Effect of Season and Machine Type on Performance of Semi- and Fully Mechanized Harvesting Systems in Beech-Dominated Stands

doi: 10.5552/crojfe.2024.2281

volume: 45, issue: 2

pp: 13

- Author(s):

-

- Labelle Eric R.

- Borchert Herbert

- Aurenhammer Peter K.

- Breinig Lorenz

- Spinelli Raffaele

- Magagnotti Natascia

- Article category:

- Original scientific paper

- Keywords:

- hardwood, productivity, CTL, tracked harvester, wheeled harvester, time study, efficiency

Abstract

HTML

It is common to have large trees in mature hardwood-dominated stands. This is especially true for European beech (Fagus sylvatica L.), which can also have a complex architecture. Such trees have predominantly been harvested using motor-manual operations. However, in an effort to increase occupational safety and allow for a more continuous wood flow to processing facilities, fully-mechanized systems are also being employed more frequently. This study was established to determine the effect of season (Fall or Winter) and harvester type (wheeled or tracked) on the performance of semi- and fully- mechanized harvesting systems deployed in beech-dominated stands. Time-and-motion analysis was conducted on a total of 927 trees located in two forest sites in Germany. The study indicated that new silvicultural prescriptions make it impossible to harvest all trees exclusively with mechanized systems, even in the case of the tracked harvester with its 14.5 m boom. Motor-manual intervention was needed with trees that were too large, malformed or out of reach. Motor-manual intervention was significantly more frequent for the wheeled (30%) than for the tracked harvester (18%). Once again, tree size had the strongest effect on time consumption in a linear model, which varied from 0.5 to over 6 min per tree. Season and machine effect were also significant but could only account for a small fraction of the total variability. For the same tree size, time consumption was higher with the wheeled harvester and during the fall. The model also indicated a significant relationship between tree form and time consumption, even though the explanatory contribution of this independent variable was relatively small, too. Good stem form resulted in a lower time consumption. The larger tracked harvester was generally more efficient, but also more expensive to own and operate: its higher costs must be weighed against the higher revenues. New silvicultural trends make it difficult to achieve full mechanization, but the results of this study may guide managers towards technical solutions that minimize motor-manual intervention to the advantage of higher productivity and better occupational safety.

Effect of Season and Machine Type on Performance of Semi- and Fully Mechanized Harvesting Systems in Beech-Dominated Stands

Eric R. Labelle, Herbert Borchert, Peter K. Aurenhammer, Lorenz Breinig, Raffaele Spinelli, Natascia Magagnotti

Abstract

It is common to have large trees in mature hardwood-dominated stands. This is especially true for European beech (Fagus sylvatica L.), which can also have a complex architecture. Such trees have predominantly been harvested using motor-manual operations. However, in an effort to increase occupational safety and allow for a more continuous wood flow to processing facilities, fully-mechanized systems are also being employed more frequently. This study was established to determine the effect of season (Fall or Winter) and harvester type (wheeled or tracked) on the performance of semi- and fully- mechanized harvesting systems deployed in beech-dominated stands. Time-and-motion analysis was conducted on a total of 927 trees located in two forest sites in Germany. The study indicated that new silvicultural prescriptions make it impossible to harvest all trees exclusively with mechanized systems, even in the case of the tracked harvester with its 14.5 m boom. Motor-manual intervention was needed with trees that were too large, malformed or out of reach. Motor-manual intervention was significantly more frequent for the wheeled (30%) than for the tracked harvester (18%). Once again, tree size had the strongest effect on time consumption in a linear model, which varied from 0.5 to over 6 min per tree. Season and machine effect were also significant but could only account for a small fraction of the total variability. For the same tree size, time consumption was higher with the wheeled harvester and during the fall. The model also indicated a significant relationship between tree form and time consumption, even though the explanatory contribution of this independent variable was relatively small, too. Good stem form resulted in a lower time consumption. The larger tracked harvester was generally more efficient, but also more expensive to own and operate: its higher costs must be weighed against the higher revenues. New silvicultural trends make it difficult to achieve full mechanization, but the results of this study may guide managers towards technical solutions that minimize motor-manual intervention to the advantage of higher productivity and better occupational safety.

Keywords: hardwood, productivity, CTL, tracked harvester, wheeled harvester, time study, efficiency

1. Introduction

In coniferous stands, fully-mechanized timber harvesting has been established as a standard working method for decades. In this field, the market offers adapted machine technology for almost all tree species and sizes, thus enabling an economic and safe work process. However, a significant increase in the proportion of hardwoods is required to improve the resilience of European forests to the effects of climate change (Pretzsch et al. 2020). In addition, the effective use of hardwood stands is now seen as a way of responding to the high price fluctuations in the softwood sector. Hardwood accounted for 27% of the wood harvested in Germany in 2013 (BMEL 2014). Moreover, beech (Fagus sylvatica L.) is the most important deciduous tree species in Germany, with a share of almost 17% of the total national forest stock (BMEL 2012). Unfortunately, the mechanized processing of hardwoods is more difficult compared to softwoods. With a few exceptions (e.g., alder (Alnus spp)), hardwoods have a sympodial growth: a distinct bole section is usually formed only in the lower portion and does not extend in a straight form to the top of the tree, but often forms a multitude of bends and thick branches (Millet 2016). As a consequence, quality differentiation is more pronounced in hardwoods than in softwoods. Conversely, when grading hardwood assortments, almost no mass assortments are encountered. These factors combine in making mechanical processing very difficult. As a matter of fact, most harvesting heads available on the market are designed for processing softwood trees and quickly reach their limits when used in hardwoods (Labelle et al. 2018, Bennemann et al. 2023). Several studies have demonstrated that complex stem form (e. g. sweeps or forks) and heavy branching result in a sharp drop of harvester productivity (Suchomel et al. 2012, Labelle et al. 2016). Moreover, quality grading of hardwoods remains a challenge, which is much more complicated than for softwoods. This is evident from the specifications of the grading rules for logs in Germany (DFWR and DHWR 2015). Some of the assessment characteristics simply cannot be assessed from the operator's viewpoint inside the harvester cabin.

Hardwood felling is therefore mostly done with motor-manual methods. However, occupational safety requires at least a partial shift towards fully-mechanized harvesting. That is made the more urgent by nature conservation prescriptions that require retaining an even larger number of habitat trees and standing deadwood. Their presence greatly increases the risk of accidents caused by falling branches during motor-manual felling. Furthermore, extreme weather conditions and the effects of climate change have increased the presence of dead crowns or branches, which pose a significant threat to manual loggers. Winch-assisted motor-manual felling and remote-controlled felling devices can improve work safety during motor-manual timber harvesting, but they cannot entirely remove all risk.

Recently, increased hazard is being caused by an expanding hardwood felling season. Triggered by a growing demand for hardwood logs, operators are no longer tackling hardwoods in winter only, but they start the harvest in the autumn or even in the late summer (Gößwein et al. 2019). When trees are still in leaf, the view into the crowns is obstructed by foliage, and hazards are more difficult to detect.

Therefore, it is urgent to evaluate the potential for expanding mechanized harvesting to hardwood operations. That is the best way to assure a steady raw material supply to the wood industries without putting the scarce workforce in harm's way. In Germany, one major limit to full mechanization is the requirement by some authorities or certification schemes that the distance between machine operating trails may not be shorter than at least 30 or, more often, 40 meters, which makes it very difficult to reach all trees with a standard boom – the more so when trees are especially large and heavy. For that reason, some manufacturers offer larger tracked-based harvesters, equipped with especially long and powerful booms.

The present experiment is the first comprehensive field-test of the main mechanized harvesting alternatives (conventional wheeled harvester vs. heavy tracked harvester) for beech dominated stands under leaves-on and leaves-off conditions. Specifically, the experiment was designed to address the following research objectives:

determine what is the proportion of motor-manual assistance in the selection cut of a mixed hardwood (beech) forest in Germany, and examine whether that proportion changes with season of harvesting and/or harvester type

assess if trees needing motor-manual assistance present specific characteristics that make them different from trees that can be cut entirely mechanically

develop a model for predicting the probability that a given tree cannot be managed entirely mechanically and will need motor-manual assistance; and

quantify the effect of season and machine type on the performance of harvesters when trees are felled and processed entirely mechanically.

2. Materials and Methods

2.1 Experimental Design and Site Description

A factorial split-plot design was chosen to assess the effect of harvesting season (leaves-on or leaves-off) and harvester type (conventional wheeled or heavy tracked) on harvesting productivity and product recovery. Two test sites were selected in the Hammelburg and Kelheim forest districts of the Bavarian State Forest Enterprise, Germany. Each test site was divided into two plots thus permitting to harvest approx. half of the volume with the leaves on and half with the leaves off (conventionally named as »Fall« and »Winter«, respectively). The Hammelburg site was harvested with a conventional wheeled harvester and the Kelheim site with a heavy tracked harvester. Loggers were deployed at both sites to assist with the felling and processing of the trees that could not be treated entirely mechanically for various reasons (out of reach, too large, too malformed, etc.).

2.1.1 Hammelburg Forest District

The Hammelburg forest district is located in the Main-Spessart administrative district. The test stand is at an altitude of 370–450 m above sea level; mean annual precipitation is 640 mm and mean annual temperature is 9.5 °C. Upper red sandstone forms the geological bedrock. The soil is a clayey sand. The entire test site is located on a slope of about 17–23%, on the southeast and northeast faces for the fall and winter treatment plots, respectively. Fall and winter operations were carried out in September 2018 and March 2019, respectively. According to the data from the nearest weather station, the air temperature during the operation averaged 10.8 °C in the fall and 7.4 °C in the winter. The sum of precipitation during the operation in the fall was 1.1 mm and 2 mm in the winter. The harvest site had a total area of 32 ha, with 14 ha being harvesting in the fall and the remainder in the winter. The position (entrance point) of each machine operating trail was recorded using a Juniper Allegro 2 GNSS device and identified by painting a letter on a tree adjacent to the trail. Spacing between adjacent machine operating trails varied within a broad range. Sometimes trails ran towards each other and joined at the forest road; in other places, distances of up to 110 m were measured. The average distances were estimated at 38 m in the fall treatment and 34 m in the winter treatment.

2.1.2 Kelheim Forest District

The Kelheim stand is located at an altitude of 400–470 m above sea level, with a mean annual precipitation of 640 mm, and a mean annual temperature of 8.8 °C. The bedrock is white Jurassic in the form of marl, limestone, and dolomite. The soil is a calcareous weathered clay. In some areas, the soil is a loam derived from aeolian silt deposit. The experimental site is situated in a large flat location. Fall felling was carried out in October 2019 and winter felling in February 2020. The mean temperature during the operation was 12.5 °C in the fall and 3.3 °C in the winter. The sum of precipitation during the operation in the fall was 5.7 mm and 10.7 mm in the winter. This test site also had a size of 32 ha, of which 15 ha were worked in the fall and 17 ha in the winter. The distance between machine operating trails remained variable with an average distance of 35 m in the fall treatment and 34 m in the winter treatment.

2.2 Tree Inventory

All deciduous trees selected and marked for removal by the district forest manager were inventoried: researchers noted the species, diameter at breast height (DBH), height and form of each tree. DBH was obtained with a caliper by averaging two perpendicular diameter measurements at a height of 1.3 m above ground (cm accuracy), whereas total tree heights were recorded with a Haglöf Vertex device (meter accuracy). Tree form was visually assessed as good or poor, separately for each of three vertical segments constituting the estimated merchantable height of a tree: bottom third, middle third, top third (Labelle et al. 2017). Any form characteristics (large branch, fork, elbow, severe sweep) deemed to potentially increase processing time meant that a segment was coded as poor. A numeric code composed of three numbers (one number per segment) was thus given to each inventoried tree with 0 for good and 1 as poor. As an example, a tree exhibiting a good form in the first »bottom« segment and poor form in the second and third segments on the vertical axis would be recorded as 011. Once all information was collected, a unique alpha-numeric code (letter referring to machine operating trail and number for tree identification) was painted at a height of 2 to 3 m on each removal tree, e. g. the first tree measured at trial »A« was identified as »A1«. The codes were oriented at about a 45-degree angle to the machine operating trail to facilitate visibility by the operator and the researcher performing the time-and-motion study.

2.3 Machines and Operating Procedure

Both test sites were subjected to semi-mechanized harvesting by applying a combination of harvester and motor-manual work. In Hammelburg, the harvester was a 6-wheeled Rottne H20 harvester equipped with a Rottne EGS 700 harvesting head. The Rottne had a modified 14 m telescopic boom and weighed 23 tons. In Kelheim, the harvester was a tracked Atlas Kern T50, weighing 48 tons. The machine was equipped with 700 mm wide rigid steel tracks and a 14.5 m telescopic boom (Table 1). A Ponsse H8 harvesting head was mounted on the boom tip, which also carried a tree holding clamp designed to keep cut trees upright for improved handling.

Table 1 Harvester specifications

|

Specifications |

Test site |

|

|

Hammelburg |

Kelheim |

|

|

Base machine |

Rottne H20 |

Atlas Kern T50 |

|

Engine |

John Deere, 187 kW |

Deutz, 180 kW |

|

Boom |

Rottne RK 200, modified |

Atlas Kern |

|

Lifting force |

10.7 kN at 10.0 m * |

30 kN at 14.5 m |

|

Boom reach |

14 m, 2 x telescope |

14.5 m, 2 x telescope |

|

Harvesting head |

Rottne EGS 700 |

Ponsse H8 |

|

Maximum felling diameter |

750 mm |

720 mm |

|

Delimbing diameter |

50–700 mm |

50–740 mm |

|

Feed force, feed rate |

27 kN, 4 m/s |

36 kN, 5 m/s |

|

Weight |

23 t |

48 t |

|

* Refers to the lifting force of Rottne H20 conventional boom at its 10 m maximum reach. Unfortunately, there is no information about the lifting force at maximum boom extension |

||

2.4 Data Collection and Analysis

2.4.1 Productivity and Time Studies

To assess all harvesting activities, a detailed time-and-motion study was conducted. Time data was recorded with a hand-held computer running FPInnovations' TS1000 time study software. A harvesting cycle was divided into the work elements presented in Table 2. Tree volume was calculated as solid cubic meters without bark from DBH and tree height on a tree-by-tree basis using the Bdat V1.1 program (Kublin 2002). In addition, the produced logs including pulpwood were measured on the ground with a caliper and measuring tape. The volume of the logs was aggregated to a total log volume for the whole tree. In some cases, not all logs could be identified and the affected trees were excluded from the evaluations in terms of wood volume.

Table 2 Description of work cycle elements used during time-and-motion study

|

Work Element |

Start |

End |

|

Moving |

Wheels or tracks are moving |

Wheels or tracks are stopped, or other elements dominate |

|

Brush |

Harvesting head is used to clean the base of a removal tree from vegetation |

Head is positioned at base of tree and saw is ready to be activated |

|

Felling |

Head is in vertical position and saw is activated |

Tree crown touches the ground or feed rollers are activated |

|

Processing |

Feed rollers are activated with stem in harvesting head |

Tree top is released |

|

Manipulation |

Other boom tasks (e.g., manipulating processed logs, building a brush mat, etc.) |

Other work elements dominate |

|

Operational delays |

Any delay linked to organizational issues lasting more than a few seconds |

Other work elements dominate |

|

Nonoperational delays |

Any delay linked to personal, mechanical, or study design issues lasting more than a few seconds |

Other work elements dominate |

2.5 Statistical Analyses

First, the frequency of motor-manual and mechanized felling was considered. Differences between treatments were tested for significance using the chi-square test. Then, tree characteristics in these groups were compared. The Shapiro-Wilk test was used to test whether a normal distribution was present. If this was not the case, significant differences were tested using the Mann-Whitney-U-test. Logistic regression was used to test which parameters had an influence on whether a tree was felled entirely mechanically or needed motor-manual intervention. Before analyzing harvester performance, we tested again whether there were significant differences in tree characteristics between treatments using the Mann-Whitney-U-test. The effect of various factors on time consumption were explored with the General Linear Model (GLM) technique. The observation unit (replication) was the single tree. Significance level was set at α<0.05. Time consumptions were logarithmically transformed to meet homoscedasticity and normality requirements (Hildt et al. 2020). Cases in which the studentized residuals exceeded three times the standard deviation were excluded as outliers. An antilogarithmic transformation was applied to the estimations of the models. The model logarithmic bias was corrected by 1+RMSE2/2 (Zeng and Tang 2011).

3. Results

3.1 Motor-Manual Intervention in Felling – Frequency

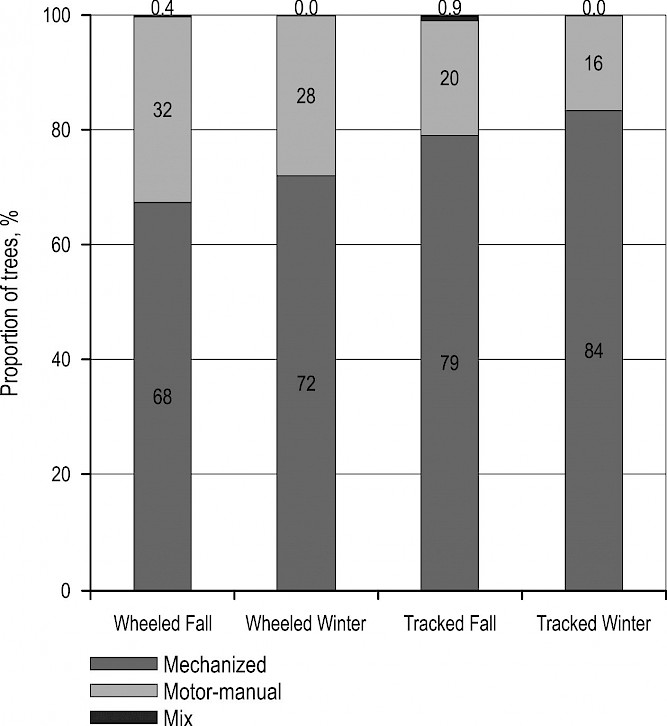

The database contained data for the felling and processing of 927 trees. These were evenly distributed amongst the four treatments (min=24%, max=26%). Between 68% and 84% of the total tree number could be felled entirely by machine, without any motor-manual intervention (Fig. 1). Chi-square testing showed that motor-manual intervention was significantly more frequent for the wheeled harvester than for the tracked one. Motor-manual intervention was also more frequent in the fall than in the winter for both harvester types, but the seasonal difference (p=0.077) was slightly above the selected significance level. Therefore, any inferences in that regard must be considered suggestive, not conclusive. Motor-manual intervention was also more frequent when the trees had a poor form in the upper stem section (p=0.017).

Fig. 1 Proportion of trees felled mechanically vs. motor-manually and a mix of both techniques

3.2 Motor-Manual Intervention in Felling – Determining Factors

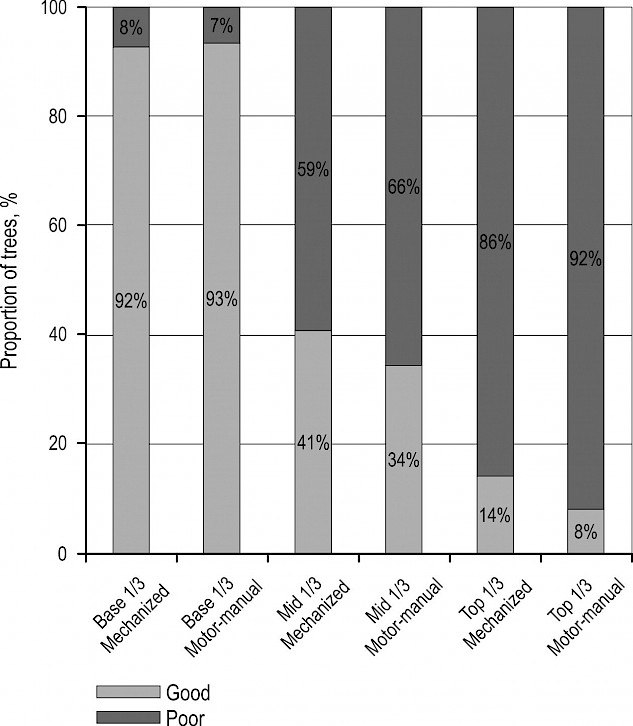

As an average, trees felled entirely mechanically were significantly smaller than trees requiring motor-manual intervention during felling (Table 3). Their girth was 9% narrower, their height was 1% shorter and their total volume was 20% smaller. Furthermore, trees felled motor-manually had a significantly larger proportion of malformed tops (upper 1/3 of total height) (Fig. 2).

Table 3 Comparison of tree characteristics for trees felled with harvester and trees felled by chainsaw operators

|

Motor-manual |

Mechanized |

Shapiro-Wilk |

Mann-Whitney U (Two-sided) |

|||

|

Parameter |

Mean |

Median |

Mean |

Median |

p-Value |

p-Value |

|

DBH, cm |

48.0 |

51 |

43.5 |

45 |

<0.0001 |

<0.0001 |

|

Height (m |

35.3 |

36 |

34.3 |

35 |

<0.0001 |

0.0477 |

|

Tree volume*, m3 |

3.1 |

3.1 |

2.5 |

2.4 |

<0.0001 |

<0.0001 |

|

Merchantable volume*, m3 |

2.6 |

2.6 |

2.1 |

2.1 |

<0.0001 |

<0.0001 |

|

Log yield |

0.87 |

0.86 |

0.90 |

0.86 |

<0.0001 |

0.1337 |

|

*Tree volume: tables standing tree volume above ground with ≥ 7 cm diameter without bark, without size allowances and cutting losses |

||||||

Fig. 2 Proportion of well-formed and poorly formed stem sections in trees felled by harvester and trees felled by chainsaw operators

3.3 Motor-Manual Intervention in Felling – Prediction Models

Having found that there are potential correlations between different tree characteristics and the odds that they are felled by the harvester alone, a logistic regression analysis was conducted to determine whether the correlations were still significant when the interaction of the parameters was considered. Several models were tested, which included independent variables such as: DBH, harvester type, season, and tree form in different stem sections. The probability of mechanized felling decreased with increasing DBH and increased if the tracked harvester was chosen instead of the wheeled harvester. The parameter »season« was only just outside the required significance level. There was also no significant correlation to tree form. The odds ratio can be computed by raising e to the power of the logistic coefficient of machine type: e-0.62182 = 0.54. Thus, the odds of a tree being felled by the wheeled harvester were about half as large as the odds of being felled by the tracked one. According to good practice, verification was conducted by using the model for estimating the probability of mechanized felling separately for the trees that were actually felled by the harvester and for those that were felled motor-manually (Allison 2014). The mean estimated probability of mechanized felling was 77% for the trees that were actually felled by the harvester and 72% for the trees being felled motor-manually. This small difference (5%) indicated that the model did work but was relatively weak – likely because the variable »distance from the machine operating trail« was not measured and could thus not be included in the model.

Table 4 Logistic regression coefficients for probability of a tree being felled by harvester

|

Parameter |

Estimate |

Std. Error |

P > ChiSq |

|

Intercept |

2.9494 |

0.3406 |

<0.0001 |

|

DBH |

–0.0319 |

0.0069 |

<0.0001 |

|

Machine type |

–0.6218 |

0.1605 |

0.0001 |

|

Note: Machine type – Indicator variable: 0 – if Tracked, 1 – if Wheeled |

|||

3.4 Harvester Performance

Additional analyses were conducted on trees that were managed entirely mechanically to detect possible machine and/or seasonal effects. Since data were heteroscedastic, the analyses were again conducted with non-parametric techniques. There were no significant seasonal differences (winter vs. fall) in the characteristics of trees managed by the tracked harvester, whereas trees treated by the wheeled harvester were significantly larger in winter than in fall (Table 5). Tree size differences were also detected between machine treatments. In any case, these differences were relatively small and their effect on machine performance could be accounted for by including tree size as a covariate in all further analyses.

Table 5 Comparison of the main characteristics of trees harvested mechanically

|

Parameter |

Tracked Fall |

Tracked Winter |

Wheeled Fall |

Wheeled Winter |

|

|

DBH, cm |

Mean |

43.3 |

42.7 |

40.1 |

46.1 |

|

Median |

44ac |

43ab |

42b |

47c |

|

|

Height, m |

Mean |

35.9 |

34.6 |

31.1 |

34.5 |

|

Median |

35.8a |

34.7ac |

33.5b |

35.3c |

|

|

Tree volume, m3 |

Mean |

2.43 |

2.37 |

2.04 |

2.77 |

|

Median |

2.26ac |

2.23a |

1.85b |

2.75c |

|

|

Merchantable volume, m3 |

Mean |

2.13 |

2.33 |

1.59 |

2.28 |

|

Median |

2.00a |

2.19a |

1.55b |

2.24a |

|

|

% Log yield |

Mean |

89 |

103 |

82 |

83 |

|

Median |

87a |

102b |

79c |

82c |

|

|

Note: Different letters presented after medians indicate significant differences according to pairwise Mann-Whitney U tests |

|||||

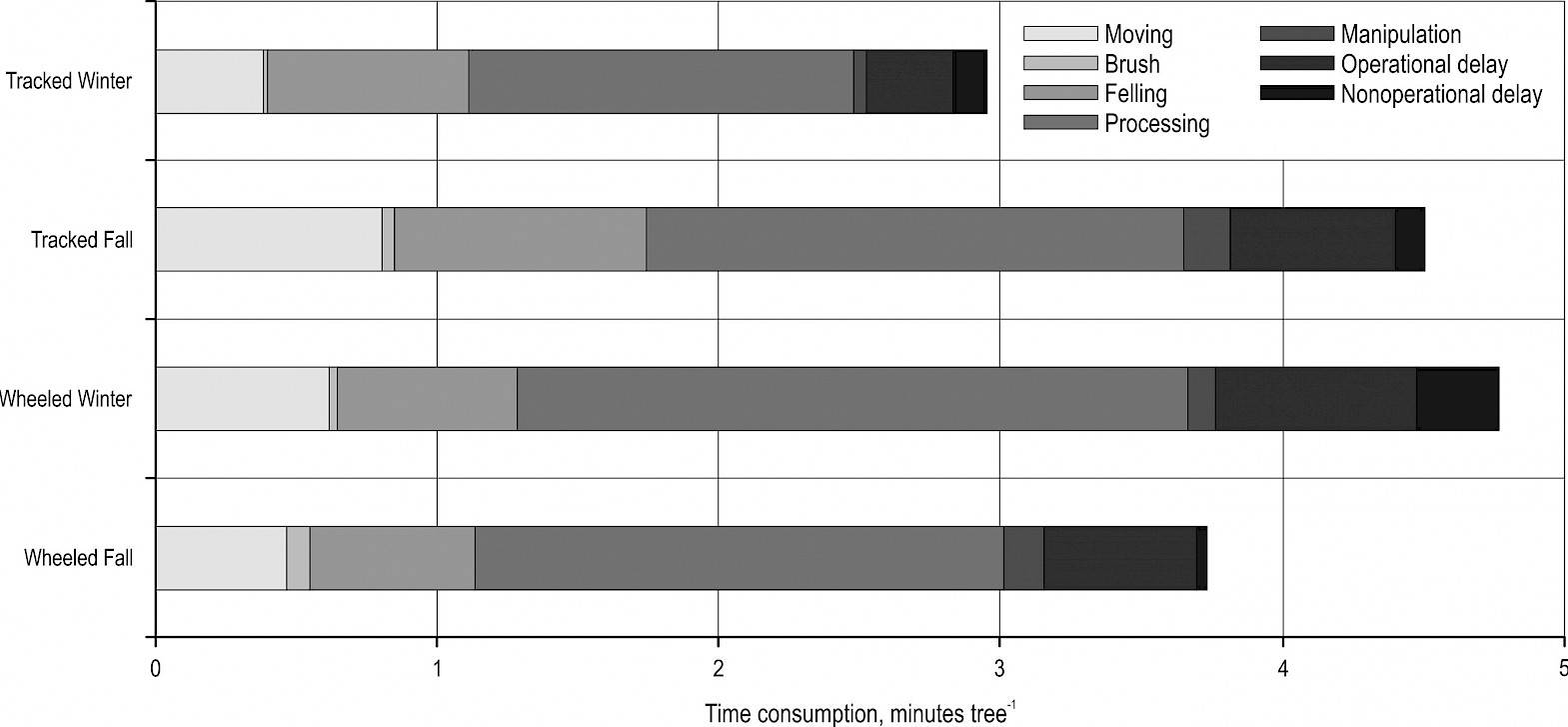

The time consumption of harvesters differed significantly between machine types and seasons (Fig. 3). The mean time consumption of the wheeled harvester was greater in winter than in fall, while the contrary was true for the tracked harvester. That could be explained by the fact that the wheeled harvester negotiated larger trees during winter than it did during the fall. The main difference in the distribution of element times between the two machine types was in the work elements »felling« and »processing« (Table 6). The tracked harvester invested a larger proportion of total cycle time in the felling task, and the wheeled harvester in the processing task.

Fig. 3 Mean time consumption per tree for two machines and seasons. Only trees being felled and processed solely by harvester are considered. Cycle time is broken down between different work elements

Table 6 Proportion of elemental time consumption over total cycle time – excluding delays (PMH0)

|

Work element |

Wheeled Fall |

Wheeled Winter |

Tracked Fall |

Tracked Winter |

|

Moving |

15% |

16% |

21% |

15% |

|

Brush |

3% |

1% |

1% |

1% |

|

Felling |

19% |

17% |

23% |

28% |

|

Processing |

59% |

63% |

50% |

54% |

|

Manipulation |

5% |

3% |

4% |

2% |

|

Total |

100% |

100% |

100% |

100% |

The effects of various factors on time consumption were explored with the General Linear Model (GLM) technique, according to model 1:

(1)

(1)

Statistical analysis aimed at checking the effects of tree size, tree form, season, and machine type on cycle time consumption (Table 7). The latter was meant to include: A) moving, removing the brush, felling and processing, or alternatively B) removing the brush, felling and processing. While neither »moving« nor »removing the brush« were strictly cyclic, they were frequent enough and were assumed capable of reflecting the different visibility conditions characterizing the two seasons under scrutiny (Eliasson and Lageson 1999, Hånell et al. 2000).

Table 7 ANCOVA tables of two GLM models to explain harvester time consumption (logarithmically transformed)

|

A) Time consumption, incl. »moving« |

Adj RSq RMSE |

0.6456 0.3792 |

– |

– |

||

|

Parameter |

DF |

Param. estimate |

SS |

Eta |

F |

P |

|

Intercept |

– |

–1.0208 |

||||

|

DBH, cm |

1 |

0.0405 |

166.9 |

60% |

1160 |

< 0.0001 |

|

Machine type |

1 |

0.1431 |

2.2 |

1% |

15 |

0.0001 |

|

Season |

1 |

0.2102 |

7.1 |

3% |

49 |

< 0.0001 |

|

Tree form |

1 |

0.1554 |

3.1 |

1% |

22 |

< 0.0001 |

|

Error |

684 |

– |

98.4 |

35% |

– |

– |

|

Total |

688 |

– |

277.6 |

– |

– |

|

|

B) Time consumption, excl. »moving« |

Adj RSq RMSE |

0.7176 0.3670 |

– |

– |

||

|

Parameter |

DF |

Param. estimate |

SS |

Eta |

F |

P |

|

Intercept |

– |

–1.4984 |

– |

– |

– |

– |

|

DBH, cm |

1 |

0.0477 |

225.2 |

68.9% |

1672 |

< 0.0001 |

|

Machine type |

1 |

0.1174 |

1.5 |

0.5% |

11 |

0.0009 |

|

Season |

1 |

0.1887 |

5.7 |

1.8% |

43 |

< 0.0001 |

|

Tree form |

1 |

0.1224 |

1.9 |

0.6% |

14 |

0.0002 |

|

Error |

685 |

– |

92.2 |

28.2% |

– |

– |

|

Total |

689 |

– |

326.6 |

– |

– |

– |

|

Note: Tree form, turned into a categorical variable with two levels (Poor – 1 values in both the first and second section; Good – otherwise); Season – Indicator variable: 0 – if Winter, 1 – if Fall; Machine type – Indicator variable: 0 – if Tracked, 1 – if Wheeled |

||||||

The selected independent variables accounted for 65% of the total variability in the dataset when the time spent for moving was included into the model (see AdjRSq in Table 7). Once the (large) variability associated with moving time was removed, the model became stronger and could account for 72% of the variability in the dataset. Tree size had the effect on time consumption, by far. Tree size could be represented in terms of DBH or tree volume (estimated at inventory or measured after harvesting) without any meaningful differences on model form, significance, and power.

Season and machine effect were generally significant but could only account for a small fraction of the total variability (see column »Eta« in Table 7). Time consumption was higher for the wheeled harvester and during the fall. The model also indicated a significant relationship between tree form and time consumption, even though the explanatory contribution of this independent variable was relatively small, too. Good stem form resulted in a lower time consumption.

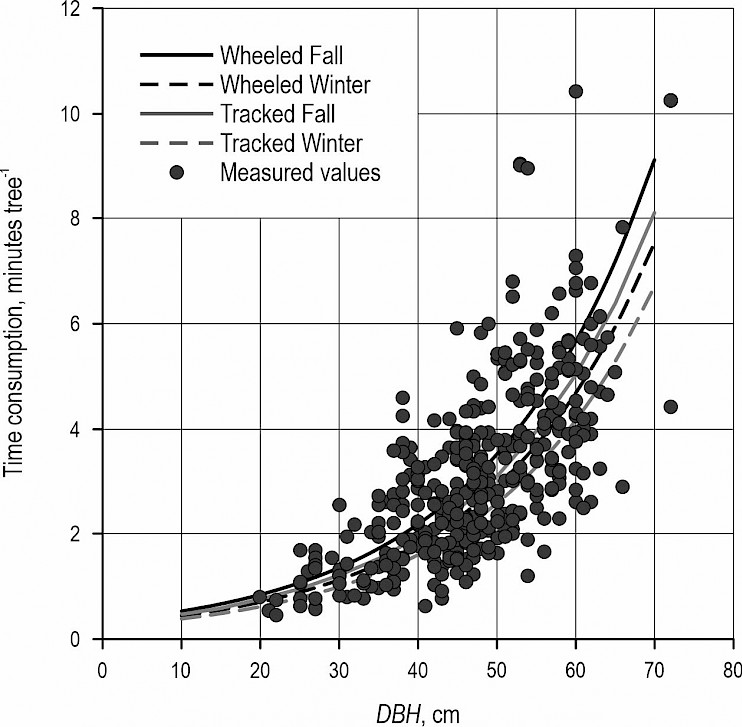

Time consumption for the model without »moving« can be calculated using eq. 2:

(2)

(2)

The curves in Fig. 4 show the time consumption of the different harvesters in both seasons according to this model. It is clear that the differences become larger with increasing diameter and that the season had a stronger influence than the machine type.

Fig. 4 Time consumption of different harvesters in both seasons according to the model excluding the time element »moving« for well-formed trees and measured values

4. Discussion

Despite its inevitable limitations, this study contributed valuable new knowledge that allowed drawing meaningful considerations on study methodology, logging technology and forest management – all of which are being discussed individually in the following paragraphs.

4.1 Study Limitations

Flawless studies are quite rare, and they often have the considerable merit of hiding well their small faults. This study is no exception: its main limitations are with site and operator selection, and with the inevitable measurement errors.

Concerning site and operator, the fact that the two machines were operated by different operators and deployed on different sites implied that any differences between machines could be obscured by differences between operators or sites. To minimize the variability introduced by site and operator, the authors selected sites and operators that were as similar as possible – and the statistical analysis did confirm similarity between sites, at least. However, »similar« is not the same as »identical«, and it generally carries along some unwanted variability. Furthermore, the similarity between operators was supported more by the subjective evaluation of experts than by objective elements (Schwegman et al. 2021). Therefore, it was impossible to state that machine differences were independent of an operator effect and any inferences in that regard must be considered suggestive, rather than conclusive. However, this is a common limitation of many forest engineering studies that must rely on the available resources offered by commercial operations and are often observational in character (Magagnotti et al. 2013).

Finally, measurement errors may have confounded some of the main effects, especially for what concerned total tree volume. This was estimated based on dedicated volume tables, which were inevitably approximated – as shown by the occasional instances of log yield exceeding 100% of total tree volume, which was mathematically absurd. However, any such errors were randomly distributed between the machine and season treatments and would not invalidate the eventual comparisons.

4.2 Technology and Operational Considerations

From the operational viewpoint, the study indicates that new silvicultural prescriptions make it impossible to harvest all trees exclusively with mechanized systems (cf. Schweier and Ludowicy 2020). A significant proportion of the total harvest requires motor-manual intervention. In that regard, the experiment clarified three important issues. First, it indicated that the proportion of trees needing motor-manual intervention changes with tree size and machine type, depending on machine (and/or operator) capability. Second, it made it clear that the need for motor-manual intervention does not just depend on extended machine operating trail spacing, but also on tree characteristics – and especially tree size. Since distance from the machine operating trail was not recorded, the unknown tree position became a strong confounding factor that would weaken the power of any analytical technique. For that reason, the same fact that tree size was found to be significant is a strong witness to the role of tree characteristics as a limiting factor to mechanized harvesting in close-to-nature forestry. The third important issue is the very limited share of trees that were felled with a combination of motor-manual and mechanized techniques meaning that trees with large girth and/or with a wide taper at the cutting point received motor-manual preparation in order to facilitate the positioning of the harvesting head. This fact highlights the logistical and safety concerns raised by mixed manual-mechanical teams (Newman et al. 2018). According to good practice, work teams should operate independently, at a safe distance from each other, to avoid interference but enable mutual rescue (ILO 1998).

Concerning harvester productivity, the study confirms the dominant effect of tree size on time consumption (Holzscher and Bossy 1997, Nakagawa et al. 2007, Nurminen et al. 2006, Visser and Spinelli 2012, Labelle et al. 2018). This is the prevalent effect that overpowers all others and clearly emerges from random variability. Nevertheless, machine and season effects are still visible, and the fact that they rise above the significance threshold confirms their important role. While it is still necessary to consider the possible interference of an operator effect, the findings of this study seem logical and can be explained with relative ease. It is quite reasonable to attribute the better performance of the tracked harvester to its heavier weight, stronger boom and a secondary grapple for holding cut trees in the upright position, all of which give it better stability and enable a dexterous handling of cut trees. In fact, the tracked harvester was faster than the wheeled one especially for delimbing and crosscutting – not felling and handling. The tracked harvester removed most of the cut trees keeping them upright while standing on the machine operating trail and laid them down there. The work element »felling« ended when the tree was released on the trail edge. Thus, moving a tree in an upright direction to the trail right after cutting it with the tracked harvester was assigned to the felling task, whereas moving a tree already laying on the ground was assigned to the work step »processing«. However, it is always somewhat dangerous to analyze the results in isolation when they are part of the same interconnected sequence. Therefore, we did not statistically test the relationships between process variables and separate time elements for significance.

Statistical analysis also confirmed a significant seasonal effect. A credible argument could be built about the association between the better performance recorded in winter and the absence of leaves on the trees and the understory, which did allow for a better visibility of the work area and object (Ireland and Kerr 2008, Niemistö et al. 2012). The absence of leaves may have also played a role in reducing the »sail effect« of the remarkably tall trees found at both test sites. The greater time required in the fall would also lead to higher logging costs. Forest managers must balance these higher costs with higher revenues.

Motor-manually felled trees were more often poorly shaped in the upper stem section than mechanically felled trees. However, in the explanatory model for the decision whether trees would be felled mechanically or motor-manually, the relationship to tree form was not significant. In contrast, according to the harvester time consumption model, cycle time was significantly greater for trees that were poorly formed in the lower two sections. The higher time consumption of the harvester for malformed trees is plausible because thick branches, forks and tight sweeps can make processing more difficult. Motor-manual felling is more likely for trees that are poorly formed in the lower stem section. However, poor form would have to be very severe for the harvester to be unable to fell the tree. Based on the visual assessment of stem forms, beech trees in both stands were of above average quality. Stems were mostly straight and free of branches. It could be seen that decades of silvicultural tending by forestry professionals had created excellent quality. Therefore, it is not surprising that no relationship between the tree form in the lower stem section and the likelihood for motor-manual felling could be detected. Why poor form in the upper stem section should increase the likelihood of motor-manual felling is unclear. In the logistic regression, in which the interaction of the various influencing variables is taken into account, the stem form in the upper section was not significant. Incidentally, one must also consider that the attribution of a representative tree form factor is quite difficult (Labelle et al. 2016, Puttock et al. 2005). Any systems developed so far are just approximations that may or may not reflect the actual effect of a given tree form on harvester performance (Pelletier et al. 2013).

4.3 Forest Management Considerations

New silvicultural prescriptions that promote structural diversity of the stands and minimize in-stand traffic are incompatible with full mechanization. Their implementation makes it very hard to achieve the ultimate work safety goal expressed by the motto »no boots on the ground, no hands on the log« (Anon. 2018). Current forest technology reflects Nordic designs originating in the 1970s, adapted to the even-aged softwood stands of this region and period. Despite 50 years of changes and improvements, cut-to-length technology still conforms to the same fundamental principles and is forced out of its optimum when deployed in uneven-aged hardwood forests, characterized by large and poorly formed trees – the more so if machine operating trail spacing is doubled or tripled compared with the original design. This basic consideration implies the necessity of a compromise between environmental, financial and safety benefits and the results of this study can assist in reaching an efficient solution.

In particular, the study clarifies that machine selection affects the proportion of trees that can be treated with exclusive mechanical means. Opting for a heavy tracked harvester can cut by half the odds of a tree requiring motor-manual felling compared with the same operation conducted with a lighter wheeled harvester. In contrast, a seasonal effect could not be confirmed. Certainly, the risk of accidents is increased during motor-manual felling if the leaves are on, but the proportion of trees that have to be cut motor-manually does not change with phenology, i.e. whether the leaves are on or off. However, concentrating hardwood operations in winter offers additional benefits when tops and branches are harvested for energy biomass because the leaves would be left in the stand, minimizing nutrient removal.

Finally, it is worth remarking that tree size has the strongest effect on the proportion of trees that can be harvested without motor-manual intervention, and on harvester performance. While that does not deny the important influence of machine type and season, it still makes it clear that the impact of any silvicultural decisions on operational efficiency is mediated by their consequences on tree size (Spinelli and Magagnotti 2013). A previous study on harvester operator performance and mental effort also came to the same conclusions, which are not entirely unexpected, given the large evidence about the primary role of tree size on operational efficiency (Spinelli et al. 2020). Knowing that, forest managers may consider applying modified close-to-nature principles in a way that keeps tree size within the optimum levels for efficient mechanization, so as to maximize the environmental benefits while minimizing any negative effects on work productivity and safety. In particular, habitat trees marked for indefinite retention would be best selected furthest away from the designated machine operating trails, if any multi-entry trail system were adopted, as in the German case. For the rest, it is not efficient to extend rotations beyond the limit when tree size exceeds harvester capacity, imposing motor-manual felling and processing. In fact, in an uneven-age system, longer rotations could be applied to the trees that are too far away for the machine to reach and must be felled motor-manually anyway, while trees within reach of the machines might be cut slightly earlier in order to reap all the financial and safety benefits of mechanization. Certainly, if the distances between the machine operating trails were reduced, considerably more trees could be felled by machine, which would also reduce the risk of accidents. However, it is not expected that this would be enforceable with the public forestry companies in Germany.

5. Conclusions

Continuous-cover forestry of hardwood-dominated stands in combination with a widely spaced multi-entry machine operating trail system do not allow all trees to be harvested and processed mechanically. In this study, both harvesters (wheeled and tracked) required support from motor-manual teams, but the frequency of motor-manual interventions was significantly higher for the lighter wheeled harvester. Based on a logistic regression model, the odds of any given tree being felled by the wheeled harvester were about half as large as the odds of it being felled by the tracked harvester. Harvesting in the fall does not require more motor-manual felling than in winter. The results of this study can be used as a guide for forest managers towards finding technical solutions that will reduce motor-manual intervention and allow more flexibility in scheduling operations in hardwood-dominated stands. The existing model does not include the distance of the target tree from the machine operating trail among its variables, and that may be addressed by future research if an even stronger predictive power is desired. Harvesting in the fall increases the time consumption of the harvester. The resulting higher costs must be weighed against higher revenues.

Acknowledgments

The research leading to these results has received funding from the Kuratorium für Forstliche Forschung (project A038 MechSysLH) and the August-Wilhelm Scheer Visiting Professor Program, Technical University of Munich International Centre. We are also grateful to Sandra Großkopf, Michael Miesl, Chien Chen, Sayantan Basu, Florian Binner, Helene Aurenhammer, Prabha Neupane, Iván Viveros Gongora, Julia Kemmerer, Caroline Bennemann, Joachim Heppelmann, Maximilian Mayer and Joelean Hall. Special thanks are also due to Andreas Hohenadl for his contributions during manuscript preparation. All productivity studies require good and open-minded forest entrepreneurs. In this context, we wish to thank Tobias Eich and Robert Frischholz for their continuous support during all trials. Lastly, we wish to extend our gratitude to Sebastian Berger from the Bavarian State Forest as well as, amongst others, to Sascha Walter and Daniel Meyer, from the individual State Forest units, for their commitment to the project.

6. References

Allison, P.D., 2014: Measures of fit for logistic regression. In Proceedings of the SAS global forum 2014 conference, Paper 1485-2014. Cary, NC, USA: SAS Institute Inc. 13 p.

Anon., 2018: Forestry work in the modern age. Business Case prepared for the Ministry for Primary Industries. Rotorua, New Zealand, 99 p.

Axelsson, S-Ă., 1998:The mechanization of logging operations in Sweden and its effect on occupational safety and health. Journal of Forest Engineering 9(2): 25–31. https://doi.org/10.1080/08435243.1998.10702715

Bennemann, C., Labelle, E.R., Lussier, J-M,. 2023: Influence of Tree, Stand, and Site Attributes on Hardwood Product Yield: Insights into the Acadian Forests. Forests 14(2): 182. https://doi.org/10.3390/f14020182

BMEL 2012: Bundesministerium für Ernährung und Landwirtschaft. Ergebnisse der Bundeswaldinventur 2012, 280 p.

BMEL 2014: Bundesministerium für Ernährung und Landwirtschaft. Holzmarktbericht 2013, 31 p.

DFWR/DHWR 2015: Deutscher Forstwirtschaftsrat und Deutscher Holzwirtschaftsrat. Rahmenvereinbarung für den Rohholzhandel in Deutschland (RVR). 2. Auflage, 56 p.

Eliasson, L., Lageson, H,. 1999: Simulation study of a single-grip harvester in thinning from below and thinning from above. Scandinavian Journal of Forest Research 14(6): 589–595. https://doi.org/10.1080/02827589908540824

Gößwein, S., Schusser, M., Borchert, H., 2019: Marktstudie Rundholzlogistik Bayern 2017. Endbericht, 83 p.

Hǻnell, B., Nordfjell, T., Eliasson, L., 2000: Productivity and costs in shelterwood harvesting. Scandinavian Journal of Forest Research 15(5): 561–569. https://doi.org/10.1080/028275800750173537

Hildt, E., Leszczuk, A., Donagh, P.M., Schlichter, T., 2020: Time Consumption Analysis of Forwarder Activities in Thinning. Croatian Journal of Forest Engineering 41(1): 13–24. https://doi.org/10.5552/crojfe.2020.615

Holtzscher, M.A., Bossy, L.L., 1997: Tree diameter effects on cost and productivity of CTL systems. Forest Products Journal 47(3): 25–30.

ILO (International Labour Office) 1998: Safety and health in forestry work: An ILO code of practice. Geneva, International Labour Office. /Code of practice/, /Occupational safety/, /Occupational health/, /Forestry/. 13.04.2, 132 p.

Ireland, D., Kerr, G., 2008: CCF harvesting method development: harvester head visibility. Internal Project Information Note 10/08. Technical Development, Forest Research, Forestry Commission, UK.

Kublin, E. 2002: Programmbibliothek zur Berechnung von Durchmessern, Sorten- und Derbholzvolumen auf der Basis von Schaftformgleichungen. Forstliche Versuchs- und Forschungsanstalt Baden-Württemberg, 37 p.

Labelle, E.R., Soucy, M., Cyr, A., Pelletier, G., 2016: Effect of Tree Form on the Productivity of a Cut-to-Length Harvester in a Hardwood Dominated Stand. Croatian Journal of Forest Engineering 37(1): 175–183.

Labelle, E.R., Bergen, M., Windisch, J., 2017: The effect of quality bucking and automatic bucking on harvesting productivity and product recovery in a pine-dominated stand. European Journal of Forest Research 136: 639–652. https://doi.org/10.1007/s10342-017-1061-4

Labelle, E.R., Breinig, L., Syncheva, E., 2018: Exploring the Use of Harvesters in LargeDiameter Hardwood-Dominated Stands. Forests 9(7): 424. https://doi.org/10.3390/f9070424

Millet, J., 2016 : L'Architecture des arbres des régions tempérées: son histoire, ses concepts, ses usages. Editor Multimondes, 395 p.

Nakagawam, M., Hamatsu, J., Saitou, T., Ishida, H., 2007: Effects of tree size on productivity and time required for work elements in selective thinning by a harvester. International Journal of Forest Engineering 18(2): 24–28. https://doi.org/10.1080/14942119.2007.10702547

Newman, S.M., Keefe, R.F., Brooks, R.H., Ahonen, E.Q., Wempe, A.M., 2018: Human Factors Affecting Logging Injury Incidents in Idaho and the Potential for Real-Time Location-Sharing Technology to Improve Safety. Safety 4(4): 43. https://doi.org/10.3390/safety4040043

Niemistö, P., Korpunen, H., Laurén, A., Salomäki, M., Uusitalo, J., 2012: Impact and productivity of harvesting while retaining young understorey spruces in final cutting of downy birch. Silva Fennica 46(1): 81–97.

Nurminen, T., Korpunen, H., Uusitalo, J., 2006: Time consumption analysis of mechanized cut-to-length harvesting systems. Silva Fennica 40(2): 335–363.

Pelletier, G., Landry, D., Girouard, M., 2013: A Tree Classification System for New Brunswick. Northern Hardwoods Research Institute, Edmundston, New Brunswick, 53 p.

Pretzsch, H., Steckel, M., Heym, M., Biber, B., Ammer, C., Ehbrecht, M., Bielak, K., Bravo, F., Ordóñez, C., Collet, C., Vast, F., Drössler, L., Brazaitis, G., Godvod, K., Jansons, A., de-DiosGarcía, J., Löf, M., Aldea, J., Korboulewsky, N., Reventlow, D.O.J., Nothdurft, A., Engel, M., Pach, M., Skrzyszewski, J., Pardos, M., Ponette, Q., Sitko, R., Fabrika, M., Svoboda, M., Černý, J., Wolff, B., Ruíz-Peinado, R., del Río, M., 2020: Stand growth and structure of mixed-species and monospecific stands of Scots pine (Pinus sylvestris L.) and oak (Q. robur L., Quercus petraea (MATT.) LIEBL.) analysed along a productivity gradient through Europe. European Journal of Forest Research 139: 349–367. https://doi.org/10.1007/s10342-019-01233-y

Puttock, D., Spinelli, R., Hartsough, B.R., 2005: Operational trials of cut-to-length harvesting of poplar in a mixed wood stand. International Journal of Forest Engineering 16(1): 39–49. https://doi.org/10.1080/14942119.2005.10702506

Schwegman, K., Spinelli, R., Magagnotti, N., Ramantswana, M., McEwan, A., 2021: Selecting successful harvester operators through aptitude tests and demographics. Australian Forestry 84(1): 25–32. https://doi.org/10.1080/00049158.2020.1837492

Schweier, J., Ludowicy, C., 2020: Comparison of a cable-based and a ground-based system in flat and soil-sensitive area: a case study from Southern Baden in Germany. Forests 11(6) 611. https://doi.org/10.3390/f11060611

Spinelli, R., Magagnotti, N., 2013: The effect of harvest tree distribution on harvesting productivity in selection cuts. Scandinavian Journal of Forest Research 28(7): 701–709. https://doi.org/10.1080/02827581.2013.821517

Spinelli, R., Magagnotti, N., Labelle, E.R., 2020: The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators. Croatian Journal of Forest Engineering 41(2): 177–190. https.//doi.org/10.5552/crojfe.2020.747

Suchomel, C., Spinelli, R., Magagnotti, N., 2012: Productivity of Processing Hardwood from Coppice Forests. Croatian Journal of Forest Engineering 33(1): 39–47.

Visser, R., Spinelli, R., 2012: Determining the shape of the productivity function for mechanized felling and felling-processing. Journal of Forest Research 17(5): 397–402. https://doi.org/10.1007/s10310-011-0313-2

Zeng, W.S.; Tang, S.Z., 2011: Bias correction in logarithmic regression and comparison with weighted regression for nonlinear models. Nature Precedings 1-1. https://doi.org/10.1038/npre.2011.6708.1

© 2023 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Prof. Eric R. Labelle, PhD *

e-mail: eric.labelle@sbf.ulaval.ca

Université Laval

Faculty of Forestry, Geography and Geomatics

Department of Wood and Forest Sciences

2405 rue de la Terrasse

Québec, QC, G1V 0A6

CANADA

Herbert Borchert, PhD

e-mail: herbert.borchert@lwf.bayern.de

Bavarian State Institute of Forestry

Hans-Carl-von-Carlowitz Platz 1

85354 Freising

GERMANY

Peter K. Aurenhammer, PhD

e-mail: postmaster@prosilva.at

Technical University of Munich

Department of Ecology and Ecosystem Management

Hans-Carl-von-Carlowitz Platz 2

85354 Freising

GERMANY

Lorenz Breinig, PhD

email: lorenz.breinig@uni-goettingen.de

University of Göttingen

Department of Forest Work Science and Engineering

Büsgenweg 4

37077 Göttingen

GERMANY

Raffaele Spinelli, PhD

e-mail: raffaele.spinelli@ibe.cnr.it

Institute of Bioeconomy

Italian National Research Council

Sesto Fiorentino

ITALY

and Forest Research Institute – University of the Sunshine Coast

Maroochydore, DC,

AUSTRALIA

Natascia Magagnotti, PhD

e-mail: natascia.magagnotti@ibe.cnr.it

Institute of Bioeconomy

Italian National Research Council

Sesto Fiorentino

ITALY

* Corresponding author

Received: February 03, 2023

Accepted: May 26, 2023

Original scientific paper