Evaluating Productivity of Small-Scale Cable Yarding System Integrated with a Portable Winch

doi: 10.5552/crojfe.2023.1957

volume: 44, issue:

pp: 14

- Author(s):

-

- Akay Abdullah Emin

- Gümüş Selçuk

- Başaran Adil

- Article category:

- Original scientific paper

- Keywords:

- forest harvesting, logging operation, mini-yarder, production rate

Abstract

HTML

Small-scale forestry operations, which are used in non-industrial and site specific forestry, provide alternative logging methods suitable for precision forestry approach. In this study, a small-scale cable yarding system integrated with a portable winch was considered as alternative timber extraction method compared to a standard tower yarder. It was aimed to evaluate productivity of this yarding method, which was implemented during commercial harvesting activities performed in a 10.74 ha black pine stand located in Bursa province of Turkey. The main factors (i.e. slope, yarding distance, lateral pulling distance, log volume, log length), significantly affecting the productivity, were evaluated based on two slope classes (34–50% and 50–70%) and two yarding distances (100 m and 200 m). The results indicated that the average productivity was 0.95 m3/PMH and 0.90 m3/SMH. It was revealed that the productivity of the small-scale cable yarding decreased as the ground slope and the yarding distance increased. Statistical analysis indicated that there was a significant (p<0.001) relationship between productivity and log volume and length in four applications. On the other hand, it was found that there was a significant (p<0.05) relationship between productivity and lateral pulling distance in only the first application (34–50% slope; 100 m yarding distance). Considering the volume classes of the logs, it was determined that the productivity increased from the low volume class to the high volume class.

Evaluating Productivity of Small-Scale Cable Yarding System Integrated with a Portable Winch

Abdullah E. Akay, Selçuk Gümüş, Adil Başaran

Abstract

Small-scale forestry operations, which are used in non-industrial and site specific forestry, provide alternative logging methods suitable for precision forestry approach. In this study, a small-scale cable yarding system integrated with a portable winch was considered as alternative timber extraction method compared to a standard tower yarder. It was aimed to evaluate productivity of this yarding method, which was implemented during commercial harvesting activities performed in a 10.74 ha black pine stand located in Bursa province of Turkey. The main factors (i.e. slope, yarding distance, lateral pulling distance, log volume, log length), significantly affecting the productivity, were evaluated based on two slope classes (34–50% and 50–70%) and two yarding distances (100 m and 200 m). The results indicated that the average productivity was 0.95 m3/PMH and 0.90 m3/SMH. It was revealed that the productivity of the small-scale cable yarding decreased as the ground slope and the yarding distance increased. Statistical analysis indicated that there was a significant (p<0.001) relationship between productivity and log volume and length in four applications. On the other hand, it was found that there was a significant (p<0.05) relationship between productivity and lateral pulling distance in only the first application (34–50% slope; 100 m yarding distance). Considering the volume classes of the logs, it was determined that the productivity increased from the low volume class to the high volume class.

Keywords: forest harvesting, logging operation, mini-yarder, production rate

1. Introduction

The harvested trees that are fallen, bucked, and delimbed in the woods are transported to the landing areas located on the edge of the forest roads using various logging methods. Planning and implementation of logging methods requires special attention particularly in mountainous regions since inadequately planned and implemented logging methods can have serious adverse effects on timber quality, residual trees, forest soil, and forest productivity (Gümüş and Acar 2010, Stanczykiewicz et al. 2015, Picchio et al. 2020, Kizha et al. 2021, Cântar et al. 2022). In order to ensure sustainability of the forest resources, suitable logging methods should be selected according to the precision forestry approach, which aims to provide optimum efficiency from forest resources and minimize environmental damage by using modern techniques and technological tools (Gülci et al. 2015).

Small-scale forestry operations used in non-industrial and site-specific forestry offer alternative methods suitable for the precision forestry approach (Sennblad 1993). In small-scale forest harvesting, tree felling is generally carried out manually by using a chainsaw, while semi-mechanized logging operations, such as small or medium-sized tractors with winch, are preferred in logging operations. In this respect, this equipment with low purchase prices and operating costs can be afforded by the logging contractors that carry out the timber extraction works. In addition, systems used in small-scale forestry operations result in less damage to the residual trees in the stand (Russell and Mortimer 2005). These systems are successfully applied in coniferous and/or deciduous stands with different characteristics in various regions of the world (Kent et al. 2011).

In recent years, when other logging methods cannot be used due to steep ground slope or high operating costs, the method of extracting timber with a small-scale cable yarding has emerged as an important alternative. This method provides great convenience especially in removing medium and small diameter forest products from the harvesting area. In addition, the method has the potential to offer benefits such as reducing stand damage and minimizing quality and volume losses in the extracted products (Spinelli and Magagnotti 2012). When farm tractors are not suitable due to economic or ecological concerns, timber extraction methods integrated with a portable winch system can be a good solution in small-scale logging operations (Akay et al. 2014, Gülci et al. 2015, Gülci et al. 2017, Bilici et al. 2019a).

In countries where small-scale forestry operations are widely preferred such as Estonia, Finland, Italy, Sweden, and USA, it has been observed that the small-scale cable yarding is an effective solution for timber extraction in mountainous regions (Russell and Mortimer 2005, Spinelli et al. 2010, Yu et al. 2016). Especially in stands with relatively small diameter trees, it would not be economically feasible to prefer large cable yarding methods that are used to transport large diameter trees (Rickenbach and Steele 2006, Jourgholami et al. 2014, Lee et al. 2018). In a study conducted by Spinelli et al. (2010), the performance of the small-scale cable yarding was evaluated in a mountainous region of Italy. The results indicated that cable yarding is an effective logging method as an alternative to other available logging methods such as animal and winch logging. It was also stated that tear and wear may be higher with the use of a small-scale cable yarding method compared to other standard cable yarding methods. Stanczykiewicz et al. (2015) reported that small-scale cable yarding can be used effectively in the production of high quality logs. They also stated that its impact on forest soil is much less than ground-based mechanical logging methods.

Yu et al. (2016) reported that small-scale cable yarding was the most economically viable option for timber extraction works in the Mark Twain National Forest in southern Missouri in US. It was found that this method increased the logging productivity and decreased the unit cost of logging operations especially in pure and small stands. Acar (2017) developed a small-scale cable yarding method as an alternative to the existing ones in mountain regions in Turkey. When the cable yarding was tested in an uphill yarding operation, the productivity was found to be about 3.06 m3/hour for an average of 140 m yarding distance. Lee et al. (2018) examined the performance of a small-scale cable yarding (HAM300) for uphill and downhill yarding directions in South Korea. In the study, sensitivity analyses were conducted to determine the effects of different yarding directions and distances on productivity and unit cost of the cable yarding method. The results showed that the productivity in the uphill and downhill direction was 6.29 m3/hour and 4.65 m3/hour, respectively, while the unit costs were 9.06 $/m3 and 10.04 $/m3, respectively. Thus, it was observed that the yarding direction has an effect on productivity and unit cost of the small-scale cable yarding operation.

In timber extraction works, hourly productivity of the logging method needs to be determined in order to plan the work properly, select the appropriate machine, control the machine performance and evaluate efficiency of the method. Time study is one of the methods used to examine the productivity of the logging machines based on three techniques including continuous time measurement, repeated time measurement and work sampling (Marčeta and Košir 2016). In the continuous time measurement technique, the work is continuously monitored, and the value read from the chronometer is recorded at the end of the work. In the repeated time measurement technique, the chronometer is started at the beginning of the work, and it is started again after being reset to zero at the end of each work stage. In the work sampling technique, work is observed at equal time intervals and the flow phases made at that moment are recorded (Gülci 2014).

In this study, productivity analysis of small-scale cable yarding integrated with portable winch and synthetic rope was performed for the first time in Turkey. Time measurements were carried out by on-site tracking of work stages using chronometers and surveying forms. In the study, the effects of various factors (slope, yarding distance, lateral pulling distance, log volume, log length) on productivity of the cable yarding method were evaluated using statistical analysis, and regression models were developed to estimate yarding productivity.

2. Materials and Methods

2.1 Study Area

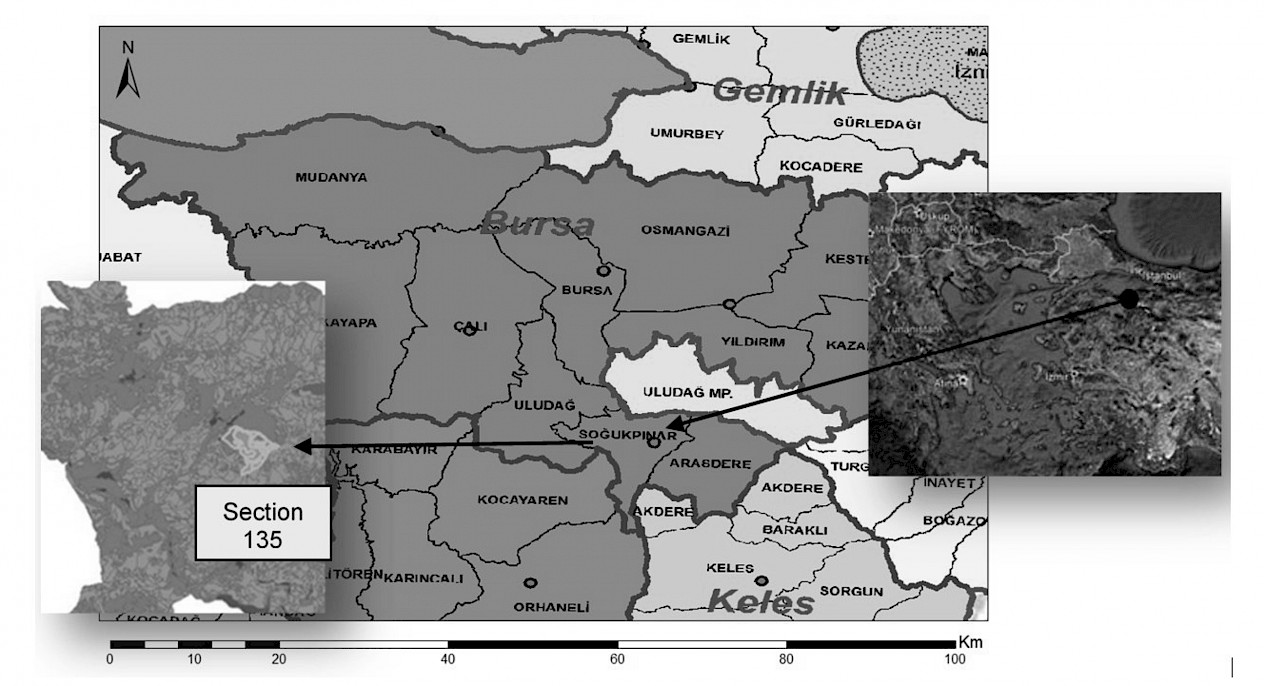

The small-scale cable yarding was implemented during the harvesting operation carried out in Soğukpınar FEC located in Bursa Forest Enterprise Directorate (FED). In the FED, about 40% of the area is covered with forest lands in which about 77% of the forest (61,659 hectares) are high forest, while the remaining forests (18,231 ha) are degraded. Bursa FED is located between 40˚37′4”–39˚58′07” north latitudes and 28˚32′32”–29˚56′10” east longitudes. The dominant tree species in the study area is black pine and the average elevation and slope are 1164 m a.s.l. and 45%, respectively. The logging operation, which was carried out using a small-scale cable yarding method, was applied in Section 135, within the border of the Soğukpınar FEC (Fig. 1). The study implemented in a thinning operation took place in a black pine stand (10.74 ha) using cut-to-length method.

Fig. 1 Section 135 within Soğukpınar FEC

2.2 Small-Scale Cable Yarding

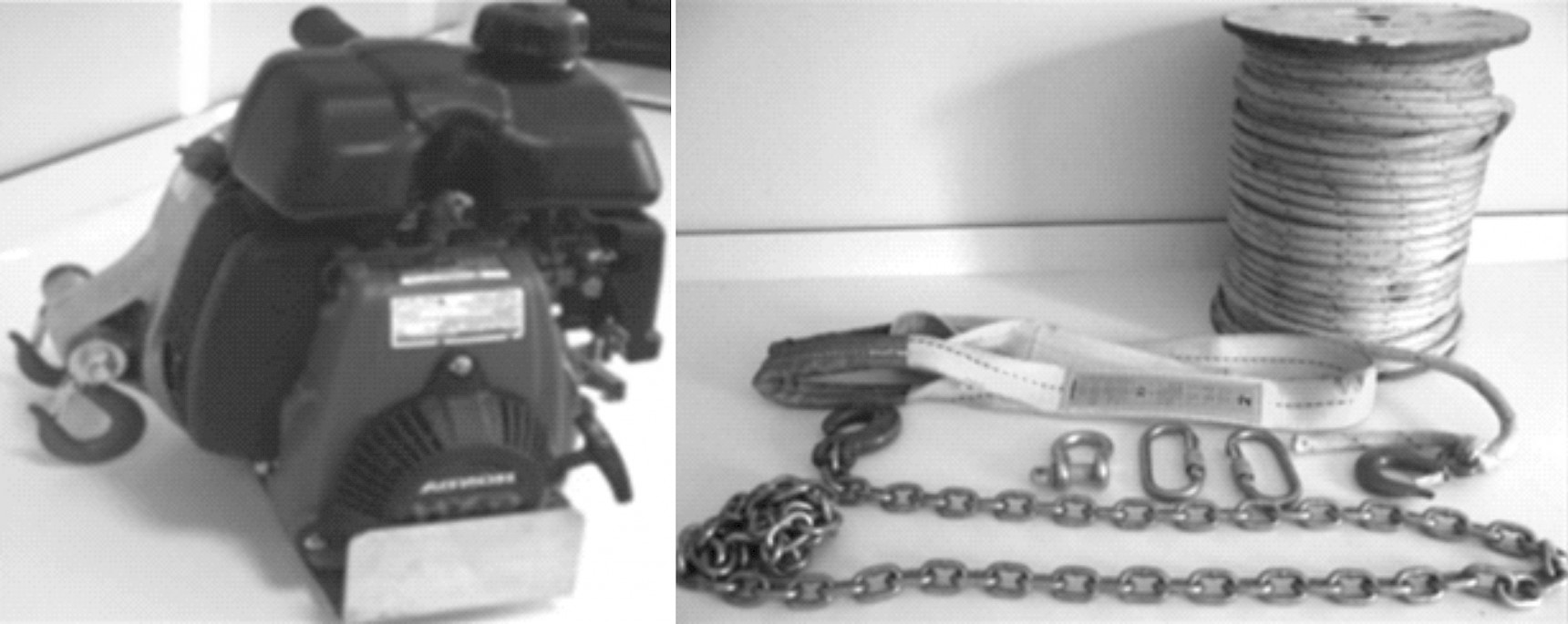

The Maxwald model carriage (40 kg) was used for the implementation of small-scale cable system during the uphill yarding operation (Fig. 2). Small-scale cable yarding method enables logging operations in steep terrain at low cost and provides improved safety (Raymond 2014). In addition, it causes much less damage to the forest soil than other conventional methods. According to the manufacturer of the Maxwald carriage, the efficient yarding distance is defined as 200 m (maximum 300 m), while the lateral pulling distance is 30 m. The suggested load capacity of the system is 1000 kg and average installation time is defined as about two hours with two men. The »PCW5000« model portable winch from Portable Winch Co. (Quebec, Canada) equipped with synthetic rope was used in the cable yarding method to pull the carriage back to the landing area.

In the study, static synthetic ropes (12 mm; 110 gr/m), made of high-strength technical polyester, were used as the skyline, mainline and guylines for easy installation and removal of the cable yarding system. The carriage rides on the skyline and the mainline pulls the carriage back to the landing area while guylines support the tower and tail tree. The synthetic ropes contain independent wires, and they are produced by passing reinforcements with reverse braid. These ropes have a maximum tensile strength of 3700 kg, are resistant to cutting effects such as sharp rocks, have very little elongation and deflection, and are well resistant to all weather conditions. A total of 600 m synthetic rope was used in the system, including skyline (200 + 50 m), mainline (200 + 50 m) and guylines (100 m). The chain chokers (1.5 m) and metal hooks were used to pull the forest products with the mainline. Besides, polyester chokers (2 m), metal locks, direction pulley and metal hooks were used for the installation of the skyline to the tower and tail tree, establishment of guylines to the anchors, and installation of portable winch in the landing area (Fig. 3).

Fig. 2 Maxwald carriage equipped with plastic-stop (left) on valley-side and locking device (right) on mountain-side

Fig. 3 Portable winch (left) and other equipment such as synthetic rope, polyester choker, metal locks, direction pulley and metal hooks (right) used in cable yarding operation

2.3 Field Studies

During the commercial harvesting operation in the black pine stand, the cable yarding method was implemented in four applications:

- 34–50% slope and 100 m yarding distance

- 34–50% slope and 200 m yarding distance

- 50–70% slope and 100 m yarding distance

- 50–70% slope and 200 m yarding distance.

About 130 m3 of timber was harvested by using chainsaws in the field. In the selected four sites suitable for the specified conditions (i.e. slope and yarding distance), the logging operation using portable winch was carried out by three experienced forestry workers. In the application, one of the workers used the portable winch, one worker carried out the choker-setting in the field, and the third worker released the logs on the landing area. The work stages during each cycle of cable yarding operation include:

- carriage moving downhill by gravity and reaching the loading place

- dropping hook onto ground and pulling it to the logs

- choker-setting of the logs using chokers attached to the hook

- pulling hook back to carriage and pulling loaded carriage uphill back to the landing area

- dropping hook onto ground and pulling hook up to the carriage after releasing the logs.

The time spent on additional activities such as minor repairs and recovery of the stuck forest products, breaks due to equipment or personnel reasons were considered as delay time. In addition, time consumption caused by other activities such as the installation of cable yarding and portable winch were noted in the surveying form.

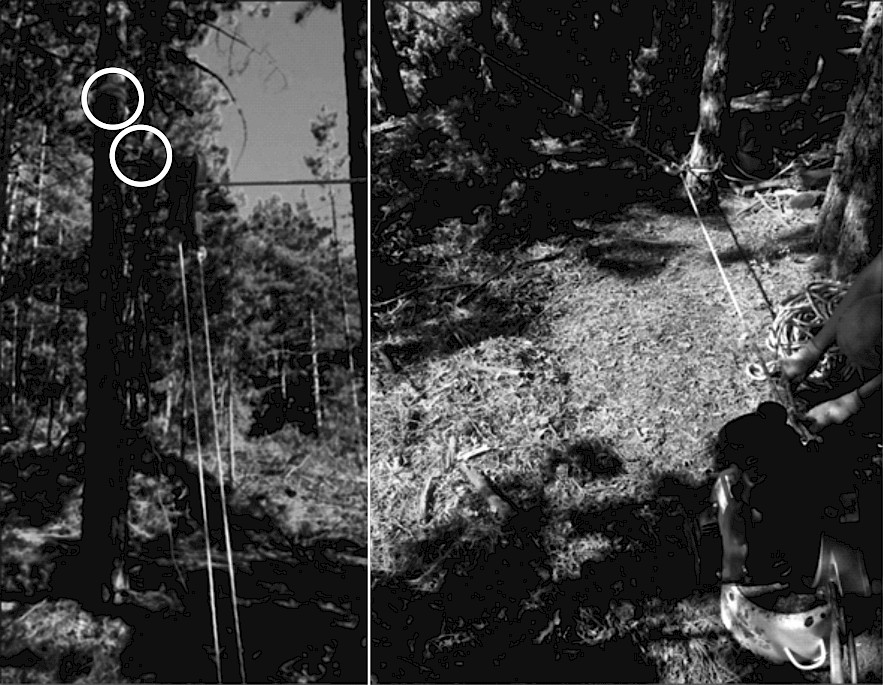

During the timber extraction, first of all, strong and stable trees were selected as tower tree (headspar) at the landing area and a tail tree (tailspar) at the lower station. Secondly, suitable tree anchors were selected and they were tied to the tower tree and tail tree with guylines to secure the cable yarding for safe operation. After the tree selection stage, one of the forestry workers climbed up to the tower tree at the landing, fixed the skyline using synthetic choker and metal locks, and then tied the tower tree with the tree-anchor behind the tower tree in the direction of the cable yarding. This work is the most time consuming, difficult and risky stage during the installation of the cable yarding system. Then, the skyline was mounted to the tower tree with the help of synthetic ropes and locking device, which is used to fix the carriage on the skyline at the landing (Fig. 4). While one end of the mainline was connected to the portable winch, the other end first passed through a direction pulley mounted on the tower tree and through the loading equipment where the hook was attached under the carriage, and then it was fixed to the opposite end of the carriage (Fig. 5).

Fig. 4 Installation of skyline (using synthetic ropes and locking device) (left) and portable winch (right) at landing area

Fig. 5 Mainline fixed to carriage (left) after passing through pulley (middle) and hook (right) direction

After the skyline and mainline installations were completed, the portable winch was mounted on a suitable standing tree or a stump near to the tower tree using a synthetic choker and two hooks on the side of the winch. Then, the other end of the skyline was pulled to the lower station by a worker and mounted to the selected tail tree using the same procedure of installing skyline to the tower tree. In addition, the plastic-stop, which is used to safely stop the carriage descending by gravity down the slope, was mounted on the skyline. A farm tractor was used to tie skyline to the tower tree tightly.

In the work flow of the timber extraction, the first stage started with the movement of the carriage from the mountain-side by gravity and ended when it reached the point where the group of logs to be yarded were placed on the ground. The second stage started when the hook landed on the ground, then the hook was pulled by the worker to the stump, and the stage ended when it reached next to the log to be loaded. Since the loading hook takes a very short time to land on the ground, it was not considered as a separate work stage. Choker-setting of the logs using chokers attached to the hook was the third stage in the cable yarding operation. The fourth stage started as the workers pulled the loaded hook to the carriage, then the carriage was pulled back to the landing area using the portable winch, and the stage ended when the carriage reached the landing area and was fixed on the skyline with the locking device. In the final stage, the hook was lowered to the ground and the log was released from the choker. For each cycle, the time spent on each work stage was recorded by using the chronometer and written in the surveying form (Tunay and Melemez 2005, Acar et al. 2010).

2.4 Productivity Analysis

The productivity of mechanized harvesting equipment is generally determined by using the time study methods. In this study, repeated time measurement, which is one of the most preferred time study methods in precision forestry applications, was used in investigating the productivity of the yarding system (Gülci 2014). In order to prevent time loss between reading and resetting the chronometer, chronometers with multiple screen were used. In addition, other measurement tools such as clinometer, steel tape, and diameter gauge were used. Surveying forms were used in order to record the time measurements for the cable yarding operation. Then, using the time data obtained by time study analysis, the hourly productivity (m3/hour) of the small-scale cable yarding was calculated as follows (Bilici et al. 2019b):

(1)

(1)

Where:

P productivity, m3/hr

V volume per cycle, m3

t cycle time, second.

Productivity analysis was conducted for both the scheduled machine hour (SMH) and productive machine hour (PMH). Productive machine hour does not take into account delay time (Spinelli et al. 2021).

2.5 Statistical Analysis

Time study measurements were carried out in four applications with 30 repetitions, for a total of 120 cycles. The log volume transported in each cycle was evaluated in three classes (low: <0.12 m3, medium: 0.12–0.14 m3, high: >0.14 m3) to investigate the effect of timber volume on productivity. The ranges of the volume classes were determined based on the distribution of the timber volumes transported during the yarding operation. One-Way ANOVA (Analysis of Variance) was applied at the significance level of 0.05 to determine the effects of lateral pulling distance, log volume, and log length factors on productivity of the small-scale cable yarding method. Then, correlation test was used to investigate the relationships between the independent variables (lateral pulling distance, log volume, log length) and productivity of the yarding system. Finally, regression models were developed for each application in order to determine mathematical models for variables that are correlated with productivity. Even though log volume potentially correlates with log length by nature, it is still considered in the regression analysis due to fact that handling of the large size logs is difficult and may require more time.

3. Results

3.1 Productivity Analysis Results

The average time measurement of the work stages for four applications are given in Table 1. In the first application, the average log diameter, length and volume were determined as 22.20 cm, 3.33 m and 0.13 m3, respectively. The results indicated that the average cycle time for PMH, delay time and total working time (SMH) were calculated as 369.90 seconds, 18.43 seconds and 388.33 seconds, respectively. The average productivity of the small-scale cable yarding method was found to be 1.25 m3/hour and 1.20 m3/hour for PMH and SMH, respectively. The overall duration of the time study was 18.19 hours.

Table 1 Average time (second) and STD of work stages for cable yarding applications

|

Work stages |

Application I * |

Application II |

Application III |

Application IV |

||||

|

|

Avr. |

STD |

Avr. |

STD |

Avr. |

STD |

Avr. |

STD |

|

Carriage moving downhill by gravity and reaching loading place |

100.97 |

3.01 |

159.40 |

3.88 |

80.37 |

3.85 |

133.93 |

4.87 |

|

Dropping hook onto ground and pulling it to the logs |

14.37 |

1.79 |

15.53 |

1.78 |

18.43 |

1.41 |

20.10 |

1.88 |

|

Choker-setting of the logs using chokers attached to the hook |

19.80 |

2.21 |

19.67 |

2.20 |

23.50 |

1.96 |

25.47 |

2.21 |

|

Pulling hook back to carriage and pulling loaded carriage uphill back to the landing area |

220.30 |

3.32 |

366.63 |

6.98 |

282.00 |

6.22 |

440.30 |

12.25 |

|

Dropping hook onto ground and pulling hook up to the carriage after releasing the logs |

14.47 |

2.08 |

31.33 |

2.80 |

28.27 |

3.82 |

30.37 |

2.97 |

|

Cycle time |

369.90 |

7.20 |

592.57 |

13.27 |

432.57 |

12.01 |

650.17 |

17.73 |

|

Delay time |

18.43 |

19.29 |

36.93 |

27.15 |

27.90 |

25.41 |

54.40 |

34.41 |

|

Total time |

388.33 |

19.58 |

629.50 |

32.26 |

460.47 |

31.47 |

704.57 |

43.35 |

|

* I) 34–50% slope and 100 m yarding distance; II) 34–50% slope and 200 m yarding distance III) 50–70% slope and 100 m yarding distance; IV) 50–70% slope and 100 m yarding distance |

||||||||

In the second application, the average log diameter, length and volume were determined as 22.07 cm, 3.33 m and 0.13 m3, respectively. The results indicated that the average cycle time for PMH, delay time and total working time (SMH) were calculated as 592.57 seconds, 36.93 seconds and 629.50 seconds, respectively. The average productivity of the small-scale cable yarding method was found to be 0.77 m3/hour and 0.73 m3/hour for PMH and SMH, respectively. In the third application, the average log diameter, length and volume were determined as 22.20 cm, 3.40 m and 0.13 m3, respectively. The results indicated that the average cycle time for PMH, delay time and total working time (SMH) were calculated as 432.57 seconds, 27.90 seconds and 460.47 seconds, respectively. The average productivity of the small-scale cable yarding method was found to be 1.07 m3/hour and 1.01 m3/hour for PMH and SMH, respectively. In the fourth application, the average log diameter, length and volume were determined as 22.10 cm, 3.37 m and 0.13 m3, respectively. The results indicated that the average cycle time for PMH, delay time and total working time (SMH) were calculated as 650.17 seconds, 54.4 seconds and 704.57 seconds, respectively. The average productivity of the small-scale cable yarding method was found to be 0.72 m3/hour and 0.66 m3/hour for PMH and SMH, respectively. The average time allocated for the installation of the small-scale cable yarding was 1.5 hours, while the average dismantling was 45 minutes.

3.2 Statistical Analysis Results

The effect of timber volume on productivity was evaluated based on three volume classes (low: <0.12 m3, medium: 0.12–0.14 m3, high: >0.14 m3). Statistical analysis showed that the productivity values of the volume classes were significantly different (p<0.001). The average productivity for both PMH and SMH changed increasingly from the low volume class to the medium and high volume class (Table 2).

Table 2 Mean productivity (m3/hour) and STD of volume classes in cable yarding applications

|

|

Volume classes |

Application I * |

Application II |

Application III |

Application IV |

||||

|

|

|

Avr. |

STD |

Avr. |

STD |

Avr. |

STD |

Avr. |

STD |

|

Productivity PMH |

Low |

1.03 |

0.058 |

0.64 |

0.039 |

0.90 |

0.046 |

0.60 |

0.041 |

|

|

Medium |

1.26 |

0.053 |

0.78 |

0.032 |

1.08 |

0.015 |

0.72 |

0.721 |

|

|

High |

1.56 |

0.10 |

0.97 |

0.048 |

1.31 |

0.033 |

0.92 |

0.059 |

|

Productivity SMH |

Low |

0.98 |

0.05 |

0.61 |

0.047 |

0.87 |

0.017 |

0.56 |

0.040 |

|

|

Medium |

1.21 |

0.07 |

0.75 |

0.055 |

1.01 |

0.022 |

0.67 |

0.052 |

|

|

High |

1.49 |

0.15 |

0.89 |

0.057 |

1.20 |

0.026 |

0.82 |

0.040 |

|

* I) 34–50% slope and 100 m yarding distance; II) 34–50% slope and 200 m yarding distance III) 50–70% slope and 100 m yarding distance; IV) 50–70% slope and 100 m yarding distance |

|||||||||

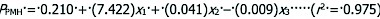

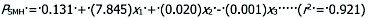

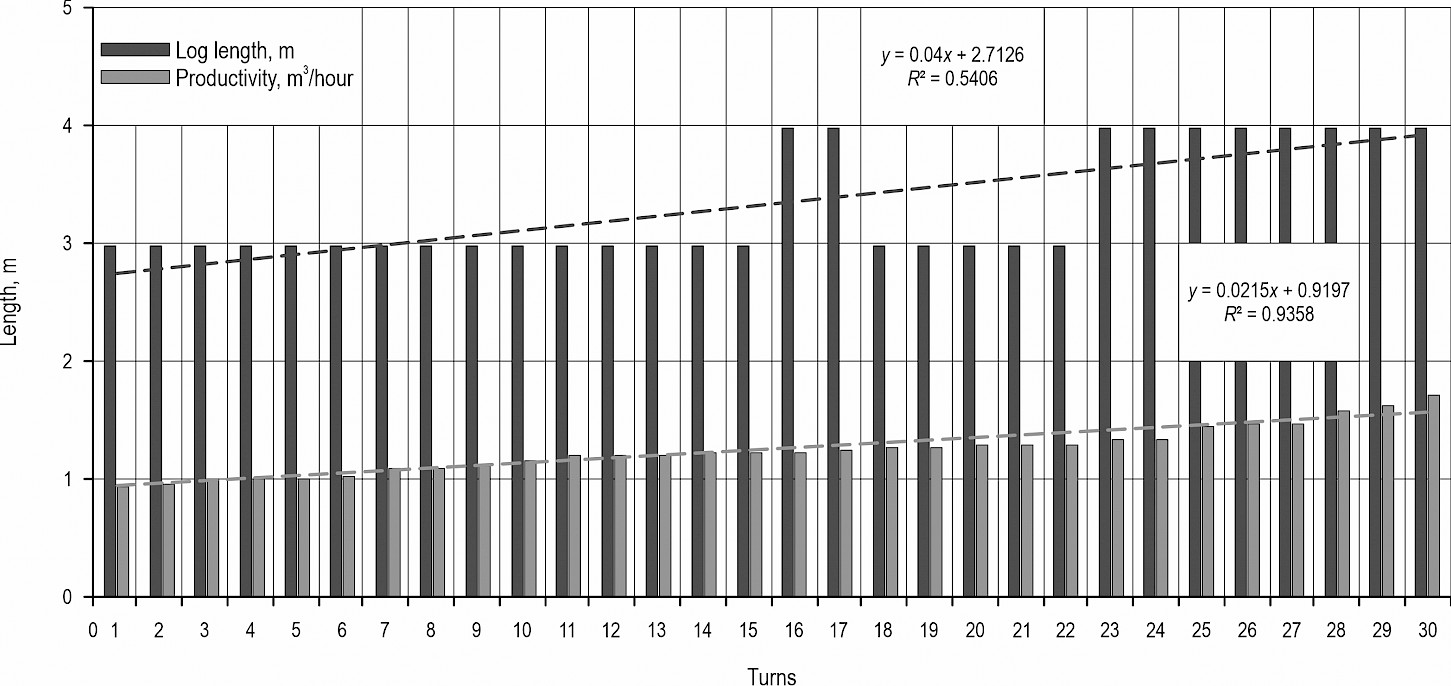

3.2.1 Application I

The relationship between the productivity of the cable yarding method and the independent variables considered in the study (lateral pulling distance, log volume and log length) were tested with the correlation analysis. The results indicated that there was a significant relationship between log volume, log length (p<0.001) and lateral pulling distance (p<0.05) and system productivity. This relationship was found to be positive for volume and length, and negative for lateral pulling distance. The regression model was developed to obtain the mathematical model related to the independent variables that were found to be correlated with the productivity of the cable yarding method. According to the ANOVA test, the model was found to be significant for both PMH and SMH (Table 3). Regression models (PPMH and PSMH) including the dependent variable (y=productivity) and the correlated independent variables (x1=log volume; x2=log length; x3=lateral pulling distance) are given in Eq. 3 and 4. The results showed that the log volume was the factor with the highest impact on productivity.

(3)

(3)

(4)

(4)

Table 3 Summary table of One-Way ANOVA test

|

Model |

Sum of Squares |

df |

Mean Square |

F |

Sig. |

|

|

Productivity PMH |

Regression |

1.085 |

3 |

0.362 |

380.61 |

0.000a |

|

|

Residual |

0.025 |

26 |

0.001 |

– |

– |

|

|

Total |

1.110 |

29 |

– |

– |

– |

|

Productivity SMH |

Regression |

1.070 |

3 |

0.357 |

114.00 |

0.000a |

|

|

Residual |

0.081 |

26 |

0.003 |

– |

– |

|

|

Total |

1.152 |

29 |

– |

– |

– |

|

a. Predictors: (Constant), lateral pulling distance, log volume and log length |

||||||

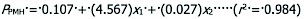

3.2.2 Application II

Correlation analysis showed that there was a significant positive correlation between log volume and log length and system productivity (p<0.001). On the other hand, it was revealed that there was no significant relationship between lateral pulling distance and productivity (p>0.05). Regression model related to the independent variables (x1=log volume; x2=log length) that were correlated with the productivity of the cable yarding method was found to be significant (Table 4). Regression models for both PMH and SMH are given in Eq. 5 and 6, respectively.

(5)

(5)

(6)

(6)

Table 4 Summary table of One-Way ANOVA test

|

Model |

Sum of Squares |

df |

Mean Square |

F |

Sig. |

|

|

Productivity PMH |

Regression |

0.482 |

2 |

0.241 |

885.33 |

0.000a |

|

|

Residual |

0.007 |

27 |

0.000 |

– |

– |

|

|

Total |

0.489 |

29 |

– |

– |

– |

|

Productivity SMH |

Regression |

0.386 |

2 |

0.193 |

196.88 |

0.000a |

|

|

Residual |

0.026 |

27 |

0.001 |

– |

– |

|

|

Total |

0.412 |

29 |

– |

– |

– |

|

a. Predictors: (Constant), log volume and log length |

||||||

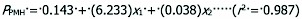

3.2.3 Application III

According to the correlation analysis, there was a significant positive correlation between log volume and log length and system productivity (p<0.001), while there was no significant relationship between lateral pulling distance and productivity (p>0.05). The regression model developed was found to be significant for both PMH and SMH (Table 5). Regression models including dependent variable (y) representing productivity and correlated independent variables (x1=log volume; x2=log length) are given in Eq. 7 and 8.

(7)

(7)

(8)

(8)

Table 5 Summary table of One-Way ANOVA test

|

Model |

Sum of Squares |

df |

Mean Square |

F |

Sig. |

|

|

Productivity PMH |

Regression |

0.807 |

2 |

0.404 |

106.500 |

0.000a |

|

|

Residual |

0.010 |

27 |

0.000 |

– |

– |

|

|

Total |

0.817 |

29 |

– |

– |

|

|

Productivity SMH |

Regression |

0.500 |

2 |

0.250 |

93.635 |

0.000a |

|

|

Residual |

0.072 |

27 |

0.003 |

– |

– |

|

|

Total |

0.572 |

29 |

– |

– |

– |

|

a. Predictors: (Constant), log volume and log length |

||||||

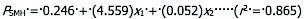

3.2.4 Application IV

Correlation test results indicated that there was a positive significant relationship between log volume and log length and system yield (p<0.001). However, there was no statistically significant relationship between lateral pulling distance and productivity (p>0.05). Regression Model was developed in order to determine the mathematical model related to the variables (log volume and length) that were found to be correlated with productivity. It was found that the model developed for both PMH and SMH was significant (Table 6). Regression models including dependent variable representing productivity (y) and affecting independent variables (x1=log volume; y2=log length) are given in Eq. 9 and 10.

(9)

(9)

(10)

(10)

Table 6 Summary table of One-Way ANOVA test

|

Model |

Sum of Squares |

df |

Mean Square |

F |

Sig. |

|

|

Productivity PMH |

Regression |

0.430 |

2 |

0.215 |

957.502 |

0.000a |

|

|

Residual |

0.006 |

27 |

0.000 |

– |

– |

|

|

Total |

0.436 |

29 |

– |

– |

– |

|

Productivity SMH |

Regression |

0.299 |

2 |

0.150 |

149.970 |

0.000a |

|

|

Residual |

0.027 |

27 |

0.001 |

– |

– |

|

|

Total |

0.326 |

29 |

– |

– |

– |

|

a. Predictors: (Constant), log volume and log length |

||||||

4. Discussion

4.1 Time Studies

The average time consumption of the work stages according to the PMH for small-scale cable yarding applications are given in Table 7. Pulling hook back to carriage and pulling loaded carriage uphill back to the landing area was the most time-consuming work stage in all four applications. The second most time-consuming work stage was carriage moving downhill by gravity and reaching loading place. In a similar study conducted by Acar (2017), it was noted that pulling loaded carriage up to the landing area over the small-scale cable yarding method was the most time-consuming work stage, followed by moving carriage downhill by gravity. When the effect of ground slope on the most time consuming work stage is examined, it was found that as the slope increased the time to pull up the logs increased, while the time of moving carriage downhill decreased.

Table 7 Average time consumption of work stages for four applications with respect to PMH

|

Work stages |

Slope of 34–50% |

Slope of 50–70% |

||

|

|

100 m |

200 m |

100 m |

200 m |

|

Carriage moving downhill by gravity and reaching loading place |

27.30 |

26.90 |

18.58 |

20.60 |

|

Dropping hook onto ground and pulling it to the logs |

3.88 |

2.62 |

4.26 |

3.09 |

|

Choker-setting of the logs using chokers attached to the hook |

5.35 |

3.32 |

5.43 |

3.92 |

|

Pulling hook back to carriage and pulling loaded carriage uphill back to the landing area |

59.56 |

61.87 |

65.19 |

67.72 |

|

Dropping hook onto ground and pulling hook up to the carriage after unloading the logs |

3.91 |

5.29 |

6.53 |

4.67 |

|

Total |

100 |

100 |

100 |

100 |

Erdaş and Eroğlu (1999), in a study evaluating the short-distance cable yarding method, stated that the ground slope showed a similar relationship with the time of pulling up the loaded carriage and moving unloaded carriage downhill. When the other work stages are examined, it was revealed that all of the work stages, except unloading of the logs on the landing, took more time in parallel with the increase in the slope. When the yarding distance is examined, it was determined that the time of pulling up the loaded carriage increased in direct proportion to the yarding distance. Previous studies analyzing small-scale solutions have also shown that the yarding distance has an effect on the time of pulling the carriage to the landing area (Spinelli et al. 2010, Proto et al. 2016).

In Table 8, the average time consumption of the work stages according to the SMH are given for small-scale cable yarding applications. Delay time due to equipment or personnel reasons has been taken into account during the scheduled machine hour. In the case of SMH, the most time-consuming work stage was again pulling hook back to carriage and pulling loaded carriage uphill back to the landing area, followed by carriage moving downhill by gravity and reaching loading place.

Table 8 Average time consumption of work stages for four applications with respect to SMH

|

Work stages |

Slope of 34–50% |

Slope of 50–70% |

||

|

|

100 m |

200 m |

100 m |

200 m |

|

Carriage moving downhill by gravity and reaching loading place |

26.00 |

25.32 |

17.45 |

19.01 |

|

Dropping hook onto ground and pulling it to the logs |

3.70 |

2.47 |

4.00 |

2.85 |

|

Choker-setting of the logs using chokers attached to the hook |

5.10 |

3.12 |

5.10 |

3.61 |

|

Pulling hook back to carriage and pulling loaded carriage uphill back to the landing area |

56.73 |

58.24 |

61.24 |

62.49 |

|

Dropping hook onto ground and pulling hook up to the carriage after unloading the logs |

3.73 |

4.98 |

6.14 |

4.31 |

|

Delay time |

4.75 |

5.87 |

6.06 |

7.72 |

|

Total |

100 |

100 |

100 |

100 |

For the case of PMH, it was found that the time to pull up the logs increased while the time of moving carriage downhill decreased as the slope increased similar to the case of SMH. In the applications where the pulling distance was 200 m, it was found that the duration of the work stages increased as the slope increased, except for the unloading of the logs on the landing and the choker-setting of the products to the hook in the application where the yarding distance was 100 m. It was determined that, as the ground slope increases, the delay time increases in cable yarding applications. Lee et al. (2018) reported that the increase in slope increased the delay time in the small-scale cable yarding method. Also, when considering two yarding distances in the same slope group, the delay time was higher in the longer yarding distance due to the greater likelihood of snagging.

The results indicated that the average time spent for the installation and dismantling of the small-scale cable yarding integrated with portable winch and synthetic rope was 1.5 hours and 45 minutes, respectively. This time was much shorter than the time allocated for the installation (3–5 hours) and dismantling (1–2 hours) of short-distance cable yarding method (Erdaş and Eroğlu 1999). Lee et al. (2018) stated that the total time allocated for installation and dismantling a small-scale cable yarding in the uphill cable yarding was approximately 3.5 hours. In a similar study conducted by Acar (2017), it was reported that the installation of the small-scale cable yarding took an average of 2.5 hours and dismantling took one hour. Within the scope of this study, the main reason for the installation and dismantling of the cable yarding method to take significantly less time is the use of a portable winch, a relatively light carriage (40 kg) and synthetic ropes. On the other hand, factors such as the synthetic rope being less resistant to difficult terrain conditions and the limited load capacity of the portable winch and the carriage should be taken into account in the planning, installation and implementation of the system.

4.2 Productivity

The average productivity of the small-scale cable yarding method considering four applications was determined as 0.95 m3/hour and 0.90 m3/hour for PMH and SMH, respectively. The productivity value was found to be 5.83% higher in PMH, where delay time was not taken into account. Spinelli et al. (2010) evaluated the productivity of a small-scale cable yarding method where the average slope was 60%, the yarding distance was 118 m and log volume was 0.202 m3. They reported that the productivity of the yarding system integrated with tractor winch was found to be 2.42 m3/hour and 1.52 m3/hour for the PMH and SMH, respectively. Among the reasons for this relatively high productivity could be the higher log volume to be transported and the integration of the system with the tractor winch. In another cable yarding application, which was operated with tractor power with a yarding distance of 140 m and an average timber volume of 0.287 m3, it was found that the average productivity was 3.05 m3/hour (Acar 2017).

The results showed that the productivity value was higher for the applications with shorter yarding distances when installation and removal of the cable yarding is not considered. In a study where the productivity of four small-scale cable yarding methods was examined by Cho et al. (2018), it was found that the application with shorter yarding distance had higher productivity when the average slope was the same. On the other hand, it was determined that there was a negative correlation between the ground slope and the productivity of the cable yarding method when the yarding distance was constant. Spinelli et al. (2010), examining the effect of land profile on cable yarding efficiency, reported that concave land structure was more preferable than convex land structure. In another study conducted by Erdaş and Eroğlu (1999) comparing two cable yarding method with similar ground slope, it was found that the productivity was higher in the system with the short yarding distance.

When the productivity of cable yarding applications was compared, it was revealed that the productivity was below the average productivity in the low volume class for four applications, while it was above the average productivity value in the high volume class. In a similar study evaluating the small-scale cable yarding, it was determined that the increase in the volume of forest product transported in a cycle increased the productivity when the other factors were similar or the same (Cho et al. 2018) (Fig. 6).

Fig. 6 Relationship between log volume and productivity of cable yarding method

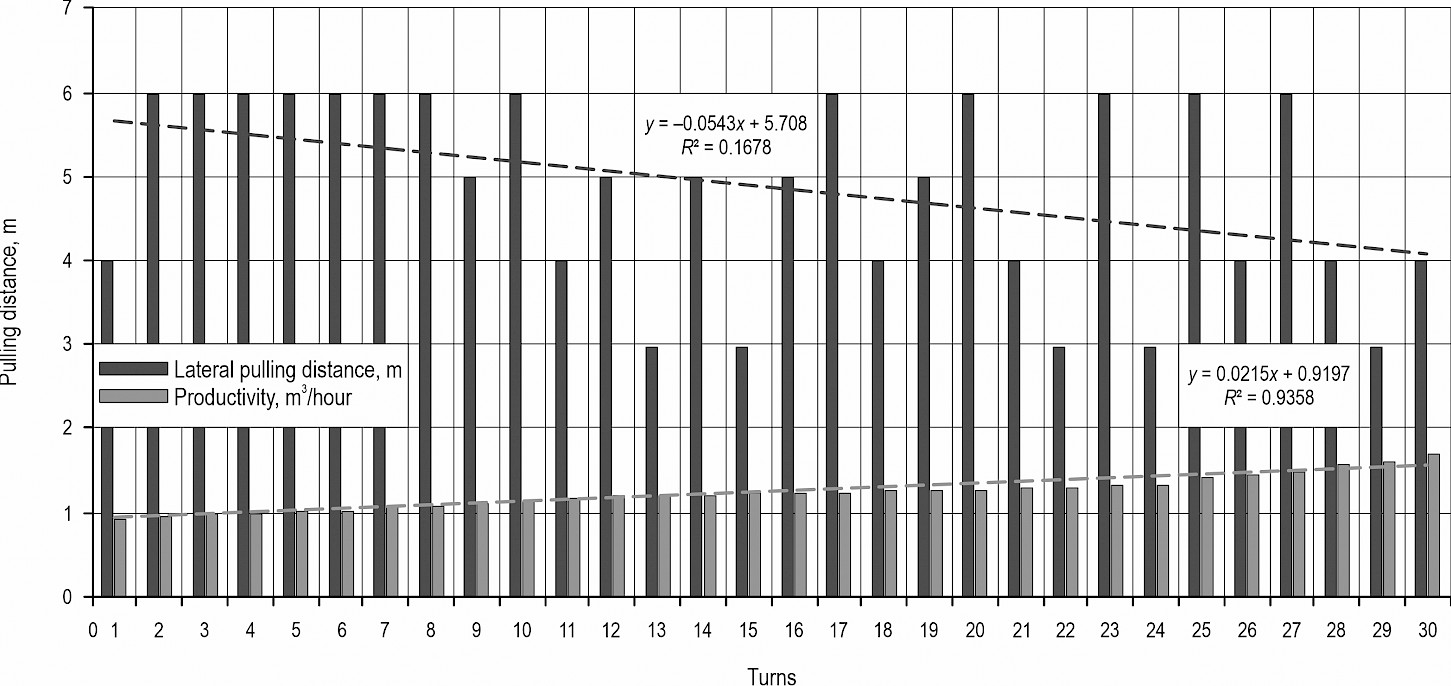

In the study, the effect of log length and lateral pulling distance on productivity of small-scale cable yarding method was also examined. The results indicated a positive relationship between log length and productivity. The relationship between lateral pulling distance and productivity in three applications (i.e. II, III, IV) was not significant presumably due to shorter lateral pulling distance (30 m), while there was still a slight relationship in negative way (Fig. 7, Fig. 8). In a study conducted in mountain forests, Spinelli et al. (2015) reported that the productivity of the cable yarding method increased depending on the size of the logs transported. Erdaş and Eroğlu (1999) stated that productivity decreased in a short-distance cable yarding method when the lateral pulling distance increased. It was revealed that the total time taken to pull the hook to the point where the logs are located and pull the hook back to the carriage after the loading, where the lateral pulling distance is effective, is the most time-consuming stage in a cycle.

Fig. 7 Relationship between log length and productivity of cable yarding method

Fig. 8 Relationship between lateral pulling distance and productivity of cable yarding method

5. Conclusions

The cable yarding is the most preferred logging method in mountainous forest areas as it is suitable for steep terrains (Stampfer et al. 2006). Besides, cable yarding is cost effective and it results in low damage to the residual trees and forest soil properties compared with other logging methods (Spinelli et al. 2017, Schweier et al. 2020). In the study, the productivity of the small-scale cable yarding method equipped with portable winch and synthetic rope was evaluated in two slope classes (34–50%, 50–70%) and two yarding distances (100 m and 200 m). According to the results of the time study analysis, it was observed that the most time-consuming work stage in all four applications was pulling hook back to carriage and pulling loaded carriage uphill back to the landing area, followed by the stage of moving carriage downhill by gravity and reaching loading place. It was found that the installation and dismantling time of the small-scale cable yarding method using portable winch and synthetic rope took less time compared to other small-scale yarding methods equipped with tractor winch and steel rope. In addition, it was observed that the delay time had an effect on the total cycle time for the case of SMH.

The productivity analysis results indicated that the productivity of the cable yarding method decreased due to the increase in the yarding distance and ground slope. In the study, it was found that there was a positive significant relationship between the volumes and lengths of the transported logs and the productivity of the cable yarding method. On the other hand, while there was a negative correlation between lateral pulling distance and productivity, it was observed that this relation was statistically significant only in the first application (34–50% slope and 100 m yarding distance). Considering the work stages, it was revealed that the most effective stage on the productivity was pulling up the loaded carriage to the landing, followed by moving unloaded carriage downhill. The lateral pulling time, which increased depending on the lateral pulling distance, also slightly affects the productivity of the cable yarding method in a negative way.

In the installation of the small-scale cable yarding method, installation of the skyline and mainline to the selected tower tree and tail tree by a forest worker climbing up the trees took the highest time. This work can be considered as the riskiest task in terms of occupational health and safety during the installation and operation of the cable yarding method. Thus, experienced workers should perform this task and necessary occupational safety measures should be taken. It should be ensured that the skyline is as tight as possible during the installation. As in this study, if synthetic ropes are used, static synthetic ropes with very low deflection should be preferred. The tension of the skyline will contribute to the unloaded carriage to go down the slope faster, and will also reduce the lost time due to snagging both during lateral pulling and pulling up the loaded wagon to the landing. Although synthetic rope contributes positively to the light and economical nature of the small-scale cable yarding method, the effective usage time is lower and the risk of deformation is much higher compared to steel ropes. Considering these disadvantages, direction pulleys and metal hooks should be used where necessary to prevent the contact of the tree stems or branches with synthetic rope. In order for the unloaded carriage to reach the loading point down the slope quickly and in a controlled manner, the mainline to which the carriage is connected must be twisted into the drum of the portable winch for a few turns. In order to stop the carriage at the nearest place at the loading point, it will be beneficial to carry the plastic-stop used in the lower station to the appropriate place on the skyline. After the wagon is stopped close to the logs to be loaded, the hook should be expected to completely drop to the ground and then the hook should be pulled next to the logs. Since pulling the hook to the logs to be transported and back to carriage are time consuming tasks, it would be appropriate to skid the logs to the cable yarding corridor after tree felling. Ideally, in the harvesting units where the cable yarding method will be used, the felling order should be planned by considering the previously determined cable yarding corridors.

Acknowledgments

This work was supported by the Scientific and Technological Research Council of Turkey (TUBITAK) under Grant 119O013.

6. References

Acar, H.H., Ünver, S., Özkaya, M.S., 2010: Investigation on efficiency of the harvesting machineries at Artvin Regional Directorate of Forestry. Artvin Çoruh University Faculty of Forestry Journal 11(2): 12–19.

Acar, H.H., 2017: Development of the small yarder system (AcarMHH300) for logging from forest stands. Turkish Journal of Forestry 18(3): 226–231. https://doi.org/10.18182/tjf.305369

Akay, A.E., Sert, M., Gülci, N., 2014: Evaluating productivity of mobile winch system used in logging operation on gentle ground slope. 2nd National Forest and Environment Symposium, 22–24 October, Isparta, Turkey, 22–24 p.

Bilici, E., Andiç, V.G., Akay, A.E., Sessions, J., 2019a: Productivity of a portable winch system used in salvage logging of storm-damaged timber. Croatian Journal of Forest Engineering 40(2): 311–318. https://doi.org/10.5552/crojfe.2019.590

Bilici, E., Akay, A.E., Abbas, D., 2019b: Assessing the effects of site factors on the productivity of a feller buncher: a time and motion analysis. Journal of Forestry Research 30: 1471–1478. https://doi.org/10.1007/s11676-018-0696-4

Cântar, I.-C., Ciontu, C.-I., Dinc ˘a, L., Borlea, G.F., Cri¸san, V.E., 2022: Damage and Tolerability Thresholds for Remaining Trees after Timber Harvesting: A Case Study from Southwest Romania. Diversity 14(3): 193. https://doi.org/10.3390/d14030193

Cho, M., Cho, K., Choi, B., Cha, D., 2018: Yarding productivity of tree-length harvesting using a small cable-yarder in steep slope, South Korea. Forest Science and Technology 14(3): 132–137. https://doi.org/10.1080/21580103.2018.1478887

Erdaş, O., Eroğlu, H., 1999: Technical and Economical Analysis of Short Distance Koller K 300 Yarder Used for the Extraction of Timber in Artvin Region. Turkish Journal of Agriculture and Forestry 23(11): 1249–1256.

Gülci, N., 2014: Researches on precision forestry in forest planning. Dissertation, Kahramanmaraş Sütçü İmam University, Kahramanmaraş, 264 p.

Gülci, N., Akay, A.E., Erdaş, O., Wing, M.G., Sessions, J., 2015: Planning optimum logging operations through precision forestry approaches. European Journal of Forest Engineering 1(2): 56–60.

Gülci, N., Yüksel, K., Akay, A.E., 2017: Productivity assessment of portable hand winch based skidding operation on snow cover. Kastamonu University Faculty of Forestry Journal 17(1): 124–131. https://doi.org/10.17475/kastorman.296910

Gümüş, S., Acar, H.H., 2010: Evaluation of consecutive skylines yarding and gravity skidding systems in primary forest transportation on steep terrain. Journal of Environmental Biology 31(1): 213–218.

Kent, T., Kofman, P.D., Coates, E., 2011: Harvesting wood for energy: Cost-effective woodfuel supply chains in Irish forestry. Dublin, Coford, 96 p.

Kizha, A.R., Nahor, E., Coogen, N., Louis, L.T., George, A.K., 2021: Residual Stand Damage under Different Harvesting Methods and Mitigation Strategies. Sustainability 13(14): 7641. https://doi.org/10.3390/su13147641

Lee, E., Im, S., Han, S.K., 2018: Productivity and cost of a small-scale cable yarder in an uphill and downhill area: a case study in South Korea. Forest Science and Technology 14(1): 16–22. https://doi.org/10.1080/21580103.2017.1409662

Maxwald, 2020: https://www.maxwald.eu/app/download/17627227/12seiter+GB.pdf. Accesed: 02 April 2021

Marčeta, D., Košir, B., 2016: Comparison of Two Felling & Processing Methods in Beech Forests. Croatian Journal of Forest Engineering 37(1): 163–174.

Picchio, R., Mederski, P.S., Tavankar, F., 2020: How and How Much, Do Harvesting Activities Affect Forest Soil, Regeneration and Stands? Current forestry reports 6(2): 115–128. https://doi.org/10.1007/s40725-020-00113-8

Proto, A.R., Skoupy, A., Macri, G., Zimbalatti, G., 2016: Time consumption and productivity of a medium size mobile tower yarder in downhill and uphill configurations: a case study in Czech Republic. Journal of Agricultural Engineering 47(4): 216–221. https://doi.org/10.4081/jae.2016.551

Raymond, K., 2014: New harvesting technology for a safer future – Challenges of harvesting steep land. New Zealand Tree Grower 35(4): 3–6.

Rickenbach, M., Steele, T., 2006: Logging firms, nonindustrial private forests, and forest parcelization: evidence of firm specialization and its impact on sustainable timber supply. Canadian Journal of Forest Research 36(1): 186–194. https://doi.org/10.1139/x05-238

Russell, F., Mortimer, D., 2005: A review of small-scale harvesting systems in use worldwide and their potential application in Irish forestry. Dublin, Coford, 48 p.

Schweier, J., Klein, M.L., Kirsten, H., Jaeger, D., Brieger, E., Sauter, U.H., 2020: Productivity and cost analysis of tower yarder systems using the Koller 507 and the Valentini 400 in southwest Germany. International Journal of Forest Engineering 31(3): 172–183. https://doi.org/10.1080/14942119.2020.1761746

Sennblad, G., 1993: Eurofortech Thinning Harvesting and Extraction (Small-scale Technology).

Spinelli, R, Visser, R., 2008: Analyzing and Estimating Delays in Harvester Operations. International Journal of Forest Engineering 19(1): 36–41. https://doi.org/10.1080/14942119.2008.10702558

Spinelli, R., Magagnotti, N., Lombardini, C., 2010: Performance, capability and costs of smallscale cable yarding technology. Small-scale Forestry 9: 123–135. https://doi.org/10.1007/s11842-009-9106-2

Spinelli, R., Magagnotti, N., 2012: Wood Extraction with Farm Tractor and Sulky: Estimating Productivity, Cost and Energy Consumption. Small-scale Forestry 11: 73–85. https://doi.org/10.1007/s11842-011-9169-8

Spinelli, R., Maganotti, N., Visser, R., 2015: Productivity Models for Cable Yarding in Alpine Forests. European Journal of Forest Engineering 1(1): 9–14.

Spinelli, R., Marchi, E., Visser, R., Harrill, H., Gallo, R., Cambi, M., Neri, F., Lombardini, C., Magagnotti, N., 2017: The effect of carriage type on yarding productivity and cost. International Journal of Forest Engineering 28(1): 34–41. https://doi.org/10.1080/14942119.2016.1267970

Spinelli, R., Magagnotti, N., Assirelli, A., Martins, J.P., Mihelič, M., 2021: A Long-term follow-up study of slash bundling in fast-growing Eucalypt plantations. Forests 12(11): 1548. https://doi.org/10.3390/f12111548

Stampfer, K., Visser, R., Kanzian, C., 2006: Cable corridor installation times for European yarders. International Journal of Forest Engineering 17(2): 71–77. https://doi.org/10.1080/14942119.2006.10702536

Stanczykiewicz, A., Szewczyk, G., Kulak, D., 2015: Damage to advance growth resulting from timber harvesting during final cuttings. Baltic Forestry 21: 144–151.

Tunay, M., Melemez, K., 2005: A research on harvesting operations which are made with power-saw. Journal of the Faculty of Forestry Istanbul University 55(2): 31–41.

Yu, A., Gallagher, T., Mitchell, D., O'Neal, B., 2016: Application of a smallscale equipment system for biomass harvesting. Small-scale Forestry 16(1): 133–146. https://doi.org/10.1007/s11842-016-9347-9

© 2023 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Prof. Abdullah E. Akay, PhD *

e-mail: abdullah.akay@btu.edu.tr

Adil Başaran, MSc

e-mail: adilbasara@ogm.gov.tr

Bursa Technical University

Faculty of Forestry

Department of Forest Engineering

16310 Bursa

TURKEY

Prof. Selçuk Gümüş, PhD

e-mail: sgumus@ktu.edu.tr

Karadeniz Technical University

Faculty of Forestry

Department of Forest Engineering

61080 Trabzon

TURKEY

* Corresponding author

Received: December 04, 2021

Accepted: April 23, 2023

Original scientific paper