Timber Harvesting Economics in Early Commercial Thinning and Group Selection Prescriptions

doi: 10.5552/crojfe.2024.2425

volume: 45, issue: 2

pp: 11

- Author(s):

-

- Alex Ashish

- Kizha Anil Raj

- George Alex K.

- Louis Libin T.

- Bolding M. Chad

- Bick Steven

- Rogers Nicole S.

- Article category:

- Original scientific paper

- Keywords:

- cut-to-length, forest operations, machine productivity, silvicultural prescriptions, timber harvest layout

Abstract

HTML

<p>Forest management decisions that consider both short- and long-term objectives are becoming more challenging and costly, due to market uncertainty, labor shortages, and the evolving forest industry. Under such unpredictable circumstances, a better understanding of the production economics of various silvicultural prescriptions is crucial in implementing sound forest management activities. The objectives of this study were to: a) estimate stump to landing productivity and cost for Early Commercial Thinning (ECT) and Group Selection (GS) prescriptions; and b) compare the harvest system cost ($/PMH) using machine rate and PATH (Planning and Analysis in Timber Harvesting) methods. Detailed time-motion studies were conducted in the spruce-fir forest of Northern Maine, USA, during the summer of 2019. The results, as expected, indicated the harvesting costs were 23% higher for ECT (21.08 $/m3) compared to GS (16.32 $/m3). The average productivity of the harvester and forwarder were reduced by 15 and 37%, respectively, for ECT compared to GS. The estimated harvesting system cost ($/PMH) was 4% higher as indicated by PATH compared to machine rate method. Higher operational productivity in GS can be attributed to the larger volume of logs, and shorter travel loaded distance than ECT. These findings can help forest managers make more informed decisions while implementing appropriate silvicultural prescriptions under varying conditions based on management objectives and market conditions.</p>

Timber Harvesting Economics in Early Commercial Thinning and Group Selection Prescriptions

Ashish Alex, Anil Raj Kizha, Alex K. George, Libin T. Louis, M. Chad Bolding, Steven Bick, Nicole S. Rogers

Abstract

Forest management decisions that consider both short- and long-term objectives are becoming more challenging and costly, due to market uncertainty, labor shortages, and the evolving forest industry. Under such unpredictable circumstances, a better understanding of the production economics of various silvicultural prescriptions is crucial in implementing sound forest management activities. The objectives of this study were to: a) estimate stump to landing productivity and cost for Early Commercial Thinning (ECT) and Group Selection (GS) prescriptions; and b) compare the harvest system cost ($/PMH) using machine rate and PATH (Planning and Analysis in Timber Harvesting) methods. Detailed time-motion studies were conducted in the spruce-fir forest of Northern Maine, USA, during the summer of 2019. The results, as expected, indicated the harvesting costs were 23% higher for ECT (21.08 $/m3) compared to GS (16.32 $/m3). The average productivity of the harvester and forwarder were reduced by 15 and 37%, respectively, for ECT compared to GS. The estimated harvesting system cost ($/PMH) was 4% higher as indicated by PATH compared to machine rate method. Higher operational productivity in GS can be attributed to the larger volume of logs, and shorter travel loaded distance than ECT. These findings can help forest managers make more informed decisions while implementing appropriate silvicultural prescriptions under varying conditions based on management objectives and market conditions.

Keywords: cut-to-length, forest operations, machine productivity, silvicultural prescriptions, timber harvest layout

1. Introduction

Sustainable and effective silvicultural prescriptions are crucial for achieving forest management objectives (Helman et al. 2020). The Northeastern United States is characterized by naturally regenerated hardwood, softwood, and mixed stands with diverse commercially valuable species providing an opportunity to implement a wide range of silvicultural prescriptions in the region (Carter et al. 2017, Muñoz Delgado et al. 2019). One of the major challenges faced by the forest managers in the region is the abundance of small diameter trees (SDT) in dense stands which cover a major portion of the forest (Louis and Kizha 2021). These overstocked stands with SDTs can result in the increased harvesting costs due to reduced productivity and low value products (Han et al. 2004, Bolding and Lanford 2005, Hanzelka et al. 2016, Germain et al. 2019). Many of these stands face similar challenges due to economic feasibility of forest operations (Hiesl and Benjamin 2012); therefore they require appropriate silvicultural treatments, such as thinnings, to improve the stand growth, vigor, and future revenue (Pitt et al. 2013, Keyser and Loftis 2021). The spruce-fir forest in the Northeastern US are conventionally managed using pre-commercial and commercial thinning (Wagle et al. 2022). Early commercial thinnings (ECT) are primarily done to reduce the stand density, thereby minimizing the competition for residual trees (Nyland 2016). The opportunity for individual stems to grow quickly can reduce the rotation period for the residual stand (Pitt et al. 2013). The partial harvest silvicultural prescriptions, including group selection (GS), imitate natural dynamics and disturbance patterns that create or maintain multi-aged, structurally and functionally diverse, complex forest stands. These strategies are considered as an appropriate ecological approach for sustainable management of forest resources (Brockway and Outcalt 2015, Nolet et al. 2018).

Partial harvests accounted for 91% of the harvest done in Maine (Maine Forest Service 2023). Partial harvest prescriptions can be efficiently executed using the cut-to-length (CTL) method, which has been proven to work in stands dominated with SDT and medium sized trees (Louis and Kizha 2021, George et al. 2022). The ability to reduce residual stand damage and to operate in limited space (smaller landings and woodlots) are some of the major advantages of CTL over the whole-tree harvesting method (Adebayo et al. 2007, Kizha et al. 2021). Being the second most prevalent harvesting method in Maine (Leon and Benjamin 2012), the major factor influencing the productivity of a harvester was tree volume or thinning intensity; whereas, forwarder productivity depended on load volume, travel loaded distance, number of pieces, and movement time between piles/decks during loading and unloading (Strandgard and Mitchell 2019, Louis et al. 2022). The partial harvest CTL studies in Maine showed that productivity of a harvester ranged from 4.9 to 27 tonne/PMH (productive machine hours, 9.8 to 54 m3/PMH) and cost ranged from 20 to 51 $/tonne (Benjamin et al. 2013, Hiesl et al. 2015a, George et al. 2019, 2022). The forwarder operational productivity and cost of group selection study done in Central Maine was 11.45 m3/PMH (5.7 tonne/PMH) and 2.34 $/m3 (4.68 $/tonne), respectively (Bustos-Letelier et al. 2021). The hourly cost of operating a harvester and forwarder for ECT in Maine ranged from 124 to 161 $/PMH and 118 to 153 $/PMH, respectively, and CTL harvesting system cost was 47.5 $/tonne (Benjamin et al. 2013). A better understanding of the productivity and cost along with influential stand and site factors are crucial in determining the feasibility of conducting silvicultural prescriptions for SDT dominated stands (Hiesl et al. 2015b, Kizha and Han 2016, Williams and Ackerman 2016, Louis and Kizha 2021).

Hourly owning and operating costs for forest harvesting machines can be calculated using machine rate and cash flow methods, of which the most frequently used one is machine rate calculation (Miyata 1980, Brinker et al. 2002). Both approaches use fixed (owning), variable (operating), and labor costs for an individual machine within a system to estimate the hourly rate ($/PMH). In 1990, Goldratt developed the throughput accounting (TA) method which uses net profit and return on investment (ROI) as an easy way of measuring financial results and was first adopted by the logging industry through PATH (Planning and Analysis in Timber Harvesting) (Bick and Benjamin 2018). PATH estimates hourly ownership, operating, overhead, and job-specific cost to calculate system cost, ROI, and profit or loss (Germain et al. 2016). PATH analysis aids managers in making more informed decisions related to harvesting system balance and equipment replacement (Germain et al. 2016). The machine rate method exclusively focuses on the cost elements of a harvesting system, whereas PATH focuses on the revenue and expenses. Along with the understanding of system productivity and harvesting cost, strategies to ensure continuous flow of raw materials (wood) are also needed for the long-term viability of logging businesses.

In this study, an attempt was made to understand the difference in productivity and cost in similar stand conditions when the equipment, harvest method, and operators were the same for both silvicultural prescriptions (ECT and GS). The cost of conducting silvicultural prescriptions such as group selection has not been widely studied. The objectives of this study were to:

estimate stump to landing productivity and cost for Early Commercial Thinning (ECT) and Group Selection (GS) prescriptions

compare the harvest system cost ($/PMH) using machine rate and PATH (Planning and Analysis in Timber Harvesting) methods.

These findings can help forest managers to make more informed decisions while planning for the sustainable management of forests.

2. Materials and Methods

2.1 Study Area

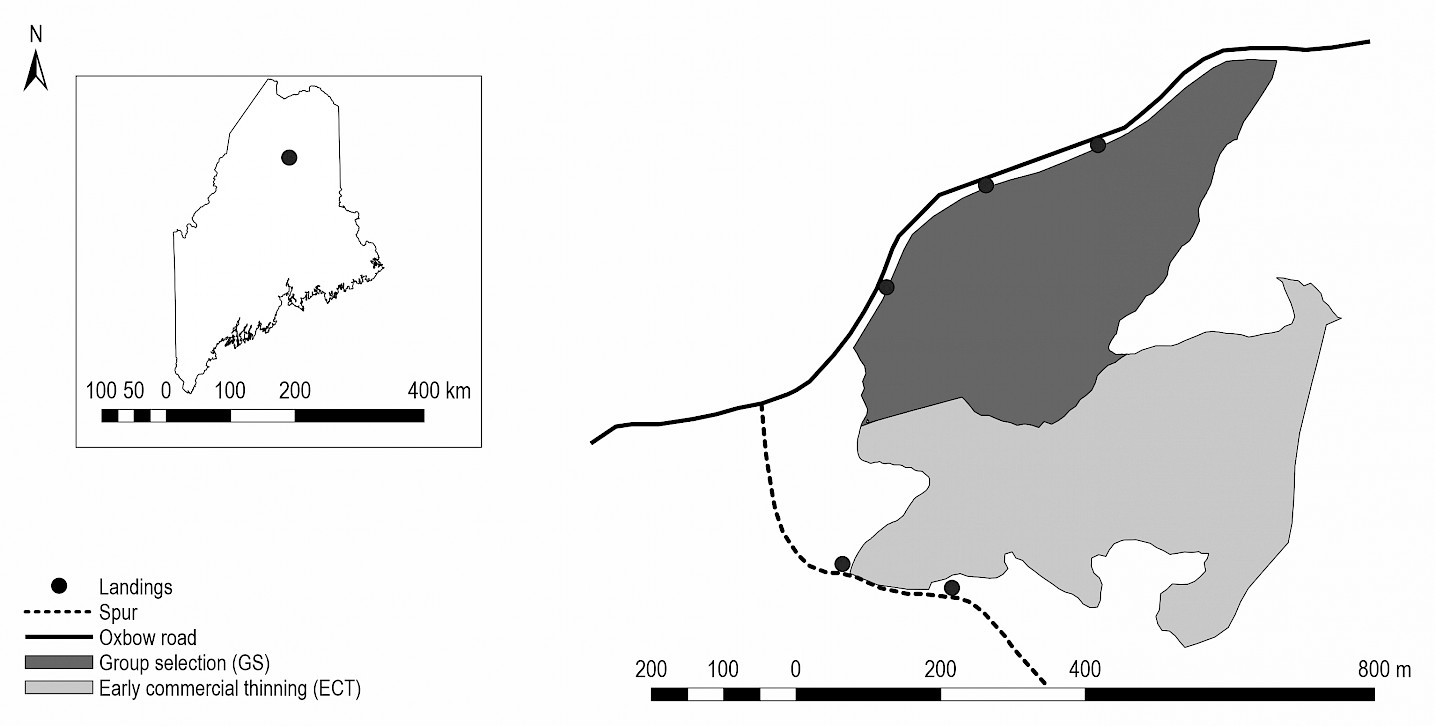

The study site was in Oxbow (46° 19' 51.6'' N and 68° 47' 24.0" W, Fig. 1), Aroostook County, Maine. Two adjacent stands, ECT (17 ha) and GS (14 ha) were harvested in August 2019 using CTL harvesting method with harvesters and forwarders. Previously, both treatments were pre-commercially thinned in 2000. The overstory consisted of red spruce (Picea rubens Sarg.), black spruce (Picea mariana Mill.), white pine (Pinus strobus L.), northern white cedar (Thuja occidentalis L.), balsam fir (Abies balsamea (L.) Mill.), eastern hemlock (Tsuga canadensis (L.), red maple (Acer rubrum L.), sugar maple (Acer saccharum Marsh), aspen (Populus spp.), white birch (Betula papyrifera M.), and yellow birch (Betula alleghaniensis Britt.) in both prescription stands. Major soil types were Dixmont, very stony silt loam, (83%) and Monarda-Burnham complex (Soil Survey 2021). The elevation of the site was 122 m above mean sea level. The average annual temperature ranged from –16°C (minimum) to 26°C (maximum), the annual precipitation was 1076 mm (NOAA 2022).

Fig. 1 The location of study area in Oxbow, Maine (left). Enlarged layout of early commercial thinning (ECT) and group selection (GS) prescriptions along with landings (right)

2.2 Stand Inventory

Pre- and post-harvest inventory data was collected for both treatments in 2019 and 2021, respectively; a total of 23 variable radius points were inventoried using a 20 Basal Area Factor (BAF) prism. Parameters such as species, tree heights, and diameter at breast height (DBH) were recorded.

2.3 Silvicultural Prescription

In ECT, the basal area was reduced to approximately 30–40% by retaining all crop trees which had no major external defect along with 35% live crown. The target species for harvest were in the following order: balsam fir, aspen, white birch, red maple, yellow birch, and red spruce. The anticipated outcome for ECT was to promote accelerated growth of desired crop trees in the residual stands. Rough spacing around the crop trees should be 3 to 4 m. For GS, small gaps and canopy openings (0.1 to 0.2 ha, 15 to 30 m apart) were created along the trails in areas that had a higher component of poor-quality balsam fir to mimic a natural stand disturbance, allowing sunlight to reach the forest floor. The trails were spaced 24 to 30 m apart. The desired outcome was to create canopy openings by capturing groups of declining stems, and desirable regeneration was expected to become established within the newly created canopy openings. The next anticipated entry to the stands will be after 10 years (2029) for both stands.

2.4 Harvesting Operations

Both prescriptions were harvested using the same machines and operators. The machines were a Timberpro TN 725D harvester (Rolly III harvester head; boom length 7.23 m) and a Timberpro TF830B forwarder (lift capacity 3420 kg; boom length 7.65 m). Detailed time and motion studies were conducted to determine delay-free cycle (DFC) time elements and explanatory variables for the production cycles of both machines (Table 1). For the harvester, time taken to travel during decking (bunching processed logs based on products) at the stump (in-woods) was regarded as decking time. The time taken to arrange slash on the skid trail was the scattering time. When space was a limiting factor, the harvester carried felled tree to a conveniently short distance to process it.

Table 1 Delay free cycle (DFC) elements and explanatory variables for the cut-to-length harvesting operation

|

Operational phases |

DFC element, s |

Explanatory variables |

|

Felling and processing (Harvester) |

Travel to next tree |

Distance travelled to next tree, m |

|

Felling |

Number of cuts per cycle |

|

|

Processing |

Number of logs per cycle |

|

|

Decking |

Butt-end diameters, cm |

|

|

Scattering slash |

Decking distance, m |

|

|

Species (softwood or hardwood) |

||

|

Extraction (Forwarder) |

Travel empty |

Travel empty distance, m |

|

Loading |

Travel distance between log piles, m |

|

|

Travel loaded |

Number of pieces |

|

|

Unloading |

Butt-end diameter, cm |

|

|

Travel loaded distance, m |

||

|

Species (softwood or hardwood) |

The forwarder cycle began when the forwarder started traveling empty from the landing and ended when the logs were unloaded at the roadside landing (Table 1). There were two roadside landings for ECTand three for GS (Fig. 1). Travel empty time started when the forwarder travelled empty from the landing and ended when it stopped to collect the first pile of logs. Loading (inwoods) and unloading (at the landing) included move time between log piles, swing empty, grapple and re-grapple, swing loaded, and sorting time. Travel loaded time was regarded as the travel time from the last loaded log pile to reach the roadside landing. The harvesting operation lasted for 35 days. The harvester started working in the stand four to five days prior to forwarder arrival, hence the system was decoupled and bottlenecks were avoided.

2.5 Log Scaling

The average volume of each log was estimated from both scale ticket and log scaling. Small- and large-end diameters of random logs were measured, along with the log length to calculate the average volume of roundwood using Smalian's formula (Avery and Burkhart 1983).

2.6 Cost Calculation

The purchase price, salvage value of machines, interest and insurance cost, economic life, fuel and lubricant consumption, repair and maintenance cost, labor charge, and utilization rates were obtained from the management company (Table 2). The salvage value was set at 40% for the analysis. Hourly machine costs ($/PMH) were calculated using the standard machine rate calculation method (Miyata et al. 1980) and PATH V.3.0. (Bick and Benjamin 2018). Machine rate and PATH were compared to determine the most contributing factors to the operating cost of the system. For PATH analysis, details not provided by the management company were obtained from the industry average provided for the Northeast region to calculate the daily overhead cost, financial measurements, and projections (break-even revenue, throughput accounting, and ROI) (Bick 2017, Regula et al. 2018). Operating cost was calculated using machine rate, average DFC time, and timber volume (Soman et al. 2019, Sahoo et al. 2019).

The cost input values used were: advertising (400 $), car and truck expense (12,000 $), contract labor (2500 $), depreciation (other than equipment) (4000 $), insurance (other than health 10,000 $), legal and professional services (1000 $), office expense (2000 $), supplies (12,000 $), taxes and licenses (2000 $), utilities (3000 $), job-specific cost (1500 $), daily investment (19 $), and a targeted rate of return (12%). The average number of annual working days was 210 days (approximately 7 months). Daily PMH for the harvester and forwarder were seven and nine hours, respectively.

Table 2 Hourly machine rate and inputs used for the harvester and forwarder estimated using machine rate and PATH

|

Factors |

Harvester |

Forwarder |

|

Preliminary data |

||

|

Make and Model |

Timberpro TN 725D, 2019 |

Timberpro TF830B, 2013 |

|

Purchase price, $ |

575,000 |

400,000 |

|

Salvage value, $ |

230,000 |

160,000 |

|

Loan term, years |

5 |

5 |

|

Economic life, years |

7 |

8 |

|

Machine hours until the significant repair |

4000 |

4000 |

|

Fuel consumption, L/PMH |

21.19 |

23.46 |

|

Scheduled machine hours, SMH/year |

1800 |

1800 |

|

Productive machine hours, PMH/year |

1350 |

1350 |

|

Utilization, % |

75 |

75 |

|

Fixed costs |

||

|

Depreciation, machine rate, $/year PATH, $/PMH |

49,286 |

30,000 |

|

57.5 |

40 |

|

|

Insurance, % |

1 |

1 |

|

Interest, % |

8 |

8 |

|

Operating costs |

||

|

Repair and maintenance cost, $/PMH |

20.00 |

15.00 |

|

Fuel cost, $/liter |

0.80 |

0.80 |

|

Lube cost for 1000 hours of service, $ |

2,000 |

2,000 |

|

Wages and fringe benefits, $/SMH |

39.00 |

39.00 |

2.7 Statistical Analysis

Statistical analysis was performed using R Core Team version 3.5.2 (2023). Linear regression models were fitted for each machine separately for both the prescriptions with DFC as the response variable and other non-time elements as predictor variables (Table 1). Natural logarithm transformation was used for the response variables to attain normality. Forward/backward stepwise model selection was based on the lowest AIC values using the MASS package (Venables and Ripley 2002). Z test was used to compare the DFC time and factors influencing it in both prescriptions (p<0.05). The results are presented with the average value of the variables and the standard error.

3. Results

3.1 Stand Inventory

The target basal area of the ECT stand after harvest was 17.4 m2/ha (40% of the initial basal area to be removed), but due to a severe storm event right after the harvest, the basal area was reduced to 10 m2/ha (66% removed, Table 3); and in GS, the target basal area was 24 m2/ha (25% of the initial basal area to be removed) and basal area was reduced to 23 m2/ha (29% removed) after storm event.

Table 3 Pre- and post- harvest inventory summarized for early commercial thinning (ECT) and group selection (GS) prescriptions

|

Prescriptions |

ECT |

GS |

||

|

Inventory |

Pre |

Post |

Pre |

Post |

|

Number of sample points |

12 |

12 |

11 |

11 |

|

Year of inventory |

2019 |

2021 |

2019 |

2021 |

|

Trees per hectare |

1292 |

342 |

1650 |

818 |

|

Basal area, m2/ha |

29 |

10 |

32 |

23 |

|

Quadratic mean diameter (QMD), cm |

20.86±1.17 |

22.70±5.68 |

±1.40 |

23.56±1.80 |

3.2 Felling and Processing

A total of 104 and 123 harvester cycles were observed for ECT and GS prescriptions, respectively. The average DFC for ECT was significantly lower than GS (p<0.05; Table 4). Processing time accounted for half (54 and 55%; p<0.05) of the harvester DFC time in ECT and GS prescriptions followed by travel time to the next tree (22 and 18%) and felling time (10 and 11%), respectively. The average distance travelled by the harvester to the next tree was not significantly different (p=0.38; ECT 0.80±0.12 m and GS 0.97±0.12 m) between both prescriptions. Average decking distance was not significantly different between ECT (1.4±0.24 m) and GS (1.8±0.30 m, p=0.20). The average butt-end diameter of felled trees in ECT (16.50±0.50 cm) was significantly smaller than that of GS (19.07±0.58 cm; p<0.05). The average number of cuts per harvester cycle was significantly less for ECT (2.89±0.14) than GS (3.48±0.12; p<0.05). Similarly, the average number of pieces per cycle in ECT (1.73±0.07) was significantly less than GS (2.29±0.08, p<0.05). The logs were cut into lengths of 3 m (average diameter 14.53 cm) and 6 m (22.12 cm). The regression model predicted distance between the felled trees, and butt-end diameter significantly influenced the DFC time in both prescriptions (adjusted R2 for ECT and GS being 0.38 and 0.30, respectively; Table 5).

Table 4 Average values of delay-free cycle (DFC) time elements (s) (average ± SE) for the harvester in early commercial thinning (ECT) and group selection (GS) prescriptions. p-value less than 0.05 indicates a significant difference existed

|

DFC elements |

ECT, s |

GS, s |

p-value |

|

Travel time to the next tree |

8.88±0.90 |

8.20±0.81 |

0.58 |

|

Felling time |

3.87±0.23 |

4.91±0.28 |

<0.05 |

|

Processing time |

21.00±0.87 |

25.72±1.26 |

<0.05 |

|

Scattering time |

14.52±1.76 |

17.36±1.83 |

0.27 |

|

Decking time |

15.81±2.90 |

23.44±3.90 |

0.11 |

|

DFC |

39.64±1.92 |

46.43±2.31 |

<0.05 |

Table 5 Regression models predicting the delay-free cycle (DFC) time of the harvester in early commercial thinning (ECT) and group selection (GS) prescriptions

|

Machines |

Silviculture prescriptions |

Adjusted R2 |

The model predicting DFC time |

|

Harvester |

ECT |

0.38 |

Log DFC = 2.17 (Distance between trees, m) ** + 1.12 (Butt-end diameter, cm) ** |

|

GS |

0.30 |

Log DFC = 4.08 (Distance between trees, m) ** + 1.40 (Butt-end diameter, cm) ** |

|

|

** ≤ 0.05 |

|||

3.3 Primary Extraction

The forwarding DFC time in ECT was significantly greater than GS (p<0.05, Table 6). Loading time (33%) accounted most for the DFC time, followed by unloading time (28%), travel loaded (26%), and travel empty (13%) in ECT. Similarly, in GS, loading time (48%) accounted for most time, followed by unloading (22%), travel loaded (17%), and travel empty time (13%). The average DFC time for ECT was significantly greater than GS (p<0.05). The average travel empty distance was significantly greater for ECT (265±65 m) than GS (99±18 m; p<0.05). There was a significant difference between the average travel distance from one pile to another (in-woods) for ECT (2.56±0.37 m) and GS (7.80±1.78 m; p<0.05). The average travel loaded distance to the landing was significantly higher in ECT (250±100 m) than GS (86±30 m; p<0.05). Similarly, the average number of pieces was significantly higher in ECT (134±65) than GS (69±10; p<0.05).

Table 6 Average values of delay-free cycle (DFC) time elements (average ± SE) for the forwarder in early commercial thinning (ECT) and group selection (GS) treatments. p-value less than 0.05 indicates a significant difference existed

|

Work elements |

ECT, s |

GS, s |

p-value |

|

Travel empty |

300.00±60.00 |

127.00±16.00 |

<0.05 |

|

Loading |

24.88±1.47 |

27.03±2.09 |

0.40 |

|

Travel loaded |

596.00±212 |

160.00±66.50 |

<0.05 |

|

Unloading |

22.21±1.69 |

17.10±0.69 |

<0.05 |

|

DFC, minutes |

33.00±7.76 |

17.00±1.13 |

<0.05 |

3.4 Harvesting Cost

The hourly cost of the harvester in the machine rate and PATH were 156.05 $/PMH and 161.38 $/PMH, respectively, and for the forwarder 129.72 $/PMH and 135.84 $/PMH. The harvest system cost for machine rate and PATH were 285.78 $/PMH and 297.22 $/PMH, respectively. The average volume per log in GS was significantly higher than ECT (p<0.05). Average number of logs per turn in the harvester cycle was significantly higher for GS than ECT (p<0.05), whereas vice versa in forwarding cycles (Table 7). The cost of harvesting wood was calculated as 21.08 $/m3 and 16.32 $/m3 for ECT and GS prescriptions, respectively.

Table 7 Cost and productivity of the harvester and forwarder in early commercial thinning (ECT) and group selection (GS) treatments

|

Machine |

Harvester |

Forwarder |

||

|

Prescriptions |

ECT |

GS |

ECT |

GS |

|

Logs/turn |

1.73 |

2.29 |

134 |

68.8 |

|

Volume per log, m3 |

0.10 |

0.16 |

0.10 |

0.16 |

|

Productivity, m3/PMH a |

11.38 |

13.38 |

17.64 |

27.99 |

|

Cost, $/m3 |

13.72 |

11.67 |

7.36 |

4.65 |

|

a productive machine hour |

||||

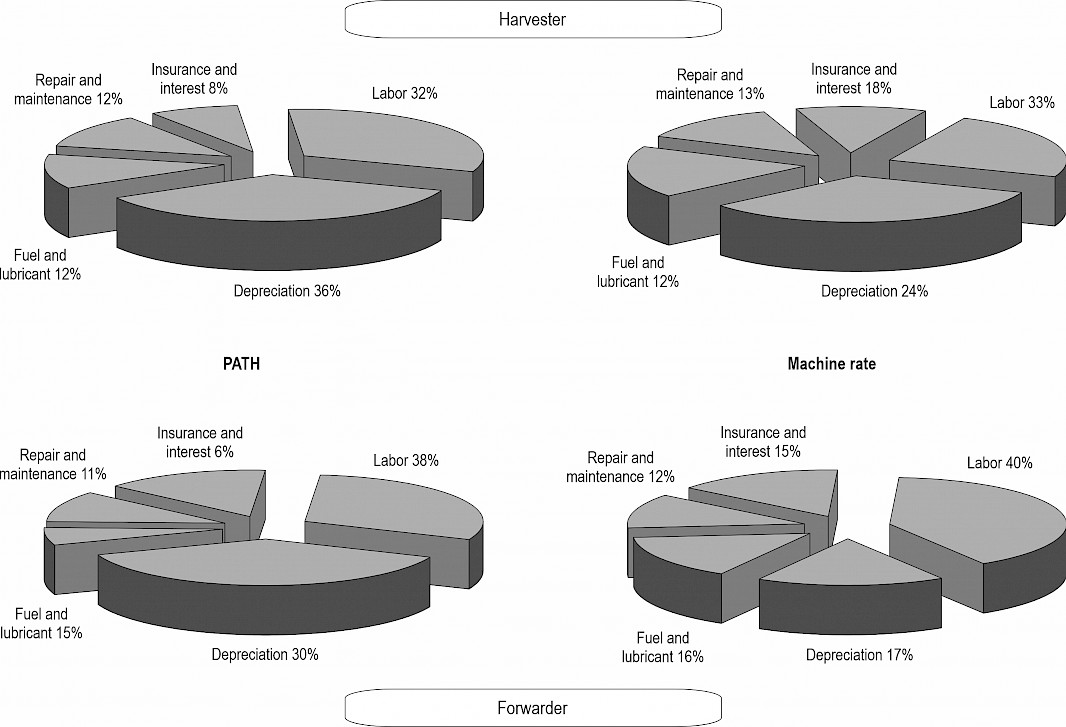

3.5 Hourly Cost Estimation

Labor cost and depreciation were major contributors to the hourly cost for both machines in the machine rate and PATH methods. The insurance and interest estimated in the machine rate calculation were more than double that of PATH, whereas the depreciation was higher in PATH compared to machine rate. The total hourly operating cost calculated for the harvester using machine rate (depreciation, interest, and insurance) estimated the fixed cost at 42%, whereas 8% in PATH (interest and insurance; Table 8 and Fig. 2). The variable cost was 25% in machine rate (fuel, lubricant, and repair and maintenance) and 60% in PATH (depreciation, fuel, lubricant, and repair and maintenance; Fig. 2). Variation in fixed and variable cost for both methods was due to how the depreciation component was determined. Depreciation was included in the fixed cost for machine rate and to the variable cost in PATH. Fixed cost for the forwarder contributed 32% of hourly operating cost in the machine rate method, whereas in PATH it was 6%. The variable cost was 28% in the former and 56% in the latter.

Fig. 2 The percentage contribution of fixed and variable cost to total hourly cost for the harvester and forwarder estimated using machine rate and PATH method

The daily overhead cost and annual expense in PATH were estimated to be 259 $ and 54,450 $, respectively, for 210 productive annual working days. Daily production of sawlog and stud wood was 16.88 and 10.43 tonnes, respectively. Daily investment in fixed assets was 19 $. Daily revenue and cost were 1223 $ and 2654 $, respectively. The results from financial management and projection showed that this harvesting operation should generate a minimum daily revenue of 2488 $ to be operational and 2654 $ to break-even.

Table 8 Comparison of hourly machine costs for the harvester and forwarder. Costs are expressed in terms of productive machine hours (PMH)

|

Machine |

Harvester |

Forwarder |

||

|

Method |

Machine rate |

PATH |

Machine rate |

PATH |

|

Fixed cost, $/PMH |

64.98 |

13.08 |

41.89 |

8.24 |

|

Variable cost, $/PMH |

39.07 |

96.30 |

35.83 |

75.60 |

|

Labor cost, $/PMH |

52.00 |

52.00 |

52.00 |

52.00 |

|

Total hourly cost, $/PMH |

156.05 |

161.38 |

129.72 |

135.84 |

4. Discussion

Early thinning prescriptions can provide long term benefits to the stand by inducing conditions that can increase merchantable volume, tree size, and financial value (Wagle et al. 2022). From an economic perspective, ECT in overstocked stands dominated by SDT leads to low operational productivity and high cost (Mederski et al. 2018). The average tree size of the felled trees and location of the landings were the key factors that influenced the cost of harvesting in both the prescriptions of this study.

4.1 Comparing Cost and Equipment Performance in ECT and GS

The average DFC time of the harvester in GS was higher than that of ECT, which can be attributed to the larger size of trees handled, resulting in higher number of cuts and more pieces per cycle. Additionally, in GS, for securing the next regeneration, processing was done at skid trails leading to longer decking distance. ECT was generally meant for removing smaller and less valuable trees to provide open space and growing conditions for the residual stand; whereas in GS, larger trees were cut to provide open space for the establishment of the regeneration (Wing et al. 2019). In both prescriptions, DBH was a significant factor influencing the harvester felling time (Ghaffariyan et al. 2015). Wood processing contributed most to the harvester working cycle time (Donagh et al. 2019, George et al. 2022). The average number of pieces per cycle ranged between 1.73 and 2.29, which was in accordance with previous studies (1.23–2.78) (Grönlund and Eliasson 2019, George et al. 2022). The estimated productivity of the harvester in this study (ECT 11.38 m3/PMH and GS 13.38 m3/PMH) was within the range of previous studies done in Maine (Benjamin et al. 2013, Hiesl et al. 2015a).

The average DFC time of the forwarder in ECT was higher than that of GS, mainly due to the higher average number of logs per cycle, which can be attributed to smaller piece size. The number of logs per cycle is directly proportional to loading time, the more number of smaller logs often decreased the productivity of the forwarder (Strandgard and Mitchell 2019). The volume of logs in GS was greater than that of ECT resulting in increased productivity. The forwarder productivity (ECT 17.64 m3/PMH and GS 27.99 m3/PMH) aligned with the other studies in Maine (Hiesl and Benjamin 2013, George et al. 2022). GS had better access to the three roadside landings (shorter average travel loaded distance) compared to ECT, resulting in lower extraction cost (Fig. 1 and Table 6). The harvest layout heavily influenced the travel loaded distance for both prescriptions. The travel distance between the log piles (inwoods) in GS was twice that of ECT, which was primarily due to the harvest gap size (0.1–0.2 ha) and spacing. In GS, the starting and ending points (landing) for the forwarding cycles may not be the same. In ECT, as felling was not concentrated in pockets and rather distributed evenly, the location of the landings at one end of the stand led to higher travel loaded distance. As balsam fir was the primary product in GS, the sorting time at the landing was reduced.

The scattered distribution of the harvest gaps influenced the productivity of GS (Hassler et al. 2000). The cost of harvesting wood for ECT (21.08 $/m3) and GS (16.32 $/m3) were within the range of other cost using CTL operations conducted in Maine (10.28 to 30.45 $/m3) (Benjamin et al. 2013, Hiesl et al. 2015a, George et al. 2019). Compared to the present study, the cost of harvesting on sensitive and fragile ground was higher (George et al. 2022), whereas increased extraction volume and machine utilization lower the cost (Benjamin et al. 2013). CTL is preferred over whole-tree harvesting method due to lower residual stand damage and fewer operators required (Kizha et al. 2021).

Harvest cost analysis showed an increase in the cost of operating in ECT compared to GS. This can be attributed to larger piece size, increased volume of timber harvested, and lower travel loaded distance in GS. Group selection is a commercial prescription intended to generate revenue.

4.2 Comparison of Cost Estimation Methods

The machine rate calculation method is appropriate for general cost estimation; however, it is not designed and has limited application as a tool for individual, equipment, and situation-specific estimation of cost (Dodson et al. 2015). PATH captures costs across the entire harvest system (machine, overhead, and job-specific costs) incurred for the individual logging operation excluding the road construction and maintenance costs (Bick 2017), which are not considered in the conventional analysis (Kizha and Han 2016). The hourly cost of harvester and forwarder estimated using both machine rate and PATH fell within the range of 124 to 161 $/PMH (Benjamin et al. 2013). The major reason for the difference in total hourly cost between machine rate and PATH is due to the difference in calculating depreciation, interest, and insurance.

Depreciation was higher for new equipment than old (Table 2). The harvester was a new machine, while the forwarder was an older one (2013 model). The machine rate treated the depreciation as part of fixed cost and it was estimated for the entire life of the equipment using the straight-line method, whereas in PATH, the functional depreciation (amount of value of the equipment used while operating) was treated as the variable cost (Germain et al. 2016, Bick 2017). The machine rate relies heavily on the rule of thumb to estimate the fixed and variable cost of the specific equipment (Dodson et al. 2015). The cost input variables in machine rate were accounted in yearly cost (for e.g., repair and maintenance cost are calculated as a percentage of annual depreciation), whereas in PATH, cost is being accounted in PMH. The interest and insurance estimation in machine rate is based on the average value of yearly investment over the entire economic life of the machine, which is calculated based on the purchase price, salvage value, and economic life (years). On the contrary, for PATH, monthly payment, number of re-payments (for a loan), financed amount, and machine ownership life (hours) were the input variables. The difference in the approach of calculating interest and insurance resulted in a higher percentage of estimated value for machine rate than PATH.

5. Conclusions

As expected, the harvesting of larger size trees in GS reduced the cost of operation compared to ECT. Along with this, better accessibility to roadside landing (shorter travel loaded distance) reduced the extraction cost in GS compared to ECT

the distance between felled trees and butt-end diameter were the significant factors influencing harvester DFC for both prescriptions

the harvest system cost was 4% higher for PATH than the machine rate method. The functional depreciation (PATH) value was higher than the straight-line depreciation (machine rate) value

labor cost and depreciation were the major contributors to the hourly cost of harvester and forwarder in machine rate and PATH methods.

Acknowledgement

We would like to thank Jonathan Swallow (Forester) and LandVest for the support and help in various stages of the study.

Funding

This research was supported by 1) US Department of Energy, Office of Energy Efficiency and Renewable Energy, Bioenergy Technology Office (Award # EE0006638), and the Agriculture and Food Research Initiative Competitive Grant No. 2019-67020-29287 from the USDA National Institute of Food and Agriculture; 2) McIntire-Stennis project number #ME042415 through the Maine Agricultural and Forest Experiment Station.

6. References

Adebayo, A.B., Han, H-S., Johnson, L., 2007: Productivity and cost of cut-to-length and whole-tree harvesting in a mixed-conifer stand. Forest Products Journal 57(6): 59–69.

Avery, T.E., Burkhart, H.E., 1983: Forest measurements. 3rd edn. McGraw-Hill Book Company, New York, USA, 331 p.

Benjamin, J.G., Seymour, R.S., Meacham, E., Wilson, J., 2013: Impact of whole-tree and cut-to-length harvesting on postharvest condition and logging costs for early commercial thinning in Maine. Northern Journal of Applied Forestry 30(4): 149–155. https://doi.org/10.5849/njaf.13-016

Bick, S., 2017: Planning and Analysis in Timber Harvesting | Manuals. Northern Loggers' Association and Forest Enterprise Institute, Thendara, NY, 43 p.

Bick, S., Benjamin, J.G., 2018: Continuous Improvement in Logging. Northeast Forests, LLC, Thendara, NY.

Bolding, M.C., Lanford, B.L., 2005: Wildfire fuel harvesting and resultant biomass utilization using a cut-to-length/small chipper system. Forest Products Journal 55(12): 181–188.

Brinker, R.W., Kinard, J., Rummer, R., Lanford, B., 2002: Machine rates for selected forest harvesting machines. Circular 296 (revised). Alabama Agricultural Experiment Station, Auburn University, Auburn, 32 p.

Brockway, D.G., Outcalt, K.W., 2015: Influence of selection systems and shelterwood methods on understory plant communities of longleaf pine forests in flatwoods and uplands. Forest Ecology and Management 357: 138–150. https://doi.org/10.1016/j.foreco.2015.08.020

Bustos-Letelier, O., Mena, C., Bussenius, W., Briceño, M., 2021: The influence of old and new machines on productivity and costs of four yarding methods in small-scale forestry in a Maine forest. Small-scale Forestry 20(9): 97–117. https://doi.org/10.1007/s11842-020-09458-1

Carter, D.R., Seymour, R.S., Fraver, S., Weiskittel, A., 201: Effects of multiaged silvicultural systems on reserve tree growth 19 years after establishment across multiple species in the Acadian forest in Maine, USA. Canadian Journal of Forest Research 47(10): 1314–1324. https://doi.org/10.1139/cjfr-2017-0120

Dodson, E., Hayes, S., Meek, J., Keyes, C.R., 2015: Montana logging machine rates. International Journal of Forest Engineering 26(2): 85–95. https://doi.org/10.1080/14942119.2015.1069497

Donagh, P.M., Roll, J., Hahn, G., Cubbage, F., 2019: Timber Harvesting Production, Costs, Innovation, and Capacity in the Southern Cone and the U.S. South. IntechOpen. https://doi.org/10.5772/intechopen.85412

George, A.K., Kizha, A.R., Kenefic, L., 2022: Timber harvesting on fragile ground and impacts of uncertainties in the operational costs. International Journal of Forest Engineering 33(1):12–21. https://doi.org/10.1080/14942119.2022.1988432

George, A.K., Kizha, A.R., Kenefic, L., 2019: Economic feasibility of timber harvesting in lowlands. In: Czupy, Imre, ed. Exceeding the vision: forest mechanisation of the future. University of Sopron Press, Sopron, Hungary, 379–393.

Germain, R., Bick, S., Kelly, M., Benjamin, J., Farrand, W., 2016: Case study of three high-performing contract loggers with distinct harvest systems: are they thriving, striving, or just surviving? Forest Products Journal 66(1–2): 97–105. https://doi.org/10.13073/FPJ-D-15-00010

Germain, R., Regula, J., Bick, S., Zhang, L., 2019: Factors impacting logging costs: A case study in the Northeast, US. The Forestry Chronicle 95(1): 16–23. https://doi.org/10.5558/tfc2019-005

Ghaffariyan, M.R., Spinelli, R., Magagnotti, N., Brown, M., 2015: Integrated harvesting for conventional log and energy wood assortments: a case study in a pine plantation in Western Australia. Southern Forests: a Journal of Forest Science 77(4): 249–254. https://doi.org/10.2989/20702620.2015.1052946

Grönlund, Ö., Eliasson, L., 2019: Birch shelterwood removal – harvester and forwarder time consumption, damage to understory spruce and net revenues. International Journal of Forest Engineering 30(1): 26–34. https://doi.org/10.1080/14942119.2019.1595943

Han, H-S., Lee, H.W., Johnson, L.R., 2004: Economic feasibility of an integrated harvesting system for small-diameter trees in southwest Idaho. Forest Products Journal 54(2): 21–27.

Hanzelka, N.C., Bolding, M.C., Sullivan, J., Barrett, S.M., 2016: Productivity and costs of utilizing small-diameter stems in a biomass-only harvest. International Journal of Forest Engineering 27(1): 43–52. https://doi.org/10.1080/14942119.2015.1135615

Hassler, C.C., Grushecky, S.T., LeDoux, C.B., 2000: The Effects of group selection harvest size on logging productivity. Northern Journal of Applied Forestry 17(2): 51–56. https://doi.org/10.1093/njaf/17.2.51

Helman, A., Kelly, M., Rouleau, M., Dickinson, Y., 2020: Preferences for northern hardwood silviculture among family forest owners in Michigan's upper peninsula. Journal of Forestry 119(2): 113–129. https://doi.org/10.1093/jofore/fvaa051

Hiesl, P., Benjamin, J., 2012: Cycle time analysis of harvesting equipment from an early-commercial-thinning treatment in Maine. In: Engineering new solutions for energy supply and demand. COFE, New Bern, North Carolina, 116–122 p.

Hiesl, P., Benjamin, J., 2013: Harvesting equipment cycle time and productivity guide for logging operations in Maine. Miscellaneous Publication 762, Maine Agricultural and Forest Experiment station, 56 p.

Hiesl, P., Benjamin, J., Roth, B., 2015a: Evaluating harvest costs and profit of commercial thinnings in softwood stands in west-central Maine: A case study. Forestry Chronicle 91(2): 150–160. https://doi.org/10.5558/tfc2015-026

Hiesl, P., Waring, T.M., Benjamin, J.G., 2015b: The effect of hardwood component on grapple skidder and stroke delimber idle time and productivity – An agent based model. Computers and Electronics in Agriculture 118: 270–280. https://doi.org/10.1016/j.compag.2015.09.010

Keyser, T.L., Loftis, D.L., 2021: Long-term effects of alternative partial harvesting methods on the woody regeneration layer in high-elevation Quercus rubra forests of the southern Appalachian Mountains, USA. Forest Ecology and Management 482: 118869. https://doi.org/10.1016/j.foreco.2020.118869

Kizha, A.R., Han, H-S., 2016: Processing and sorting forest residues: Cost, productivity and managerial impacts. Biomass and Bioenergy 93: 97–106. https://doi.org/10.1016/j.biombioe.2016.06.021

Kizha, A.R., Nahor, E., Coogen, N., Louis, L.T., George, A.K. 2021: Residual stand damage under different harvesting methods and mitigation strategies. Sustainability 13(14): 7641. https://doi.org/10.3390/su13147641

Leon, B.H., Benjamin, J.G., 2012: A survey of business attributes, harvest capacity and equipment infrastructure of logging businesses in the northern forest. School of Forest Resources, University of Maine, Orono, 29 p.

Louis, L.T., Kizha, A.R., 2021: Wood biomass recovery cost under different harvesting methods and market conditions. International Journal of Forest Engineering 32(2): 164–173. https://doi.org/10.1080/14942119.2021.1874206

Louis, L.T., Kizha, A.R., Daigneault, A., Han, H-S., Weiskittel, A., 2022: Factors affecting operational cost and productivity of ground-based timber harvesting machines: a meta-analysis. Current Forestry Reports 8(1): 38–54. https://doi.org/10.1007/s40725-021-00156-5

Maine Forest Service, 2023: Annual Reports: Publications: Maine Forest Service: Maine ACF. Forest Policy and Management Division, Augusta.

Mederski, P., Venanzi, R., Bembenek, M., Karaszewski, Z., Rosińska, M., Pilarek, Z., Luchenti, I., Surus, M., 2018: Designing thinning operations in 2nd age class Pine stands – economic and environmental implications. Forests 9(6): 335. https://doi.org/10.3390/f9060335

Miyata, E.S., 1980: Determining fixed and operation costs of logging equipment. North Central Forest Experiment Station, St Paul, Minnesota. https://doi.org/10.2737/NC-GTR-55

Muñoz Delgado, B.L., Kenefic, L.S., Weiskittel, A.R., Fernandez, I.J., Benjamin, J.G., Dibble, A.C., 2019: Northern mixedwood composition and productivity 50 years after whole-tree and stem-only harvesting with and without post-harvest prescribed burning. Forest Ecology and Management 441: 155–166. https://doi.org/10.1016/j.foreco.2019.03.032

NOAA, 2022: Local Climatological Data Station Details: FRENCHVILLE NORTHERN AROOSTOOK AIRPORT, ME US, WBAN:04836 | Climate Data Online (CDO) | National Climatic Data Center (NCDC). In: National centers for environmental information. https://www.ncdc.noaa.gov/cdo-web/datasets/LCD/stations/WBAN:04836/detail. Accessed 7 Sep 2022

Nolet, P., Kneeshaw, D., Messier, C., Béland, M., 2018: Comparing the effects of even- and uneven-aged silviculture on ecological diversity and processes: A review. Ecology and Evolution 8(2): 1217–1226. https://doi.org/10.1002/ece3.3737

Nyland, R.D., 2016: Silviculture: Concepts and Applications, Third Edition. Waveland Press, 680 p.

Pitt, D., Lanteigne, L., Hoepting, M.K., Plamondon, J., Duchesne, I., Bicho, P., Warren, G., 2013: Effects of precommercial thinning on the forest value chain in northwestern New Brunswick: Part 6 – Estimating the economic benefits. The Forestry Chronicle 89: 502–511. https://doi.org/10.5558/tfc2013-091

R Foundation, 2023: The R Project for Statistical Computing. https://www.r-project.org/. Accessed 14 May 2024

Regula, J., Germain, R., Bick, S., Zhang, L., 2018: Assessing the economic viability of loggers operating tree-length harvest systems in the northeast. Journal of Forestry 116(4): 347–356. https://doi.org/10.1093/jofore/fvy006

Sahoo, K., Bilek, E., Bergman, R., Kizha, A.R., Mani, S., 2019: Economic analysis of forest residues supply chain options to produce enhanced‐quality feedstocks. Biofuels, Bioproducts and Biorefining 13(3): 514–534. https://doi.org/10.1002/bbb.1958

Soil Survey, 2020: Citing web soil survey as a source of soils data. In: Natural resources conservation service, United States Department of Agriculture. http://websoilsurvey.sc.egov.usda.gov/. Accessed 9 Jan 2020

Soman, H., Kizha, A.R., Roth, B.E., 2019: Impacts of silvicultural prescriptions and implementation of best management practices on timber harvesting costs. International Journal of Forest Engineering 30(1): 14–25. https://doi.org/10.1080/14942119.2019.1562691

Strandgard, M., Mitchell, R., 2019: Comparison of cost, productivity and residue yield of cut-to-length and fuel-adapted harvesting in a Pinus radiata D.Don final harvest in Western Australia. New Zealand Journal of Forestry Science 49(9): 1–12. https://doi.org/10.33494/nzjfs492019x37x

Venables, B., Ripley, B., 2002: Modern Applied Statistics With S, Fourth. Springer US, New York, USA, 498 p.

Wagle, B.H., Weiskittel, A.R., Kizha, A.R., Berrill, J.P., D'Amato, A.W.,Marshall, D., 2022: Long-term influence of commercial thinning on stand structure and yield with/without pre-commercial thinning of spruce-fir in northern Maine, USA. Forest Ecology and Management 522: 120453. https://doi.org/10.1016/j.foreco.2022.120453

Williams, C., Ackerman, P., 2016: Cost-productivity analysis of South African pine sawtimber mechanised cut-to-length harvesting. Southern Forests: a Journal of Forest Science 78(4): 267–274. https://doi.org/10.2989/20702620.2016.1183096

Wing, B.M., Boston, K., Ritchie, M.W., 2019: A technique for implementing group selection treatments with multiple objectives using an airborne lidar-derived stem map in a heuristic environment. Forest Science 65(2): 211–222. https://doi.org/10.1093/forsci/fxy050

© 2023 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Ashish Alex, MSc

e-mail: ashish.alex@maine.edu

Assoc. prof. Anil Raj Kizha, PhD *

e-mail: anil.kizha@maine.edu

Assist. prof. Nicole S. Rogers, PhD

e-mail: nicole.s.rogers@maine.edu

University of Maine

School of Forest Resources

Orono, Maine, 04469

UNITED STATES

Assist. prof. Alex K. George, PhD

e-mail: ageorge2@paulsmiths.edu

Paul Smith's College

Paul Smiths, NY, 12970

UNITED STATES

Assist. prof. Libin T. Louis, PhD

e-mail: libin.thaikkattil@maine.edu

University of Maine at Fort Kent

Natural Science Unit

Maine, 04743

UNITED STATES

Prof. M. Chad Bolding, PhD

e-mail: bolding@uga.edu

University of Georgia

Warnell School of Forestry and Natural Resources

Athens, GA, 30602

UNITED STATES

Steven Bick, PhD

e-mail: steve@northeastforests.com

Northeast Forests, LLC

Thendara, New York, 13472

UNITED STATES

* Corresponding author

Received: July 27, 2023

Accepted: September 09, 2023

Original scientific paper