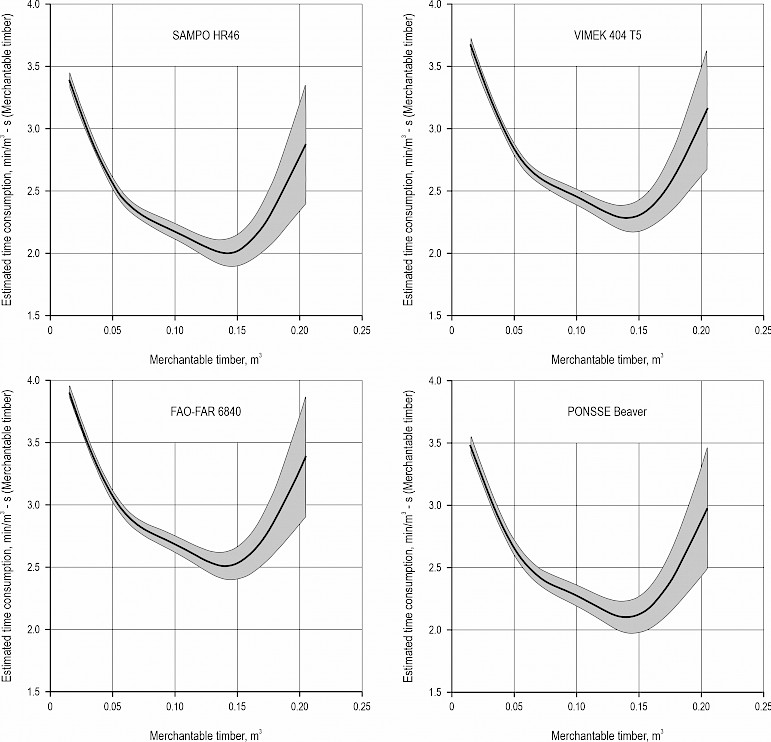

The curves presented in Fig. 5 present the relationships between the volume of harvested wood in the work cycle and the time consumption for the tested harvesters. The lowest position of the curve for SAMPO HR46 (closest to the horizontal axis) confirms its best suitability for operation in the analyzed conditions. The most time-consuming work was shown for the thinnest and thickest shafts, the least for trees of medium dimensions (volume from 0.05 m3 to 0.15 m3).

Fig. 5 Generalized Additive Mixed Model (GAMM) for harvesters tested; each panel shows time consumption as a function (splines were used) of merchantable timber; they show the models (curves) with the 95% confidence intervals (indicated by grey shading); the values presented on the y-axis relate to a specific component of the GAMM model, namely the effect of merchantable timber on time consumption, modulated by different levels of the tested harvesters variable and do not include the full effect of the model

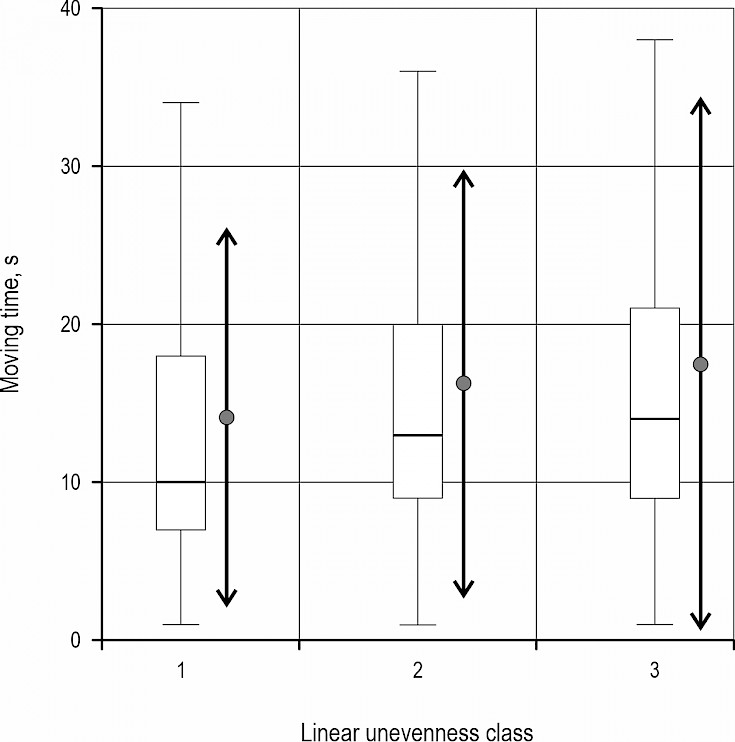

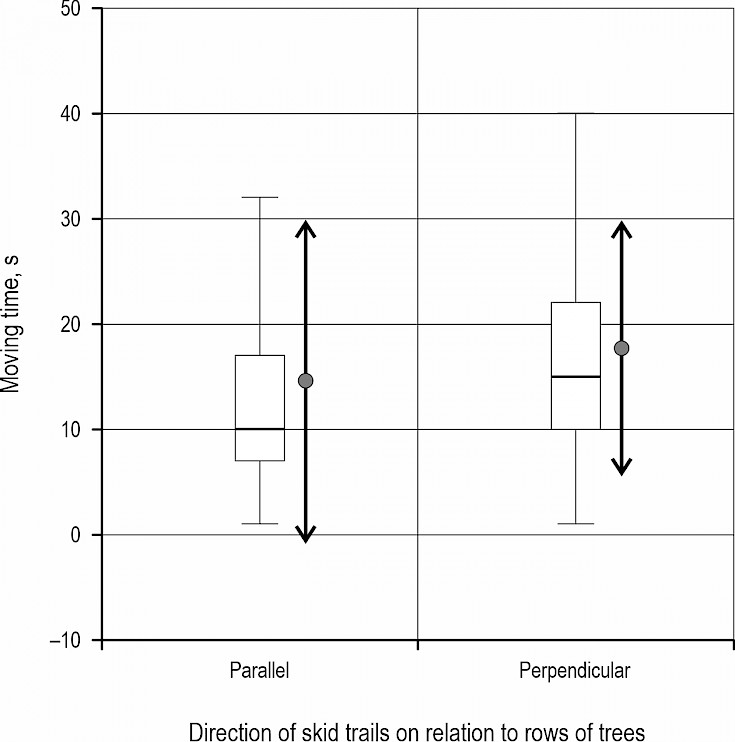

Fig. 6 shows the medians, means and variations in harvester moving times observed on research plots with different depths of linear unevenness. Analysis using the GLM model showed that passage times increased compared to the comparative level (1st inequality class) by 15% in the case of inequality class 2 and 26% for inequality class 3. The above differences are statistically significant, p values are less than 0.01 (for class 2 unevenness) and 0.001 (for class 3 unevenness), respectively. As the depth of linear unevenness increases, the time-consumption of harvester passes between trees designated for removal increases significantly. The observed trend may also influence the increase in logging unit costs in class 2, compared to class 1 linear unevenness, e.g. from about 20% with the VIMEK harvester, to more than 45% with the FAO-FAR harvester (Szewczyk et al. 2023).

Fig. 6 Moving time of harvesters within research plots with different depths of linear unevenness; the solid black line in the middle of each box is the median of the data, the box indicates the interquartile range (IQR), the »whiskers« indicate the minimum and maximum values, excluding outliers, the grey dot is the mean of the data, the bold »whiskers« are the values of the standard deviation (mean±SD)

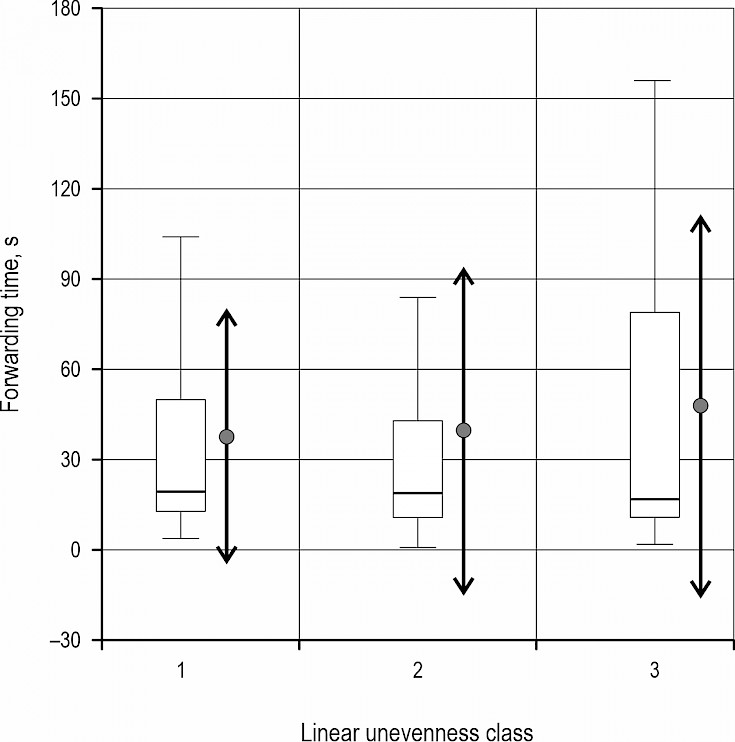

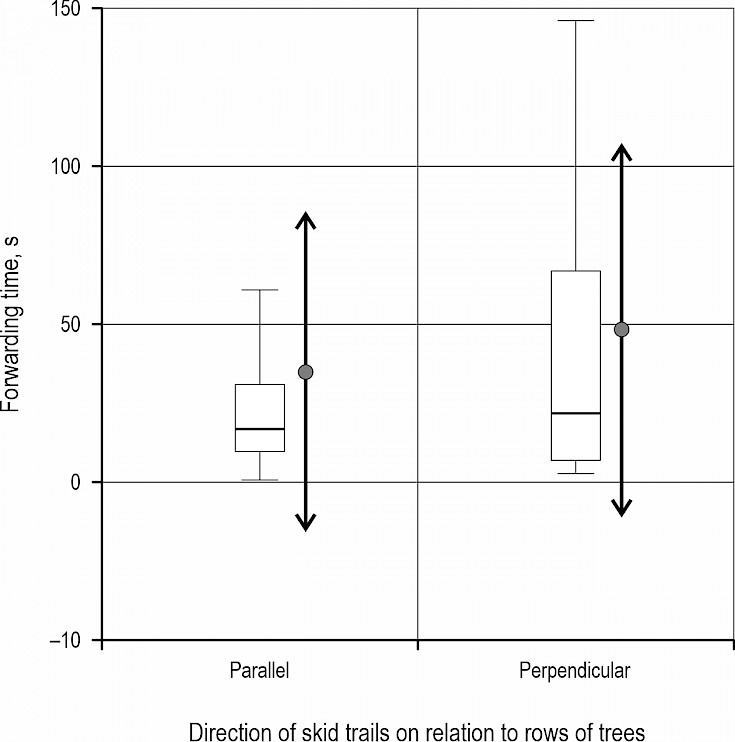

The variability of the forwarding time observed on research plots with different depths of linear unevenness is presented in Fig. 7. As in the case of harvesters, differences in forwarding times in the stand were visible, in this case between subsequent packages of harvested timber (GLM model). Compared to forwarding in easy terrain conditions (unevenness class 1), the time of forwarder passes increased by 12% in unevenness class 2 (p=0.438, no significant differences) and by 49% in unevenness class 3 (p=0.011, statistically significant difference).

Fig. 7 Forwarding time using forwarders and forwarding units within research plots with different depths of linear unevenness

Fig. 8 shows the variability of moving times between successive harvester workstations observed on research plots with a system of skid trails perpendicular and parallel to the linear unevenness. The analysis using the GLM model showed that the visible differences in moving times are statistically significant. Passes on trails located perpendicular to linear unevenness were 23% longer than passes on parallel trails (p<0.001).

Fig. 8 Moving time of harvesters within research plots with a different layout of skid trails in relation to linear unevenness (to rows of trees)

Fig. 9 shows the medians, means and variability of travel times during forwarding observed on research plots with a perpendicular and parallel arrangement of skid trails in relation to linear unevenness. Similarly, to the case of harvesters, we showed a statistically significant extension of the travel time of machines on trails located perpendicular to linear unevenness (GLM model). The time of such passes was 52% longer than that of passes on trails located parallel to linear unevenness (p<0.001). Overcoming parallel linear unevenness by forwarders is more difficult, especially since, as the weight of the machine increases by adding more logs, the resistance to movement increases when the wheels, especially those with smaller diameters, drive out of the parallel depressions in the ground made when preparing the soil for planting. No such difficulties were observed during the field tests when the forwarders were driven along the linear unevenness.

Fig. 9 Forwarding time using forwarders and forwarding units within research plots with a different layout of skid trails in relation to linear unevenness (to rows of trees)

We extended the standard classification of terrain accessibility for machines applied for timber logging (Gil 2007) by adding the parameter of the depth of linear unevenness, which had a significant impact on the time consumption at the analyzed workstations (Table 4). An example of terrain classification would have the following designation: 2/1/1/31 (strong, even, flat, medium-deep linear terrain unevenness, system of skid trails parallel to the direction of linear unevenness).

Table 4 Terrain classification in terms of timber harvesting and forwarding (summary)

|

Class |

Ground conditions |

Terrain unevenness |

Slope angle |

Linear unevenness |

||||||

|

Soil bearing class |

The class of local terrain unevenness |

Slope angle class |

Depth class of linear unevenness |

The class of the trail system in relation to |

||||||

|

1 |

2 |

|||||||||

|

1 |

Very strong |

It results from the soil type (grain size), water content and drainage, dry soil density, soil depth, share of reinforcing factors (share of skeletal parts, roots, harvesting residues) |

Even |

It is determined by the features of obstacles (terrain unevenness over 20 cm deep, and stones) and the frequency of their occurrence |

Flat |

It is related to the average slope of the terrain within the harvesting and forwarding area |

Very shallow <0.2 m |

It is related to the depth of linear unevenness (trenches, ridges) |

Parallel |

Perpendicular |

|

2 |

Strong |

Slightly uneven |

Gently inclined |

Shallow 0.2–0.4 m |

||||||

|

3 |

Medium |

Uneven |

Moderately inclined |

Medium deep 0.4–0.6 m |

||||||

4. Discussion

The most commonly used measure of effectiveness is the productivity level indicator, i.e. the size of production expressed in homogeneous natural units implemented per unit of time: productive hour (productive machine hour PMH), hour of shift time (schedule machine hour SMH) or machine work hour (Jabłoński 2006, Szewczyk 2014a). In work standardization, the indicator of unit time consumption is also used, which is the inverse of effectiveness (Zečić et al. 2005). In practice, the measure sought for individual workstations or technologies is their time consumption because it makes it possible to determine the efficiency of a single workstation or the entire technology which includes several workstations (Vusić et al. 2011). Consideration of labor consumption in relation to workstations allows for the analysis of relatively freely configurable technological systems. In timber harvesting and forwarding, the examined workstations usually do not function separately but rather complement each other to some extent (e.g. cooperation of employees when performing specific tasks).

Measurement of productive times PW is usually performed on the basis of time studies, i.e. time measurements of repetitive work elements (Behjou et al. 2008, Szewczyk 2014a, Labelle et al. 2024); hence its highest accuracy is achieved for workstations characterized by cyclical activities, as in the case of harvesters and forwarding (Szewczyk 2011a, Varch et al. 2023). In our case, the high repeatability of work sequences gave the time study measurements, performed as cumulative timing (cumulative time of work operations), appropriate accuracy (Rickards et al. 1995, Nurminen et al. 2006, Szewczyk 2011b, Proto et al. 2017, Rosińska et al. 2022). In our experiment, workday structures were defined by the method of snapshot observations, which are an extension of the classic working day picture. The technique of studying work using snapshot observations consists in recording events in a constant (regular observations) or variable, random (irregular observations) time interval (Szewczyk 2011a). A five-minute interval between observations, used in this study, gives a minimum error rate (Szewczyk 2014b, Pszenny et al. 2019).

The level of operating time utilization in the analyzed technologies corresponded to the values reported by other authors (Moskalik 2004). In our research, in the case of harvesters, a comparable share of delimbing and bucking time (approx. 50%) was observed in relation to the share of cutting and felling times and machine travel. Similar data was provided by Moskalik (2004) and Apafaian et al. (2017), while according to Maksymiak and Grieger (2008) in late thinnings this share may exceed 60%. Sadowski et al. (2014) estimated that the share of main times (productive time PW) in the structure of the harvester operation time accounts for 55–60%. Compared to the data published by Szewczyk (2011a), the share of harvester travel times in thinning stands was higher. The longer travel time, as compared to late thinnings, was associated with difficulties in maneuvering the machine head in a dense young stand. In this situation, the operator often had to change the position of the machine.

The main category of productive time (PW) in forwarding was the loading time, whose share amounted to over 35%, similarly to the study by Proto et al. (2017). Lazdinš et al. (2016) defined this share at 21% for the Vimek forwarder, Maksymiak and Grieger (2008) defined it at nearly 50% for the Valmet forwarder, while Kulak et al. (2023) at approx. 40% for forest trailers, while Apafaian et al. (2017) at 28% for Komatsu 840.4 forwarder. Productive time (PW) (about 80%), including main work and complementary work, was found to be almost identical as in other studies (Gil 2007, Glazar and Maciejewska 2008, Spinelli and Magagnotti 2010, Hildt et al. 2020). The unloading time was similar to the values reported by other researchers (Moskalik 2004) and amounted to about 25% of the work cycle time. For the Valmet forwarder, the share of unloading times ranged from 17% (Maksymiak and Grieger 2008) to 34% (Grieger et al. 2016, Apafaian et al. 2017). For the forest trailer, depending on its model, the share of unloading time ranged from 16 to 21%.

Classifications of forest areas in terms of timber harvesting and logging appeared several dozen years ago, at the time of the introduction of machines and the possibility of choosing the most appropriate work technology (Mellgren 1980, Terlesk 1983, Löffler 1984, Berg 1992, Annon 1996, Howes and Kenk 1997, Pentek et al. 2008, Dvořák et al. 2011, Đuka et al. 2017). Descriptive (primary) classifications are used to assess the features of the terrain important for timber harvesting or logging. They are usually divided into 5 main classes, which may be supplemented by subclasses. Certain features of the terrain are assigned a numerical code, enabling quick identification of the degree of accessibility. Terrain conditions are divided into three categories: ground conditions, local unevenness, terrain slope. The area in which we conducted our research was flat, therefore the discussion of the results will concern the other two parameters.

Ground conditions are understood primarily as passability, i.e. the ability to maintain a vehicle in off-road traffic. Violation of the soil structure depends on two factors. The first is soil properties: soil grain size and its derivatives (plasticity, porosity, texture, presence of organic matter, initial compaction) and soil moisture as a derivative of climatic conditions and the degree of drainage (Dvořák et al. 2011, Đuka et al. 2017). The other group of factors influencing the disturbance of the soil surface are the operating parameters of the machines used, which include their weight, axle load, tire width and number of passages (Kormanek and Gołąb 2021, Kormanek and Dvořák 2022). All these factors are reflected in the pressure of the machine on the soil (Kormanek et al. 2023). In previous publications, we have shown that, in the analyzed area, the ground bearing capacity does not in any way limit the passability of any types of machines tested (Kováč et al. 2020).

Local unevenness, also described as terrain roughness, is defined by various directional forms and ground obstacles, which may be a consequence of the tasks performed, such as logging (Đuka and Poršinsky 2016). Roughness can significantly reduce the stability of vehicles, especially when combined with slopes, as it makes parts of the machine running gear lose traction. The ability to overcome obstacles describes the location of the obstacle in the context of terrain slope and machine parameters: ground clearance, lateral stability of the vehicle and the location of the obstacle in the context of terrain slope (Kühmaier and Stampfer 2010, Kormanek and Gołąb 2021, Kormanek and Dvořák 2022). These features should be considered when designing the movement of machines in areas with terrain unevenness. The key in this respect is to determine the lateral and longitudinal stability (Alexandrovich 2013). The unevenness of the terrain encountered in our experiment was linear. The direction of vehicle movement was perpendicular or parallel to the course of the unevenness (a row of trees), which affected the effectiveness of the machines. The unique directional classification of linear terrain unevenness constructed as a result of our research was only to some extent consistent with the Eco Wood classification of terrain roughness (Owende et al. 2002, Đuka and Poršinsky 2016, Đuka et al. 2018). As assumed in our experiment, the depths of unevenness in classes 1–3, up to 0.2 m, 0.2–0.4 m, 0.4–0.6 m, respectively, are consistent with the above-mentioned classification only in its first two classes, whereas in the third terrain class, the height of terrain unevenness can reach as much as 80 cm. The height of the unevenness is always correlated with the average distance between them. In our case, the distance between the linear unevenness was always 1.5 m, whereas the Eco Wood classification associated the increase in the height of the unevenness with a greater distance. For example, for the unevenness height of 60 cm, the distance was over 5 m. Compared to Eco Wood, the different impact of terrain unevenness on the effectiveness of timber harvesting and forwarding was most likely due to the linear nature of those unevenness. Machine journeys performed perpendicular or parallel to terrain trenches resulted in a more even load distribution on individual parts of the drive system in comparison with local unevenness. As a result, the stability of the machines and their effectiveness was greater, which translated into their greater efficiency as compared to the conditions of local unevenness of a similar class.

5. Conclusions

Descriptive terrain classifications are the starting point for functional (secondary) classifications, which facilitate the selection of machines for specific terrain conditions. In the face of rapid technological progress, these classifications require adjustments in terms of the ability of machines to work in specific field conditions. Linear unevenness, e.g. in the form of trenches remaining after planting, affect the time consumption of mechanical timber harvesting and forwarding. Their impact is different depending on local, natural terrain unevenness and roughness.

Acknowledgments

This research was supported by State Forest Holding »Lasy Państwowe« in Poland (grant No. OR.271.3.6.2016).

6. References

Alexandrovich, Y.K., 2013: The issue of evaluation of stability of skidders. World Appl. Sci. J. 24(7): 971–979. https://doi.org/10.5829/idosi.wasj.2013.24.07.13251

Annon., 1996: Guidelines and standards to terrain mapping in British Columbia. Resources Inventory Committee, Surficial Geology, Task Group Earth Sciences, Task Force British Columbia, 131 p.

Annon., 2022: Statistical yearbook of Forestry; Statistics Poland: Warszawa, Poland.

Apafaian, A.I., Proto, A.R., Borz, S.A., 2017: Performance of a mid-sized harvester-forwarder system in integrated harvesting of sawmill, pulpwood and firewood. Ann. For. Res. 60(2): 227–241. https://doi.org/10.15287/afr.2017.909

Behjou, F.K., Majnounian, B., Namiranian, M., Dvořák, J., 2008: Time study and skidding capacity of the wheeled skidder Timberjack 450C in Caspian forests. J. For. Sci. 54(4): 183–188. https://doi.org/10.17221/5/2008-JFS

Berg S., 1992: Terrain Classification System For Forestry Work, Forest Operations Institute »Skogsarbeten«: Stockholm, Sweden, 28 p.

Bodył, M., 2019: Rozmiar pozyskania maszynowego w Polsce (Scope of mechanised logging in Poland). Drwal, Pismo Przedsiębiorców Leśnych 3(166): 5–9.

Bodył, M., 2022: Rozmiar pozyskania maszynowego w Polsce (Scope of mechanised logging in Poland). Drwal, Pismo Przedsiębiorców Leśnych 4(203): 24–28.

Burschel, P., Huss, J., 1997: Grundriss des Waldbaus, Berlin Parey Buchverlag: Berlin, Germany, 436 p.

Cavalli, R., Amishev, D., 2019: Steep terrain forest operations – challenges, technology development, current implementation, and future opportunities. Int. J. For. Eng. 30(3): 175–181. https://doi.org/10.1080/14942119.2019.1603030

Đuka, A., Grigolato, S., Papa, I., Pentek, T., Poršinsky, T., 2017: Assessment of timber extraction distance and skid road network in steep karst terrain. iForest 10(6): 886–894. https://doi.org/10.3832/ifor2471-010

Đuka, A., Poršinsky, T., 2015: Analysis of Terrain Roughness in Terms of Harvesting Operations. Nova meh. šumar. 36(1): 43–52.

Đuka, A., Poršinsky, T., Pentek, T., Pandur, Z., Janeš, D., Papa, I., 2018: Soil measurements in the context of planning harvesting operations and variable climatic conditions. SEEFOR 9(1): 61–71. https://doi.org/10.15177/seefor.18-04

Đuka, A., Vusić, D., Poršinsky, T., 2017: Terrain roughness evaluation for timber extraction by cable skidder. Gozdn. vestn. 75(1): 21–35.

Dvořák, J., Bystrický, R., Hošková, P., Hrib, M., Jarkovská, M., Kováč, J., Krilek, J., Natov, P., Natovová, L., 2011: The use of harvester technology in production forests, Folia Forestalia Bohemica: Kostelec nad Černými lesy, Czech Republic, 156 p.

Frutig, F., Fahrni, F., Stettler, A., Egger, A., 2007: Mechanisierte Holzernte in Hanglagen. Wald und Holz 88(4): 47–52.

Garland, J., Belart, F., Crawford, R., Chung, W., Cushing, T., Fitzgerald, S., Green, P., Kincl, L., Leshchinsky, B., Morrissette, B., Sessions, J., Wimer, J., 2019: Safety in steep slope logging operations. J. Agromedicine 24(2): 138–145. https://doi.org/10.1080/1059924X.2019.1581115

Ghaffariyan, M.R., 2014: A short review of efficient ground-based harvesting systems for steep and mountainous areas. Bull. Transilv. Univ. Bras. II: For. Wood Ind. Agric. Food Eng. 7(2): 11–16.

Gil, W., 2007: Comparative studies of agricultural tractors as wood extraction means in selected forest service companies; Uniwersytet Rolniczy im. Hugona Kołłątaja w Krakowie: Kraków, Poland, 128 p.

Glazar, K., Maciejewska, H., 2008: Time structure and efficiency of timber harvesting and skidding in pine-stands using the Buffalo Dual harwarder. Inżynieria Rolnicza 12: 111–118.

Grieger, A., Sędłak, P., Stawicki, T., Lewaszkiewicz, Ł., 2016: Performance analysis of export of wood in relation from the kind of transport. Autobusy: technika, eksploatacja, systemy transportowe 17: 574–577.

Heinimann, H.R., 1999: Ground-based harvesting systems for steep slopes. International Mountain Logging and 10th Pacific Northwest Skyline Symposium, Corvallis, Oregon, 28.03. –1.4.1996; Sessions, J., Chung, W., Eds; Department of Forest Engineering, Oregon State University: Corvallis, OR 97331, 18 p.

Hildt, E., Leszczuk, A., Donagh, P.M., Schlichter, T., 2020: Time consumption analysis of forwarder activities in thinning. Croat. J. For. Eng. 41(1): 13–23. https://doi.org/10.5552/crojfe.2020.615

Howes, D.E., Kenk, E., 1997: Terrain classification system for British Columbia: A system for the classification of surficial materials, landforms and geological processes of British Columbia. Ministry of Environment, Lands and Parks, British Columbia, 114 p.

Jabłoński, K., 2006: Optymalizacja sposobów realizacji procesu technologicznego pozyskiwania i zrywki drewna na określonym obszarze leśnym (Optimization models for the technological process of wood harvesting and extraction in a given forest area). Rozprawy Naukowe. Akademia Rolnicza im. Augusta Cieszkowskiego w Poznaniu 378: 1–88.

Jaworski, A., 2011: Charakterystyka hodowlana drzew i krzewów leśnych (Silvicultural characteristics of forest trees and shrubs), Powszechne Wydawnictwo Rolnicze i Leśne: Warszawa, Poland, 556 p.

Jodłowski, K., Kalinowski, M., 2018: Current possibilities of mechanized logging in mountain areas. For. Res. Pap. 79(4): 365–375. https://doi.org/10.2478/frp-2018-0037

Kärhä, K., Rönkkö, E., Gumse, S., 2004: Productivity and cutting costs of thinning harvesters. Int. J. For. Eng. 15(2): 43–56. https://doi.org/10.1080/14942119.2004.10702496

Kormanek, M., Dvořák, J., 2021: Ground pressure changes caused by MHT 8002HV crawler harvester chassis. Croat. J. For. Eng. 42(2): 201–211. https://doi.org/10.5552/crojfe.2021.844

Kormanek, M., Dvořák, J., 2022: Use of Impact penetrometer to determine changes in soil compactness after Entracon Sioux EH30 timber harvesting. Croat. J. For. Eng. 43(2): 325–337. https://doi.org/10.5552/crojfe.2022.1054

Kormanek, M., Dvořák, J., Tylek, P., Jankovský, M., Nuhlíček, O., Mateusiak, Ł., 2023: Impact of MHT9002HV Tracked Harvester on Forest Soil after Logging in Steeply Sloping Terrain. Forests 14(5): 1–12. https://doi.org/10.3390/f14050977

Kormanek, M., Gołąb, J., 2021: Analysis of surface deformation and physical and mechanical parameters of soils on selected skid trails in the Gorce National Park. Forests 12(6): 1–15. https://doi.org/10.3390/f12060797

Kováč, J., Dvořák, J., Krilek, J., Beňo, P., 2020: Ergonomic operational working aspects of forest machines; Cambridge Scholars Publishing: Newcastle, England, 159 p.

Kühmaier, M., Stampfer, K., 2010: Development of a multi-attribute spatial decision support system in selecting timber harvesting systems. Croat. J. For. Eng. 31(2): 75–88.

Kulak, D., Sowa, J.M., Szewczyk, G., Stańczykiewicz, A., 2020: The Accessibility of Post-Fire Areas for Mechanized Thinning Operations. Forests 11(4): 1–12. https://doi.org/10.3390/f11040471

Kulak, D., Szewczyk, G., Stańczykiewicz, A., 2023: Productivity and working time structure of timber forwarding in flatland thinned pine stand with the use of farm tractors. Croat. J. For. Eng. 44(1): 57–67. https://doi.org/10.5552/crojfe.2023.1656

Labelle, E.R., Borchert, H., Aurenhammer P.K., Breinig, L., Spinelli, R., Magagnotti, N., 2024: Effect of season and machine type on performance of semi- and fully- mechanized harvesting systems in beech-dominated stands. Croat. J. For. Eng. 45(2): 237–248. https://doi.org/10.5552/crojfe.2024.2281

Lazdiņš, A., Prindulis, U., Kalja, S., Daugaviete, M., Zimelis, A., 2016: Productivity of Vimek 404 T5 harvester and Vimek 610 forwarder in early thinning. Agron. Res. 14(2): 475–484.

Leszczyński, K., Stańczykiewicz, A., Kulak, D., Szewczyk G, Tylek, P., 2021. Estimation of productivity and costs of using a track miniharvester with a stroke head for the first commercial thinning of a Scots pine stand. Forests 12(7): 1–13. https://doi.org/10.3390/f12070870

Löffler, H.D., 1984. Terrain classification for forestry: final report to the Joint FAO/ECE/ILO Committee on the project 14.3.1.2.4 / Hans D. Löffler. – Munich: Univ. of Munich.

Maksymiak, M., Grieger, A., 2008: Analysis of productivity during mechanical timber acquisition on the example of Valmet 901.3 harvester and Valmet 840.2 forwarder. Inżynieria Rolnicza 12: 273–281.

Mederski, P.S., Karaszewski, Z., Rosińska, M., Bembenek, M., 2016: Dynamics of harvester fleet change in Poland and factors determining machine occurrence. Sylwan 160(10): 795−804. https://doi.org/10.26202/sylwan.2016030

Mederski, P.S., Schweier, J., Đuka, A., Tsioras, P.A., Bont, L.G., Bembenek, M., 2022: Mechanised harvesting of broadleaved tree species in Europe. Curr. For. Rep. 8(1): 1–19. https://doi.org/10.1007/s40725-021-00154-7

Mellgren, P.G. 1980. Terrain Classification for Canadian Forestry; Canadian Pulp and Paper Association: Montreal, Quebec, Canada; 13 p.

Moskalik, T., 2004: Model maszynowego pozyskiwania drewna w zrównoważonym leśnictwie polskim (Model of fully mechanised timber harvesting in sustainable Polish forestry); Wydawnictwo SGGW: Warszawa, Poland, 134 p.

Moskalik, T., Borz, S.A., Dvořák, J., Ferencik, M., Glushkov, S., Muiste, P., Lazdiņš, A., Styranivsky, O., 2017: Timber harvesting methods in eastern European countries: a review. Croat. J. For. Eng. 38(2): 231–241.

Moskalik, T., Stampfer, K., 2003: Efektywność pracy harwestera Valmet 911 Snake w warunkach górskich (Productivity of the harvester Valmet 911 Snake under the mountain conditions). Sylwan 147(4): 91–98. https://doi.org/10.26202/sylwan.2003045

Nordfjeld, T., Bjorheden, R., Thor, M., Wästerlund, I., 2010: Changes in technical performance, mechanical availability and prices of machines used in forest operations in Sweden from 1985 to 2010. Scand. J. For. Res. 25(4): 382–389. https://doi.org/10.1080/02827581.2010.498385

Nurminen, T., Korpunen, H., Uusitalo, J., 2006: Time consumption analysis of the mechanized cut-to-length harvesting system. Silva Fennica 40(2): 335–363.

Nuutinen, Y., 2013. Possibilities to use automatic and manual timing in time studies on harvester operations. Academic dissertation, University of Eastern Finland, Joensuu, Finland, 12.04.20213.

Owende, P.M.O., Lyons, J., Ward, S.M., 2002: Operations protocol for Eco-efficient Wood Harvesting on Sensitive Sites. Project ECOWOOD.

Pentek, T., Poršinsky, T., Šušnjar, M., Stankić, I., Neverečel, H., Šporčić, M., 2008: Environmentally sound harvesting technologies in commercial forests in the area of northern Velebit – functional terrain classification. Periodicum Biologorum 110(2): 127–135.

Proto, A.R., Macrì, G., Visser, R., Harrill, H., Russo, D., Zimbalatti G., 2018: A Case Study on the Productivity of Forwarder Extraction in Small-Scale Southern Italian Forests. Small-scale For. 17: 71–87. https://doi.org/10.1007/s11842-017-9376-z

Pszenny, D., Giedrowicz, A., Staniszewski, P., Moskalik, T., 2019: Accurancy of working day structure determining of the timber skidding by snapshot observations. Sylwan 163(4): 292–299. https://doi.org/10.26202/sylwan.2018145

R Development Core Team, 2024: R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria.

Rickards, J., Skaar, R., Haberle, S., Apel, K., Bjorheden, R., Thompson, M., 1995: Forest work study nomenclature. IUFRO 1995. WP 3.04.02., Department of Operational Efficiency, Swedish University of Agriculture Science, Garpenberg, Sweden, 16 p.

Rosińska, M., Bembenek, M., Picchio, R., Karaszewski, Z., Đuka, A., Mederski, P.S., 2022: Determining harvester productivity curves of thinning operations in birch stands of central Europe. Croat. J. For. Eng. 43(1): 1–12. https://doi.org/10.5552/crojfe.2022.1691

Sadowski, J., Moskalik, T., Zastocki, D., 2014: Efektywność pozyskiwania drewna harwesterem PONSSE Ergo w wybranych drzewostanach (The effectiveness of the timber harvesting by PONSSE harvester in selected forest stands). Studia i Materiały CEPL w Rogowie (2B)39: 126–132.

Spinelli, R., Magagnotti, N., 2010: Performance and cost of a new mini-forwarder for use in thinning operations. J. For. Res. 15(6): 358–364. https://doi.org/10.1007/s10310-010-0193-x

Stańczykiewicz, A., Szewczyk, G., Brzoza, B., 2023: Efficiency of timber harvesting using harvester in thinned young pine stands as a function of working technique. For. Res. Pap. 83(1): 16–23. https://doi.org/10.48538/lpb-2023-0002

Szewczyk, G., 2011a: Variability of the harvester operation time in thinning and windblow areas. In Book Technology and ergonomics in the service of modern forestry, Sowa, J.M. Eds; Publishing House of the University of Agriculture in Kraków, Poland: 183–196.

Szewczyk, G., 2011b: Time consumption of skidding operations using winches aggregated with chainsaws in thinned stands. Sylwan 155(6): 401–412. https://doi.org/10.26202/sylwan.2009239

Szewczyk, G., 2014a: Structural model of work variability dynamics at selected worksites in timber harvesting and skidding. Zeszyty Naukowe Uniwersytetu Rolniczego im. Hugona Kołłątaja w Krakowie, 174 p.

Szewczyk, G., 2014b: Snapshot observations in work measurement during timber harvesting and skidding. Sylwan 158(11): 803–810. https://doi.org/10.26202/sylwan.2013143

Szewczyk, G., Krilek, J., Kulak, D., Leszczyński, K., Pacia, T., Sowa, J.M., Stańczykiewicz, A., 2023. Economic efficiency of fully mechanized timber harvesting in coniferous stands of the 2nd age class. Ann. For. Res. 66(1): 155–169. https://doi.org/10.15287/afr.2023.2491

Szewczyk, G., Kulak, D., 2013: Cost effectiveness of timber harvest with a harvester in the stands rebuilt under the shelterwood system. Sylwan 157(4): 243–252. https://doi.org/10.26202/sylwan.2012024

Szewczyk, G., Sowa, J.M., 2017: The accuracy of measurements in a time study of harvester operations. N. Z. J. For. Sci. 47: 24. https://doi.org/10.1186/s40490-017-0105-3

Szewczyk, G., Sowa, J.M., Dvořák, J., Kamiński, K., Kulak, D., Stańczykiewicz, A., 2016: Analysis of accuracy of evaluating the structure of a harvester operator's workday by work sampling. Croat. J. For. Eng. 37(2): 251–259.

Szewczyk, G., Sowa, J.M., Grzebieniowski, W., Kormanek, M., Kulak, D., Stańczykiewicz, A., 2014: Sequencing of harvester work during standard cuttings and in areas with windbreaks. Silva Fennica 48(4): 1–16. https://doi.org/10.14214/sf.1159

Terlesk, C.J., 1983: A proposed terrain classification for harvesting in New Zealand. N. Z. J. For. 28(1): 43–57.

Varch, T., Malle, D., Erber, G., Gollob, Ch., Spinelli, R., Visser, R., Holzinger, A., Stampfer, K., 2023: A prototype for automated delimitation of work cycles from machine sensor data in cable yarding operations. Croat. J. For. Eng. 44(2): 233–243. https://doi.org/10.5552/crojfe.2023.2248

Visser, R., Berkett, H., 2015: Effect of terrain steepness on machine slope when harvesting. Int. J. For. Eng. 26(1): 1–9. https://doi.org/10.1080/14942119.2015.1033211

Visser, R., Raymond, K., Harrill, H., 2014: Mechanising steep terrain harvesting operations. N. Z. J. For. 59(3): 3–8.

Visser, R., Stampfer, K., 2015: Expanding ground-based harvesting onto steep terrain: a review. Croat. J. For. Eng. 36(2): 321–331.

Vusić, D., Željko, Z., Papa, I., Lepoglavec, K., Pandur, Z., 2011: Optimization of teamwork in tree-length harvesting. Technology and ergonomics in the service of modern forestry, Sowa, J.M. Eds; Publishing House of the University of Agriculture in Kraków, Poland; 159–168.

Wood, S.N., 2017: Generalized Additive Models: An Introduction with R, 2nd ed.; Chapman and Hall/CRC: New York, USA, 496 p.

Zasady Hodowli Lasu (Principles of Sylviculture) 2012: Załącznik do Zarządzenia nr 53 Dyrektora Generalnego Lasów Państwowych z dnia 21 listopada 2011 r.

Zasady Użytkowania Lasu (Principles of Forest Utilization) 2020: Załącznik do Zarządzenia nr 66 Dyrektora Generalnego Lasów Państwowych z dnia 7 listopada 2019 r.

Zečić, Ž., Krpan, A.P.B., Vukušić, S. 2005: Productivity of C Holder 870 F tractor with double drum winch Igland 4002 in thinning beech stands. Croat. J. For. Eng. 26(2): 49–56.

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Prof. Grzegorz Szewczyk, PhD

e-mail: grzegorz.szewczyk@urk.edu.pl

Assoc. prof. Dariusz Kulak, PhD

e-mail: dariusz.kulak@urk.edu.pl

Assoc. prof. Krzysztof Leszczyński, PhD

e-mail: krzysztof.leszczynski@urk.edu.pl

Assoc. prof. Arkadiusz Stańczykiewicz, PhD *

e-mail: arkadiusz.stanczykiewicz@urk.edu.pl

Assoc. prof. Pawel Tylek, PhD

e-mail: pawel.tylek@urk.edu.pl

University of Agriculture in Krakow

Faculty of Forestry

Department of Forest Utilization and Forest Technique

Al. 29 Listopada 46

31-425 Kraków

POLAND

Prof. Rafał Podlaski, PhD

e-mail: r_podlaski@pro.onet.pl

Jan Kochanowski University of Kielce

Institute of Biology

Department of Environmental Biology

ul. Żeromskiego 5

25-369 Kielce

POLAND

* Corresponding author

Received: May 06, 2024

Accepted: December 29, 2024

Original scientific paper

11