Vibration Exposure of Battery and Petrol-Powered Chainsaws

doi: https://doi.org/10.5552/crojfe.2025.3066

volume: 46, issue: 2

pp: 10

- Author(s):

-

- Pandur Zdravko

- Šušnjar Marijan

- Jurič Ivan

- Ištok Pandur Iva

- Landekić Matija

- Šporčić Mario

- Bačić Marin

- Article category:

- Original scientific paper

- Keywords:

- vibration total value, daily vibration exposure, vibration dose, battery-powered chainsaw, petrol-powered chainsaw, chainsaw operators, ISO standards, exposure value

Abstract

HTML

The substitution of petrol-powered chainsaws with battery-powered ones has still not taken place in professional forestry. With the latest battery-powered chainsaws, performance is not an issue anymore, but energy storage and recharging still are. Nevertheless, there are some ergonomic points where battery-powered chainsaws tower over petrol-powered ones. This work aims to measure, evaluate, and compare hand-arm vibration between two comparable chainsaws, one petrol, and the other battery-powered. Stihl MS 261 C-M and Stihl MSA 300 C were chosen for this task. The cutting measurement was performed on a wet trunk of sessile oak (Quercus petraea) with a diameter of 30 cm, and on thinner branches (<7 cm) in the canopy at the same felled tree. Time data that represents the ratio of chainsaw handling elements within effective working time in cutting and processing was obtained from previous research. Vibration magnitude was measured in compliance with ISO 8041-1:2017, ISO 5349-1:2001, and ISO 5349-2:2001 standards. The results regarding vibration total value (ahv), daily vibration exposure (A(8)), and time to reach exposure action value (EAV) and exposure limit value (ELV) proposed by EU Directive 2002/44/EC imply higher magnitudes on the rear handle and higher exposure of the right hand for both types of chainsaws. For petrol-powered chainsaw, results for measured vibration magnitude are 4.13 m/s2 for the left hand, 4.72 m/s2 for the right hand, and for battery-powered chainsaw 2.18 m/s2 for the left hand, and 2.82 m/s2 for the right hand. Daily vibration exposure is drastically lower when using a battery-powered chainsaw (A(8)=1.2 m/s2 – left, A(8)=1.5 m/s2 – right), likewise, the time to reach EAV and ELV is many times longer. The current state legislative restriction (Ordinance on Occupational Safety and Health in Forestry 1986) should be revised with the aim of increasing the effective working time because, according to the results of this work, it would be justified.

Vibration Exposure of Battery and Petrol-Powered Chainsaws

Zdravko Pandur, Marijan Šušnjar, Ivan Jurič, Iva Ištok Pandur, Matija Landekić, Mario Šporčić, Marin Bačić

https://doi.org/10.5552/crojfe.2025.3066

Abstract

The substitution of petrol-powered chainsaws with battery-powered ones has still not taken place in professional forestry. With the latest battery-powered chainsaws, performance is not an issue anymore, but energy storage and recharging still are. Nevertheless, there are some ergonomic points where battery-powered chainsaws tower over petrol-powered ones. This work aims to measure, evaluate, and compare hand-arm vibration between two comparable chainsaws, one petrol, and the other battery-powered. Stihl MS 261 C-M and Stihl MSA 300 C were chosen for this task. The cutting measurement was performed on a wet trunk of sessile oak (Quercus petraea) with a diameter of 30 cm, and on thinner branches (<7 cm) in the canopy at the same felled tree. Time data that represents the ratio of chainsaw handling elements within effective working time in cutting and processing was obtained from previous research. Vibration magnitude was measured in compliance with ISO 8041-1:2017, ISO 5349-1:2001, and ISO 5349-2:2001 standards. The results regarding vibration total value (ahv), daily vibration exposure (A(8)), and time to reach exposure action value (EAV) and exposure limit value (ELV) proposed by EU Directive 2002/44/EC imply higher magnitudes on the rear handle and higher exposure of the right hand for both types of chainsaws. For petrol-powered chainsaw, results for measured vibration magnitude are 4.13 m/s2 for the left hand, 4.72 m/s2 for the right hand, and for battery-powered chainsaw 2.18 m/s2 for the left hand, and 2.82 m/s2 for the right hand. Daily vibration exposure is drastically lower when using a battery-powered chainsaw (A(8)=1.2 m/s2 – left, A(8)=1.5 m/s2 – right), likewise, the time to reach EAV and ELV is many times longer. The current state legislative restriction (Ordinance on Occupational Safety and Health in Forestry 1986) should be revised with the aim of increasing the effective working time because, according to the results of this work, it would be justified.

Keywords: vibration total value, daily vibration exposure, vibration dose, battery-powered chainsaw, petrol-powered chainsaw, chainsaw operators, ISO standards, exposure value

1. Introduction

Work in the forest has always been considered physically difficult and dangerous from a safety point of view (Staněk et al. 2023, Yovi and Yamada 2019). After the invention of the first modern chainsaws, the physical demands of felling and processing were reduced, while efficiency increased, which is also the case in other forestry works that underwent the mechanization process (Poje et al. 2019). However, with the advent of chainsaws, a problem for the health of workers appeared – excessive exposure to vibrations (Bačić et al. 2020).

Since the introduction of chainsaws into forestry, numerous studies have reported signs and symptoms associated with vibration exposure during chainsaw operations in forestry (Miura et al. 1965, Axelsson 1968, Barnes et al. 1969, Taylor et al. 1971, Bačić et al. 2023a). In the profession, there are many synonyms for diseases caused by vibrations. The most common is the so-called »White finger disease« or secondary Raynaud's syndrome (Tambić Bukovac and Šenjug Perica 2017) or »Vibration White Finger« (VWF) which consists of disturbances in the blood flow disorders of the fingers (Neri et al. 2023), and disorders of neurological functions and movements of the hand and arm (Forouharmajd et al. 2017, Matache et al. 2020). Numbness in the hands and arms, tingling in the fingers, and deterioration of tactile perception have been detected in workers who have been exposed to hand-arm vibrations (HAVs) (Seppäläinen 1972, Araki et al. 1976, Brammer and Pyykkö 1987, Neri et al. 2018). The daily vibration exposure values for the hand-arm system specified by EU Directive 2002/44/EC (2002) are prescribed as a daily exposure action value of 2.5 m/s2, and a daily exposure limit value of 5 m/s2 (Bačić et al. 2020). In case of exceeding the action value, the employer must establish and implement a program of technical and organizational guidelines to reduce exposure to vibrations to the minimum extent. If workers are exposed to vibrations above the limit value of exposure, the employer must react immediately to reduce the exposure below the limit value. Due to the harmful effects of vibrations on the human body, the effective working time of chainsaw workers is regulated in the Republic of Croatia to a maximum of four hours during one working day. The official document that stipulates the above dates back to 1986 (Ordinance on Occupational Safety and Health in Forestry 1986), and the profession believes that it should be changed since modern chainsaws are ergonomically improved compared to those of 40 years ago. According to ISO 5349-1:2001 (2001), the risk of consequences depends on the level of vibration, duration of exposure, and frequency. Lower chainsaw mass, but also bigger and more powerful chainsaws produce higher vibration levels (Malchaire 2020).

When the vibrations reach a critical (resonant) frequency, the body organs begin to vibrate, which can multiply the consequences and cause considerable damage to a person's health (Goglia et al. 2008). The grip strength of a chainsaw handle, which influences the transmission of vibrations to the hand-arm system, depends on the work experience of the worker, the working method, and the density of the wood (Iftime et al. 2022). Concerning this, the grip is stronger in less-experienced workers, in felling and sawing the wood of higher hardness (Malinowska-Borowska et al. 2012, Malinowska-Borowska and Zieliński 2013). The vibration level of chainsaws is mostly influenced by factors such as dynamic forces in the drive engine with internal combustion, chain sharpness, work operation, moving parts that are not balanced, the influence of gears, bearings, and other mechanisms, but also the relationship between the worker, the chainsaw and the type of wood (ISO 116811:2011).

Although chainsaw parts degrade with years of use, Landekić et al. (2020) concluded that age, i.e. years of use do not affect the level of vibration in used petrol chainsaws. Many studies (Colantoni et al. 2016, Neri et al. 2018, Poje et al. 2018, Huber et al. 2021) indicated significantly lower noise and vibration levels in battery chainsaws compared to petrol chainsaws of the same class.

This paper considers two legislative restrictions regarding harmful HAV. The first one is the above mentioned Ordinance on Occupational Safety and Health in Forestry (1986), which prescribes the total permitted effective working time with a chainsaw of no longer than four hours in the Republic of Croatia. Another restriction is related to the EU Directive 2002/44/EC, which determines daily vibration exposure values A(8) for the hand-arm system. This restriction prescribes a daily exposure action value (EAV) of 2.5 m/s2, and a daily exposure limit value (ELV) of 5 m/s2. Furthermore, the International Labor Office (ILO), which intends to reduce injuries and health hazards, and the occurrence of occupational diseases caused by excessive exposure to noise, vibrations, exhaust gases, wood dust, etc., suggests an effective working time with a chainsaw of up to five hours per working day. To follow this recommendation, chainsaw workers should alternate their specific daily activities (chainsaw work, maintenance, chain sharpening, refueling, log measurement, etc.).

This paper aims to determine the difference in the measured hand-arm vibration level between two chainsaws with similar basic characteristics, but different powertrains (petrol-powered – Stihl MS 261 C-M and battery-powered STIHL MSA 300 C) and, based on the measured hand-arm vibrations and the conducted time study from the previous research (Bačić et al. 2023b), to determine the permissible effective work with the chainsaws tested with a critical reference to the applicable national and European legislation. The research hypothesis is that the battery-powered chainsaw has lower vibration magnitudes and that, according to the current state legislative restriction, it would be possible to work with it more than the permitted daily effective time of work of 4 hours.

2. Materials and Methods

Determining daily vibration exposure requires an understanding of the work schedule and the levels of vibration that occur on the front and rear handles of the chainsaw. The chainsaw is a two-handed tool that must be operated with both hands during cutting. The handles of the chainsaw are designed so that the left hand grasps the front (left) handle, and the right hand grasps the rear (right) handle (during cutting). However, fellers spend a significant portion of their working time holding (carrying) the chainsaw, which also produces harmful vibrations when idling. Carrying a running chainsaw is a necessity that occurs between cuts and mostly lasts for a short time, but it is frequent, involving various combinations of hand-handle positions, and constitutes a large part of the effective working time. Fellers, due to the short duration of the carrying phase, often do not turn off the chainsaw and are exposed to harmful vibrations. The time structure of chainsaw handling elements is adopted from previous research (Bačić et al. 2023b) in which a study of work and time was conducted on a sample of 91 trees (logging and processing operations), and relative shares of chainsaw handling elements were determined. In this paper, the average values of the relative shares of chainsaw handling elements for all trees from the mentioned research were used. The description of the elements and their relative share in effective working time is shown in Table 1.

Table 1 Description of chainsaw-handling elements and their relative share (Bačić et al. 2023b)

|

Chainsaw handling element |

Description |

Relative proportions of chainsaw handling elements |

|

0 |

The chainsaw is turned off or put away |

10.48% |

|

1a |

Cutting solid wood |

42.59% |

|

1b |

Repetitive cutting of thin branches (<7 cm) |

13.84% |

|

2 |

Carrying the chainsaw (idle) using both hands |

19.65% |

|

3 |

Carrying the chainsaw (idle) with the right hand on the front handle |

0.45% |

|

4 |

Carrying the chainsaw (idle) with the left hand for the front handle |

12.01% |

|

5 |

Carrying the chainsaw (idle stroke) with the right hand on the rear handle |

0.98% |

The vibration level was measured under controlled conditions. The process of determining daily vibration exposure – A(8) is very complex if the daily work consists of several elements with different durations and vibration intensities (McGeoch et al. 2005). Continuous A(8) measurements are very complex, and unwanted interruptions may occur due to the need to fix the accelerometer to the chainsaw handle, questionable instrument battery life, and harsh working conditions that could affect the accuracy of the results (Bačić et al. 2023a). The measurement equipment complies with ISO 8041-1:2017. A 4-channel module Brüel & Kjaer LAN-XI type 3676-B-040 together with a triaxial accelerometer type 4524-B-001 and holder UA 3017 attached with plastic ties and positioned on front and rear handles close to the worker's hand was used. Measurements were conducted using a laptop and specific software via a Wi-Fi connection to the router. External batteries were required for the operation of the LAN-XI module and paired router. A backpack was used to store the measurement equipment.

Fig. 1 Tested chainsaws – a), and measuring equipment – b)

During the measurements, the guidelines of ISO 5349-1:2001 and ISO 5349-2:2001 were followed. The instrument was calibrated before the measurements. When measuring vibration levels on chainsaws, the short cutting time may affect the results. ISO 5349-2:2001 recommends that a single measurement should not be shorter than 8 seconds, provided that the total measurement time is not less than one minute and at least three measurements are conducted. The cutting measurement was performed on a wet trunk of sessile oak (Quercus petraea) with a diameter of 30 cm. Crosscuts were made at full throttle until the guide bar reached the lower part of the trunk. The measurement started at least one second after the beginning of the cut to isolate only the cutting at full throttle. In addition to measurements in solid wood, vibration level measurements during cutting of thinner branches were also performed. To simulate this type of cutting, the worker repeatedly cut thinner branches (<7 cm) in the canopy for at least 20 seconds per measurement. This type of cutting involved brief stops and drops in RPM between two cuts. Idling vibration measurement was conducted in three measurements of at least 20 seconds each (only for petrol-powered chainsaw). The total vibration value (ahv) for each handling element was calculated as the arithmetic mean of repeated measurements. Due to the use of only one accelerometer, vibration levels on the front and rear handles were measured separately. A total of 12 measurement combinations were included in the measurement. The measurements were conducted on the Stihl MS 261 C-M petrol-powered chainsaw and the Stihl MSA 300 C battery-powered chainsaw (Table 2) in »Felling« mode with a maximum chain speed of 24 m/s, like the maximum chain speed of petrol-powered chainsaw Stihl MS 261 C-M (25.6 m/s). Since the battery-powered chainsaw does not idle and does not produce vibrations during carrying, vibrations were measured only during cutting. The chainsaws were equipped with the same cutting sets. Vibration level measurement was conducted at the Forest Training and Research Center (FTRC) Zagreb.

Table 2 Technical characteristics of chainsaws tested

|

Chainsaw type |

Stihl MS 261 |

Stihl MSA 300 |

|

Engine |

2-stroke petrol |

DC brushless |

|

Weight 1, kg |

4.9 |

4.5 |

|

Power, kW |

3.0 |

3.0 |

|

Bar length, cm |

40 |

40 |

|

Chain pitch |

.325" |

.325" |

|

Chain type |

RS Pro |

RS Pro |

|

Chain speed, m/s |

25.6 |

24 |

|

Vibration levels left/right 2, m/s2 |

3.5/3.5 |

2.6/2.8 |

|

1 Without fuel, oil, battery, bar and chain 2 K-factor according to DIR 2006/42/EC = 2 m/s2 |

||

By adjusting the time data on handling elements (Table 1) to 4 hours of felling and processing (Regulation NN 10/86), A(8) was calculated and presented for both hands and the two observed chainsaws using Eq. 1.

(1)

(1)

Where:

A(8) daily vibration exposure

ahvi vibration total value for i element

n total number of elements

T0 reference working time of 4 h (14,400 s)

Ti duration of i element.

The Hand-Arm Vibration Exposure Calculator (Excel tool) provided by the Health and Safety Executive (HSE) was used to calculate the expected time to reach the exposure action level (EAV) of 2.5 m/s² and the exposure limit value (ELV) of 5 m/s² (EU Directive 2002/44/EC). These times were calculated and presented for both hands/handles and the two observed chainsaws (petrol-powered and battery-powered).

Database formation, data systematization, and calculation of the measured data were performed in the software package Microsoft Excel®. Statistical analysis was conducted using the statistical software package Statistica® (TIBCO Software Inc., version 14, Palo Alto, CA, USA). Non-parametric tests were used due to the nature of the obtained data (normality and homogeneity of variance). To test differences in total vibration values (ahv) measured between chainsaw type/handle combinations, a Kruskal–Wallis test (p<0.05) was used, and the Mann–Whitney U test (p<0.05) was performed to determine which groups made the difference.

3. Results and Discussion

3.1 Vibration Magnitude

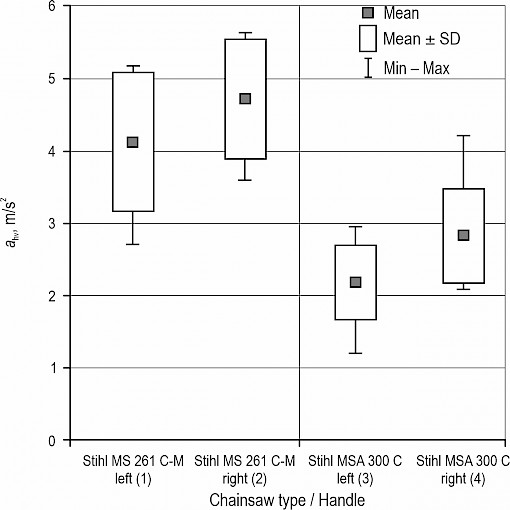

In total 47 measurements of the vibration magnitude were performed, 26 measurements on petrol-powered chainsaw Stihl MS 261 C-M and 21 measurements on battery-powered chainsaw Stihl MSA 300 C. Higher vibration magnitudes were measured working with the petrol-powered chainsaw on both hands (4.13 m/s2 – left hand, 4.72 m/s2 – right hand) compared with the battery-powered chainsaw (2.18 m/s2 – left hand, 2.82 m/s2 – right hand). Similar results were obtained by Neri et al. (2023) who measured the vibration magnitude when cutting different types of wood with a battery-powered and petrol-powered chainsaw. In our study, when comparing each saw separately, higher vibration magnitudes were measured on the right hand, i.e. on the rear handle (0.59 m/s2 for petrol-powered, 0.64 m/s2 for the battery-powered chainsaw) (Table 3).

Table 3 Descriptive statistics of measured vibration magnitude for tested chainsaws/hands

|

ahv m/s2 |

Stihl MS 261 C-M – left hand |

Stihl MS 261 C-M – right hand |

Stihl MSA 300 C – left hand |

Stihl MSA 300 C – right hand |

|

Mean |

4.13 |

4.72 |

2.18 |

2.82 |

|

Median |

4.34 |

5.06 |

2.16 |

2.65 |

|

Min. |

2.71 |

3.59 |

1.19 |

2.09 |

|

Max. |

5.18 |

5.65 |

2.95 |

4.22 |

|

Std. dev. |

0.97 |

0.83 |

0.52 |

0.66 |

|

n |

13 |

13 |

10 |

11 |

Higher vibration magnitudes on the rear handle were also measured by Bačić et al. (2023b) on large chainsaws, Stihl MS 462, MS 500i, and MS 661 C. Landekić et al. (2020) reported higher vibrations on the rear handle of the Stihl MS 660 chainsaw when idling. Investigating electric saws Stihl MSE 180 C and Stihl MSE 220 C, Neri et al. (2018) obtained significantly higher values of vibrations on the rear handle, while with battery saws Stihl MSA 160 T and Stihl MSA 200 C there was no significant difference in the measured vibrations between the front and rear handle.

Fig. 2 shows a statistically significant difference in vibration magnitudes measured on both handles and chainsaws tested (p=0.0000). Larger vibration magnitudes were measured with petrol-powered chainsaw Stihl MS 261 C-M.

Fig. 2 Measured total vibration values (ahv) for chainsaws tested

Fig. 3 shows the vibration magnitude in a boxplot diagram, where the differences between the chainsaws tested and the handles of each saw can be clearly seen. The Kruskal-Wallis test was used to determine the difference between the measured vibration magnitudes (Fig. 3), while the Mann-Whitney U post-hoc test was used to determine the difference between individual groups (chainsaw handles). The data presented in Table 4 show that a statistically significant difference does not exist only when comparing the measured vibration magnitudes of the gasoline chainsaw MS 261 C-M between the front and rear handles (p=0.1007). In all other combinations, there is a statistically significant difference, even between the front and rear handles of the Stihl MSA 300 C battery-powered chainsaw (p=0.0378).

Fig. 3 Total vibration values (ahv) measured for chainsaws tested on both handles separately

The main reason for the lower amounts of total vibration values measured in battery-powered chainsaws compared to the petrol-powered chainsaws is in the technical characteristics of the drive motor, i.e. there is no explosion phase in electric motors, which is the main characteristic of an internal combustion engine (Neri et al. 2023). Secondly, with electric motors, there is only rotary motion, while with internal combustion engines, there is also a rectilinear piston motion in addition to rotary motion. Precisely, because of the absence of forces created by the linear motion of the piston and explosion, which is the basis for the operation of the internal combustion engine, the vibrations of battery-powered (electric) chainsaws are significantly lower (Pitts 2004, Takimoto et al. 1985). In battery-powered chainsaws, the design and sharpness of the chain teeth have the greatest influence on the total vibration values (Rukat and Jakubek 2017, Rottensteiner and Stampfer 2013).

Table 4 Mann–Whitney U post-hoc test for chainsaws tested on both handles

|

Tested pairs* |

U |

Z |

p-value** |

|

1–2 |

52 |

–1.64 |

0.1007 |

|

1–3 |

3 |

3.84 |

0.0001 |

|

1–4 |

18 |

3.07 |

0.0021 |

|

2–3 |

0 |

4 |

0.0006 |

|

2–4 |

7 |

3.71 |

0.0002 |

|

3–4 |

25 |

-2.08 |

0.0378 |

|

* 1 – Stihl MS 261 C-M – left 2 – Stihl MS 261 C-M – right 3 – Stihl MSA 300 – left 4 – Stihl MSA 300 – right ** p<0.05 is significant |

|||

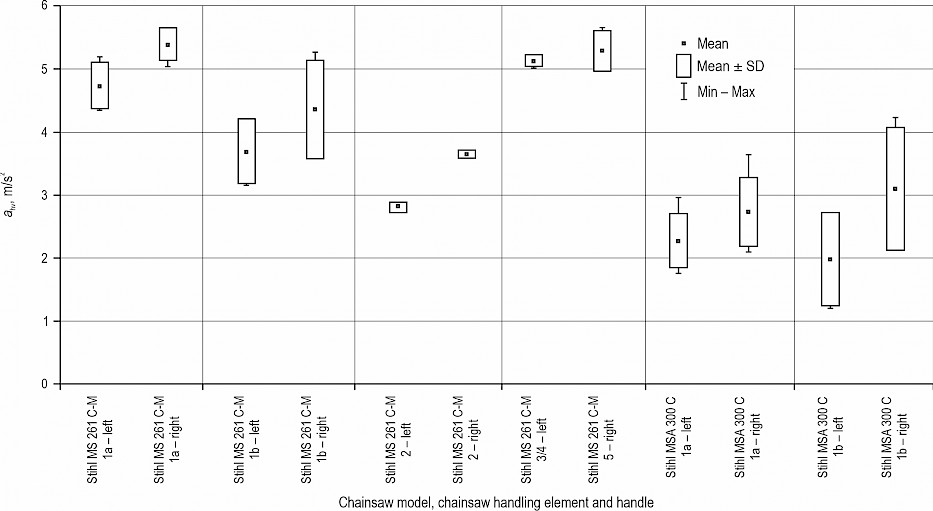

The vibration magnitudes of the chainsaws tested by chainsaw handling element are shown in Fig. 4. In all chainsaw handing elements, higher vibration magnitudes were observed on the rear handle of both chainsaws. Lower vibrations for the same handling element were measured with the Stihl MSA 300 C battery-powered chainsaw. With the petrol-powered chainsaw, the highest vibration magnitudes (ahv>5 m/s2) were measured in handling element 1a (cutting solid wood) on the rear handle, and in work operations 3/4 and 5 when the chainsaw is holding to the front or rear handle with only one hand during engine idling.

Fig. 4 Total vibration magnitudes for the specified chainsaw handling element

A Mann-Whitney U post-hoc test was used to determine the difference in measured vibration magnitudes separately for each chainsaw handling element between the handles of the chainsaws tested (Table 5). According to the obtained results, there is no statistically significant difference only in work operation 1b (repetitive cutting of small branches) on the rear handles of the chainsaws tested (p=0.3827).

Table 5 Mann–Whitney U post-hoc test for chainsaw handling element

|

Tested pairs* |

U |

Z |

p-value** |

|

1–9 |

0 |

2.55 |

0.0107 |

|

2–10 |

0 |

2.63 |

0.0085 |

|

3–11 |

0 |

1.75 |

0.0809 |

|

4–12 |

2 |

0.87 |

0.3827 |

|

* p<0.05 is significant |

|||

3.2 Daily Vibration Exposure A(8)

According to the obtained results shown in Table 6, it is evident that the daily vibration exposure A(8) is significantly lower with the battery-powered chainsaw Stihl MSA 300 C. With this chainsaw, there is no limitation of effective daily work to avoid reaching the prescribed limits with a warning value of 2.5 m/s2, and there is no work limitation at the limit value of the daily dose in the amount of 5 m/s2. The right (rear) handle is the reference handle by which daily exposure to vibrations is determined for both saws tested. With the battery-powered chainsaw, the worker may effectively work for more than 8 hours a day (641 minutes) to reach the warning value, while with the petrol-powered chainsaw Stihl MS 261 C-M, the worker may work for a total of 166 minutes, or 2 hours and 46 minutes. With a petrol-powered chainsaw, a worker can work effectively the whole working day (8 hours) whithout reaching the limit value of daily exposure to vibrations of 5 m/s2.

Table 6 Daily exposure to vibrations and time to reach the prescribed limits

|

Chainsaw type |

Hand |

A(8) m/s2 |

Time till 2.5 m/s2 min |

Time till 5 m/s2 min |

|

Stihl MS 261 C-M |

Left |

2.8 |

186 |

744 |

|

Right |

3.0 |

166 |

665 |

|

|

Stihl MSA 300 C |

Left |

1.2 |

1056 |

4224 |

|

Right |

1.5 |

641 |

2556 |

Measuring vibrations on the same chainsaws, but on two different types of wood logs (Black pine and European beech), Neri et al. (2023) obtained slightly higher vibrations on the front handle (A(8)=3.2 m/s2 – left, A(8)=3.1 m/s2 – right) in the petrol-powered chainsaw Stihl MS 261 C-M, while with the battery-powered chainsaw Stihl MSA 300 C higher vibrations were measured on the rear handle (A(8)=1.4 m/s2 – left, A(8)=1.6 m/s2 – right). Comparing these results with ours shown in Table 6, it is evident that our values are lower. The reason is that Neri et al. (2023) measured vibrations only when cutting solid wood, while our values included other chainsaw-handling elements such as repetitive cutting of thin branches (<7 cm) (1b), holding the chainsaw when it is working in idle (3/4, 5), and of course cutting solid wood (1a). Our results also show higher total vibration magnitudes for the chainsaw-handling element cutting solid wood (1a) compared to other handling elements, especially for the handling element repetitive cutting of thin branches (1b) (Fig. 4).

4. Conclusions

Higher vibration magnitudes were observed on the rear handle for both chainsaws tested. Generally higher vibration magnitudes were observed for the petrol-powered compared to the battery-powered chainsaw for the same chainsaw-handling element.

The highest vibration magnitudes were measured when cutting solid wood (chainsaw handling element 1a) on the rear handle of a petrol-powered chainsaw, and in idling operation mode when the front or rear handle of the chainsaw is held with only one hand, left or right (chainsaw handling element 3/4 and 5). To reduce vibration exposure with a petrol-powered chainsaw, it would be advisable to transfer the chainsaw with the drive engine off and avoid carrying the chainsaw with only one hand when the engine is running. A battery-powered chainsaw has fewer moving parts with an electric motor which is not running when the chainsaw is transferred. For that reason, there is no harmful vibration for these working elements. Finally, significantly lower vibration magnitudes were measured with the battery-powered than the petrol-powered chainsaw, and it is not even possible to reach the warning value of daily vibration exposure of 2.5 m/s2 during the 8-hour working day.

Although the measured vibration magnitudes and permissible daily exposure time are acceptable for both chainsaws tested, the use of protective (anti-vibration) gloves is mandatory for professional loggers.

According to the current state legislative restriction (Ordinance on Occupational Safety and Health in Forestry 1986), the permitted daily effective time of work with chainsaws is a total of 4 hours. Based on the results obtained, the revision of the mentioned ordinance should be carried out with the aim of increasing the effective working time because it would be justified according to the results of this work.

Acknowledgments

The authors express their gratitude to the company Unikomerc-uvoz Ltd. for the technical support provided.

5. References

Araki, S., Honma, T., Aoyama, K., 1976: Peripheral nerve conduction velocities in chainsaw operators. Jpn. J. Ind. Health 18(6): 516–520. https://doi.org/10.1539/joh1959.18.516

Axelsson, S.A., 1968: Analysis of Vibration in Power Saws. Stud. For. Suec. 59: 1–47.

Bačić, M., Šušnjar, M., Zečić, Ž., Koren, S., Kolarić, M., Pandur, Z., 2020: Daily vibration exposure in forestry: the difference between manual and motormanual cleaning methods. Sigurnost 62(3): 265–274.

Bačić, M., Landekić, M., Šušnjar, M., Šporčić, M., Pandur, Z., 2023a: Vibration levels and daily vibration exposure while using different tools in a forest cleaning. Cent. Eur. For. J. 69(1): 49–58. https://doi.org/10.2478/forj-2022-0015

Bačić, M., Pandur, Z., Šušnjar, M., Šporčić, M., Landekić, M., 2023b: Daily Vibration Exposure in the Context of State and European Legislature: A Case Study among Chainsaw Operators in Croatia. Forests 14(5): 929. https://doi.org/10.3390/f14050929

Barnes, R., Longley, E.O., Smith, A.R.B., Allen, J.G., 1969: Vibration disease. Med. J. Aust. 1: 901–905.

Brammer, A.J., Pyykkö, I., 1987: Vibration-induced neuropathy: Detection by nerve conduction measurements. Scand. J. Work Environ. Health 13(4): 317–322.

Colantoni, A., Mazzocchi, F., Cossio, F., Cecchini, M., Bedini, R., Monarca, D., 2016: Comparisons between battery chainsaws and internal combustion engine chainsaws: performance and safety. Contemp. Eng. Sci. 9(27): 1315–1337. http://dx.doi.org/10.12988/ces.2016.68133

Directive 2002/44/EC, 2002: The mimimum health requirement regarding the exposure of workers to the risks arising from physical agents (vibration). Official Journal of the European Communities 177: 13–19.

Forouharmajd, F., Yadegari, M., Ahmadvand, M., Pourabdian, S., 2017: Hand-arm Vibration Effects on Performance, Tactile Acuity, and Temperature of Hand. J. Med. Signals Sens. 7(4): 252–260. https://doi.org/10.4103/jmss.JMSS_70_16

Goglia, V., Žgela, J., Đukić, I., 2008: The Effectiveness of Anti-Vibration Gloves: Part I. Šum. list 132(3–4): 115–119.

Goglia, V., Žgela, J., Suchomel, J., Đukić, I., 2011: Exposure to hand-arm transmitted vibration at forest nursery and thinning. Human Resources Management and Ergonomics 5(1): 45–55.

Goglia, V., Žgela, J., Suchomel, J., Đukić, I., 2012: The effectiveness of forest pre-commercial thinning in the context of Directive 2002/44/EC. Šum. list 136(9–10): 471–478.

Huber, M., Hoffmann, S., Brieger, F., Hartsch, F., Jaeger, D., Sauter, U.H., 2021: Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws? Forests 12(8): 1120. https://doi.org/10.3390/f12081120

Iftime, M.D., Dumitrascu, A.E., Ciobanu, V.D., 2022: Chainsaw operators' exposure to occupational risk factors and incidence of professional diseases specific to the forestry field. Int. J. Occup. Saf. Ergon. 28(1): 8–19. https://doi.org/10.1080/10803548.2019.1703336

ILO: Safety and Health in Forestry Work-Code of Practice; International Labour Office: Geneva, Switzerland, 1998: 1–132 p.

ISO 11681-1:2011: Machinery for forestry – Portable chain-saw safety requirements and testing – Part 1: Chain-saws for forest service. International Standard organization, Geneva, 1–22 p.

ISO 5349-1:2001: Mechanical vibration – Measurement and evaluation of human exposure to hand transmitted vibration. Part 1: General requirements. International Standard organization, Geneva, 1–26 p.

ISO 5349-2:2001: Mechanical vibration – Measurement and evaluation of human exposure to hand-transmitted vibration – Part 2: Practical guidance for measurement at the workplace. International Standard organization, Geneva, 1–39 p.

ISO 8041-1:2017: Human Response to Vibration—Measuring Instrumentation – Part 1: General Purpose Vibration Meters. International Standard Organization, Geneva, 1–106 p.

Landekić, M., Bačić, M., Pandur, Z., Šušnjar, M., 2020: Vibration Levels of Used Chainsaws. Forests 11(2): 249. https://doi.org/10.3390/f11020249

Malchaire, J., 2020: Vibrations Mains-Bras: Serie Strategie Sobane–Gestion des Risques Professionnels. Brochure, Service public fédéral Emploi, Travail et Concertation sociale, Brussels, 1–70 p.

Malinowska-Borowska, J., Harazin, B., Zieliński, G., 2012: Measuring coupling forces woodcutters exerton saws in real working conditions. Int. J. Occup. Saf. Ergon. 18(1): 77–83. https://doi.org/10.1080/10803548.2012.11076918

Malinowska-Borowska, J., Zieliński, G., 2013: Coupling forces exerted on chain saws by inexperienced tree fellers. Int. J. Ind. Ergon. 43(4): 283–287. https://doi.org/10.1016/j.ergon.2013.04.006

Matache, M.G., Munteanu, M., Dumitru, D.N., Epure, M., 2020: Evaluation of Hand Transmitted Chainsaw Vibrations during Wood Cutting. In Proceedings of the E3S Web of Conferences; EDP Sciences, Constanta, Romania, 26–27 June; Volume 180, 3013 p.

McGeoch, K.L., Lawson, I.J., Burke, F., Proud, G., Miles, J. 2005: Diagnostic criteria and staging of hand-arm vibration syndrome in the United Kingdom. Ind. Health 43(3): 527–534. https://doi.org/10.2486/indhealth.43.527

Miura, T., Kimura, K., Tominaga, Y., Kimotsuki, K., 1965: On the Raynaud's Phenomenon of Occupational Origin due to Vibrating Tools–ts Incidence in Japan. Journal of Science of Labour 42: 725–747.

Neri, F., Laschi, A., Foderi, C., Fabiano, F., Bertuzzi, L., Marchi, E., 2018: Determining Noise and Vibration Exposure in Conifer Cross-Cutting Operations by Using Li-Ion Batteries and Electric Chainsaws. Forests 9(8): 501. https://doi.org/10.3390/f9080501

Neri, F., Laschi, A., Bertuzzi, L., Galipò, G., Frassinelli, N., Fabiano, F., Marchi, E., Foderi, C., Marra, E., 2023: A Comparison between the Latest Models of Li-Ion Batteries and Petrol Chainsaws Assessing Noise and Vibration Exposure in Cross-Cutting. Forests 14(5): 898. https://doi.org/10.3390/f14050898

Ordinance on Occupational Safety and Health in Forestry. Official Gazette, 10/86, 1986, 1–18 p.

Pitts, P., 2004: Hand-Arm Vibration Emission of Chainsaws-Comparison with Vibration Exposure. Health and Safety Laboratory: Buxton, UK.

Poje, A., Potočnik, I., Mihelič, M., 2018: Comparison of Electric and Petrol Chainsaws in Terms of Efficiency and Safety When Used in Young Spruce Stands in Small-Scale Private Forests. Small-Scale For. 17(3): 411–422. https://doi.org/10.1007/s11842-018-9395-4

Poje, A., Grigolato, S., Potočnik, I., 2019: Operator exposure to noise and whole-body vibration in a fully mechanized CTL forest harvesting system in Karst Terrain. Croat. J. For. Eng. 40(1): 139–150.

Rottensteiner, C., Stampfer, K., 2013: Evaluation of operator Vibration exposure to chainsaws equipped with a Kesper safety bar. Scand. J. For. Res. 28(2): 193–200. https://doi.org/10.1080/02827581.2012.706636

Rukat, W., Jakubek, B., 2017: The Influence of the Cutting Tooth Design and Wear of a Saw Chain on the Vibration Level of a Chainsaw. Vib. Phys. Syst. 28: 1–8.

Seppäläinen, A.M., 1972: Peripheral Neuropathy in Forest Workers. A Field Study. Work Environ. Health 9(3): 106–111.

Stanëk, L., Neruda, J., Mergl, V., Kotek, T., 2023: Difference in the magnitude of power saw vibrations affecting the operator during forest felling. Cent. Eur. For. J. 69(1): 59–67. https://doi.org/10.2478/forj-2023-0003

Takimoto, Y., Bottoms, D.J., Stayner, R.M., 1985: The Vibration Characteristics of a Chainsaw Fitted with a Two Cylinder Engine. In Noise and Vibration in Agriculture and Forestry, Proceedings of the 8th Joint Ergonomics Symposium, Silsoe, UK, 9–12 September; EurekaMag: Dallas, TX, USA.

Tambić Bukovac, L., Šenjug Perica, M., 2017: Raynaudov sindrom. Paediatr. Croat. 61: 38–42.

Taylor, W., Pearson, J., Kell, R.L., Keighley, G.D., 1971: Vibration syndrome in Forestry Commission chain saw operators. Br. J. Ind. Med. 28(1): 83–89. https://doi.org/10.1136/oem.28.1.83

Yovi, E.Y., Yamada, Y., 2019: Addressing Occupational Ergonomics Issues in Indonesian Forestry: Laborers, Operators, or Equivalent Workers. Croat. J. For. Eng. 40(2): 351–363. https://doi.org/10.5552/crojfe.2019.558

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Assoc. prof. Zdravko Pandur, PhD

e-mail: zpandur@sumfak.unizg.hr

Prof. Marijan Šušnjar, PhD

e-mail: msusnjar@sumfak.unizg.hr

Assoc. prof. Matija Landekić, PhD

e-mail: mlandekic@sumfak.unizg.hr

Prof. Mario Šporčić, PhD

e-mail: msporcic@sumfak.unizg.hr

Marin Bačić, PhD *

e-mail: mbacic1@sumfak.unizg.hr

University of Zagreb

Faculty of forestry and wood technology

Department of Forest Engineering

Svetošimunska cesta 23

10 000 Zagreb

CROATIA

Assist. prof. Iva Ištok Pandur, PhD

e-mail: iistok@sumfak.unizg.hr

University of Zagreb

Faculty of forestry and wood technology

Department of Wood Science

Svetošimunska cesta 23

10 000 Zagreb

CROATIA

Ivan Jurič, MSc

e-mail: ivanjuri.kuk@gmail.com

Kuk 37

80240 Tomislavgrad

BOSNIA and HERZEGOVINA

* Corresponding author

Received: May 03, 2024

Accepted: January 24, 2025

Original scientific paper