Development and Evaluation of Pasture Tree Cutting Robot: Proof-of-Concept Study

doi: 10.5552/crojfe.2023.1731

volume: 44, issue:

pp: 11

- Author(s):

-

- Badgujar Chetan

- Flippo Daniel

- Badua Sylvester

- Baldwin Carolyn

- Article category:

- Original scientific paper

- Keywords:

- rangeland management, eastern redcedar, honeylocust, invasive species, autonomous ground vehicle

Abstract

HTML

The encroachment of Eastern redcedar (ERC) (Juniperus virginiana L.) onto Great Plains prairies has become a serious threat to ecosystem functioning and grazing productivity. The uncontrolled spread of this invasive tree species has been called a »green glacier« converting grasslands into closed canopy woodlands. A pasture tree cutting robot was developed using a tracked Autonomous Ground Vehicle (AGV) equipped with a chainsaw bar to mitigate this green glacier dilemma. The prototype was fitted with amperage and voltage sensors to measure average power consumption and peak power requirements of tree cutting. It was evaluated on ERC and Honeylocust trees up to 20 cm in diameter. Cutting energy and time were determined to evaluate energy optimization and cutting time estimates. A pasture tree clearing energy consumption of the developed prototype was estimated for selected tree density/hectare. The prototype robot was successful in cutting down the intended size trees at a manageable power usage.

Development and Evaluation of Pasture Tree Cutting Robot: Proof-of-Concept Study

Chetan Badgujar, Daniel Flippo, Sylvester Badua, Carolyn Baldwin

Abstract

The encroachment of Eastern redcedar (ERC) (Juniperus virginiana L.) onto Great Plains prairies has become a serious threat to ecosystem functioning and grazing productivity. The uncontrolled spread of this invasive tree species has been called a »green glacier« converting grasslands into closed canopy woodlands. A pasture tree cutting robot was developed using a tracked Autonomous Ground Vehicle (AGV) equipped with a chainsaw bar to mitigate this green glacier dilemma. The prototype was fitted with amperage and voltage sensors to measure average power consumption and peak power requirements of tree cutting. It was evaluated on ERC and Honeylocust trees up to 20 cm in diameter. Cutting energy and time were determined to evaluate energy optimization and cutting time estimates. A pasture tree clearing energy consumption of the developed prototype was estimated for selected tree density/hectare. The prototype robot was successful in cutting down the intended size trees at a manageable power usage.

Keywords: rangeland management, eastern redcedar, honeylocust, invasive species, autonomous ground vehicle

1. Introduction

The Great Plains tallgrass prairies play an important role in agricultural livelihoods (Middendorf et al. 2009, Ratajczak et al. 2016) and ecosystem services, affecting rainwater movement and infiltration, soil erosion, wildlife habitat, and mitigation of nutrient deposition (Ratajczak et al. 2016, Matlack et al. 2008, Fuhlendorf et al. 2009, McLauchlan et al. 2014). Eastern redcedar (ERC) is a widely distributed North American evergreen conifer (Ramli and Epplin 2017, Semen and Hiziroglu 2005) and tolerates a broad range of precipitation, moisture, salinity, temperature, elevation, and soil conditions (Krug et al. 2017, Lawson 1990). The prairies of the Great Plains ranging from Texas to Alberta, are currently threatened by the encroachment of this woody species (Twidwell et al. 2013, Engle et al. 2008). Eastern redcedar converts grasslands into undesirable woodlands, altering not only ecosystem structure and grazing productivityof these prairies (Ratajczak et al. 2016, Fuhlendorf et al. 2009, Engle et al. 2008, Coppedge et al. 2001, Anadón et al. 2014, Eldridge et al. 2011) but also posing a threat to communities as a volatile wildfire fuel (Twidwell et al. 2013). As prairie is replaced by woodland, forage productivity and profitability for livestock operations are reduced (Smith and Stubbendieck 1990, Ortmann et al. 1998, Limb et al. 2010, Simonsen et al. 2015). Heavy ERC infestations make livestock handling more difficult.

In southeast Nebraska's tallgrass prairies, the conversion of grassland into the closed canopy ERC woodland typically takes around 40 years; relatively low forage loss occurs in the initial 15 years of invasion, but may result in an 80% reduction in livestock returns after 30 years (Fuhlendorf et al. 2009, Simonsen et al. 2015). This rapid pace of expansion has resulted in the doubling of the ERC expansion every 18 years in the Great Plains states of Nebraska, Kansas, and Oklahoma (USDA NRCS 2020). The USDA (NRCS) survey on ERC suggests that the invasion has been increasing exponentially in past decades. In 1950, around 0.6 million hectares of rangeland, pasture, and forestland had been invaded by ERC and further increased to 1.4 million hectares, 3.2 million hectares and 5.1 million hectares in 1985, 2004 and 2013, respectively, in Oklahoma with an estimated rate of conversion 344.8 hectares/day or over 121.4 thousands hectares/year (USDA NRCS 2020). ERC is also a dominant species in 30% of Nebraska's forests, covering some 130 thousand hectares and is found in nearly 70% of forests statewide (Martens 2018). In Kansas, eastern redcedar comprises less than 4% of woodlands, but is substantially increasing in volume by 23,000% since 1965 and is a primary species of concern in grasslands prairies (Kansas Forest Service, 2015).

ERC control measures include prescribed fire, herbicides, and mechanical removal. Prescribed burning is the cheapest, most effective, and most widely used method of control, and is especially effective on juvenile plants, with decreasing effectiveness as tree size increases. Prescribed burning may not be possible in some situations due to safety considerations, such as proximity to houses or other infrastructure. Herbicide application involves applying foliar sprays, injections and broadcast soil applications to individual trees. However, this method is time-consuming and expensive on dense infestations or large tracts, and effectiveness declines as the size of trees (>2 meters) increases (Simonsen et al. 2015).

ERC is a non-resprouter and if cut below the lowest foliage, will not regrow, making mechanical treatment a viable option. Tree shears, loppers, and chainsaws are typically used for mechanical control, but are labor intensive. Typical costs for treating a pasture with a 10% canopy cover are 250–300 USD/ha, with costs scaling up 25–30 USD/ha for each additional percent canopy cover (Spencer 2020). The removal of ERC above 5 m height is challenging and requires heavier machinery such as bulldozers, skid-steer mounted tree clippers, and shears, all of which require a high initial investment cost and many man-hours of skilled labor. This equipment is generally limited to low to moderate ground slopes and can cause significant soil disturbance.

Chainsaws are popular for small scale tree pruning and felling, and each year over 3 million new chainsaws are sold in the United States (Koehler et al. 2004). Despite their popularity, hand-held chainsaw use can be potentially dangerous; annually there are about 23,000 chainsaw injuries in the United States (Hammig and Jones 2015). Portable battery-powered chainsaws are a viable option due to recent advances in their performance, feature and decreased emissions as compared with gas-powered chainsaws.

Autonomous robotics are gaining popularity with numerous benefits such as precision, safety and cost effectiveness, and are rapidly becoming a part of everyday life in numerous industries. Semi-automatic robotic devices provide a cost effective tool for the removal of trees >5 m in height. Researchers in Japan have developed a novel tree pruning robot for producing high value-added wood without knots that uses self-weight and a power-saving chainsaw drive (Ishigure et al. 2013). This remote-controlled robot is equipped with several mechanisms including climbing up-down on trees, a posture adjustment, a pruning chainsaw and a controller. The chainsaw is driven using two input modes, which results in a significant reduction in electric power consumption.

Tree harvesting on a steep terrain can be challenging due to the inability of some machines to efficiently operate on slopes, reducing their overall productivity (Stampfer 1999). Therefore, Meaclem et al. (2014) developed a sensor guided biped felling machine for steep terrain harvesting and explored autonomous systems for pruning by enclosing the tree and scaling vertically. However, these systems neither perform felling operations nor do they have the ability to traverse from tree to tree; and existing robotic approaches to tree felling are limited to flat terrain and manual operation.

Removal of ERC is a critical issue to preserve the natural and productive rangelands of the Great plains and there are no semi-automatic robotic devices or solution available so far. Therefore, the objective of this project was to build and test an environmentally-friendly and low-cost robotic device for controlling the invasion of ERC. Another goal was to establish data on the cutting time, power and energy capacity needs of a robotic device for the removal of ERC up to 20 cm in diameter.

2. Materials and Methods

2.1 Structure of ERC

ERC is roughly conical in shape and forms a compact tree. The lower branches are close to the ground and spread widely, thus the robot needs to be short to fit under these branches. ERC is a relatively slow growing tree; 20 to 30 years old trees are generally 5.5–8 m tall and 5–7.5 cm in diameter. Mature trees typically reach 12–21 m tall, with 30–71 cm in trunk diameter (Lawson 1990, Ferguson et al. 1968, Brooks et al. 1986, Halls 1977, Anderson 2020). It is commonly found in ravines, riparian areas, and on rough upland topography (moderate to steep slopes & eroded limestone slopes) (Anderson 2020). Therefore, the prototype robot should be able to traverse through the moderate to steep slopes and be able to cut down up to a 20 cm diameter trunk.

2.2 Robot Design Conceptualization

The goal of this project was to develop a robot with a chainsaw bar mounted on it capable of felling trees up to 20 cm in diameter on native prairies terrain.

2.3 Design Components & Control

2.3.1 Platform

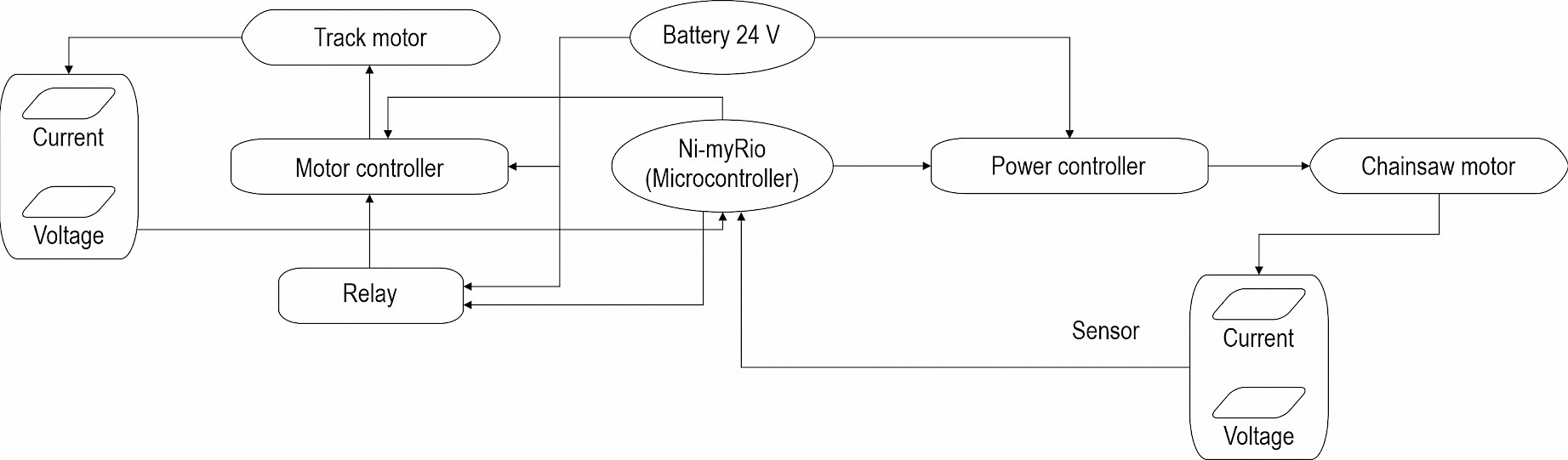

The basic motorized unit was an Autonomous Ground Vehicle (AGV) developed by Kansas State University (KSU) specifically designed for high slope field operations, and more details on the vehicle can be found in Badgujar et al. (2022a, 2022b). The AGV is a small (1.10×0.64 m), lightweight (90 kg) tracked vehicle fitted with an on-board microcontroller; re-configurable input-output device (myRIO, National Instruments, Austin, TX, USA) requiring a system-design platform in LabVIEW. An analog 50 A current sensor (Gravity series, dfrobot, Shanghai, China) and ± 30 V DC voltage sensor (Phidgets Inc., Calgary, Canada) were used to sense and record the amperage and voltage, respectively. The AGV is shown in Fig. 1 and the sensor configuration is presented in Fig. 2.

Fig. 1 Autonomous ground vehicle used in the study

2.3.2 Chainsaw Unit

A cordless electric chainsaw (Black-Decker, Maryland, USA) was used with a 25.4 cm bar, 3.5 m/s chain speed, low-kickback bar with 40 links and pitch of 0.95 cm. The chainsaw was rigidly mounted on the left support platform of the AGV using sets of U-clamps. The chainsaw unit is hereafter referred to as landshark. The landshark was placed 6–8 cm horizontally above the ground to keep the chainsaw motor from touching the ground while still generally low enough to cut below the lowest growing branch.The landshark attached to AGV was a developed prototype robot for pasture tree cutting.

Fig. 2 Flow chart showing robot sensor configuration

2.3.3 Battery Capacity

The robot was powered by a rechargeable 22.2 V, 13 Ah and 15 C Lithium Polymer (Li-Po) batteries (Venom Power, Rathdrum, Idaho, USA). Two Li-Po batteries were connected in a parallel configuration, to increase the amp-hour capacity of the battery to 26 Ah. Robot was designed to accommodate total 4 sets of Li-Po batteries with a total amp-hour capacity of 52 Ah and 22.2 V. Therefore, the total battery capacity was 4493 kJ (in-terms of energy); allowing 80% discharge, 3594 kJ was used for robot operations. This was sufficient for at least 2–3 hours of continuous robot operation between charges.

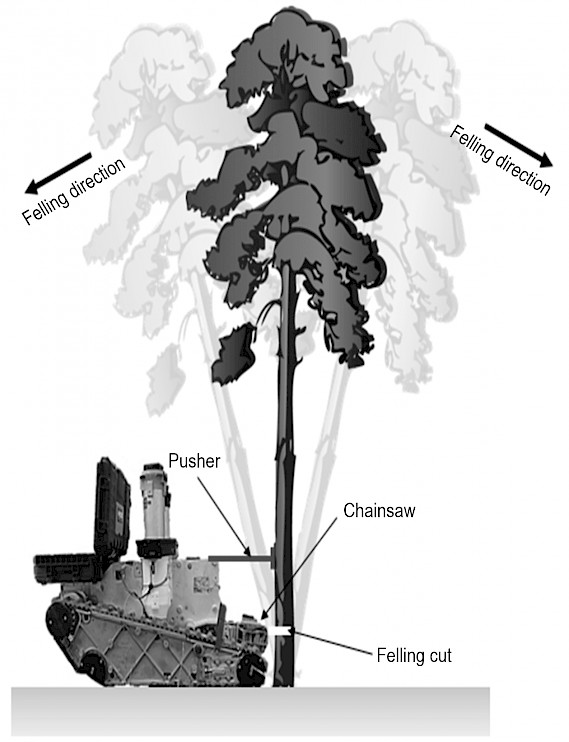

2.3.4 Pusher Bar

A tree has a natural felling direction, which depends on its center of gravity relative to the center of the stump, but can be affected by other factors such as wind direction and neighboring trees. A U-shaped pusher was fitted onto the robot (Fig. 3 and Fig. 4) to push the trees away from the landshark as they fell to avoid causing damage to the robot.

2.4 Vehicle Operation

The robot was connected and operated wirelessly via a remote device software on a tablet computer (iPad, Apple Inc., Cupertino, CA). The ground speed of the robot was controlled by a motor controller with a pulse width modulation (PWM) signal, as shown in Fig. 2. It was operated in a reverse direction at the lowest possible duty cycle (1 m/min speed) for tree felling, as shown in Fig. 4. The rpm of the chainsaw motor was constant and could not be adjusted while tree cutting was in progress.

2.5 Data Collection

Current and voltage signals of the robot (AGV+landshark) were measured and recorded by a microcontroller every 100 milliseconds (10 Hz frequency). The tree diameter was measured with a digital Vernier Caliper (Insize USA, Loganville, GA). During the tree felling operation, tree diameter, current and voltage required to perform the task both for AGV and landshark were recorded and used to calculate the total power requirement, peak power consumption and average power requirement for different size diameter tree cutting and also the length of time needed to cut each tree. Total cutting energy required to fell a single tree was also calculated with the help of eq. 1. Determining the energy and power requirements for tree felling of an entire one hectare pasture provided the total number of trees/hectare available. In the present study, the tree felling operation was performed on two different tree species, Honeylocust (Gleditsia triacanthos L.) and ERC. Honeylocust is commonly distributed throughout the Midwestern U.S.A and its wood is considered dense, hard, coarse-grained, strong and stiff (Mohlenbrock 2020).

(1)

(1)

Fig. 3 Conceptual process of cutting a tree using the tree felling robot

2.6 Performance Evaluation

2.6.1 Laboratory Test

The developed prototype was initially evaluated in the laboratory to check its intended function. A 12 cm diameter ERC trunk was rigidly attached to a fixed support platform using clamps in the laboratory and then cut down with the prototype. Necessary modifications were made to the length and shape of the pusher before proceeding to field trials.

Fig. 4 Prototype robot tested for ERC tree cutting

2.6.2 Field Test

Honeylocust trees with diameters of 8.3 cm, 9 cm, and 15.2 cm and ERC trees with diameters of 12.7 cm, 15.2 cm and 18 cm were cut down using the robot at two different locations in Kansas, U.S.A. Tree diameter, cutting time, and current and voltage were recorded.

2.7 Tree Density Based Energy Consumption Estimate

Most of the prototype's energy was consumed by the landshark unit and traveling between trees. The field test results generated an energy consumption database on the landshark unit (cutting energy for 8–18 cm diameter) and AGV field travel at different duty cycles (speeds). This data was used to estimate/predict tree felling/pasture clearing energy consumption per hectare area for a given tree density.

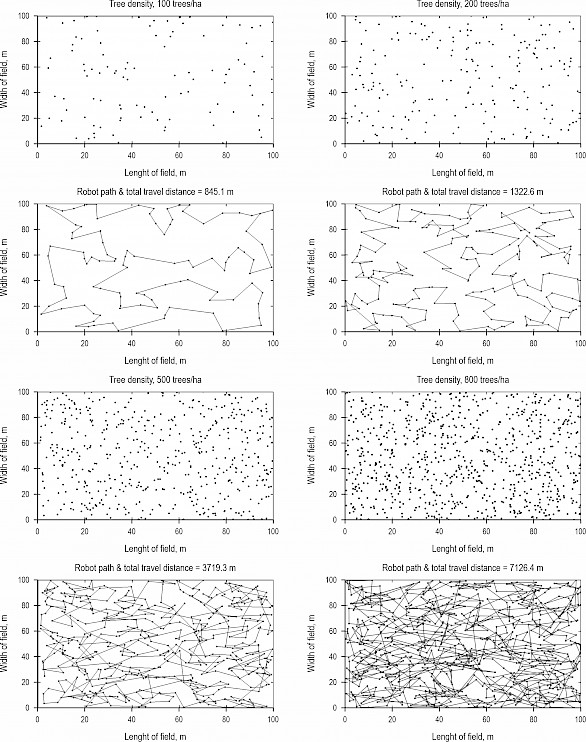

The AGV travel is directly related to the robot's overall energy consumption and efficiency, therefore, an optimized robot routing plan is needed to account for traversing from tree to tree. The Traveling Salesman Problem (TSP) algorithm is one of the studied optimization problems; this algorithm discovers the shortest possible route, i.e. the least distance for the salesman to travel to each city exactly once and return to starting city (Kirk 2018). TSP application extends well beyond a salesman tour to vehicle routing, transport routes, printing and computer wiring (Hacizade and Kaya 2018, Lenstra and Kan 1975). In this study, the TSP algorithm was used for an optimized robot routing plan, i.e. to find out the shortest robot travel distance to visit each tree once for a felling operation. A tree density/ha was input to the TSP algorithm and it randomly distributes a given number of trees in a 1 ha area. Finally, the TSP algorithm comes up with an optimized route plan to visit each tree once. The AGV actual travel distance in a 1 ha area was computed from TSP generated optimized route plan. The total AGV energy consumption for actual travel distance was evaluated from AGV velocity (m/min) and AGV average power consumption for that velocity.

The robot's pasture clearing energy consumption for selected tree densities (100, 200, 500 and 500 trees/ha) was estimated. Also, battery replacement frequency and required time of operation can be estimated. This estimation may be useful for the decision making and design of a fully autonomous system or related problems in the future. The following assumptions were made for the estimation; uniform tree diameter size, no obstruction in robot path, no major breakdown in robots, uniform soil condition and flat slope.

3. Results

A proposed prototype robot was developed at Kansas State University's 2050RL Laboratory, Manhattan, Kansas and evaluated in terms of average power, peak power, cutting time and energy requirement for varying sizes of tree diameter.

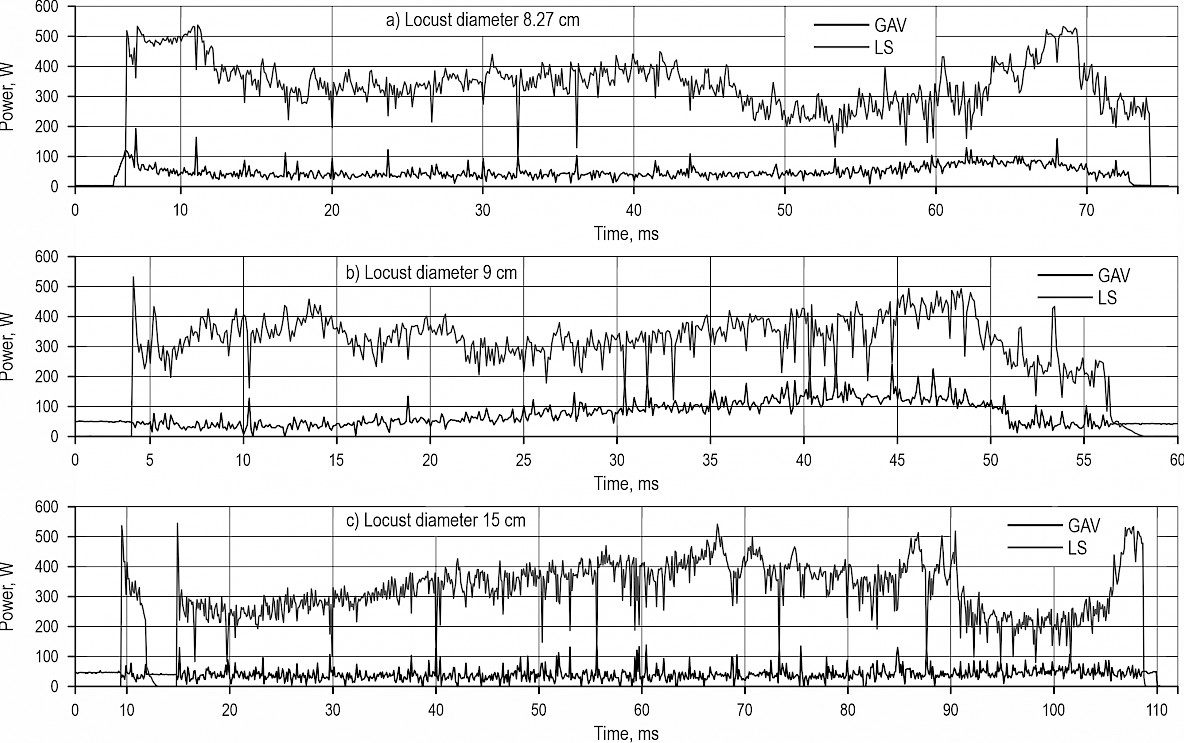

3.1 Honeylocust Felling

Robot (AGV+Landshark) power consumption for Honeylocust is shown in Fig. 5 and Table 1. For both tree species (Honeylocust & ERC), peak power requirements of landshark were high (approx. 520 W) for initial few seconds (3–5 s) when the landshark (LS) first began cutting, but once a cut was initiated, power requirements ranged between 300–400 W with some random fluctuations as shown in Fig. 5. However, while cutting 15–16 cm diameter tree, higher power usage was also observed at the end of cut possibly due to chainsaw binding. The power usage of AGV was relatively high in Fig. 5b as compared to Fig. 5a & Fig. 5c, which may be due to slippage of the AGV during the Honeylocust felling operation (Table 1). The average power requirement for landshark ranged between 287.7–310.9 W and the peak power requirement ranged between 531.7–544.2 W.

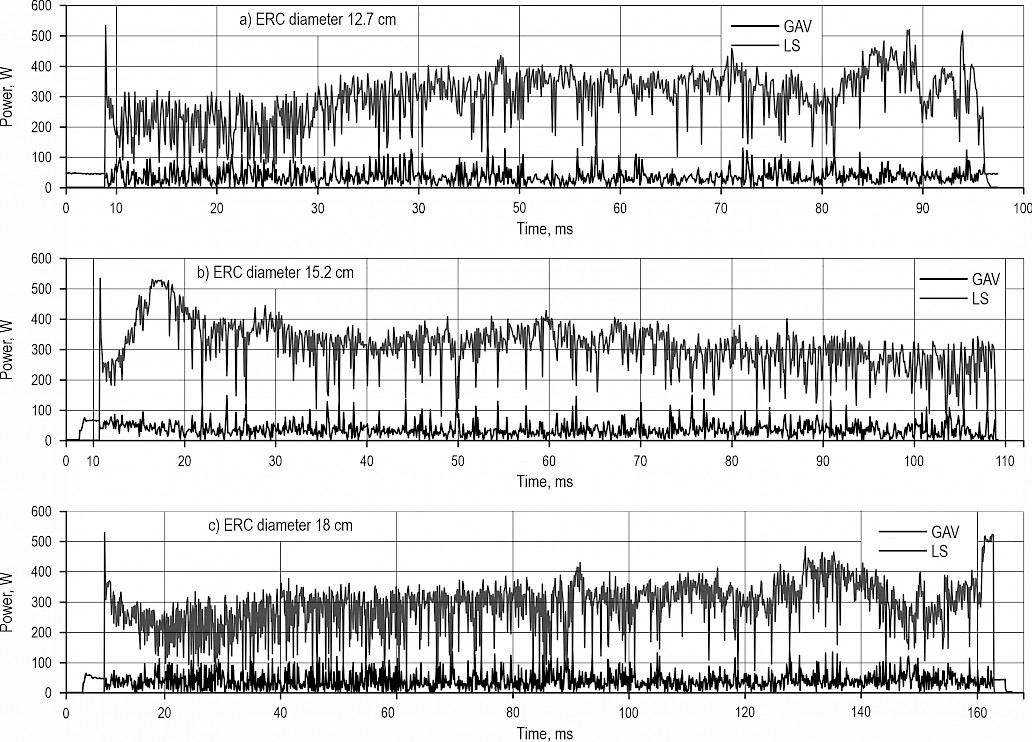

3.2 ERC Felling

The robot was also evaluated for ERC tree felling. ERC with diameters of 12.7 cm, 15.2 cm and 18 cm were felled and the power consumption was recorded (Fig. 6 and Table 1). Landshark peak power requirements ranged between 529.1–534.0 W. A similar trend was observed in power requirements, which were at their peak when the chainsaw first encountered the tree, then stabilized throughout the cutting process with a little spike at the end (Fig. 6). The average power requirement for the AGV ranged between 36.6–39.6 W for ERC felling.

The recorded data was used to determine the peak power consumption, energy optimization and application efficiency. In this study, a 25 cm chainsaw bar was effective in felling trees up to 20 cm in diameter. The chainsaw was most effective when it was at least 5-6 cm wider than the tree diameter and extended at least 2–3 cm beyond the trunk.

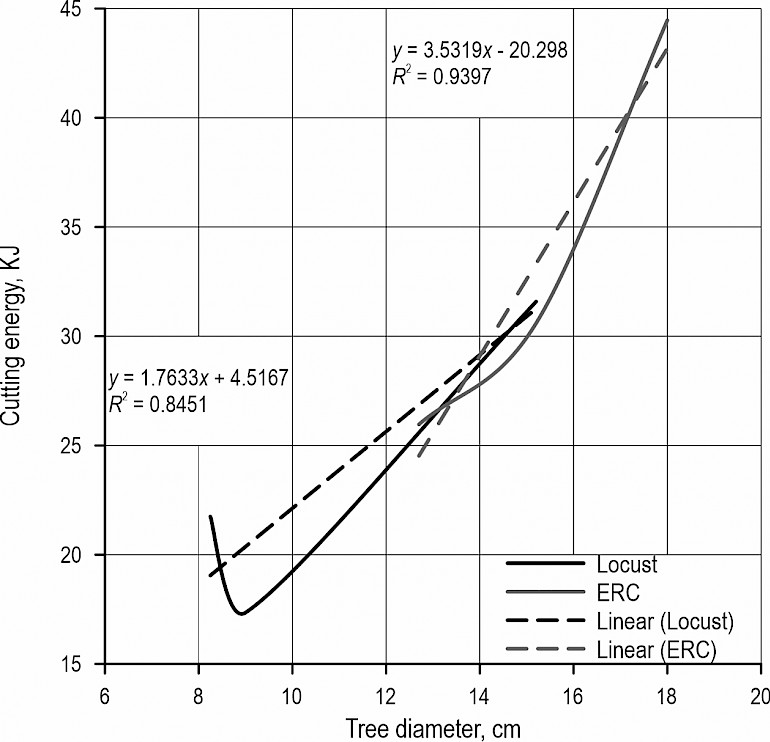

The energy needed to fell trees increased with tree diameter; 9 cm and 18 cm diameter trees required around 17.4 kJ and 44.6 kJ, respectively, for the landshark felling operation (Fig. 7 and Table 1). While the average power requirement remained nearly the same, the length of time needed to fell the tree increased with diameter. However, the energy requirement for the AGV operation ranged between 3.2 kJ to 6.5 kJ for the selected tree diameters, which was considerably less than the landshark energy requirements. This generated data on AGV can be used to refine energy optimization for the tree felling system and post felling operations such as spraying herbicides.

Table 1 Power and energy consumption data

|

Diameter, cm |

AGV |

Landshark |

||||||

|

Average power, W |

Peak power, W |

Energy, kJ |

Average power, W |

Peak power, W |

Energy, kJ |

|||

|

Locust |

8.25 |

45.1 |

192.5 |

3.2 |

310.9 |

538.0 |

21.8 |

|

|

9 |

73.7 |

243.4 |

4.4 |

289.3 |

531.7 |

17.4 |

||

|

15.2 |

41.4 |

150.9 |

4.6 |

287.7 |

544.2 |

31.6 |

||

|

ERC |

12.7 |

36.6 |

165.8 |

3.2 |

267.0 |

532.6 |

26.0 |

|

|

15.2 |

33.6 |

148.9 |

3.5 |

281.7 |

534.0 |

30.6 |

||

|

18 |

39.6 |

159.6 |

6.6 |

268.6 |

529.1 |

44.6 |

||

Power consumption was greater for felling Honeylocust as compared to ERC (Table 1). This can be explained by the difference in the hardness of the two types of wood, with Honeylocust being nearly twice as hard (7030 N) as ERC (4000 N) (Wikipedia 2019). Peak power requirements were the same for both species. Chainsaw binding may have caused power spikes at both the beginning and end of cutting operations on large trees. In case of ERC, average power consumption fluctuated more, possibly because of greater variation in wood density.

3.3 Analysis of Estimated Energy Consumption per Hectare

TSP algorithm generated the optimized route plan for the selected tree densities, as shown in Fig. 8; the AGV total travel distance is given in Table 2. The AGV maximum velocity was 4.8 m/min and the average power consumption was 230 W. It was assumed that the robot was operating on 4 m/min and the total time to cover the 1 ha field route plan was calculated. Thus, the total energy consumption for robot travel was calculated with eq. 1.

The field results showed that the cutting energy of (landshark unit) 8–18 cm diameter trees ranged between 17.4–44.6 kJ with a mean of 28.6 kJ (Table 1). Therefore, it was assumed that, for all equal diameter size trees in 1 ha area, landshark cutting energy for a single tree was 30 kJ. The total energy to fell down the given tree density was estimated. AGV travel and landshark cutting was a major energy consuming operation in pasture clearing. Thus, the total estimated energy to clear the 1 ha pasture area was the energy consumption sum of landshark unit and AGV travel (Table 2). Also, battery charging frequency/ha was estimated for respective tree density (Table 2).

The aim of this estimation was to interpret or assess the capabilities and limitations of the robotic approach to large scale pasture clearing operations assuming ideal conditions. The developed prototype robot, with necessary modifications in vehicle design and operation, can be applied to large scale pasture clearing. Moreover, analysis on energy estimates could be helpful in planning and designing of similar/ related forestry management vehicles in the future. A procedure used for energy estimation resulted in approximate energy estimation for a given tree density, and a more realistic energy estimation can be obtained for an actual pasture clearing site.

Table 2 Robot estimated energy consumption for pasture clearing per hectare area

|

Tree density/ha |

AGV travel distance m |

AGV travel energy kJ |

Landshark tree felling energy kJ |

Total energy kJ |

Battery charging frequency |

|

100 |

845.1 |

2915.6 |

3000 |

5915.6 |

1.6 |

|

200 |

1322.6 |

4563.0 |

6000 |

10563.0 |

2.9 |

|

500 |

3719.3 |

12831.6 |

15000 |

27831.6 |

7.7 |

|

800 |

7126.1 |

24585.0 |

24000 |

48585.0 |

13.5 |

Fig. 5 Robot power for Honeylocust trees with varying tree diameter

Fig. 6 Robot power for ERC trees with varying tree diameter

Fig. 7 Cutting energy of landshark for ERC and Honeylocust trees with varying tree diameter

Fig. 8 TSP algorithm output: optimized route plan for selected tree density

3.4 Future Directions

Þ Minimize chainsaw blade bending by providing additional support for the blade

Þ Install a linear activator on the pusher so the pusher length can be adjusted during the cutting operation

Þ Adjust chainsaw mounting height to reduce tree stub height. The current stub height is tall enough to impede vehicle movement across the pasture

Þ Add LIDAR and GPS capabilities to assist in locating trees and tree recognition.

5. Conclusions

A novel robot prototype was developed for pasture clearing, which can combat ERC infestations by mechanically removing trees up to 20 cm in diameter, and potentially provide larger tree removal with modifications. The average power requirement for the landshark and AGV were 284.2 W and 44.9 W, respectively. Building on the preliminary data from this project, the creation of a database of the average power requirement, cutting time and energy required to fell various tree species and sizes would be useful. Estimated energy consumption analysis results can predict the energy requirement per hectare for a given tree density as well aid in decision making and exploring system energy optimization. The prototype with necessary modifications in design and operation could show potential to large scale pasture clearing. Cutting time will likely be the best parameter for estimating time management, felling efficiency and chainsaw life span.

6. References

Middendorf, G., Becerra, T.A., Cline, D., 2009: Transition and resilience in the Kansas flint hills. Online Journal of Rural Research and Policy 4(3): 1–28. https://doi.org/10.4148/ojrrp.v4i3.109

Ratajczak, Z., Briggs, J.M., Goodin, D.G., Luo, L., Mohler, R.L., Nippert, J.B., Obermeyer, B., 2016: Assessing the potential for transitions from tallgrass prairie to woodlands: Are we operating beyond critical fire thresholds? Rangeland Ecology & Management 69(4): 280–287. https://doi.org/10.1016/j.rama.2016.03.004

Matlack, R.S., Kaufman, D.W., Kaufman, G.A., 2008: Influence of woody vegetation on small mammals in tallgrass prairie. The American Midland Naturalist 160(1): 7–19. https://doi.org/10.1674/0003-0031(2008)160[7:IOWVOS]2.0.CO;2

Fuhlendorf, S.D., Engle, D.M., Kerby, J., Hamilton, R., 2009: Pyric herbivory: Rewilding landscapes through the recoupling of fire and grazing. Conservation Biology 23(3): 588–598. https://doi.org/10.1111/j.1523-1739.2008.01139.x

McLauchlan, K.K., Craine, J.M., Nippert, J.B., Ocheltree, T.W., 2014: Lack of eutrophication in a tallgrass prairie ecosystem over 27 years. Ecology 95(5): 1225–1235. https://doi.org/10.1890/13-1068.1

Ramli, N.N., Epplin, F., 2017: Cost to produce liquid biofuel from invasive eastern redcedar biomass. Biomass and Bioenergy 104: 45–52. https://doi.org/10.1016/j.biombioe.2017.06.008

Semen, E., Hiziroglu, S., 2005: Production, yield and derivatives of volatile oils from Eastern Redcedar (Juniperus Virginiana L.). American Journal of Environmental Science 1(2): 133–138. https://doi.org/10.3844/ajessp.2005.133.138

Krug, A.S., Uden, D.R., Allen, C.R., Twidwell, D., 2017: Culturally induced range infilling of eastern redcedar: A problem in ecology, an ecological problem, or both? Ecology and Society 22(2): 46. https://doi.org/10.5751/ES-09357-220246

Lawson, E.R., 1990: Eastern Redcedar. In: Silvics of North America, Vol. 1, Conifers; Miscellaneous Publication, 131–139.

Twidwell, D., Fuhlendorf, S.D., Taylor, C.A., Rogers, W.E., 2013: Refining thresholds in coupled fire–vegetation models to improve management of encroaching woody plantsin grasslands. Journal of Applied Ecology 50(3): 603–613. https://doi.org/10.1111/1365-2664.12063

Engle, D.M., Coppedge, B.R., Fuhlendorf, S.D., 2008: From the dust Bowl to the green glacier: Human activity and environmental change in Great Plains grasslands. In: Western North American Juniperus Communities: A Dynamic Vegetation Type. Springer New York, 253–271. https://doi.org/10.1007/978-0-387-34003-6_14

Coppedge, B.R., Engle, D.M., Masters, R.E., Gregory, M.S., 2001: Avian response to landscape change in fragmented Southern Great Plains grasslands. Ecological Applications 11(1): 47–59. https://doi.org/10.1890/1051-0761(2001)011[0047:ARTLCI]2.0.CO;2

Anadón, J.D., Sala, O.E., Turner, B.L., Bennett, E.M., 2014: Effect of woody-plant encroachment on livestock production in North and South America. Proceedings of the National Academy of Sciences 111(35): 12948–12953. https://doi.org/10.1073/pnas.1320585111

Eldridge, D.J., Bowker, M.A., Maestre, F.T., Roger, E., Reynolds, J.F., Whitford, W.G., 2011: Impacts of shrub encroachment on ecosystem structure and functioning: towards a global synthesis. Ecology Letters 14(7): 709–722. https://doi.org/10.1111/j.1461-0248.2011.01630.x

Smith, S.D., Stubbendieck, J., 1990: Production of tall-grass prairie herbs below Eastern redcedar. Prairie Naturalist 22(1): 19–18.

Ortmann, J., Stubbendieck, J., Masters, R.A., Pfeiffer, G.H., Bragg., T., 1998: Efficacy and costs of controlling Eastern redcedar. Journal of Range Management 51(2): 158–163.

Limb, R.F., Engle, D.M., Alford, A.L., Hellgren., E.C., 2010: Tallgrass prairie plant community dynamics along a canopy cover gradient of Eastern redcedar (Juniperus virginiana L.). Rangeland Ecology and Management 63(6): 638–644. https://doi.org/10.2111/REM-D-09-00056.1

Simonsen, V.L., Fleischmann, J.E., Whisenhunt, D.E., Volesky, J.D., Twidwell, D., 2015: Act now or pay later: Evaluating the cost of reactive versus proactive eastern redcedar management. University of Nebraska Extension. Institute of Agriculture and Natural Resources EC1784.

USDA NRCS, 2020: Fact sheet about Eastern Red Cedar. Available online: http://plant-materials.nrcs.usda.gov/ (accessed 05 January 2020).

Martens, K.R., 2018: Annual report 2018: Nebraska Forest Service action plan. Technical report, University of Nebraska-Lincoln.

Kansas Forest Service, 2015: Kansas forests and related resources: Kansas forest action plan. Technical report, Kansas State University.

Spencer, D., 2020: Natural resources conservation service – Kansas. Personal communication from Doug Spencer, NRCS State Grazing Specialist-Kansas.

Koehler, S.A., Luckasevic, T.M., Rozin, L.S., Shakir, A.M., Ladham, S., Omalu, B.I., Dominick, J.T., Wecht, C.H., 2004: Death by chainsaw: fatal kickback injuries to the neck. Journal of Forensic Sciences 49(2): 345–350.

Hammig, B., Jones, C., 2015: Epidemiology of chain saw related injuries, United States: 2009 through 2013. Advances in Emergency Medicine 2015: article ID 459697. https://doi.org/10.1155/2015/459697

Ishigure, Y., Hirai, K., Kawasaki, H., 2013: A pruning robot with a power-saving chainsaw drive. 2013 IEEE International Conference on Mechatronics and Automation, 1223–1228. https://doi.org/10.1109/ICMA.2013.6618088

Stampfer, K., 1999: Influence of terrain conditions and thinning regimes on productivity of a track-based steep slope harvester. Proceedings of the International Mountain Logging and 10th Pacific Northwest Skyline Symposium, 78–87.

Meaclem, C.V., Shao, L., Parker, R., Gutschmidt, S., Hann, C.E., Milne, B.J.E., Chen, X., 2014: Sensor guided biped felling machine for steep terrain harvesting. 2014 IEEE International Conference on Automation Science and Engineering (CASE): 984–989. https://doi.org/10.1109/CoASE.2014.6899446

Ferguson, E.R., Lawson, E.R., Maple, W.R., Mesavage, C., 1968: Managing eastern redcedar. Research paper SO-37 New Orleans, LA: U.S. Department of Agriculture, Forest Service, Southern Forest Experiment Station, 14 p.

Brooks, R.E., Schofield, E.K., McGregor, R.L., Barkley, T.M., 1986 Great Plains Flora Association (U.S.)., Flora of the Great Plains. In Flora of the Great Plains; University Press of Kansas: Lawrence, Kansas, 1392 p.

Halls, L.K. (ed.), 1977: Southern Fruit Producing Woody Plants Used by Wildlife. General Technical Report SO-16. New Orleans, LA: U.S. Dept of Agriculture, Forest Service, Southern Forest Experiment Station, 235 p.

Anderson, M.D., 2020: Juniperus virginiana. In: Fire Effects Information System. U.S. Department of Agriculture, Forest Service, Rocky Mountain Research Station, Fire Sciences Laboratory (Producer). Available online: https://www.fs.fed.us/database/feis/plants/tree/junvir/all.html (accessed 24 January 2020).

Badgujar, C., Flippo, D., Brokesh, E., Welch, S., 2022a: Experimental investigation on traction, mobility & energy usage of the tracked Autonomous Ground Vehicle on a sloped soil bin. Journal of the ASABE 65(4): 835–847. https://doi.org/10.13031/ja.14860

Badgujar, C., Flippo, D., Welch, S., 2022b. Artificial neural network to predict traction performance of autonomous ground vehicle on a sloped soil bin and uncertainty analysis. Computers and Electronics in Agriculture 196: 106867. https://doi.org/10.1016/j.compag.2022.106867

Mohlenbrock, R., 2020: Plant Guide: Honey Locust Gleditisia triacanthose L. Available online: https://plants.usda.gov/plantguide/ pdf/pg-gltr.pdf. (accessed 21 January 2020).

Kirk, J., 2020: Traveling Salesman Problem – Genetic Algorithm, MATLAB Central File Exchange. Available online: https://www.mathworks.com/matlabcentral/fileexchange/13680-traveling-salesman-problem-genetic-algorithm (accessed 21 January 2020).

Hacizade, U., Kaya, I., 2018: GA Based Traveling Salesman Problem Solution and its Application to Transport Routes Optimization. IFAC-PapersOnLine 51(30): 620–625. https://doi.org/10.1016/j.ifacol.2018.11.224

Lenstra, J.K., Kan, A.H.G.R., 1975: Some simple applications of the travelling salesman problem. Journal of the Operational Research Society 26(4): 717–733. https://doi.org/10.1057/jors.1975.151

Wikipedia, 2019: Janka hardness test. Wikipedia, The Free Encyclopedia. Available online: http://en.wikipedia.org/w/index. php?title=Janka%20hardness%20test&oldid=896623051 (accessed 05 July 2019).

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Chetan Badgujar, PhD *

e-mail: cmbadgujar94@gmail.com

Kansas State University

Biological and Agricultural Engineering

1037A Seaton Hall

Manhattan, Kansas 66506

USA

Assoc. prof. Daniel Flippo, PhD

e-mail: dkflippo@ksu.edu

Kansas State University

Biological and Agricultural Engineering

1041 Seaton Hall

Manhattan, Kansas 66506

USA

Assist. prof. Sylvester Badua, PhD

e-mail: sabadua@clsu.edu.ph

Central Luzon State University

College of Engineering

Department of Agricultural and Biosystems Engineering

Science City of Muñoz, Nueva Ecija

PHILIPPINES

Assoc. prof. Carolyn Baldwin, PhD

e-mail: carolbaldwin@ksu.edu

Kansas State University

Agriculture, Natural Resources and Community Vitality

Umberger 103, 1612 Claflin

Manhattan, Kansas 66506

USA

* Corresponding author

Received: June 22, 2021

Accepted: September 9, 2021

Original scientific paper