A Comparison of Two Felling Techniques Considering Stump-Height-Related Timber Value Loss

doi: 10.5552/crojfe.2023.1743

volume: 44, issue:

pp: 8

- Author(s):

-

- Gülci Neşe

- Gülci Sercan

- Akay Abdullah Emin

- Sessions John

- Article category:

- Original scientific paper

- Keywords:

- forest operation, biomass production, stump recovery, tree felling, brutian pine

Abstract

HTML

Harvest from plantations can provide both industrial wood and forest residues for bioenergy, including stumps. The literature suggests that the choice of cutting system can affect the division between industrial wood recovery and remaining stump volume. In this study, two felling techniques - motor-manual chainsaw and feller-buncher, were compared based on stump-height-related timber value loss for four ground slope classes: high, medium, low, and flat. The economic value loss of wood material for three products - sawlogs, pulpwood, and fiber-chip wood, was determined based on the estimated volume of stumps left in the woods. The results indicated that the average stump height for the motor-manual chainsaw and feller-buncher was 17.16 cm and 8.69 cm. The economic value loss of wood material per stump was higher in felling by manual chainsaw as compared to the feller-buncher operation (log: €0.60, paper wood: €0.29, fiber-chip: €0.15). However, volume loss due to high stumps could contribute to wood for bioenergy if stumps are subsequently removed. Additional research is needed to evaluate the benefits and costs of stump removal for bioenergy as part of a total supply chain to provide both industrial wood and wood for bioenergy.

A Comparison of Two Felling Techniques Considering Stump-Height-Related Timber Value Loss

Neşe Gülci, Sercan Gülci, Abdullah E. Akay, John Sessions

Abstract

Harvest from plantations can provide both industrial wood and forest residues for bioenergy, including stumps. The literature suggests that the choice of cutting system can affect the division between industrial wood recovery and remaining stump volume. In this study, two felling techniques - motor-manual chainsaw and feller-buncher, were compared based on stump-height-related timber value loss for four ground slope classes: high, medium, low, and flat. The economic value loss of wood material for three products - sawlogs, pulpwood, and fiber-chip wood, was determined based on the estimated volume of stumps left in the woods. The results indicated that the average stump height for the motor-manual chainsaw and feller-buncher was 17.16 cm and 8.69 cm. The economic value loss of wood material per stump was higher in felling by manual chainsaw as compared to the feller-buncher operation (log: €0.60, paper wood: €0.29, fiber-chip: €0.15). However, volume loss due to high stumps could contribute to wood for bioenergy if stumps are subsequently removed. Additional research is needed to evaluate the benefits and costs of stump removal for bioenergy as part of a total supply chain to provide both industrial wood and wood for bioenergy.

Keywords: forest operation, biomass production, stump recovery, tree felling, brutian pine

1. Introduction

Due to the global climate change crisis, energy demands in developed and developing countries have shifted to renewable sources as they emit less CO2 than fossil fuels. Due to the gas shortage in the 1970s, renewable energy research has emerged in the world. With more than 20 years of experience in renewable energy research, economic and environmental impacts of fossil fuels have been discussed with interconnected challenges in demographic, ergonomic, ecological and social aspects (Koh and Ghazoul 2008).

Wood-based renewable sources have been broadly studied as an alternative energy source. Recent investigations identify limits to biomass utilization due to land availability for various human needs, particularly agriculture (Reid et al. 2020). Even though wood-based biomass utilization cannot fully meet the global renewable energy needs, it still seems a promising alternative for the future (Lauri et al. 2014). According to the international global climate change agreements and acts, many countries, including Turkey, seek and promote alternative energy sources to fossil fuels (EU 2018). Turkey's renewable energy production capacity has increased 2.56 times between 2010 and 2019 (IRENE 2020). However, in Turkey, wood-based energy production has still the lowest share of renewable energy. Considering the policy of the 11th development plans in Turkey, the production rates of renewable energy sources is planned to increase by 2023 (Görücü et al. 2020, TDP 2019). Thus, employing suitable forest harvesting equipment plays an important role in wood-based biomass production in terms of both sustainability and productivity.

Tree felling is the first stage in forest harvesting operations, and it is considered as one of the most difficult and dangerous tasks, which requires skill and good judgment. Felling is mainly carried out by motor-manual chainsaw or by fully mechanized felling machines using a harvester or feller-buncher (Tunay and Melemez 2005, Bilici et al. 2019). In motor-manual tree felling, an undercut and back cut is performed by using a chainsaw. In mechanized harvesting operations, feller-bunchers use hydraulic cutting heads to cut and lift trees, and then use hydraulic arms to place them on the ground.

In Turkey, the chainsaw is commonly used for felling, delimbing, bucking, and debarking of trees. Recently, the feller-buncher has been introduced in northwestern Turkey, primarily for clear-cut operations in Brutian pine (Pinus brutia Ten.) stands (Bilici et al. 2019). In felling operations, chainsaw felling is not limited by ground slope, soil conditions, and tree size, while the feller-buncher is usually limited by these factors. In addition, working with feller-bunchers on a rocky surface may damage the tracks, cutting saw and discs of the feller-buncher (Han and Renzie 2005).

As wood-based biomass is in a leading position among other sources of renewable energy (Lauri et al. 2014), forest harvesting operations are potentially the main source of material. However, utilization of wood-based biomass is not at the expected level due to management challenges and some practices in forest harvesting operations (Matthews et al. 2014). During the extraction of both below- and above-ground biomass from forestlands, some utilizable parts of the tress are not being harvested and are left in the woods. For example, after the tree felling operations, stumps are mostly left in the woods in many countries, including Turkey. In addition to ensuring the desired felling direction, the height of the stump left in the woods should also be controlled (Akay et al. 2006). The stump height remaining in the forest should be as low as possible as it plays an important role in the amount of wood-based biomass (Díaz-Yáñez et al. 2013).

Leaving high stumps, which leads to a lower amount of wood material being recovered, can result in considerable timber value and volume loss. The height of the stump varies depending on several factors such as ground slope, tree felling technique, and operator experience. The stump-height-related value loss is mostly affected by the forest harvesting tools, environmental conditions, and human factors (Ramantswana et al. 2017). Boston and Dysart (2000) investigated the possible value losses due to stump heights considering a range of feller-buncher heads and manual felling. It was reported that motor-manual felling resulted in the highest stump height. Han and Renzie (2005) studied the effect of ground slope and stump diameter on the stump height for motor-manual felling technique using chainsaw and feller-bunchers. It was observed that average stump heights increased up to a ground slope of 45% for both felling techniques. In a similar study, the mean measured stump height from motor-manual felling was 8.8 cm higher than that of mechanized felling (Hall and Han 2006).

In the present study, the stump height and potential value loss were investigated for motor-manual chainsaw and feller-buncher. Since mechanized felling using a feller-buncher has been recently introduced to forestry operations in Turkey, there have been no studies conducted on the determination of stump height for feller-buncher operations. The effect of ground slope on the stump height was also examined for the two felling methods. Finally, the importance of stump height and roots in stump sites were evaluated considering bioenergy production and resin extraction.

2. Materials and Methods

2.1 Study Area

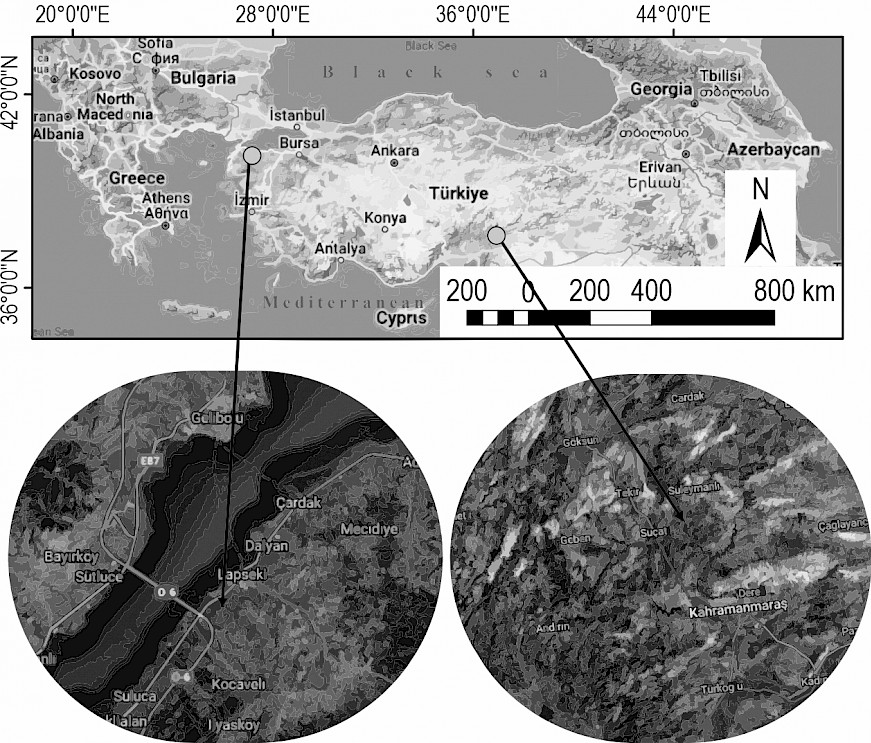

The study was implemented in two Brutian pine stands, one located in the northwestern city of Çanakkale and the other in eastern Mediterranean city of Kahramanmaraş in Turkey. The tree felling was performed by a feller-buncher in Lapseki Forest Enterprise Chief (FEC) located in Çanakkale, while motor-manual tree felling by chainsaw was conducted in Çınarpınar FEC located in Kahramanmaraş (Fig. 1). The average ground slopes of these two study sites were 38% and 37%, respectively. Both felling techniques were performed in Brutian pine stands with similar characteristics. According to the statistical data of General Directorate of Forestry (GDF), the total volume and distribution area of Brutian pine is estimated as 305,581,835 m3 (88.6 m3 ha-1) and 3,450,000 ha, respectively, in Turkey (GDF 2018).

Fig. 1 Geo-location and general overview of study area

2.2 Field Study

In the study site located in Çanakkale, tree felling was carried out with a 2015 model WoodCracker C450 brand feller-buncher. A Stihl MS 381 chainsaw was used in the second site located in Kahramanmaraş. In both sites, cutting operations were carried out by operators with at least one year of work experience. The study paid attention to factors such as similarity in average slope, tree size and log diameter in both study sites. During the fieldwork, stump diameter, stump height, and terrain slope were measured using calipers, steel-tape, and clinometer, and were recorded into data sheets (Fig. 2). The stump height was measured from both uphill and downhill sides and then the average value of both measurements was used in the study.

Fig. 2 Sample stumps cut with feller-buncher (left) and with chainsaw (right)

2.3 Analysis of Stump Height and Timber Value Loss

In each study site, the stump data were collected from 120 randomly selected Brutian pine trees. Within the scope of statistical analysis, the mean of stump data (i.e. diameter, height, volume, and slope) was first calculated using the SPSS program. First, to compare with obtained values from the two different fields (i.e. the slope, stump height, stump diameter and stump volume), Paired-Samples t-test was applied. Then, the effect of slope classes on stump height was examined with a 95% confidence level using One-Way ANOVA and Duncan Multiple Comparison Test. In order to examine the effect of ground slope on stump height, the slopes were divided into classes specified by IUFRO slope classification (i.e. steep >50%, high 34–50%, medium 21–33%, low 11–20%, flat <0–10%). However, in the present study, steep terrain was not available in the study sites; therefore, 30 sample trees were measured from four slope classes including high, medium, low and flat. Finally, the correlations among diameter, height, volume and slope were investigated using a Pearson correlation test.

In order to compare the two felling techniques in terms of timber value loss, the economic value of each stump was computed by multiplying volume of the stump with the average unit sale price of the wood in the most recent auctions. Considering the shape of the Brutian pine stump, the volume of the stump was computed based on cylinder formula using Eq. 1 (Cailliez 1980).

(1)

(1)

Where:

V volume of stump, m3

r top radius of stump, m

h height of stump, m

Depending on the field observations, it was estimated that the wood quality grade of the stump was similar to grade 3 wood with the normal length for three forest products (i.e. sawlog, pulpwood, and fiber-chip wood) produced in both study sites. According to the economic data obtained from the Forest Enterprise Directorates, the most recent unit sale price for sawlog, pulpwood, and fiber-chip wood was estimated as €67.66, €32.47, and €17.00 per m3, respectively (1 Turkish Lira = 0.17 Euro obtained from the Central Bank of Turkey at the time of study).

3. Results and Discussion

3.1 Comparison of Stump Height

The results of t-test showed that there was a significant difference (p<0.01) between collected values (i.e. the slope, stump height, stump diameter and stump volume) from the two different sites. For the feller-buncher study, the average stump data of diameter, height, volume, and slope were computed as 39.79 cm, 8.69 cm, 0.01 m3, and 22%, respectively. For the chainsaw study, the average stump data was 36.50 cm, 17.16 cm, 0.02 m3, and 22%, respectively. Thus, the average stump height at the chainsaw study was higher by 8.47 cm compared to the feller-buncher site study. The difference in stump heights corresponded closely to a similar study by Hall and Han (2006), who reported that the average stump height of the trees cut by feller-buncher was 8.8 cm lower compared to chainsaw.

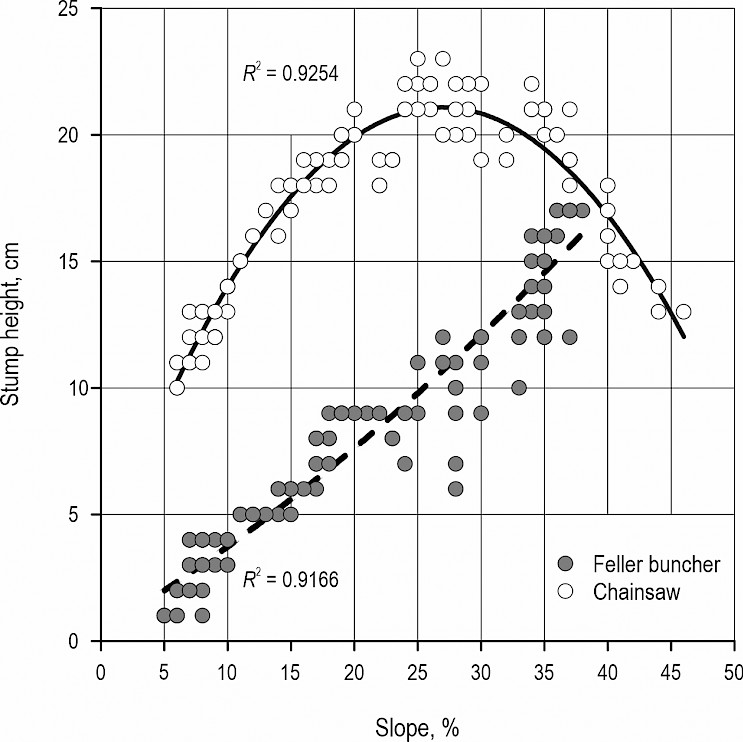

The results of the One-Way ANOVA and Duncan Multiple Comparison Test run for feller-buncher and chainsaw felling techniques are presented in Table 1. The statistical data demonstrated that slope classes had a significant effect (p<0.00) on stump height for both felling techniques. For the feller-buncher, the average stump height increased from flat to low, medium, and high slope classes. The flat class (0–10%) showed the lowest impact on the stump height (2.57 cm), while the high slope class (34–50%) showed the highest impact on the stump height (15.43 cm). Han and Renzi (2005) also indicated that feller-bunchers produced lower stump height than chainsaws at less than 30% slope.

Table 1 One-Way ANOVA analysis results and Duncan’s multiple comparison test for stump height

|

Slope classes |

Number of samples |

Mean±Std. deviation |

Duncan test |

|

|

Feller-buncher p=0.00<0.05 |

Flat (0–10%) |

30 |

2.57±1.14 |

A |

|

Low (11–20%) |

30 |

6.67±1.47 |

B |

|

|

Medium (21–33%) |

30 |

10.10±1.92 |

C |

|

|

High (34–50%) |

30 |

15.43±1.68 |

D |

|

|

All classes |

120 |

8.69±4.99 |

– |

|

|

Chainsaw p=0.00<0.05 |

Flat (0–10%) |

30 |

12.17±1.26 |

A |

|

Low (11–20%) |

30 |

18.10±1.67 |

B |

|

|

Medium (21–33%) |

30 |

20.57±1.45 |

C |

|

|

High (34–50%) |

30 |

17.80±2.93 |

B |

|

|

All classes |

120 |

17.16±3.63 |

– |

The average stump height for chainsaw felling increased from the flat slope class to low, high, and medium slope classes. The medium slope classes (21–33%) had the highest impact on stump height (20.57 cm), while the flat slope class had the lowest impact on stump height (12.17 cm). The results of the present study indicated similarities with related research. For example, Han and Renzi (2005) also reported that the average stump heights in chainsaw technique tended to decrease at slopes higher than 45%.

The distributions of stump height, diameter, volume and slope classes are shown in Fig. 3 with bar and line graphs. The scatter plots shown in the lower left corner of the figure represent the relationships between the variables. According to the correlation test for the feller-buncher, there was a strong positive correlation between stump height and slope classes (r=0.95), and stump volume and slope classes (r=0.59). Besides, there was a strong positive correlation between stump height and slope classes (r=0.56), and stump DBH and stump volume (r=0.31). On the other hand, there was a strong negative correlation between slope classes and stump DBH (r=-0.40), and stump height and stump DBH (r=-0.47). The correlation test for chainsaw indicated that there was a strong positive correlation between stump height and slope classes (r=0.60), stump volume and stump height (r=0.39), and stump volume and stump DBH (r=0.89) (Fig. 4).

Fig. 3 Results of correlation tests for feller-buncher and linear relation plots of variables

Fig. 4 Results of correlation tests for chainsaw and linear plot of variables

The results indicated that the stump height and stump volume increased as the slope increased for the feller-buncher, while they decreased as the slope increased for the chainsaw (Fig. 5). Similarly, Han and Renzi (2005) reported that there were no significant differences between the stump heights of both felling techniques (p>0.05) at a slope of 2 to 17.5%. At a slope of 20 to 28.5%, the average stump height of the trees cut by the chainsaw was significantly higher compared to the feller-buncher (p<0.0066).

Fig. 5 Stump height as a function of slope between two felling methods. Data fit with a quadratic polynomial

3.2 Estimating Timber Value Loss

Based on the volume of the stump and the average unit sale price of the wood, the economic value of each stump was computed for both felling techniques. For the feller-buncher, the total value loss for the 120 Brutian pine trees based on the stump volume was calculated as €82.85, €39.76, and €20.82 for sawlog, pulpwood, and fiber-chip wood, respectively. On the other hand, for chainsaw felling, the total value loss was calculated as €155.03, €74.40, and €38.95 for these three forest products, respectively. Therefore, the total value loss from the stumps of 120 Brutian pine trees cut by a chainsaw was €72.18 (€0.60 per stump), €34.64 (€0.29 per stump), and €18.14 (€0.15 per stump) higher compared to feller-buncher for sawlog, pulpwood, and fiber-chip wood, respectively.

Hall and Han (2006) reported that the chainsaw felling had value losses of €0.29 and €0.19 higher compared to the feller-buncher for sawlog and pulpwood recovered per stump, respectively. In a similar study, Boston and Dysart (2000) stated that chainsaw felling significantly reduced the value of the logs recovered compared to the feller-buncher, the difference being approximately 600 €/ha in their study. In Turkey, the average Brutian pine stand is approximately 900 trees/ha (GDF 2018). For 900 trees/ha, after chainsaw felling and feller-buncher felling, the post-harvest stump volume is 18 m3/ha and 9 m3/ha in forest, respectively. If the remaining stump volume after chainsaw felling is converted into value using the sawlog, pulpwood, and fiber-chip wood sale prices, 1218 €/ha, 584 €/ha, and 306 €/ha is left in the forest. The feller-buncher left only one-half of the value compared to the chainsaw.

3.3 Assessment of Stumps for Bioenergy

In Turkey, research on below- and above-ground biomass still requires additional research, including harvesting costs and the net energy productivity of Brutian pine trees. Considering the current technology and machinery in Turkey, recovery of stumps in high forests can be challenged due to the impact of harvesting efficiency and cost based on the net energy of the study area. The loading and unloading costs of trucks, transportation and other processing machinery require further study. Lindholm et al. (2010) found that the net energy benefit generated by tree stumps is very low. However, this result may be different for Brutian pine tree stumps, which have a high volatile content and have huge potential uses in bioenergy or resins (Güler 2019, Önal and Ferah 1986). Due to the lack of a comprehensive tree stump harvesting efficiency and cost analysis, we can only speculate at this time. Therefore, there is an urgent need to propose a measurement system (i.e. model-based estimates) and site-specific stump harvest management procedures (Palander et al. 2009).

Harvesting of stumps and roots is usually carried out in industrial forest plantations managed by the General Directorate of Turkish Forestry. In Turkey, the possible equipment for stump removal operations are excavators, or dozers for stump removal, tractors with cable crane for pulling and skidding, loaders for loading to truck, and trucks for transport to mills, plants, or depots. Stump removal stages are divided into two main processes 1) lifting, splitting, piling, filling and moving and 2) extraction from stump site to landing site.

Currently, the cost of stump logging using existing tools is expensive. According to interviews with contractors, stumps and roots can be purchased at a unit price of approximately 1.17 €/ton (excluding VAT). In addition, suppliers and contractors stated that the total cost of extraction and transportation of fresh Brutian pine stumps and roots is between 42.44 €/ton for short distance and 76.40 €/ton for distances greater than 100 km.

An energy plant with an installed capacity of 16 MW requires 400–500 tons of fresh Brutian pine stumps and roots per day. According to the data of an average of 900 trees/ha with a range of ground slope of the Brutian pine in forest plantation areas, the stump volumes of the trees felled by the feller-buncher and chainsaw are 5.2 ton/ha and 9.5 ton/ha, respectively. For bioenergy purposes, the stumps from chainsaw felling are more profitable than feller-buncher felling activities in low- and medium ground slopes (Table 1). However, the opportunity cost for industrial use of stumps is currently higher than the use of stumps to bioenergy. The stump harvesting effect on soils is an issue that needs long term studies on short and long term environmental effects (Persson and Egnell 2018, Walmsley and Godbold 2010). Hence, the balance of positives and negatives of tree stump recovery for bioenergy is uncertain for Brutian pine. Industrial sawlogs, pulpwood, and fiber-chip wood instead of bioenergy are still considered preferable to stump harvesting.

4. Conclusion

In this study, two different felling techniques, feller-buncher (mechanized) and chainsaw (motor-manual) techniques, were compared based on stump height and timber value loss with respect to ground slope classes (i.e. high, medium, low, and flat). The findings indicated that the average stump height of the trees cut with chainsaw were 50% higher compared to the stump height using feller-buncher. It was found out that the stump height, and stump volume for the feller-buncher were directly proportional to the slope, while they decreased as the slope increased for the chainsaw. When the slope exceeded 33%, the productivity of the mechanized felling decreased since the stump height of the trees cut by feller-buncher considerably increased in the field. On the other hand, chainsaw had the most productive felling performance after 33% slope. The current stump utilization for heating energy can be considered as an alternative use in forestry. However, many knowledge gaps remain about stump removal operations in Turkey. Calculated recovery value of stumps for bioenergy is currently very low when compared to feller-buncher for sawlog, pulpwood, and fiber-chip wood. As a result, the felling operation with the feller-buncher yielded more industrial wood compared to chainsaw felling. Therefore, mechanical harvesting equipment should be used for effective timber production, especially in forest areas with favorable ground slopes. At the same time, increasing the use of mechanical harvesting equipment in Turkish forest management can help prevent volume loss caused by leaving high stumps.

5. References

Akay, A.E., Yilmaz, M., Tonguc, F., 2006: Impact of mechanized harvesting machines on forest ecosystem: Residual stand damage. Journal of Applied Sciences 6(11): 2414–2419. https://doi.org/10.3923/jas.2006.2414.2419

Bilici, E., Akay, A.E., Abbas, D., 2019: Assessing the effects of site factors on the productivity of a feller buncher: a time and motion analysis. Journal of Forestry Research 30(4): 1471–1478. https://doi.org/10.1007/s11676-018-0696-4

Boston, K., Dysart, G., 2000: A comparison of felling techniques on stump height and log damage with economic interpretations. Western Journal of Applied Forestry 15(2): 59–61. https://doi.org/10.1093/wjaf/15.2.59

Cailliez, F., 1980: Forest volume estimation and yield prediction. vol. 1: Volume estimation, UN Food and Agriculture Organization (FAO) Paper 22/1, Rome. 98 p.

Díaz-Yáñez, O., Mola-Yudego, B., Anttila, P., Röser, D., Asikainen, A., 2013: Forest chips for energy in Europe: Current procurement methods and potentials. Renewable and Sustainable Energy Reviews 21: 562–571. https://doi.org/10.1016/j.rser.2012.12.016

European Union (EU), 2018: On the promotion of the use of energy from renewable sources. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018. (Official Journal of the European Union). Available at: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001&qid=1618351654940&from=EN

GDF, 2018: Forestry Statistics 2017. General Directorate of Forestry. https://www.ogm.gov.tr/ekutuphane/StratejikPlan/Forms/AllItems.aspx

Görücü, Ö., Tolunay, A., Güneş, Y., Topçu, P., 2020: Industrial plantations and forest products industry. Journal of Bartin Faculty of Forestry 22(3): 939–952. https://doi.org 10.24011/barofd.783160

Güler, G., 2019: A Comparison of Brutian Pine (Pinus brutia Ten.) Root volatile compounds vs. the stem wood. BioResources 14(4): 9307–9316.

Hall, R., Han, H-S., 2006: Improvements in value recovery through low stump heights: mechanized versus manual felling. Wester Journal of Applied Forestry 21(1): 33–38. https://doi.org/10.1093/wjaf/21.1.33

Han, H-S., Renzie, C., 2005: Effect of ground slope, stump diameter, and species on stump height for feller-buncher and chainsaw felling. International Journal of Forestry Engineering 16(2): 81–88. https://doi.org/10.1080/14942119.2005.10702517

IRENE, 2020: Renewable energy statistics 2020. The International Renewable Energy Agency, Abu Dhabi.

Koh, L.P., Ghazoul, J., 2008: Biofuels, biodiversity, and people: understanding the conflicts and finding opportunities. Biological Conservation 141(10): 2450–2460. https://doi.org/10.1016/j.biocon.2008.08.005

Lauri, P., Havlik, P., Kindermann, G., Forsell, N., Böttcher, H., Obersteiner, M., 2014: Woody biomass energy potential in 2050. Energy Policy 66: 19–31. https://doi.org/10.1016/j.enpol.2013.11.033

Lindholm, E., Berg, S., Hansson, P., 2010: Energy efficiency and the environmental impact of harvesting stumps and logging residues. European Journal of Forest Research 129(6): 1223. https://doi.org/10.1007/s10342-010-0412-1

Matthews, R., Sokka, L., Soimakallio, S., Mortimer, N., Rix, J., Schelhaas, M-J., Jenkins, T., Hogan, G., Mackie, E., Morris, A., Randle, T., 2014: Review of literature on biogenic carbon and life cycle assessment of forest bioenergy. Final Task 1 Report (No. Ener/C1/427). The Research Agency of the Forestry Commission.

Önal, S., Ferah, O., 1986: Sudies on the resin production from calabrian pine (P. brutia Ten.) stumps and roots by extraction method. Forestry Research Institute Publications Technical Bulletin.

Palander, T., Vesa, L., Tokola, T., Pihlaja, P., Ovaskainen, H., 2009: Modelling the stump biomass of stands for energy production using a harvester data management system. Biosystems Engineering 102(1): 69–74. https://doi.org/10.1016/j.biosystemseng.2008.09.020

Persson, T., Egnell, G., 2018: Stump harvesting for bioenergy: A review of climatic and environmental impacts in northern Europe and America. Wiley Interdisciplinary Reviews – Wires Energy and Environment 7(6): 307. https://doi.org/10.1002/wene.307

Ramantswana, M., Mcewan, A., Spinelli, R., 2017: The effect of coppice management on stump volume recovery in mechanized operations. Annals of Forest Science 74(3): 58. https://doi.org/10.1007/s13595-017-0656-8

Reid, W.V., Ali, M.K., Field, C.B., 2020: The future of bioenergy. Global Change Biology 26(1): 274–286. https://doi.org/10.1111/gcb.14883

TDP, 2019: 11th Development Plan (2019–2023). Presidency of the Republic of Turkey.

Tunay, M., Melemez, K., 2005: A research on harvesting operations which are made with power-saw. Journal of the Faculty of Forestry Istanbul University 55(2): 31–41.

Walmsley, J.D., Godbold, D.L., 2010: Stump harvesting for bioenergy–a review of the environmental impacts. Forestry 83(1): 17–38. https://doi.org/10.1093/forestry/cpp028

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Asst. prof. Neşe Gülci, PhD *

e-mail: nesegulci@gmail.com

Assoc. prof. Sercan Gülci, PhD

e-mail: sercangulcu@gmail.com

Kahramanmaras Sutcu Imam University

Faculty of Forestry

Avsar Mah. Bati Cevreyolu Blv.

46040 Onikisubat-Kahramanmaras

TURKEY

Prof. Abdullah E. Akay, PhD

e-mail: abdullah.akay@btu.edu.tr

Bursa Technical Univesity

Faculty of Forestry

Eflak Cad. No:177

16310 Yıldırım-Bursa

TURKEY

Prof. John Sessions, PhD

e-mail: john.sessions@oregonstate.edu

Oregon State University

College of Forestry

336 Peavy Forest Science Complex

Corvallis OR 97331-5704

USA

* Corresponding author

Received: July 05, 2021

Accepted: October 15, 2021

Original scientific paper