Effects of Changing Drive Control Method of Idling Wood Size Reduction Machines on Fuel Consumption and Exhaust Emissions

doi: 10.5552/crojfe.2023.1700

volume: 44, issue:

pp: 14

- Author(s):

-

- Warguła Łukasz

- Lijewski Piotr

- Kukla Mateusz

- Article category:

- Original scientific paper

- Keywords:

- speed control, combustion, small SI engine, CO emissions, CO2 emissions, HC emissions, NOx emissions

Abstract

HTML

Operating conditions often fluctuate during processing of branches and sawmill offcuts using low-power wood size reduction machines (WSRMs), mainly due to changes in wood supply frequency. This results in relatively high proportions of idling time. Fuel consumption and associated exhaust emissions of WSRMs with combustion engines can be reduced by using innovative drive unit control systems during idling. The objective of the research was to determine the effects of two speed control systems on the fuel consumption and exhaust emissions of a WSRM with a two-cylinder cutting mechanisms driven by a small 9.5 kW spark ignition engine. Speed control system A (commercially available) had a substantially higher rotational speed than system B (an innovative, adaptive solution subject to patent application No. P433586). Pine (Pinus sylvestris L.) wood sawmill offcuts (average cross-sectional area, length and water content: 25×40 mm, 3000 mm and ca. 12

, respectively) were used in system tests at a feed rate of ca. 5 pieces min-1. Material of this size is typically processed by such machines. Operating conditions were monitored by recording the rotational speed and torque. Emissions of harmful exhaust compounds–carbon monoxide (CO), carbon dioxide (CO2), hydrocarbons (HC), and nitrogen oxides (NOx) – were recorded using a portable emission measurement system. Fuel consumption values were also calculated from the data. The following effects were observed: application of innovative system B resulted in 33% lower fuel consumption, as well as 30%, 37% and 33% lower CO, CO2 and NOx emissions, respectively, than system A, but at the same time 290% higher HC emissions were registered. In operating conditions with higher proportions of idling time, solution B provides even higher reductions in fuel consumption and exhaust emissions.

Effects of Changing Drive Control Method of Idling Wood Size Reduction Machines on Fuel Consumption and Exhaust Emissions

Łukasz Warguła, Piotr Lijewski, Mateusz Kukla

Abstract

Operating conditions often fluctuate during processing of branches and sawmill offcuts using low-power wood size reduction machines (WSRMs), mainly due to changes in wood supply frequency. This results in relatively high proportions of idling time. Fuel consumption and associated exhaust emissions of WSRMs with combustion engines can be reduced by using innovative drive unit control systems during idling. The objective of the research was to determine the effects of two speed control systems on the fuel consumption and exhaust emissions of a WSRM with a two-cylinder cutting mechanisms driven by a small 9.5 kW spark ignition engine. Speed control system A (commercially available) had a substantially higher rotational speed than system B (an innovative, adaptive solution subject to patent application No. P433586). Pine (Pinus sylvestris L.) wood sawmill offcuts (average cross-sectional area, length and water content: 25×40 mm, 3000 mm and ca. 12

, respectively) were used in system tests at a feed rate of ca. 5 pieces min-1. Material of this size is typically processed by such machines. Operating conditions were monitored by recording the rotational speed and torque. Emissions of harmful exhaust compounds–carbon monoxide (CO), carbon dioxide (CO2), hydrocarbons (HC), and nitrogen oxides (NOx) – were recorded using a portable emission measurement system. Fuel consumption values were also calculated from the data. The following effects were observed: application of innovative system B resulted in 33% lower fuel consumption, as well as 30%, 37% and 33% lower CO, CO2 and NOx emissions, respectively, than system A, but at the same time 290% higher HC emissions were registered. In operating conditions with higher proportions of idling time, solution B provides even higher reductions in fuel consumption and exhaust emissions.

Keywords: speed control, combustion, small SI engine, CO emissions, CO2 emissions, HC emissions, NOx emissions

1. Introduction

Reducing air pollution and energy consumption during wood size reduction (WSR) operations is important in applications such as generation of wood and wood-based products, biomass harvesting and maintenance of forests, orchards, and urban green areas. The most widely used wood size reduction machines (WSRMs) for energy generation purposes are woodchippers, which produce wood of 5–50 mm. Others reduce wood to sizes of 50–150 mm (chunks) and 150–500 mm (firewood). Research on WSRMS has mainly addressed the cutting mechanism effect on the energy used for chipping, in fuel consumption terms. Many studies have examined effects of blade wear (Nati et al. 2010, Manzone and Spinelli 2013, Facello et al. 2013, Spinelli et al. 2014, Spinelli and Magagnotti 2014, Nati et al. 2014, Spinelli et al. 2015), screen size settings (Nati et al. 2010, Assirelli et al. 2013, Han et al. 2015, Laitila and Routa 2015, Eliasson et al. 2015), and type of cutting mechanism (Manzone 2015, Spinelli et al. 2015, Manzone and Balsari 2015, Nati et al. 2014) on fuel consumption. Findings have shown that blade wear and use of screens with smaller holes increase energy consumption during WSR (Nati et al. 2010). The relationship between blade durability and geometry has also been studied. Generally, reducing a knife blade point angle decreases the cutting force at the expense of blade lifetime (Gao et al. 2021, Flizikowski et al. 2021). Other studies have shown that efficiency can be increased by improving biomass production management, highlighting the significant proportion of undesirable idling time in these processes (Spinelli and Visser 2009). Three main sets of factors affecting idling time have been identified: mechanical, organisational, and human. Spinelli and Visser (2009) set the average idle time of WSRMs at 26% but focused on chipping machines used in industrial biomass production that can shred logs and are often operated by loaders that enable a continuous feeding. Operational parameters of low-power machines, used in urban areas for reducing the size of wood up to ca. 100 mm in diameter, are substantially different. In the European Union, such machines are usually powered by engines in the non-road small Spark Ignition (SI) category up to 19 kW (Regulation 2016/1628/EU). Their operation varies considerably, depending on wood feeding frequency, and thus distances to wood piles, their entanglement, and the crew size (Warguła et al. 2019, Warguła et al. 2020b). Wood from urbanized areas usually consists of branches or sawmill cuttings. Even when the pile of wood is close to the machine (e.g. approx. 1 m), it is still very difficult to ensure continuous operation. For example, it takes four seconds to reduce the size of a branch ca. 3 m long using a machine with a two-cylinder cutting mechanism. Hence, the ideal wood supply frequency would be around 15 pieces min-1, but the average actual frequency is ca. 4 pieces min-1. Under these conditions, the idling time can account for 73% of the machine operating time and other delays can increase it.

Negative effects of long idling times of machines or vehicles powered by internal combustion engines can be reduced using state-of-the-art technology, e.g. the start and stop systems in automotive vehicles (Ji et al. 2016) or the deactivation of selected cylinders (Ding et al. 2016, Abas et al. 2017). Cylinder deactivation is beneficial for multi-cylinder engines, but it cannot be applied in many small engines as they are often single cylinder. In contrast, a start and stop system automatically stops the engine when the car comes to a standstill and is deactivated by pressing the accelerator pedal (Sommer et al. 2010). For WSRMs with a feeding rate of 4 pieces min-1 and a processing time of 4 s per piece, the idle time is 11 s per piece. In such cases, it seems advantageous to change the rotational speed rather than stop the engine. In addition, a classic WSRM with a low-power motor (hereafter solution A) idles at high speed, allowing the WSR process to continue using maximum power. Such a system cannot detect the material to be processed, so there is no information about whether to change the drive parameters. The system only monitors the rotational speed, which changes when thick wood is being processed, due to use of a centrifugal mechanism on the engine crankshaft, which is integrated with the carburettor flap. After detecting a significant load on the working mechanism, the system opens the throttle valve, increasing inflow of the fuel-air mixture, thus allowing an increase in power during the size reduction process. This compensates for the loss of driving power due to the significant load and also for the reduction in rotational speed of the drive and cutting mechanism.

We previously described an adaptive system (patent application No. P.423369) for WSRMs, equipped with a fuel injection system that changes the drive rotational speed during idling from high to low (Warguła et al. 2020a, c). The system is controlled by engine load signals from the throttle position sensor (TPS) and rotational speed information. When an optical system detects wood in the feed channel and the air damper flap position changes, it shifts from idling mode to high rotational speed and maximum power. When wood is no longer detected, the system maintains this operating state for 2 s to ensure that the material remaining in the feed channel is completely processed and then idles at low rotational speed. Under real operating conditions, we showed that the system reduced fuel consumption and emissions of both carbon dioxide (CO2) and nitrogen oxides (NOx) (Warguła et al. 2020a, c). However, failure to detect loads of thick wood results in slowing the cutting mechanism. In addition, even after an update in 2019, EU emission regulations still allow the use of carburettor systems (Waluś et al. 2018). Thus, a limited number of engines can use the system in the EU, as 89% of the small non-road SI engines for sale in the EU in 2018 were equipped with a carburetted fuel supply system (Warguła et al. 2018).

To address these problems, we have developed a system that reduces effects of idling on fuel consumption and emissions of engines with a carburetted fuel supply system. The system (designated solution B) is subject to patent application No. P.433586. Like the previous system (P.423369), solution B detects branches in the feed channel, but also recognises the load resulting from, for example, thick wood as in commercial solution A.

This paper describes the results of tests of WSRMs both with and without the new adaptive system (solutions B and A, respectively). The objective of this research was to determine the effects of two speed control systems on the fuel consumption and exhaust emissions. Relatively disadvantageous working conditions were used for the adaptive system, i.e. the shortest possible idle time resulting from the frequency of wood supply. Based on the review of the available literature and on previous authors own research, we hypothesized that the use of a control system (solution B) would reduce fuel consumptions and emissions of harmful exhaust compounds, especially those directly related to consumed fuel volume. The operation of the internal combustion engine at a lower idle speed results in a lower number of combustion cycles. Therefore, as a result, a reduction in fuel consumption and quantitative exhaust gas emissions can be expected. The said reduction of exhaust gases concerns mainly CO and CO2, because they are the main components of exhaust gases, and their emission strongly depends on the amount of fuel burned. To test the hypothesis, solutions A and B were subjected to tests with similar operating conditions in which we monitored key operating parameters (torque, rotational speed, power, mass productivity, frequency of wood supply to the machine), fuel consumption and harmful exhaust gas emissions–carbon monoxide (CO), CO2, hydrocarbons (HC), and NOx–as a function of time.

2. Materials and Methods

2.1 Wood Size Reduction Machine, Combustion Engine and Tested Fuel

A Red Dragon RS-100 (Remet CNC Technology Sp. Z O.O., Kamień, Poland) WSRM with a two-cylinder cutting mechanism (Fig. 1) was used in the tests. This is a commonly deployed machine, especially in urban areas, working on material up to ca. 100 mm diameter, mostly fresh and medium-soft wood, according to the Janka hardness scale (Warguła et al. 2019a). For the trial, it was powered by a Lifan GX390 SI 9.56 kW internal combustion engine (American Honda Motor Co., Torrance, CA, USA) (Table 1). In the EU, this engine is classified as small according to Regulation 2016/1628/EU, which applies to SI engines powering non-road machines up to 19 kW. Specifications of the WSRM, combustion engine, and fuel are shown in Table 1.

Table 1 Specifications of wood size reduction machine, combustion engine and fuel (gasoline)

|

Parameter |

Specifications |

|

Red Dragon RS-100 wood size reduction machine |

|

|

Cutting mechanism type |

Two-cylinder |

|

Wood maximum diameter |

100 mm |

|

Wood length (mechanism has 4 blades) |

140±50 mm |

|

Average mass flow rate (Warguła et al. 2020b) |

0.66 t ∙ h-1 |

|

Average volumetric flow rate (Warguła et al. 2020b) |

3.5 m3 ∙ h-1 |

|

Lifan GX390 small engine |

|

|

Engine maximum power at 3600 rpm |

9.56 kW/13 HP |

|

Engine maximum torque at 2500 rpm |

26.5 Nm |

|

Bore/Stroke |

88 mm/64 mm |

|

Engine type |

Four-stroke, OHV (Overhead Valve) |

|

Number of cylinders |

1 |

|

Ignition |

Electronic, without ignition timing adjustment |

|

Weight |

31 kg |

|

Tested fuel – gasoline (Merkisz et al. 2016) |

|

|

Density under reference conditions (liquid phase) |

720 kg∙(m3)-1–775 kg∙(m3)-1 |

|

Fuel calorific value |

38 MJ∙kg-1 |

|

Boiling temperature |

40 °C–210 °C |

|

Excess air coefficient λ up to the ignitability boundaries |

0.4–1.4 |

|

Motor octane number (MON) (research octane number (RON)) |

85 (95) |

|

Air-fuel ratio (AFR) for stoichiometric mixture (mass) |

14.7:1 |

Fig. 1 a) Pine (Pinus sylvestris L.) wood sawmill offcuts and b) wood size reduction machine used in tests

2.2 Description and Comparison of Two Solutions A and B

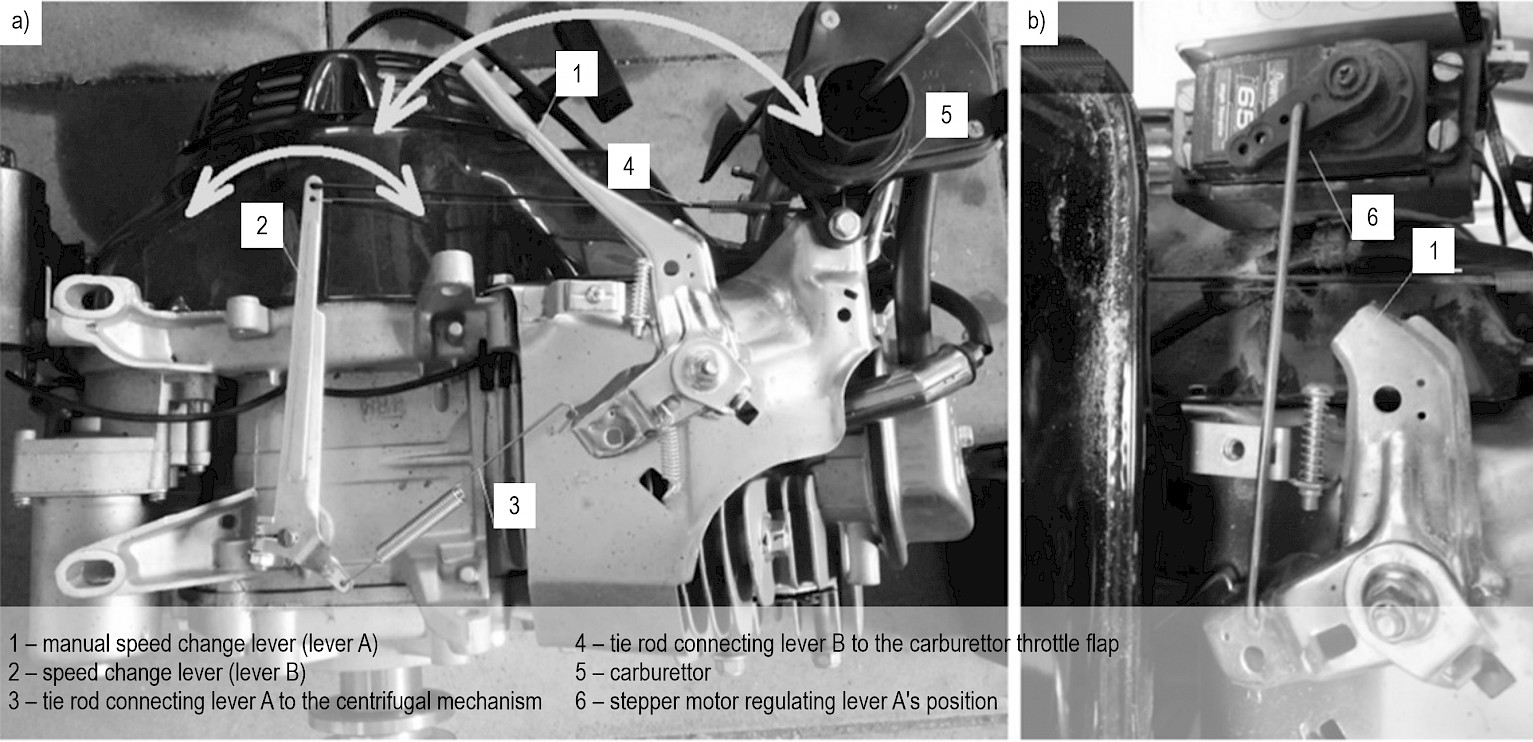

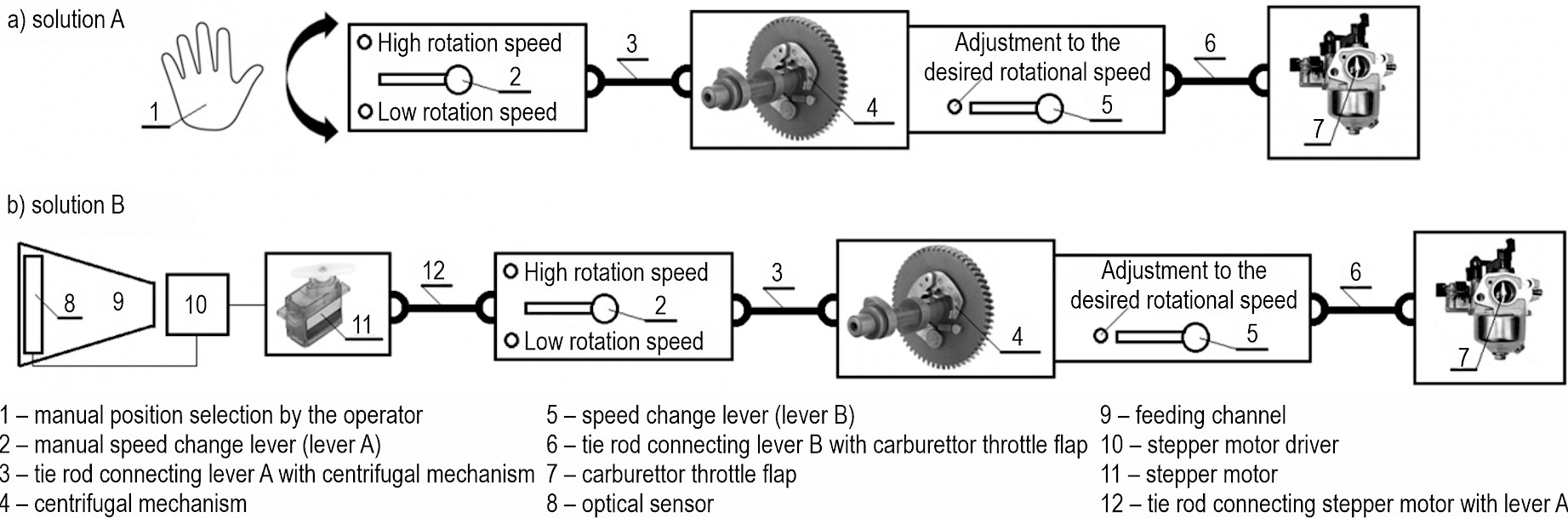

After starting, the classically controlled WSRM (solution A) reaches a high rotational speed, ensuring size reduction with maximum power. The degree of power or torque during WSR in such a machine is related to the resistance to wood cutting. When there is no material in the feed channel, the machine idles. The rotational speed is positively related to the number of combustion cycles, fuel consumption and exhaust emissions, so when no material is detected in the feed channel by the optical sensors, the algorithm in solution B slows down by activating a stepper motor that changes the position of the speed control lever (a in Fig. 2). Lever A is connected to a centrifugal mechanism, which (depending on the position of lever A and the engine rotational speed) changes the position of the second speed control lever (b in Fig. 2). The speed regulation of the output shaft of an SI internal combustion engine with a carburettor fuel supply system depends mainly on the position of the throttle flap in the carburettor, so in solution B this flap position is adjusted by an electronically controlled lever (which replaced the mechanical-manual speed change lever) using a stepper motor (Fig. 2 and Fig. 3). This solution does not interfere with the control system for the centrifugal throttle flap position, which changes as the load increases.

Fig. 2 Speed control system of wood size reduction machine drive in solutions A (a) and B (b)

Fig. 3 Wood size reduction machine drive speed control systems in solutions A (a) and B (b)

2.3 Wood Size Reduction Material and Working Conditions

Pine (Pinus sylvestris L. Sp. Pl. 1000. 1753) offcuts (3 m long, average cross-section 25×40 mm, moisture content ca. 12%) obtained from the production of boards and beams were used in the study (Fig. 1). This is typical material for the WSRM, which enabled to maintain a relatively high feeding pace of ca. 5 pieces min-1, which would be difficult to maintain using branches, as they are often entangled. Under these conditions the machine was idle for 66% of the processing time as the offcuts were converted into ca. 140 mm long chunks, which can be used (for example) in domestic heating applications.

2.4 Measurement Method and Measuring Devices

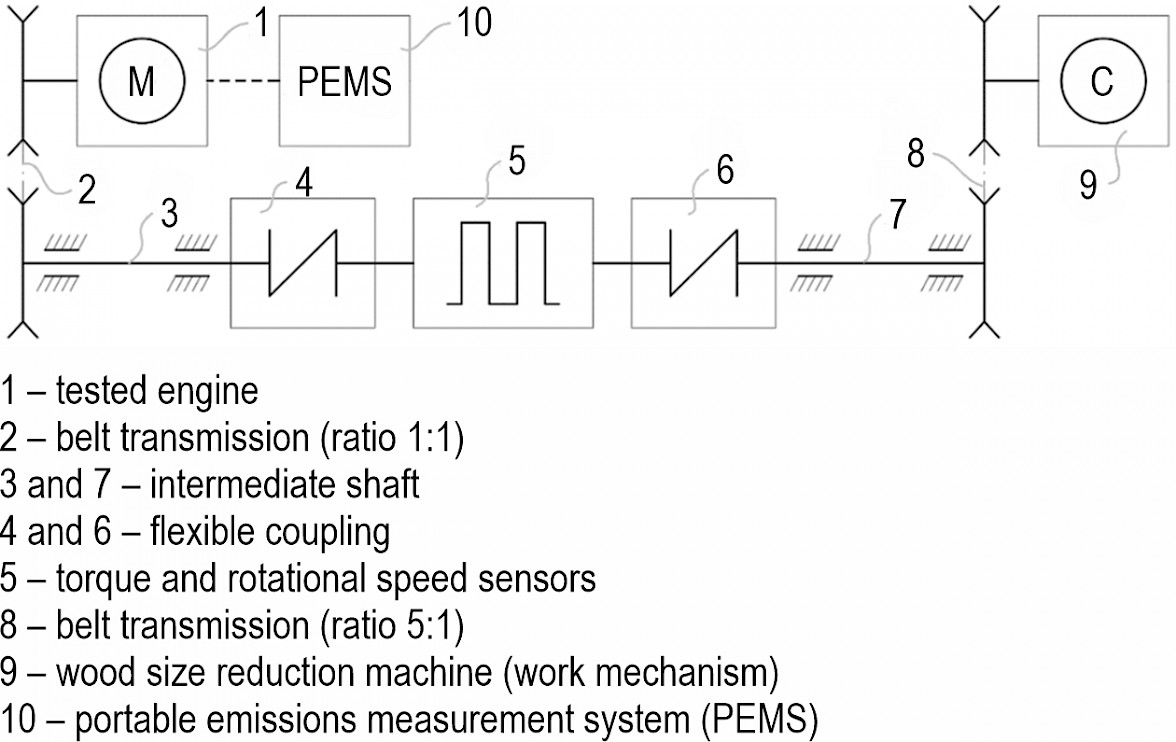

When comparing Systems A and B, the operating conditions were controlled by monitoring the rotational speed and torque between the drive unit and the cutting mechanism as they processed the offcuts described above (Fig. 4). The interconnection of the drive unit, torque meter (Electronic Workshop Roman Pomianowski, Poznań, Poland) and wood size reduction machine required the use of a belt transmission, couplings, and intermediate shafts, whose effects were included in the torque analysis. A detailed analysis of these factors using the same methodology is presented by Warguła et al. (2020d).

An Axion RS+ portable emissions measurement system (PEMS) from Global MRV was used to measure CO, CO2, HC and NOx exhaust emissions (Table 2). Fuel consumption was determined from the carbon balance (Lijewski et al. 2019). Emission levels were calculated from measured concentrations of the gases and air mass supplied to the combustion chamber (obtained by measuring the pressure in the inlet manifold). The input energy Einput during the WSR process was determined from the amount of fuel consumed and from the calorific value of the fuel (38 MJ or 10.5 kW kg-1). The output energy Eoutput was calculated from the measured torque M in N m-1 and the rotational speed n in rpm. Thus, the power P was expressed, assuming one working hour, in kW h-1, using eq. 1:

(1)

(1)

Table 2 Specifications of Axion RS portable exhaust emissions analyser (Lijewski et al. 2019)

|

Gas |

Measurement range |

Sensitivity |

Specifications |

|

HC Propane |

0–4000 ppm |

±3% |

1 ppm |

|

CO |

0–10% |

±3% |

0.01 vol.% |

|

CO2 |

0–16% |

±3% |

0.01 vol.% |

|

NOx |

0–4000 ppm |

±4% |

1 ppm |

|

O2 |

0–25% |

±3% |

0.01 vol.% |

Fig. 4 Schematic of test station

All results presented in the following sections in x±y format are means and standard deviations.

3. Results

3.1 Working Conditions

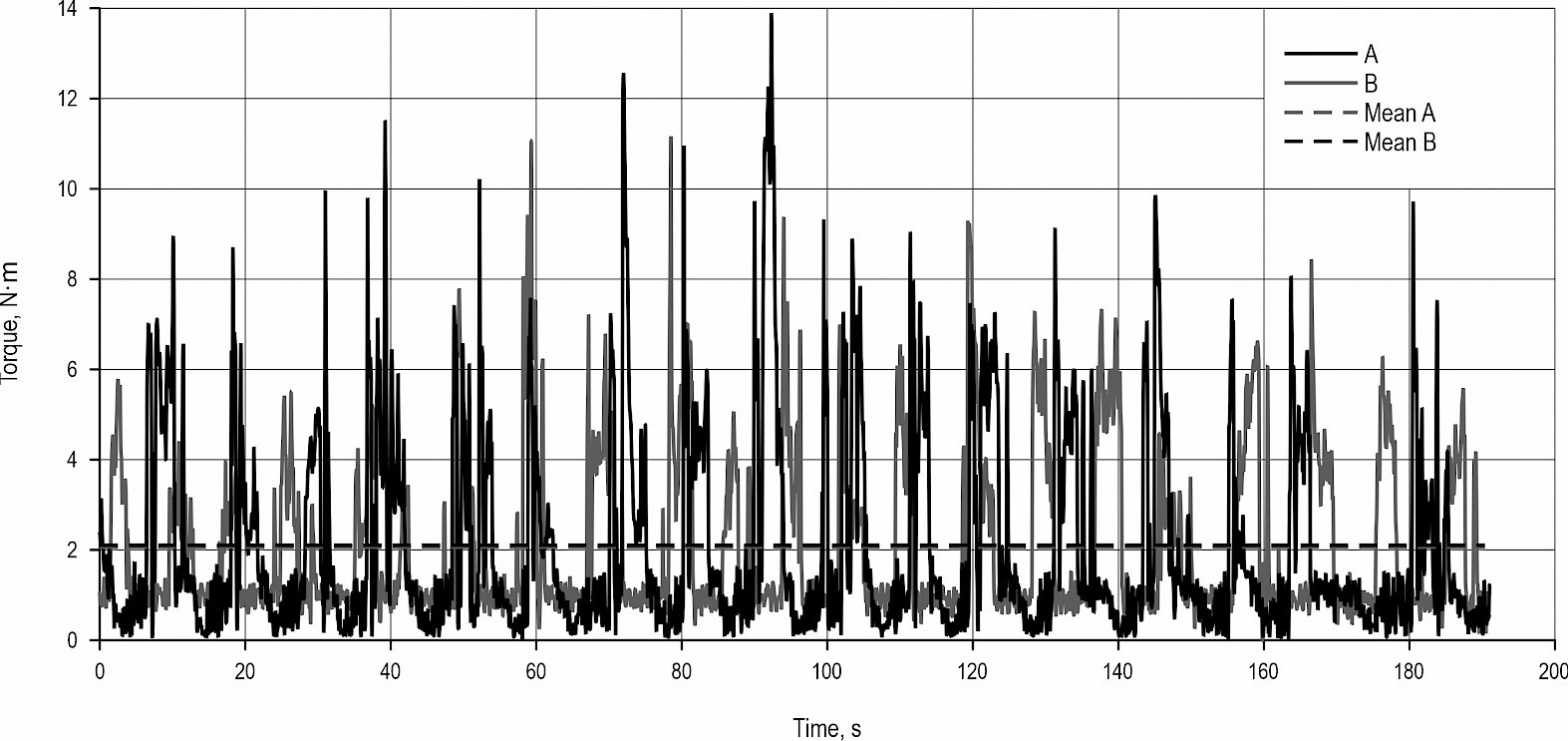

To allow a meaningful comparison of the results between systems A and B, similar operating conditions were used (Table 3). Torque (the main parameter related to the machine load) curves were used to determine the average machine load and frequency of wood supply (Fig. 5). Torque values obtained for solutions A and B were very similar (2.01±1.8 N m-1 and 2.05±2.2 N m-1, respectively). Peaks indicate the increased load on the cutting mechanism during WSR (Fig. 5). Rotational speed was also high during WSR for both solutions (approximately 3600 rpm, corresponding to working conditions of the engine at maximum power: Fig. 6 and Table 1). Solution B reduces the rotational speed during idling to ca. 1350 rpm, but longer idling times (and thus, for example, slower wood delivery) would be required for stable idling. Power values derived from the torque and rotational speed values differed significantly between the operating conditions for solutions A and B due to the significant changes in speed when using solution B (Fig. 7). The average power for solutions A and B was 0.74±7 kW and 0.63±0.7 kW, respectively. Work values, and hence energy intensities, of the studied systems obtained from the power curves are shown in Table 3.

Fig. 5 Torque during wood size reduction process with solutions A and B

Fig. 6 Rotational speed during wood size reduction process with solutions A and B

Fig. 7 Power during wood size reduction process with solutions A and B

3.2 Fuel Consumption

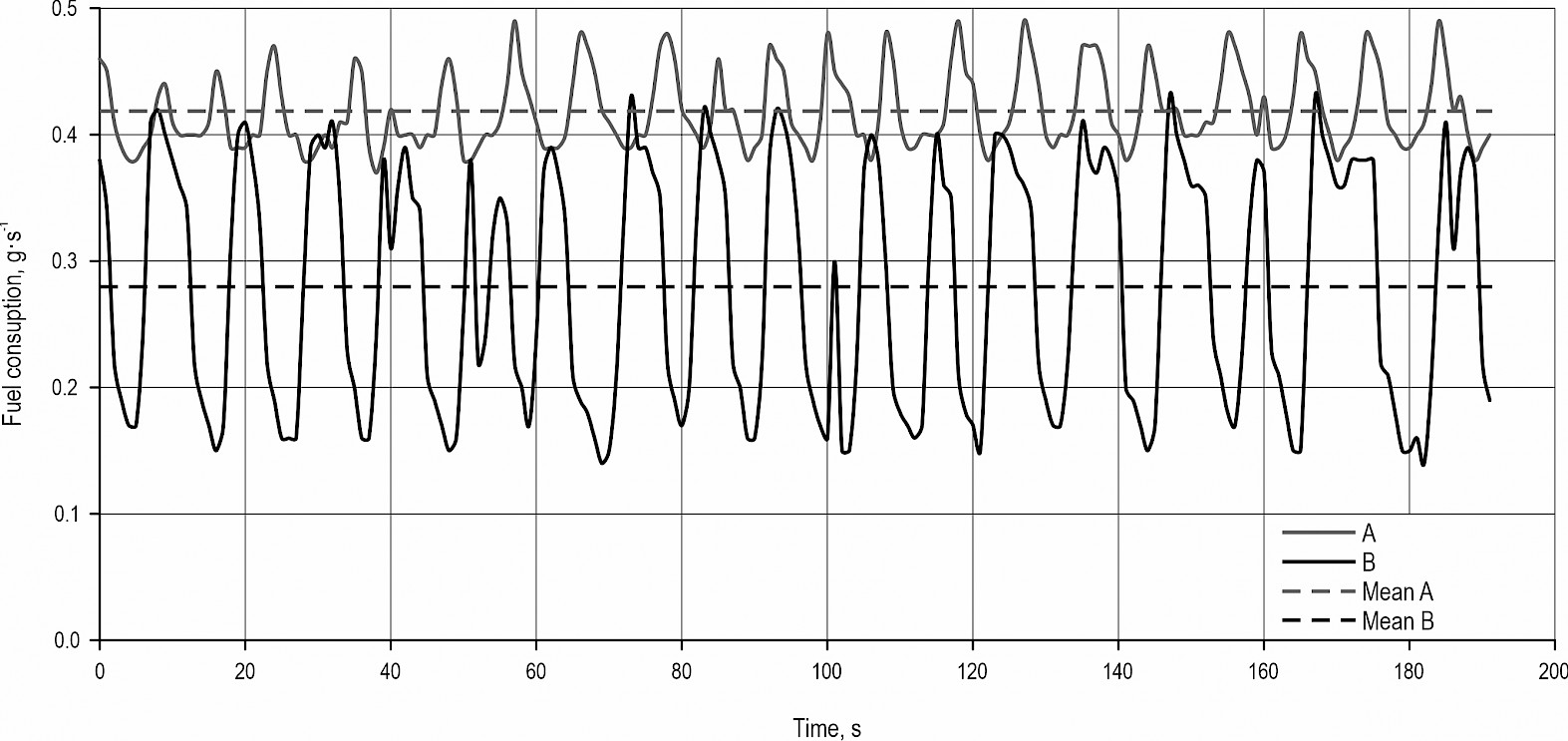

The implementation of solution B resulted in lower fuel consumption (a key parameter for assessing the efficiency of any WSRM) than solution A (0.28±0.10 g∙s-1 and 0.42±0.03 g∙s-1, respectively, Table 3) as far as average values are considered. However, the nature of the change in amplitude of fuel consumption is greater as can be seen in Fig. 8. Fuel consumption, and hence input energy for the WSR process, decreased with reductions in rotational speed and increased with acceleration.

Fig. 8 Fuel consumption during wood size reduction process with solutions A and B

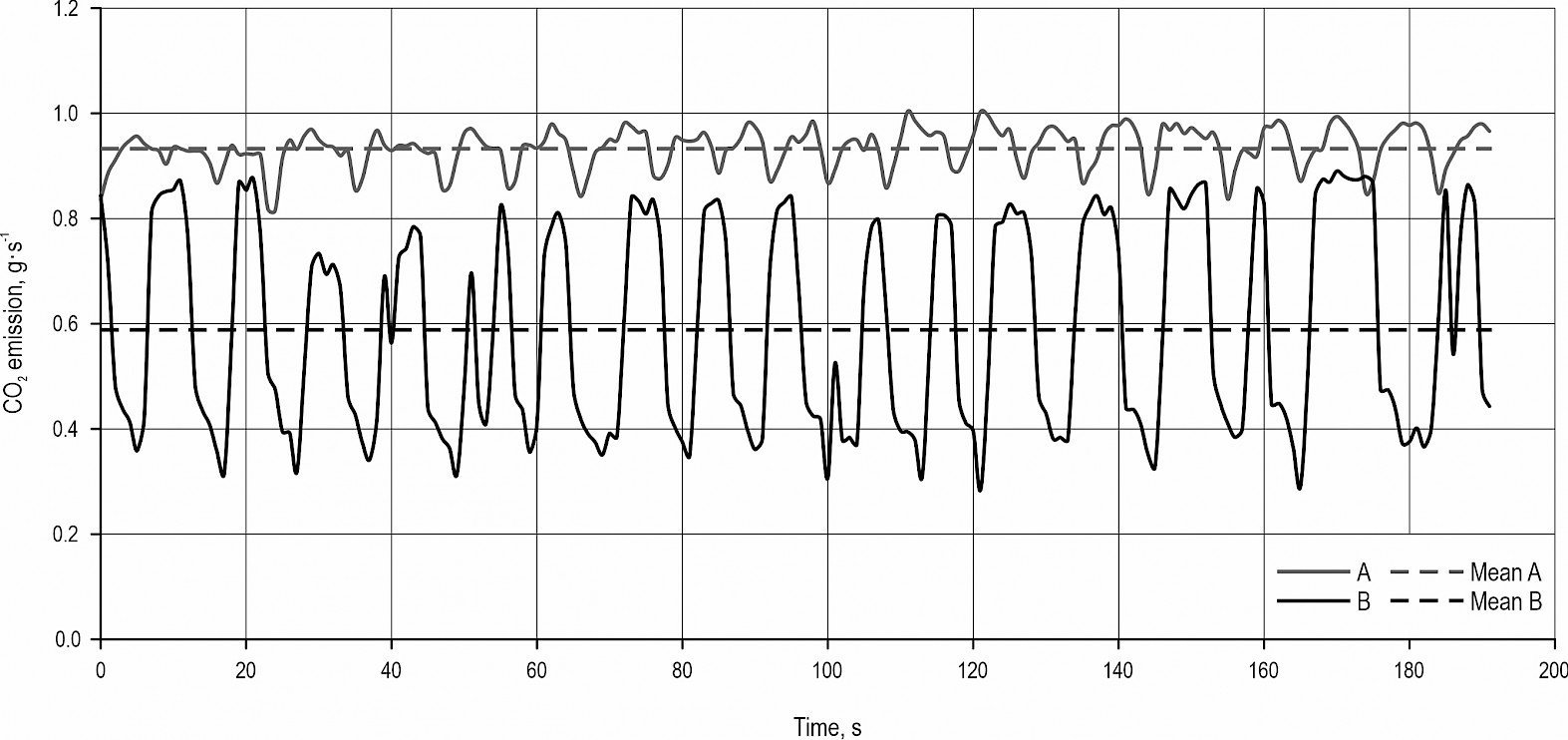

3.3 Harmful Exhaust Gas Emissions

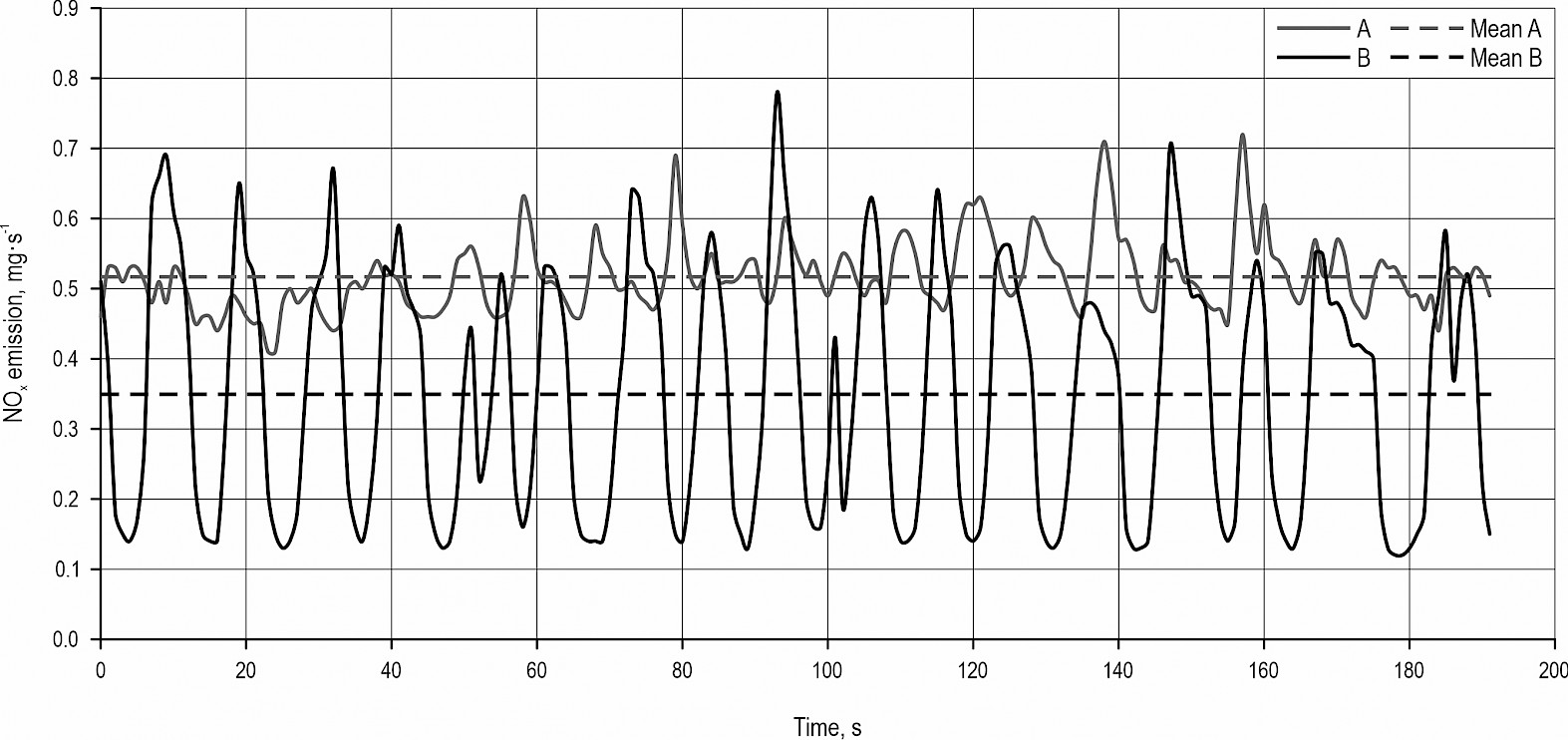

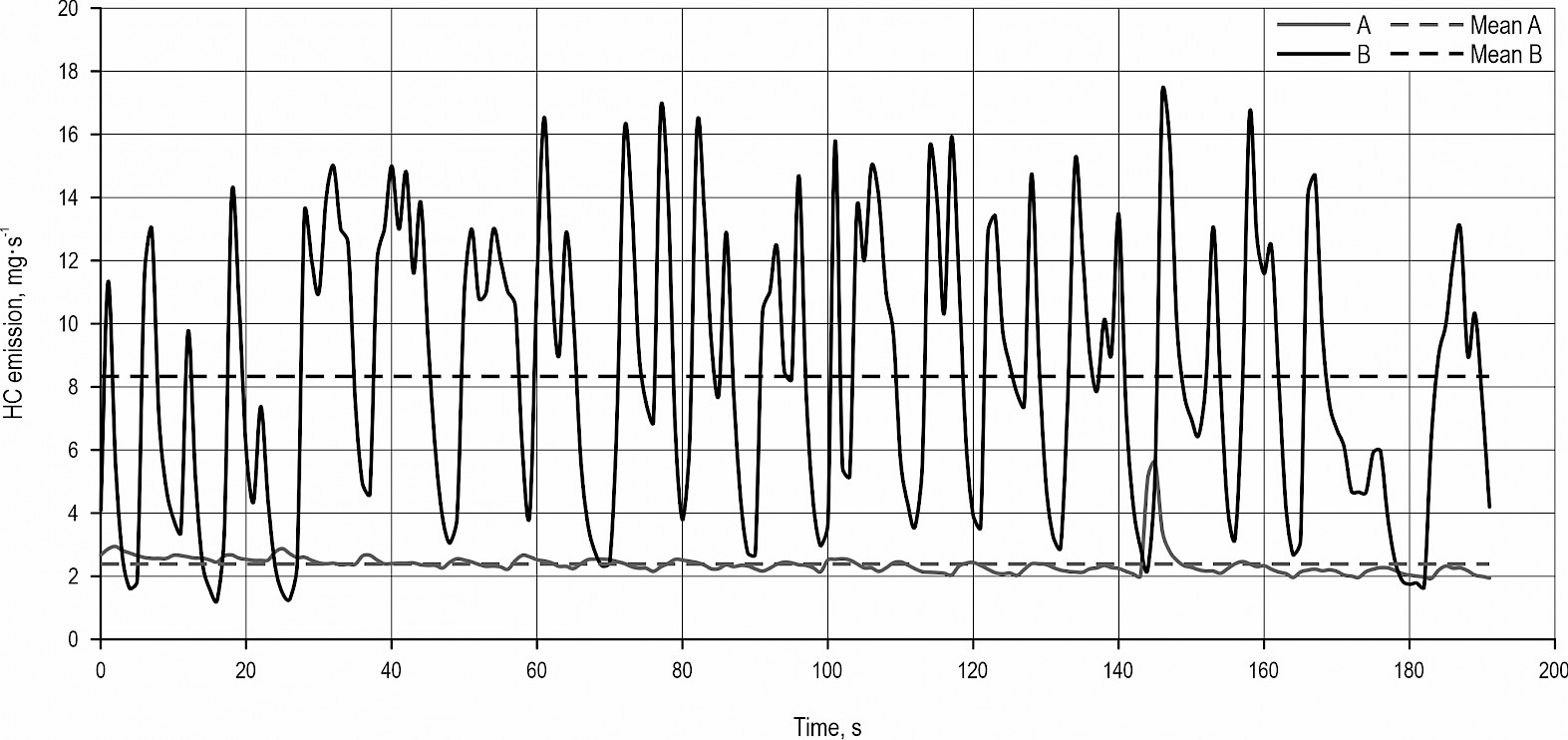

Fuel consumption was positively associated with emissions of CO2, CO and NOx (Fig. 9–11), but negatively associated with HC emissions (Fig. 12). CO2 emissions were lower on average for solution B than solution A (0.59±0.20 g∙s-1 and 0.93±0.04 g∙s-1, respectively, Table 3). CO emissions, resulting from the incomplete combustion of the fuel, were also lower for solution B than solution A (171±71 g∙s-1 and 245 g∙s-1 ±81 mg∙s-1, respectively, Table 3). In addition, the rotational speed was positively related to CO emissions. High combustion temperature and oxygen radicals in the fuel-air mixture contribute to NOx emissions, which are usually associated with combustion of poor fuel-air mixtures. NOx emissions were less varied, due to the more stable operation, but higher on average, for solution A than solution B (0.52±0.05 g∙s-1 and 0.35±0.17 mg∙s-1, respectively, Table 3). These emissions significantly declined with increases in rotational speed, due to associated mixture enrichment. However, the enrichment also contributes to increases in HC emission due to non-combustion of fuel particles. Hence, HC emissions had a higher amplitude and were higher on average for solution B than solution A (8.34±4.37 g∙s-1 and 2.39±0.38 mg∙s-1, Table 3). Emissions obtained with solution A had lower variability, particularly CO2 and HC emissions (Fig. 9 and Fig. 12, respectively). The increases in amplitude may be due to the enrichment of the air-fuel mixture during WSR, and could represent a significant load on the machine drive unit. The load on the drive unit is the result of an increase in the resistance to movement of the cutting mechanism, which is influenced by the increasing cutting force (required to process the wooden material).

Fig. 9 CO2 emissions during wood size reduction process with solutions A and B

Fig. 10 CO emissions during wood size reduction process with solutions A and B

Fig. 11 NOx emissions during wood size reduction process with solutions A and B

Fig. 12 HC emissions during wood size reduction process with solutions A and B

3.4 Mass Productivity

The productivity of solutions A and B, expression of the unit of mass produced per unit of time, was 605±14 kg∙h-1 and 614±11 kg∙h-1, respectively, similar to that reported about other low-power WSRMs (Warguła et al. 2020b).

3.5 Energy Output, Energy Input and Efficiency of Wood Size Reduction Process

The test results enabled to determine the output and input energy of the WSR process, while their ratio allowed to assess the efficiency of the process with solutions A and B (Table 3).

Table 3 Mean operational parameters and emissions during wood size reduction process with solutions A and B

|

Working conditions |

||||

|

Solution |

Torque, N m-1 |

Rotational speed, rpm |

Power, kW |

Frequency of feeding pieces min-1 |

|

A |

2.01±1.8 |

3539±30 |

0.74±7 |

5 |

|

B |

2.05±2.2 |

2708±885 |

0.63±0.7 |

5 |

|

Harmful exhaust gas emissions |

||||

|

Solution |

CO2 emission, g∙s-1 |

CO emission, mg∙s-1 |

NOx emission, mg∙s-1 |

HC emission, mg∙s-1 |

|

A |

0.93±0.04 |

245±81 |

0.52±0.05 |

2.39±0.38 |

|

B |

0.59±0.20 |

171±71 |

0.35±0.17 |

8.34±4.37 |

|

B/A ratio |

63% |

60.7% |

67.3% |

349% |

|

Fuel consumption and energy output, energy input and efficiency of wood size reduction process |

||||

|

Solution |

Fuel consumption, g s-1 |

Energy output, kW h-1 |

Energy input, kW h-1 |

Efficiency of wood size reduction process, % |

|

A |

0.42±0.03 |

15.8 |

0.74 |

4.7 |

|

B |

0.28±0.10 |

10.6 |

0.63 |

6.0 |

|

B/A ratio |

67% |

67% |

85% |

127% |

3.6 Fuel Savings and Changes in Emissions

As shown in Table 3, the rotational speed system provided an approximate 33% reduction in fuel consumption, with 37, 30 and 33% reductions in CO2, CO, and NOx emissions, respectively, but it also increased HC emissions by 290% (Table 3). By reducing fuel consumption with solution B, it allowed to reduce the average input energy of the WSR process by approximately 33% (solution A, 15.8 kW h-1; solution B, 10.6 kW h-1). The average output energy, i.e. the energy used to drive the cutting mechanism during the entire WSR process (wood size reduction, idling and transitions) was 15% lower for solution B (0.63 kW h-1) than solution A (0.74 kW h-1). The lower output energy is mainly due to the lower rotational speed during idle operation. Due to its lower energy demand and consumption, the efficiency of solution B was 28% higher.

4. Discussion

The most efficient use of a wood size reduction machine, expecting the greatest productivity, can be achieved by ensuring that the load to the cutting mechanism is of a nominal value, thus making the drive unit operate at maximum power. In practice, such operating conditions are very difficult to maintain, and the load depends on the material being processed. For example, feeding WSRMs with larger quantities of material are recommended when processing treetops, to counterbalance their smaller overall size. In addition, increasing the width of chipper drums and number of rollers improves the feeding of small pieces of material to the cutting mechanism, and hence the processing (Assirelli et al. 2013). Conversely, interrupting the flow of raw material reduces WSRMs productivity, results in idling and prevents exploitation of their full production capacity (Spinelli et al. 2009). As already mentioned, the average idling time of WSRMs used in industrial biomass production is about 26%, but in difficult working conditions, such as in the mountains, it may be up to 44% (Spinelli et al. 2009). WSRMs are often equipped with inlet ducts that can supply surplus material or interface with wood supply systems. Examples of such solutions are machines with hydraulic feeders, which, in the event of an overload of the cutting mechanism, delay the delivery of wood by storing it in the feed channel. Furthermore, material is transported to WSRMs using grabs or loaders (Manzone and Balsari 2015, Spinelli et al. 2016a). Due to limited branch storage space, for manually fed machines designed to facilitate clearing of tree branches from urban areas, idling time can account for up to 71% of working time (Warguła et al. 2019b, Warguła et al. 2020b).

For these reasons, there have been considerable efforts to reduce idling of machines powered by internal combustion engines. One approach is to reduce idling through organisational adjustments of the material supply and delivery chain (Perić et al. 2020, Yoshida and Takata 2019), technological measures to facilitate loading, such as improving shapes of feed channels (Assirelli et al. 2013), or using cranes and grapples (Röser et al. 2012). The efficiency of delivering wood for processing is also influenced by operator skill (Mola-Yudego et al. 2015). Another approach, as in this study, is to reduce adverse effects of machine idling (increases in fuel consumption and harmful exhaust gas emissions). Changing the rotational speed during idling from ca. 3600 rpm to ca. 1350 rpm, afforded an approximate 33% reduction in fuel consumption, along with 37, 30 and 33% reductions in CO2, CO, and NOx emissions, respectively. However, it also increased HC emissions by 290% (Table 3). Surprisingly, the only other solution we found in a literature review for reducing fuel consumption and harmful emissions of WSRMs during idling is the one we previously developed for rotational speed control of systems with small SI engines (subject to patent application P.423369; and Warguła et al. 2020a, c). Both systems reduce fuel consumption and targeted emissions. However, solution B, described here, allows the use of a cheaper, more popular (Warguła et al. 2022) fuel supply system and automatically adjusts the air-fuel mixture in response to changes in loads on the cutting mechanism. The previous system provided similar reductions in fuel consumption (29–60%), but smaller reductions in CO2, CO, NOx emissions (35, 8 and 21%, respectively) compared to solution A in similar operating conditions (Warguła et al. 2020a, c). Like the carburettor system reported here, it also resulted in a high (188%) increase in HC emissions, which could probably be reduced by improving air-fuel mixture control during acceleration, thus reducing the number of unburned fuel particles. HC emissions can also be significantly reduced by using a three-phase catalytic reactor (Herner and Hans-Jurgen 2013, Warguła et al. 2020c), or fuels with lower carbon content, such as liquified petroleum gas (Beik et al. 2020) or compressed natural gas (Dziewiątkowski et al. 2020, Rimkus et al. 2020), rather than gasoline. Spinelli et al. (2018) also found that simple adjustment of an engine reduced its fuel consumption and CO2 emissions by 17% (although such savings depend on the suboptimality of control settings). Other studies of CO2 emissions of compression ignition (CI) combustion engines with 103 to 420 kW power driving industrial WSRMs with various cutting mechanisms found that their average emissions during operation were 10.80 kgCO2eq Mg DM−1 (Manzone 2015) and 7.6 kgCO2e MWhchip−1 (Prada et al. 2015). Results of these studies provide indications of average environmental impact of WSRMs, but not possible ways to improve them.

Effects of systems intended to reduce effects of idling in other applications have also been studied. For example, Lijewski et al. (2021) found that a start and stop system reduced fuel consumption of a low-power scooter engine in real operating conditions, with 12 and 10% lower CO2 and NOx emissions, respectively, but also 57 and 4% increases in CO and HC emissions, respectively. Such a system can also reduce fuel consumption and NOx emissions of cars, while increasing total hydrocarbon and CO emissions (Qiao et al. 2014). Other systems can stop operation of selected cylinders of multi-cylinder engines during idling, thus reducing fuel consumption and exhaust emissions (Zasiga et al. 2021). In addition, hybrid drives with combustion engines and electric motors can provide approximate reductions of 6.5% in WSRMs fuel consumption and lower energy intensity compared to machines driven solely by combustion engines (Prinz et al. 2018). When there is no raw material to be processed (which, for classic WSRMs driven by a combustion engine, corresponds to idling), machines equipped with hybrid drives can generate electricity to charge the batteries (Di Fulvio et al. 2015).

Other ways to improve the efficiency of processing machinery or processes are being explored by many researchers, and any findings that contributes to this improvement are valuable. Adjustments to blade geometry can reportedly improve the efficiency of cutting processes by up to 70% (Wojtkowiak et al. 2018, Wojtkowiak and Talaśka 2019), although again the potential gains depend on the initial sub-optimality. Improvements in the efficiency of comminution processes have been made by decreasing blower speed when full ejection power is not required (Spinelli et al. 2016a). Improving the efficiency of the WSR process may be associated with a reduction in fuel consumption and, thus, pollutant emissions. Machine operators are particularly exposed to such harmful exhaust gases (Magagnotti et al. 2014, Warguła et al. 2020e) in conjunction with wood dust (Gulci et al. 2018). Furthermore, using solution B reduces the rotational speed, which can reduce further impacts on operators such as noise (Spinelli et al. 2016b) and vibration (Kończak et al. 2020), thus improving their well-being (Kymäläinen et al. 2021). However, stopping the internal combustion engine of many machines during idling is not acceptable, because in addition to its main function it provides energy for auxiliary systems such as maintaining comfort in the driver's cabin by providing power for accessories such as air conditioning, heating, TV, a refrigerator, and lighting (Rahman et al. 2013).

5. Conclusion

Comparative tests of systems with and without the innovative rotational speed control system showed that it reduced mean fuel consumption by 33%, with 37, 30, and 33% reductions in emissions of CO2, CO and NOx, respectively. However, it increased HC emissions by 290%. Thus, with mass productivity of 600 kg∙h-1, it reduced the energy input by 33% and energy output by 15%, with a 28% increase in efficiency. The presented results show that regulating WSRMs rotational speed can have economic and ecological benefits. More research is needed, especially for limiting HC emissions, perhaps by changing the fuel, but in the future systems providing such capacities may become mandatory for WSRMs, like start and stop systems in cars.

6. Patents

The design solution described in this paper is subject to a patent application in Poland: Warguła, Ł., Kukla, M., Wieczorek, B., Krawiec, P., 2020: Rotational speed control system for wood size reduction machines with a spark ignition engine (original text in Polish: Układ sterowania prędkością obrotową napędu rębaka do drewna z silnikiem spalinowym o zapłonie iskrowym), Poznan University of Technology, Poznań, Poland, application number: P.433586, date of filing 17.04.2020.

Acknowledgments

The present research was part of the project »Design and research of mobile machines chipping wastes from urban agriculture processes for innovative construction solutions limiting the impact on the natural environment and machine operators« (33/32/SIGR/3334), financed by the Poznan University of Technology. Some support was also provided through funding for research at the Faculty of Mechanical Engineering of the Poznań University of Technology in 2021 on »Design, research and analysis of parts, assemblies of machines and vehicles for the needs of searching for innovative solutions« (Grant No. 0611/SBAD/0115).

7. References

Abas, M.A., Abidin, S.F.Z., Rajoo, S., Martinez-Botas, R., Ismail, M.I., 2017: Evaluation between engine stop/start and cylinder deactivation technologies under southeast Asia urban driving condition. SAE Technical Paper. No. 2017-01-0986.

Assirelli, A., Civitarese, V., Fanigliulo, R., Pari, L., Pochi, D., Santangelo, E., Spinelli, R., 2013: Effect of piece size and tree part on chipper performance. Biomass and Bioenergy 54: 77–82. https://doi.org/10.1016/j.biombioe.2013.03.029

Beik, Y., Dziewiątkowski, M., Szpica, D., 2020: Exhaust emissions of an engine fuelled by petrol and liquefied petroleum gas with control algorithm adjustment. SAE International Journal of Engines 13(5): 739–759. https://doi.org/10.4271/03-13-05-0047

Coronado, C.R., de Carvalho Jr, J.A., Yoshioka, J.T., Silveira, J.L., 2009: Determination of ecological efficiency in internal combustion engines: The use of biodiesel. Applied Thermal Engineering 29(10): 1887–1892. https://doi.org/10.1016/j.applthermaleng.2008.10.012

Di Fulvio, F., Eriksson, G., Bergström, D., 2015: Effects of wood properties and chipping length on the operational efficiency of a 30 kW electric disc chipper. Croatian Journal of Forest Engineering 36(1): 85–100.

Ding, C., Roberts, L., Fain, D.J., Ramesh, A.K., Shaver, G.M., McCarthy Jr, J., Ruth, M., Koeberlein, E., Nielsen, D., 2016: Fuel efficient exhaust thermal management for compression ignition engines during idle via cylinder deactivation and flexible valve actuation. International Journal of Engine Research 17(6): 619–630. https://doi.org/10.1177/1468087415597413

Dziewiatkowski, M., Szpica, D., Borawski, A., 2020: Evaluation of impact of combustion engine controller adaptation process on level of exhaust gas emissions in gasoline and compressed natural gas supply process. Engineering for Rural Development 19: 541–548. http://dx.doi.org/10.22616/ERDev.2020.19.TF122

Eliasson, L., von Hofsten, H., Johannesson, T., Spinelli, R., Thierfelder, T., 2015: Effects of sieve size on chipper productivity, fuel consumption and chip size distribution for open drum chippers. Croatian Journal of Forest Engineering 36(1): 11–17.

Facello, A., Cavallo, E., Magagnotti, N., Paletto, G., Spinelli, R., 2013: The effect of chipper cut length on wood fuel processing performance. Fuel Processing Technology 116: 228–233. https://doi.org/10.1016/j.fuproc.2013.07.002

Flizikowski, J., Kruszelnicka, W., Macko, M., 2021: The development of efficient contaminated polymer materials shredding in recycling processes. Polymers 13(5): 713. https://doi.org/10.3390/polym13050713

Gao, Y., Kang, F., Kan, J., Wang, Y., Tong, S., 2021: Analysis and experiment of cutting mechanical parameters for Caragana korshinskii (C.k.) branches. Forests 12(10): 1359. https://doi.org/10.3390/f12101359

Gulci, S., Akay, A.E., Spinelli, R., Magagnotti, N., 2018: Assessing the exposure of chipper operators to wood dust in a roadside landing area. Fresenius Environmental Bulletin 27(6): 4132–4138.

Han, S.K., Han, H.S., Bisson, J.A., 2015: Effects of grate size on grinding productivity, fuel consumption, and particle size distribution. Forest Products Journal 65(5–6): 209–216. http://dx.doi.org/10.13073/FPJ-D-14-00072

Herner, H., Hans-Jurgen, R., 2013: Electrical engineering and electronics in motor vehicles. Original Title in Polish: Elektrotechnika i Elektronika w Pojazdach Samochodowych, WKŁ, Warszawa, Poland.

Ji, C., Yang, J., Liu, X., Wang, S., Zhang, B., Wang, D., 2016: Enhancing the fuel economy and emissions performance of a gasoline engine-powered vehicle with idle elimination and hydrogen start. Applied Energy 182: 135–144. https://doi.org/10.1016/j.apenergy.2016.08.099

Kończak, M., Kukla, M., Warguła, Ł., Talaśka, K., 2020: Determination of the vibration emission level for a chipper with combustion engine. In IOP Conference Series: Materials Science and Engineering 776(1): 012007. http://dx.doi.org/10.1088/1757-899X/776/1/012007

Kymäläinen, H., Laitila, J., Väätäinen, K., Malinen, J., 2021: Workability and well-being at work among cut-to-length forest machine operators. Croatian Journal of Forest Engineering 42(3): 405–417. https://doi.org/10.5552/crojfe.2021.874

Laitila, J., Routa, J., 2015: Performance of a small and a medium sized professional chippers and the impact of storage time on Scots pine (Pinus sylvestris) stem wood chips characteristics. Silva Fennica 49(5): 1382. https://doi.org/10.14214/sf.1382

Leach, F., Kalghatgi, G., Stone, R., Miles, P., 2020: The scope for improving the efficiency and environmental impact of internal combustion engines. Transportation Engineering 1: 100005. https://doi.org/10.1016/j.treng.2020.100005

Lijewski, P., Fuć, P., Markiewicz, F., Dobrzyński, M., 2019: Problems of exhaust emissions testing from machines and mobile devices in real operating conditions. Combustion Engines 179(4): 292–296. https://doi.org/10.19206/CE-2019-449

Lijewski, P., Szymlet, N., Fuć, P., Domowicz, A., Rymaniak, Ł., 2021: The effect of start-stop systems on scooter exhaust emissions. Transportation Research Part D: Transport and Environment 91: 102684. https://doi.org/10.1016/j.trd.2020.102684

Liu, H., Ma, J., Tong, L., Ma, G., Zheng, Z., Yao, M., 2018: Investigation on the potential of high efficiency for internal combustion engines. Energies 11(3): 513. https://doi.org/10.3390/en11030513

Magagnotti, N., Picchi, G., Sciarra, G., Spinelli, R., 2014: Exposure of mobile chipper operators to diesel exhaust. Annals of Occupational Hygiene 58(2): 217–226. https://doi.org/10.1093/annhyg/met059

Manzone, M., 2015: Energy consumption and CO2 analysis of different types of chippers used in wood biomass plantations. Applied Energy 156: 686–692. https://doi.org/10.1016/j.apenergy.2015.07.049

Manzone, M., Balsari, P., 2015: Productivity and woodchip quality of different chippers during poplar plantation harvesting. Biomass and Bioenergy 83: 278–283. https://doi.org/10.1016/j.biombioe.2015.10.010

Manzone, M., Spinelli, R., 2013: Wood chipping performance of a modified forager. Biomass and Bioenergy 55: 101–106. https://doi.org/10.1016/j.biombioe.2013.01.006

Merkisz, J., Dobrzyński, M., Kozak, M., Lijewski, P., Fuć, P., 2016: Environmental aspects of the use of cng in public urban transport. In Alternative Fuels, Technological and Environmental Conditions: 1–22. http://dx.doi.org/10.5772/62978

Mola-Yudego, B., Picchi, G., Röser, D., Spinelli, R., 2015: Assessing chipper productivity and operator effects in forest biomass operations. Silva Fennica 49(5): 1–14. https://doi.org/10.14214/sf.1342

Nati, C., Eliasson, L., Spinelli, R., 2014: Effect of chipper type, biomass type and blade wear on productivity, fuel consumption and product quality. Croatian Journal of Forest Engineering 35(1): 1–7.

Nati, C., Spinelli, R., Fabbri, P., 2010: Wood chips size distribution in relation to blade wear and screen use. Biomass and Bioenergy 34(5): 583–587. https://doi.org/10.1016/j.biombioe.2010.01.005

Qiao, S., Yanding, Y., Yinghao, L., Zhi, Y., Zhen, W., Xiaoyun, Z., Xuan, Z., 2014: Application of engine intelligent start-stop system in technology of vehicle fuel saving. In 2014 Sixth International Conference on Measuring Technology and Mechatronics Automation, 7 May. IEEE: 128–131. https://doi.org/10.1109/ICMTMA.2014.35

Perić, M., Antonijević, D., Komatina, M., Bugarski, B., Rakin, M., 2020: Life cycle assessment of wood chips supply chain in Serbia. Renewable Energy 155: 1302–1311. https://doi.org/10.1016/j.renene.2020.04.026

Prada, M., Martínez-Alonso, C., Sánchez-García, S., Canga, E., 2015: Analysis of three forest chippers: productivity, costs and GHG emissions in Northern Spain. Journal of Cleaner Production 101: 238–244. https://doi.org/10.1016/j.jclepro.2015.03.066

Prinz, R., Laitila, J., Eliasson, L., Routa, J., Järviö, N., Asikainen, A., 2018: Hybrid solutions as a measure to increase energy efficiency–study of a prototype of a hybrid technology chipper. International Journal of Forest Engineering 29(3): 151–161. https://doi.org/10.1080/14942119.2018.1505350

Rahman, S.A., Masjuki, H.H., Kalam, M.A., Abedin, M.J., Sanjid, A., Sajjad, H.J.E.C., 2013: Impact of idling on fuel consumption and exhaust emissions and available idle-reduction technologies for diesel vehicles–A review. Energy Conversion and Management 74: 171–182. https://doi.org/10.1016/j.enconman.2013.05.019

Rimkus, A., Stravinskas, S., Matijošius, J., 2020: Comparative study on the energetic and ecologic parameters of dual fuels (diesel–NG and HVO–biogas) and conventional diesel fuel in a CI Engine. Applied Sciences 10(1): 359. https://doi.org/10.3390/app10010359

Röser, D., Mola-Yudego, B., Prinz, R., Emer, B., Sikanen, L., 2012: Chipping operations and efficiency in different operational environments. Silva Fennica 46(2): 275–286. https://doi.org/10.14214/sf.60

Regulation EU: (EU) No 2016/1628 of the European Parliament and of the Council of 14 September 2016. On Requirements for Emission Limit Values of Gaseous and Particulate Pollutants and Type-Approval with Respect to Internal Combustion Engines for Mobile Machines Non-Road, Amending Regulations (EU) No 1024/2012 and (EU) No 167/2013 and Amending and Repealing Directive 97/68/WE; EU: Brussels, Belgium, 2016.

Sommer, C., Reinhard G., Falko D., 2010: Bidirectionally coupled network and road traffic simulation for improved IVC analysis. IEEE Transactions on Mobile Computing 10(1): 3–15. https://doi.org/10.1109/TMC.2010.133

Spinelli, R., de Arruda Moura, A.C., da Silva, P.M., 2018: Decreasing the diesel fuel consumption and CO2 emissions of industrial in-field chipping operations. Journal of Cleaner Production 172: 2174–2181. https://doi.org/10.1016/j.jclepro.2017.11.196

Spinelli, R., Cavallo, E., Eliasson, L., Facello, A., Magagnotti, N., 2015: The effect of drum design on chipper performance. Renewable Energy 81: 57–61. https://doi.org/10.1016/j.renene.2015.03.008

Spinelli, R., Eliasson, L., Magagnotti, N., 2016a: Increasing wood fuel processing efficiency by fine-tuning chipper settings. Fuel Processing Technology 151: 126–130. https://doi.org/10.1016/j.fuproc.2016.05.026

Spinelli, R., Glushkov, S., Markov, I., 2014: Managing chipper knife wear to increase chip quality and reduce chipping cost. Biomass Bioenergy 62: 117–122. https://doi.org/10.1016/j.biombioe.2014.01.007

Spinelli, R., Magagnotti, N., 2014: Determining long-term chipper usage, productivity and fuel consumption. Biomass and Bioenergy 66: 442–449. https://doi.org/10.1016/j.biombioe.2014.04.016

Spinelli, R., Visser, R.J., 2009: Analyzing and estimating delays in wood chipping operations. Biomass and Bioenergy 33(3): 429–433. https://doi.org/10.1016/j.biombioe.2008.08.003

Spinelli, R., Magagnotti, N., Deboli, R., Preti, C.. 2016b: Noise emissions in wood chipping yards: Options compared. Science of the Total Environment 563–564: 145–151. https://doi.org/10.1016/j.scitotenv.2016.04.105

Waluś, K.J., Warguła, Ł., Krawiec, P., Adamiec, J.M., 2018: Legal regulations of restrictions of air pollution made by non-road mobile machinery–the case study for Europe: a review. Environmental Science and Pollution Research 25(4): 3243–3259. https://doi.org/10.1007/s11356-017-0847-8

Warguła, Ł., Kaczmarzyk, P., Dziechciarz, A., 2019a: The assessment of fire risk of non-road mobile wood chopping machines. Journal of Research and Applications in Agricultural Engineering 64(1): 58–64.

Warguła, Ł., Krawiec, P., Waluś, K.J., Kukla, M., 2020a: Fuel consumption test results for a self-adaptive, maintenance-free wood chipper drive control system. Applied Sciences 10(8): 2727. https://doi.org/10.3390/app10082727

Warguła, Ł., Kukla, M., Krawiec, P., Wieczorek, B., 2020b: Impact of number of operators and distance to branch piles on woodchipper operation. Forests 11(5): 598. https://doi.org/10.3390/f11050598

Warguła, Ł., Kukla, M., Lijewski, P., Dobrzyński, M., Markiewicz, F., 2020c: Influence of innovative woodchipper speed control systems on exhaust gas emissions and fuel consumption in urban areas. Energies 13(13): 3330. https://doi.org/10.3390/en13133330

Warguła, Ł., Kukla, M., Lijewski, P., Dobrzyński, M., Markiewicz, F., 2020d: Impact of Compressed Natural Gas (CNG) fuel systems in small engine wood chippers on exhaust emissions and fuel consumption. Energies 13(24): 6709. https://doi.org/10.3390/en13246709

Warguła, Ł., Kukla, M., Lijewski, P., Dobrzyński, M., Markiewicz, F., 2020e: Influence of the use of Liquefied Petroleum Gas (LPG) systems in woodchippers powered by small engines on exhaust emissions and operating costs. Energies 13(21): 5773. https://doi.org/10.3390/en13215773

Warguła, Ł., Lijewski, P., Kukla, M., 2022: Influence of non-commercial fuel supply systems on small engine SI exhaust emissions in relation to European approval regulations. Environmental Science and Pollution Research 29: 55928–55943. https://doi.org/10.1007/s11356-022-19687-w

Warguła, Ł., Waluś, K.J., Krawiec, P., 2018: Small engines spark ignited (SI) for non-road mobile machinery—review. In Proceedings of the Transport Means 2018: 22nd International Scientific Conference, Trakai, Lithuania, 3–5 October; Kaunas University of Technology: Trakai, Lithuania. Part 2: 585–591.

Warguła, Ł. Waluś, K.J., Krawiec, P., 2019b: Working conditions of mobile wood chipping machines in the aspect of innovative drive control systems. Sylwan 163(9): 765–772.

Wojtkowiak, D., Talaśka, K., 2019: Determination of the effective geometrical features of the piercing punch for polymer composite belts. The International Journal of Advanced Manufacturing Technology 104(1): 315–332. https://doi.org/10.1007/s00170-019-03746-7

Wojtkowiak, D., Talaśka, K., Malujda, I., Domek, G., 2018: Estimation of the perforation force for polymer composite conveyor belts taking into consideration the shape of the piercing punch. The International Journal of Advanced Manufacturing Technology 98(9): 2539–2561. https://doi.org/10.1007/s00170-018-2381-3

Yoshida, M., Takata, K., 2019: Uncertainty simulation of wood chipping operation for bioenergy based on queuing theory. Forests 10(9): 822. https://doi.org/10.3390/f10090822

Zsiga, N., Ritzmann, J., Soltic, P., 2021: Practical aspects of cylinder deactivation and reactivation. Energies 14(9): 2540. https://doi.org/10.3390/en14092540

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Łukasz Warguła, PhD *

e-mail: lukasz.wargula@put.poznan.pl

Mateusz Kukla, PhD

e-mail: mateusz.kukla@put.poznan.pl

Poznan University of Technology Faculty

Faculty of Mechanical Engineering

Institute of Machine Design

pl. Marii Słodowskiej-Curie 5

60-965 Poznań

POLAND

Prof. Piotr Lijewski, PhD

e-mail: piotr.lijewski@put.poznan.pl

Poznan University of Technology Faculty

Faculty of Civil Engineering and Transport

Institute of Internal Combustion Engines and Drives

pl. Marii Słodowskiej-Curie 5

60-965 Poznań

POLAND

* Corresponding author

Received: February 16, 2022

Accepted: April 15, 2022

Original scientific paper