Operational and Environmental Comparison of Two Felling and Piling Alternatives for Whole Tree Harvesting in Quercus Coppices for Bioenergy Use

doi: 10.5552/crojfe.2023.1522

volume: 44, issue:

pp: 11

- Author(s):

-

- Tolosana Eduardo

- Laina Rubén

- Spinelli Raffaele

- Aminti Giovanni

- López-Vicens Ignacio

- Article category:

- Original scientific paper

- Keywords:

- forest operations, work study, environmental effects, feller-buncher, motor-manual cutting, operational cost

Abstract

HTML

Coppices are a major potential source of forest biomass in Spain, where they occupy around 4M ha. Quercus coppices are mostly neglected because of their high harvesting costs and the small size of their products. This makes them very interesting to test and compare alternative means for utilizing their resources in an optimized way. Hence, a comparative study of motor-manual and mechanized felling and bunching was conducted when thinning dense coppice stands of the two most important oak species in Spain to obtain biomass for bioenergy use. In particular, the study matched chainsaw felling and manual piling against the work of a drive-to-tree feller-buncher previously analyzed in the very same sites. Productivity functions for motor-manual felling and piling were fitted for each species. The derived unit cost functions show that the felling-bunching costs are lower for the motor-manual option in stands of both species, particularly for the smaller tree sizes. Nevertheless, when the strongly reduced loading times in forwarding associated to the mechanization are taken into account, the total harvesting cost is often lower for the mechanized option. That is true for all tree sizes of Q. ilex, and for trees larger than 13 cm diameter at breast height (DBH) for Q. pyrenaica. Residual stand damage was low to moderate, but always significantly greater for the mechanized option compared with the motormanual one. Soil damage was very low for both alternatives. The stumps experimented significantly greater damages in the mechanized felling and bunching, but further research is needed to determine if those damages have any impact on stump mortality, sprouting capability and future plants vigor. The greater productivity and level of tree damages found in Q. ilex when compared to Q. pyrenaica are likely due to the narrower and lighter crown of the latter.

Operational and Environmental Comparison of Two Felling and Piling Alternatives for Whole Tree Harvesting in Quercus Coppices for Bioenergy Use

Eduardo Tolosana, Rubén Laina, Raffaele Spinelli, Giovanni Aminti, Ignacio López-Vicens

Abstract

Coppices are a major potential source of forest biomass in Spain, where they occupy around 4M ha. Quercus coppices are mostly neglected because of their high harvesting costs and the small size of their products. This makes them very interesting to test and compare alternative means for utilizing their resources in an optimized way. Hence, a comparative study of motor-manual and mechanized felling and bunching was conducted when thinning dense coppice stands of the two most important oak species in Spain to obtain biomass for bioenergy use. In particular, the study matched chainsaw felling and manual piling against the work of a drive-to-tree feller-buncher previously analyzed in the very same sites. Productivity functions for motor-manual felling and piling were fitted for each species. The derived unit cost functions show that the felling-bunching costs are lower for the motor-manual option in stands of both species, particularly for the smaller tree sizes. Nevertheless, when the strongly reduced loading times in forwarding associated to the mechanization are taken into account, the total harvesting cost is often lower for the mechanized option. That is true for all tree sizes of Q. ilex, and for trees larger than 13 cm diameter at breast height (DBH) for Q. pyrenaica. Residual stand damage was low to moderate, but always significantly greater for the mechanized option compared with the motormanual one. Soil damage was very low for both alternatives. The stumps experimented significantly greater damages in the mechanized felling and bunching, but further research is needed to determine if those damages have any impact on stump mortality, sprouting capability and future plants vigor. The greater productivity and level of tree damages found in Q. ilex when compared to Q. pyrenaica are likely due to the narrower and lighter crown of the latter.

Keywords: forest operations, work study, environmental effects, feller-buncher, motor-manual cutting, operational cost

1. Introduction

Social and economic changes during the second half of the 20th century have led to the reduction of the profitability of coppice systems in Europe, so that they have been largely abandoned in most countries (Carvalho et al. 2017). Abandonment has brought about the underutilization of this relevant natural resource, as well as a loss in the biodiversity associated with traditional silvicultural practice (Mullerová et al. 2015). Aging and densification have increased vulnerability to natural disasters such as windthrow and wildfire, that have become more frequent during the last century (Schelhaas et al. 2003) and are estimated to provoke annual losses close to a million cubic meters in Europe by 2030 (Seidl et al. 2014).

Coppice thinning would reduce wildfire suppression costs, especially if whole-tree harvesting (WTH) is adopted, because complete biomass removal reduces potential fire severity compared with other harvesting methods that leave large amounts of branches and tops within the stand (Corona et al. 2015). Developing and operationalizing fuel treatment options that are technically possible, but not yet widely deployed, has been pointed out as a priority in future research for woody biomass utilization (Anderson and Mitchel 2016).

Choosing site-appropriate techniques and equipment is essential for the economic sustainability of the entire supply chain (Enache et al. 2015). This is particularly important for coppices, where operators must face small stem sizes and stump crowding, which increase operational costs (Spinelli et al. 2017).

Coppice harvesting technology is evolving toward increased mechanization and larger and more efficient equipment (Spinelli et al. 2016). Mechanization leads to higher productivity and lower unit costs for woody products from coppice forests (Laina et al. 2013).

The mechanized harvesting of coppice forests is technically and economically complex, due to the difficulty encountered by a felling head when approaching stems that are gathered in a clump on the same stump (Schweier et al. 2015). Also the undesired potential effects of mechanization – damage to soil, residual stand and stumps – have raised concern among forest managers and scientists (Spinelli et al. 2017, Pyttel et al. 2013), and must be considered when implementing a mechanized harvesting technology.

One of the available technologies for mechanized felling consists of a feller-buncher head equipped with a disk saw. Its advantage lies in the high cutting speed and in the ability to manage multiple stems in a single pass. This type of felling head has been tried recently in Mediterranean coppices, where it has proved less effective than in SRC but especially capable to contain stump damage, when compared with shears (Schweier et al. 2015).

The coppice WTH system followed by chipping has proven to be a decisive step forward in terms of sustainability, especially when measured through financial and social indicators. All environmental and social indicators – except for employment potential – perform better than those of the traditional systems producing firewood for heating (Spinelli et al. 2021).

The Spanish forest company SOMACYL began the field trial of a drive-to-tree disc saw feller-buncher for use in coppice harvesting for whole tree bioenergy use, which provided an ideal opportunity for conducting carefully designed time and motion studies with the purpose of evaluating operational productivity, cost, product recovery and site damage. The results were presented in (Tolosana et al. 2018).

Alongside mechanized felling, the same enterprise also deployed motor-manual felling and bunching, which is still the traditional mainstream method: therefore, the collection of data on motor-manual felling in a second phase of the study allowed a comparison of the two systems.

In Spain, coppice forests cover roughly 4 M ha and represent 20% of the total forest area, with Holm oak (Quercus ilex L.) and Melojo oak (Quercus pyrenaica Willd.) as the dominant species (Piqué et al. 2017). Hence, coppices are a potential major source of biomass for bioenergy or bioproducts. These species have been studied because they are the most important coppice species in Spain. Q. ilex is a common species in the Mediterranean Basin, from Portugal, Spain and Morocco, to the Aegean Islands and western Turkey, expanding also northward up to northern Italy and France. It also occurs in a few localities in Anatolia on the coast of the Black Sea, while Q. pyrenaica is abundant in West France, Portugal, Spain and North Morocco (European Atlas of Forest Tree Species, 2016). The Quercus genus is the most mentioned in Europe as coppiced in the past or in present (Unrau 2018). As coppicing has been frequently abandoned in the last decades, there are abundant dense and young Quercus coppices out of active management, particularly in Mediterranean Europe.

Coppice forests account for 16% of forest surface in Europe, ca. 23 million ha (Nicolescu et al. 2015), mainly in the western, southern and southeastern European countries (Spinelli et al. 2021). Coppice gradual thinnings that keep a continuous cover is the most recommended option for conversion of such stands (Ciancio et al. 2006), and there is a trend to increase the rotation ages in order to improve machinery efficiency and harvesting higher stocks per unit area (Fabbio 2016). Nevertheless, some authors recommend maintaining the traditional coppice systems in part of these stands, as it has shown to be sustainable in the long term (Salomon 2015) and efficient in sustaining »bio-cultural diversity« (Burgi 2015, Mullerova et al. 2015).

Coppice thinning is a challenge in Mediterranean countries, due to the abandonment of traditional uses and to the mentioned need of reducing wildfire risks and high operational costs of conventional systems, particularly in the abundant young dense stands. Mechanization has to face the growing lack of motor-manual workers, to improve the safety conditions and to gain productivity and reduce harvesting costs (Magagnotti et al. 2017); however, as it requires a removal large enough to offset the high fixed cost of moving machines to the worksites (Väätäinen et al. 2006), there are no clear economic limits set between motor-manual and mechanized methods in young coppice thinnings.

These facts justify the need to analyze the alternative systems for coppice thinnings in the species representative of Mediterranean oak coppices, to set the economic frontier in terms of unit cost and to compare the environmental effects between the already analyzed mechanized systems (Tolosana et al. 2018) and the motor manual alternative in the very same sites and treatments.

For the motor-manual system, it would be useful to obtain new predictive equations for productivity, which can be useful for similar treatments and coppice stands in Europe.

Thus, the main goals of the present phase of the study are to:

Þ develop productivity equations for motor-manual felling and bunching and for both coppice types (i.e. Q. ilex and Q. Pyrenaica)

Þ use these equations to estimate the operational cost of motor-manual felling and bunching

Þ compare the cost of motor-manual felling and mechanized felling under varying tree size conditions for both coppice types (i.e., Q. ilex and Q. pyrenaica) and for the felling and bunching only, as well as for the whole operation – from standing trees to cut trees piled at the landing

Þ assess the environmental impacts of the motor-manual option on the soil, the remaining trees and stumps, and comparing these impacts with those previously recorded for the mechanized system

Þ estimate biomass collection efficiency (percentage of available biomass actually collected) and compare this figure with those previously obtained for the mechanized option.

2. Materials and Methods

2.1 Field Trials

Two field trials were performed in 2017 and 2018, in the first case using mechanized means (feller buncher) and in the second case, felling and bunching motor-manually. Both cutting methods were tested in two stands dominated by the two chosen species.

Both test stands were located in the Palencia province (Central Spain): one of them was dominated by Holm oak (Quercus ilex) and the other by Melojo oak (Quercus pyrenaica). They were selected for the trials among several stands as the most representative of the average conditions of these oak coppices in Spain.

Mechanized felling and bunching had been conducted one year before the present trials with a John Deere 643J (130 kW, 12.7 t) carrier, equipped with a JD FD45 disc-saw accumulating head. This was a drive-to-tree feller-buncher, without a boom arm.

Motor-manual felling was conducted by a three-men team. Two workers directionally felled trees using medium-sized chainsaws, and a third worker formed trees into bunches ready for collection.

In both cases, trees were moved to the roadside landing with a John Deere 1910E forwarder (186 kW, 19 t loading capacity), connected to a compressing trailer Dutch Dragon PC-48.

Both the feller-buncher and the motor-manual team worked on a half of the 34 paired 25x25 m2 plots, which were equally distributed between the two coppices and considered as replications in the statistical analysis of results. That amounted to 8 and 9 replications per machine treatment and coppice type.

Both forests were inventoried before and after harvesting using conventional forest mensuration techniques and tools.

2.2 Pre-harvest Inventory

17 pairs of 25x25 m2 square plots were randomly allocated, 9 of the pairs in the Q. ilex coppice and the remaining 8 pairs in the Q. pyrenaica forest. The plots were paired (adjacent) to those used in the mechanized thinnings study by (Tolosana et al. 2018). The diameter at breast height (DBH) of all trees was measured. To estimate the dry weight of the felled trees, a weight table was fitted in the previous study by weighing and measuring around 30 trees per each species and sampling them for assessing moisture content, accordingly to the ISO 18134-3:2015 standard. Measured trees and plots borders were marked.

The total studied surface was 0.56 ha in the Q. ilex coppice and 0.50 ha in the Q. pyrenaica stand. The obtained biomass from the studied plots was 22.5 odt in the case of Q. ilex and 10.5 odt in the case of Q. pyrenaica. The rest of the stands were also thinned, amounting to a total surface of roughly 100 ha in the Q. ilex stand and around 20 ha in the Q. pyrenaica coppice. The forwarding time study was performed in the remaining »normal« thinnings.

2.3 Time Study and Produced Biomass Evaluation

The previous feller-buncher time study (Tolosana et al. 2018) was performed on a cycle level using a Husky Hunter field computer fitted with the software Siwork3 (Kofman 1995). For the motor-manual time study, the activity sampling method was adopted instead, because three workers had to be simultaneously studied (Magagnotti et al. 2012). Both methods would still return the same information.

To assess the biomass extracted from each plot, the forwarder piled the whole trees coming from each plot in a separate pile at the roadside. Each pile was chipped, transported, and weighed separately, and the chips from each pile were sampled for determining moisture content according to the gravimetric method.

To fit the productivity function, a multiple linear regression analysis was performed, using the data from 14 out of the 17 studied plots (one was felled before the work study, other two were rejected because of the out-of-range studentized residuals). The following independent variables were tested: species (as a dummy variable), dry weight per tree (initial stand), dry weight per extracted tree (removals only), dry weight per ha, initial number of trees per ha, extracted number of trees per ha, extracted basal area, percentage of total basal area actually extracted.

During forwarding, one whole shift was time-studied for each work system (mechanized and motor-manual), measuring the number of trips and piles in order to get an estimate of average extraction productivity.

2.4 Cost Estimation

Hourly cost for the workers team (21.0 €·Workh-1 per worker, or 63.0 €·Workh-1 for the three-men team, including chainsaws) was provided by (SOMACYL 2021). The company also produced the rental costs of the forwarder (71.5 €·Workh-1) and chipper (11.0 €·fresh tonne-1). Transportation cost was estimated for a distance of 80 km one way, as had been done for the mechanized system in (Tolosana et al. 2018) in order to ease the further cost comparison.

All estimates of revenues and costs in terms of odt were based on the following measurements: average water mass fraction of chips equal to 15.3 and 34.5%, for Q. ilex and Q. pyrenaica, respectively.

In the workers’ case, the utilization coefficient (ratio of productive work time to total paid time for the workers team) was equal to 85%.

2.5 Post-Harvest Inventory and Damage Assessment

The DBH of all remaining trees inside each plot was determined.

The damage to the remaining trees was characterized inside each of the 25x25 m2 plots, following the methodology proposed by (Tavankar et al. 2013).

Soil damage levels were determined according to the methodology proposed by (Mc Mahon 1995), applied to 4 m radius circular sub-plot, whose center was located in the crossing point of each square plot diagonal.

The stumps inside those subplots were also counted, measuring their heights and assessing the occurrence, type and severity of any possible damage.

2.6 Measurement of Biomass Collection Efficiency

Inside the above-mentioned sub-plots, the biomass left on the terrain was collected and weighed, taking two samples to estimate moisture content. That would offer a measure of possible harvesting losses and – indirectly – of overall harvesting efficiency.

3. Results

3.1 Coppice Inventory and Treatment Description

The initial density of the Q. ilex coppice was 5310 trees·ha-1, with a mean DBH of 5.9 cm, a mean height of 4.1 m, and a mean basal area of 14.3 m2·ha-1. The average number of stools per ha was 886, with an average number of 6.0 sprouts per stool. The treatment consisted of the removal of 90% of the trees and 63% of the basal area, leaving 545 remaining trees per hectare.

The Q. pyrenaica coppice had a mean initial density of 3868 trees·ha-1 and a mean DBH of 6.7 cm. Mean height was close to 6.0 m and mean basal area was 13.6 m2·ha-1. The mean number of stools·ha-1 was 1004, with an average number of sprouts per stool of 2.8. There were also 2564 isolated oaks·ha-1. The treatment led to the extraction of 81.5% of these trees and 47% of the initial basal area, leaving 716 trees·ha-1.

The removed weight ranged between 18 and 59 dry tonnes (odt)·ha-1 in the Q. ilex coppice (averaging 40 odt·ha-1) and between 6 and 38 odt·ha-1 (averaging 21 odt·ha-1) for Q. pyrenaica. Therefore, the harvest was twice as large in the Q. ilex stand, compared with the Q. pyrenaica stand.

3.2 Time Study

In Q. ilex, the productivity of motor-manual felling and bunching ranged between 2.5 and 3.5 odt per productive person hour (odt·PPH-1), for the team of three workers. Delays were almost zero, as no incident or other breakdowns occurred during the time study. Average productivity inside the studied plots was 2.85 odt·PPH-1.

In Q. pyrenaica, productivity for the same team ranged between 0.9 and 3.2 odt·PPH-1. No delays or incidents were recorded here, either, as delays were not observed in those 25x25 plots. Average productivity reached 2.18 odt·PPH-1.

3.3 Productivity Equation for Motor-Manual Felling and Bunching

Significant explanatory variables were tree species and dry weight per tree. The first was introduced as an indicator variable for Q. ilex, with Q. pyrenaica as the null baseline, while the latter was the estimated mean tree weight for the initial stand, before thinning. All other variables tested turned out to be not significant or less significant than their competitors (in the case where two independent variables would express the same general property and could not be introduced together into the same equation under pain of nullity due to autocorrelation).

The fitted regression curve is:

Productivity (odt·PPH-1) = 0.945 + 0.867·Qilex (0/1) + 0.082·DryWeightPerTree (kgDM·tree-1) (1)

Its regression statistics is shown in Table 1.

Table 1 Fitting statistics of productivity regression curve

|

Multiple regression – Productivity Dependent variable: Productivity (odt·PPHour-1) Independent variables: Qilex (1 if Species = Q. ilex, 0 if Species = Q. pyrenaica) Dry Weight ·Tree-1 (average kgDM·tree-1 before thinning) Observations number: 14 |

||||

|

Parameter |

Estimation |

Standard error |

T-Statistic |

P-Value |

|

Constant |

0.945 |

0.399 |

2.37 |

0.0372 |

|

Qilex |

0.867 |

0.205 |

4.23 |

0.0014 |

|

kgDM·tree-1 |

0.082 |

0.024 |

3.45 |

0.0055 |

|

ANOVA |

||||

|

Source |

Squares sum |

DF |

Average Square |

F-ratio |

|

Model |

2.86 |

2 |

1.43 |

11.24 |

|

Residual |

1.40 |

11 |

0.127 |

|

|

Total (Corr.) |

4.26 |

13 |

||

|

R-square = 67.2% R-square (adjusted by d.f.) = 61.2% Standard est. error = 0.36 Medium Absolute Error = 0.24 Durbin-Watson Statistic = 2.32 (P=0.60) |

||||

Using the average values of productivity and the average removal per ha, the required time per ha in the studied coppices conditions was estimated as 14.0 productive hours (16.5 Workh)·ha-1 for Q. ilex and 9.6 productive hours (11.3 Workh)·ha-1 for Q. pyrenaica.

3.4 Unit Cost Estimation

The results of cost calculation are reflected in Table 2.

Table 2 Operational costs, productivities and total unit costs for motor-manual operations

|

Operation/s |

Hourly cost Team/machine €·Workh-1 |

Hourly cost Team/machine €·Prodh-1 |

Average productivity, odt·Prodh-1 |

Unit cost renting €·fresh tonne-1 |

Unit cost, €·odt-1 |

||

|

Q-.ilex |

Q. pyrenaica |

Q. ilex |

Q. pyrenaica |

||||

|

Felling/bunching |

63.0 |

74.1 |

2.85 |

2.18 |

– |

26.00 |

33.99 |

|

Extracting w/forwarder |

71.5 |

79.4 |

4.28 |

3.88 |

– |

18.56 |

20.46 |

|

Chipping |

– |

– |

– |

– |

11.0 |

12.99 |

16.79 |

|

Chip transport (dist = 80 km) |

– |

– |

– |

– |

7.46 |

8.81 |

11.39 |

|

Total (direct unit cost) |

– |

– |

– |

– |

– |

66.36 |

82.63 |

|

+15% overheads |

– |

– |

– |

– |

– |

76.31 |

95.03 |

Delivered cost was 66 €·odt-1 for Q. ilex and 83 €·odt-1 for Q. pyrenaica chips. If these figures are increased by 15% to cover overheads (e.g., relocation, indirect and structural costs), actual delivered cost grows to 76 €·odt-1 and 95 €·odt-1, respectively. The cost for Q. ilex is slightly lower than that estimated for the mechanized option - 78 €·odt-1; in (Tolosana et al. 2018), this is partially due to the quite low chips moisture observed in the motor-manual treatment. This fact reduced the transport and chipping costs, paid on a fresh tonne basis. For Q. pyrenaica, the motor-manual cost is clearly much lower than that estimated for the mechanized option, 120 €·odt-1 (Tolosana et al. 2018).

Regarding the influence of the explanatory variables on cost, the Productivity equation (Eq. 1) (fitting statistics in Table 1) can be obtained using the team hourly cost combined with the mentioned equation, as:

Unit cost (€·odt-1) = 63.0·[0.945+0.082·DryWeightPerTree (kgDM·tree-1) + 0.867·Qilex(1/0)]-1 (2)

Total operational cost per tonne for the average observed conditions can be transformed in a cost per hectare, that is equal to 3052 €·ha-1 for Q. ilex (removal = 40 odt ha-1) and 1979 €·ha-1 for Q. pyrenaica (removal = 21 odt ha-1). These figures exclude stumpage and contractor’s profit.

Current prices (end of 2021) for a fresh tonne of whole tree chips with moisture contents of 15.3% and 34.5%, as in the studied coppices, are 63 and 46 €, respectively. Those correspond to 74 and 70 €·odt-1 (SOMACYL 2021). Under such conditions, the net operational balance is negative and equal to -92.0 €·ha-1 for Q. ilex and -509 €·ha-1 for Q. pyrenaica – without accounting for stumpage and contractor’s profit. Losses are much smaller for Q. ilex due to the larger removal and especially to the production of drier chips, which had a positive effect on pricing and transportation efficiency.

3.5 Environmental Impacts

The frequency and severity of residual tree damage are shown in Table 3, separately for each species. Damage frequency is significantly higher for Q. ilex, especially for damages that affect the wood and are caused by chainsaw felling. That might depend on the higher stand density, smaller size and thinner bark of Q. ilex trees, when compared with Q. pyrenaica.

Nevertheless, injures are mostly small or medium sized (surface smaller than 200 cm2), particularly in Q. ilex. In Q. pyrenaica, forwarder traffic accounts for most damage, while in Q. ilex, 25% of the damages are felling injures caused by the chainsaws.

The frequency of deep damage is small – close to 5% – and similar for both species. However, while deep damage in Q. ilex is mostly represented by chainsaw cuts digging into the wood, in Q. pyrenaica deep damage is mostly caused by the forwarder and results in larger wounds (exposed surface >200 cm2).

Table 3 Damages on remaining trees from motor-manual coppice harvesting by species

|

Damages in remaining trees, % damaged trees over total number |

||||||||||||||

|

Type |

Qi |

Qp |

Location |

Qi |

Qp |

Height |

Qi |

Qp |

Size |

Qi |

Qp |

Cause |

Qi |

Qp |

|

Bark |

4.0 a |

6.2 a |

Stem |

10.6 a |

9.5 a |

Low (0–0.3 m) |

2.0 a |

0.0 a |

Small (<50 cm2) |

12.1 a |

5.9 b |

Machine movem. |

75.0 a |

100.0 b |

|

Wood |

5.2 a |

0.3 b |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

Broken branches |

4.8 a |

4.5 a |

Crown |

3.6 a |

1.5 a |

Medium (0.3–1.0 m) |

4.4 a |

3.3 a |

Medium-sized (50–200 cm2) |

1.6 a |

2.1 a |

Cutting injure |

25.0 a |

0.0 b |

|

Destroyed crown |

0.0. a |

0.0 a |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

Total |

14.1 a |

11.0 a |

Roots |

0.0 a |

0.0 a |

High (>1.0 m) |

7.3 a |

7.7 a |

Large (>200 cm2) |

0.4 a |

3.0 b |

Others |

0.0 a |

0.0 a |

|

Severe |

5.2 a |

3.9 a |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

The different letters (a and b) indicate statistically significant differences (<5%) between the two species |

||||||||||||||

Results from the survey of stump and soil are summarized in Table 4. Soil damage was not severe and mostly consisted of light superficial disturbance, such as litter scuffing and shallow rutting not deeper than 5 cm. Disturbance was recorded on 6% of the total surface in Q. pyrenaica and 16% in Q. ilex, but differences were not significant. In general, disturbance was blamed on forwarder traffic, potentially more intense in Q. ilex due to larger removals and bigger crown size.

Stump damage was infrequent and generally minor: less than 10% of the stumps showed cracking or other severe damage, much less than those recorded in the previous study about the mechanized option (Tolosana et al. 2018).

Table 4 Soil and stumps damages after motor manual harvesting by species

|

Soil damages, % of total surface |

||||||||

|

Specie |

No damage evidence |

Present litter, slight alteration |

Litter removed surface soil exposed |

Litter and surface soil mixed ruts deeper than 5 cm |

||||

|

Quercus ilex |

0.0 |

15.7 |

0.0 |

0.0 |

||||

|

Quercus pyrenaica |

0.0 |

6.4 |

0.0 |

0.0 |

||||

|

Stump height, % of stumps number |

Stump status, % of stumps number |

|||||||

|

Specie |

<10 cm |

10–20 cm |

>20 cm |

No damage |

<50% bark separated |

>50% bark separated |

Cracked stump |

Destroyed stump |

|

Quercus ilex |

45.6 |

50.6 |

3.8 |

58.7 |

26.0 |

6.8 |

3.4 |

5.1 |

|

Quercus pyrenaica |

28.9 |

59.8 |

11.3 |

71.1 |

17.5 |

3.1 |

5.2 |

3.1 |

3.6 Efficiency in Biomass Collection

Biomass harvesting efficiency ranged between the 83 and 99% (Q. ilex and Q. pyrenaica, respectively), taking as a reference the theoretical weight estimated through the inventory. Biomass losses averaged 3.7 odt·ha-1 for Q. ilex and 2.1 odt·ha-1 for Q. pyrenaica, including shrubs left on site.

3.7 Comparison with Mechanized Option Studied on the Same Sites

3.7.1 Felling-bunching Costs

For the purpose of this comparison, only the data for felling and bunching were extracted from the previous study, since differences in wood moisture content between the two studies would unduly affect the results for all subsequent operations, and especially transportation. In the latter case, even the necessary normalization of data to the dry weight basis would not produce a satisfactory result, because moisture content would affect the actual payload and therefore reflect on transportation performance despite normalization.

Furthermore, the analysis also took into account the impact of different felling techniques (i.e. motor-manual or mechanized) on extraction, due to the different characteristics of bunches obtained from the two different treatments, whereby the mechanized treatment would produce larger and better aligned bunches compared with the motor-manual treatment. The longer loading time of the forwarder when under the motor-manual treatment brought about a drop in productivity compared to the mechanized option. Based on the forwarding follow-up study during a whole work shift per stratum, the extraction productivity per productive machine hour (PMH) decreased from 7.0 to 4.3 odt·PMH-1 for the Q. ilex coppice and from 6.6 to 3.9 odt·PMH-1 for the Q. pyrenaica stand, consequent to the less efficient bunching.

Data for mechanized felling and bunching were analyzed the same way as for motor-manual felling and bunching obtaining the same type of regression equation, capable of estimating productivity as a function of species, unit dry weight and percentage of removed basal area (Tolosana et al. 2018). This equation was used to estimate the productivity of mechanized felling for the same mean tree size values found in the motor-manual study and the same mean percentage of removed basal area, equal to 70% and 45% respectively, for Q. ilex and Q. pyrenaica. Trying to use an explanative factor simpler and easier to measure than the unit dry weight per tree, the weight tables developed as a function of DBHs by (Tolosana et al. 2018) are used to substitute the initial explanative variable (unit weight) by the DBH.

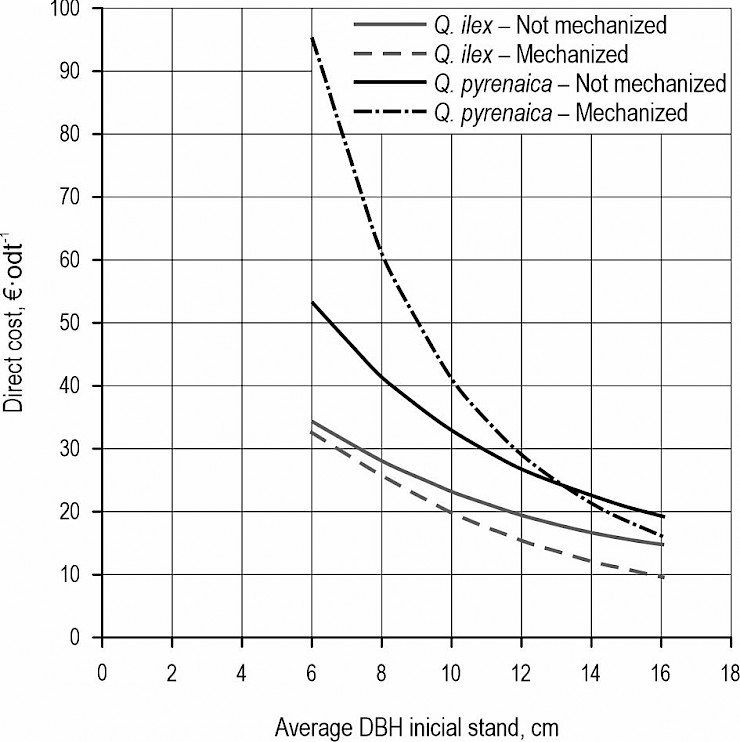

As the forwarder hourly cost was 79.4 €·PMH-1 (Table 2), the increased forwarding productivity of the mechanized option (4.3 to 7.0 odt·PMH-1 for Q. ilex and 3.9 to 6.6 odt·PMH-1 for Q. pyrenaica) brought about increments of unit costs for forwarding in the motor-manual operation, that reached 7.2 €·odt-1 for Q. ilex and 8.4 €·odt-1 for Q. pyrenaica. These costs were added to the direct costs of felling and bunching in the motor-manual case to compare both options taking into account these over costs. The result of the direct cost comparison is shown in Fig. 1, both for Q. ilex and Q. pyrenaica.

In the Q. ilex case (Fig. 1), felling and bunching – taking into account their influence in forwarding cost – is less costly for the mechanized option, particularly for the larger DBHs (for the observed range, the difference is small). In fact, in the studied case and for the mean DBH, the unit cost for felling and bunching alone was 31.5 €·odt-1, for the mechanized option and 26.0 €·odt-1 for the motor-manual one. However, once the additional forwarding cost resulting from motor-manual felling is accounted for, then the motor-manual system is a slightly (6%) more expensive chain, at 33.2 €·odt-1.

In the Q. pyrenaica coppice (Fig. 1), the mechanized option is generally more expensive, particularly for small trees such as the observed ones. The difference decreases with increasing tree size, break-even being achieved at around 13 cm – DBH out of the observed range, and that after taking into account the differences in extraction cost. For trees larger than 13 cm DBH, the mechanized option would be slightly preferable: however, Q. pyrenaica stands are dense coppice formation of generally smaller trees than that.

Fig. 1 Unit direct cost of motor-manual and mechanized felling and bunching for Quercus ilex and Quercus pyrenaica coppices

Therefore, for the average conditions encountered in the studied Q. pyrenaica coppice, the mechanized option would have an average felling and bunching unit cost of 69.0 €·odt-1, clearly more expensive than the motor-manual option (direct cost 34.0 €·odt-1, adding the 8.4 €·odt-1 forwarding extra cost it would be 42.4 €·odt-1).

3.7.2 Treatment Quality and Environmental Effects

Treatment conditions regarding thinning intensity and selectivity has been quite similar in the plots where felling and bunching were performed with a feller-buncher and those felled and bunched motor-manually.

The frequency of residual tree damage in Q. ilex was 14 and 54%, respectively, for the motor-manual and mechanized system. If only severe wounds larger than 200 cm2 and/or affecting the wood are considered, then frequency is 5.2% and 10.0%, respectively. However, these differences are not statistically significant, due to very wide variation in damage level from one plot to another.

The same trends are true for Q. pyrenaica, although the numbers are smaller: 11.0 and 22.4% for the motor-manual and mechanized treatment, respectively, in terms of total wounded tree frequency, regardless of wound type and severity. When only sever wounds are taken into account, then frequency drops to 3.9 and 10.3%, respectively. This time, differences between treatments are statistically significant.

Soil disturbance was negligible for both treatments and stand types, probably because of the flat terrain and sandy soil, which was quite dry during the harvesting operations. These conditions make the soil especially resistant to disturbance, which was once again verified by our study.

Mechanized felling resulted in extensive stump damage, and so did motor-manual felling although in a smaller measure. The consequences of such damage are still unclear and require further investigation (Spinelli et al. 2017).

4. Discussion

Regarding the productivity equations fitted for motor-manual felling and bunching, the variable tree size (DBH, unit volume or weight) is the most common explanatory variable in any productivity equation for felling and bunching (Spinelli et al. 2016, Schweier et al. 2015, Spinelli et al. 2007, Visser and Spinelli 2012, Erber et al. 2017, Chakroun et al. 2016, Ghaffariyan et al. 2019). That was verified in this study, as well. However, this same study could not find any significant association between productivity and removal (mass per hectare or basal area), as reported in many other studies (Spinelli et al. 2016, Tolosana et al. 2018). Probably the range of variation in the studied coppices was not wide enough for such association to emerge. The influence of tree species is likely explained by the different crown structure of Q. ilex and Q. pyrenaica (Ruiz-Peinado et al. 2012), which may have had an effect on handling efficiency during felling and bunching.

The values of measured productivity for motor-manual felling in WTH are below the range (1 to 4 m3·Scheduled hour-1·operator-1) as referred by (Spinelli et al. 2017a). The values are also clearly lower than those predicted by the equation developed from a meta-analysis of European coppices whole tree motor-manual felling (Spinelli et al. 2018), because the analysis did not include bunching and due to the small value of removals in the studied cases, 47 m3·ha-1 in Q. ilex and 32 in Q. pyrenaica, compared to an average value of 116 m3·ha-1 in the analyzed cases, mainly clearcuts.

The study also clearly shows that a proper evaluation of different mechanization levels must cover the whole chain and cannot be restricted to one link, only. Otherwise, mechanized felling would generally prove a poor alternative to motor-manual felling, since it generally results in a higher felling cost. In fact, the financial benefits of mechanized felling are generally accrued during extraction, due to the much better characteristics of the bunches, which are larger, more coherent and better aligned. This has been already observed in past comparisons, whereby mechanized felling turned out to offer no cost savings of itself but was instrumental to a dramatic reduction of extraction cost (Magagnotti et al. 2011, Spinelli et al. 2006).

As exposed in the Results, the studied operations would all incur financial losses, although the work in Q. ilex was very close to breaking even. Using the studied technologies, the possibilities to reach the self-financing require applying them to coppices with bigger trees – which are not available in most cases, except for very aged coppice stands. On the other hand, profitability could possibly be achieved by reducing costs – for instance by owning and managing the machinery instead of renting it, or by allowing for a better drying of trees before chipping, in order to increase transportation efficiency.

In case of financial losses, they were mainly due to the selective felling of young and dense coppices with small trees. In the case of coppices with bigger trees and higher removals, harvesting costs are lower and the operations accrue some profit in the cases studied by (Spinelli et al. 2014b), most of them clearcuts.

For these selective fellings in dense and young coppices, taking into account the silvicultural trends and the growing risks affecting this kind of stands, it would be advisable for forest policy-makers to establish a subsidy aiming to enhance resilience and maintain this cultural system.

The break-even DBH of unit cost between the motor-manual and the fully mechanized harvesting options for Q. pyrenaica is consistent with former similar studies, comparing motor-manual and mechanized felling and processing (Tolosana et al. 2017).

Concerning residual tree damage, the lower performance of mechanized felling and bunching contradicts the results of previous similar studies, which have found mechanized felling to cause less damage than motor-manual felling (Magagnotti et al. 2012, Spinelli et al. 2014a). However, the quoted studies were conducted with larger trees, using swing-to-tree feller-bunchers, which worked from corridor and were able to accurately control tree fall, so as to avoid impact on the surrounding trees. In the present study, trees were much smaller, and the issue of their impact on residual trees was not as crucial. What is more, the feller-buncher deployed in this study was a drive-to-tree type, which would manoeuvre extensively in order to approach the trees, bumping against surrounding residual trees much more often than normal for a swing-to-tree machine (Tolosana et al. 2018, Tolosana et al. 2002).

Few studies offer accurate information about the stump damage caused by mechanized felling in coppice stands. Most of them point at the rough handling of stumps and higher damage level when compared with traditional motor-manual felling (Schweier et al. 2015, Spinelli et al. 2007), although the future relevance for the vigour and growth of the regeneration has not been found to be clear (Spinelli et al. 2017b).

5. Conclusion

The main conclusions of the present work are as follows:

Þ Productivity equations for motor-manual felling and bunching in Quercus coppices harvested for bioenergy use have been developed; the main explanatory factors in these equations are: species and the average tree weight, as recorded in the pre-harvest inventory. These equations can be useful to obtain productivity estimations for this common type of young and dense coppices, especially in Mediterranean Europe.

Þ The economic balance of the studied operations is generally negative and the operation incurs financial losses, although one may get very close to break even in the case of Q. ilex when resorting to fully mechanized operations. However, the study identified measures to reduce losses and lead to profitability. This said, harvesting this type of low-yielding coppice stands remains a low-profit operation, which may find its main motivation in the need for land management and landscape preservation, rather than in the interest for sustained profits, so this kind of thinnings may require public support in many cases.

Þ Mechanized felling and bunching has a higher cost than the motor-manual equivalent operations. Nonetheless, the mechanized bunching allows for a significant reduction of extraction cost. In Q. ilex, this leads to the fact that mechanized harvesting is less costly than motor-manual harvesting, especially when dealing with tree sizes in the higher end of the range. In Q. pyrenaica, mechanized harvesting is less expensive only when the average tree DBH is greater than 13 cm, with mechanized operations at very high costs for the smaller diameters inside the studied range.

Þ Although the silvicultural results of the treatments have been similar and adequate to the management prescriptions for all mechanization levels, damage to the residual stand and stumps is significantly more frequent for the mechanized option. This has been particularly true with Q. ilex trees, which have bulkier crowns with thicker branches. Nevertheless, severe damages – larger than 200 cm2 or affecting wood tissue – were found on less than 10% of the remaining trees in all studied cases and will not be much relevant considering the destination of harvested wood – chips for energy.

Þ The stump damages were more severe with mechanized harvesting: to date, very little scientific evidence is yet available on the effect of stump damage on stump mortality and resprouting vigour, and such little evidence points at a substantial indifference. Even so, it would be safer to extend this study to a follow-up of stump regeneration.

Þ In any case, the convenience of forest operations mechanization is undeniable, both because of the higher and sustained production capacity and the dramatic improvement of workplace safety. Nevertheless, further efforts should be devoted to a better selection of specific machine types and models and to define the optimized work system for coppice harvesting for bioenergy production, despite their difficult conditions if compared to other stand types.

Acknowledgments

The authors are indebted to the SOMACYL Natural Resources Director Rubén García Pérez and the forest engineers Alberto Fernández López y Carlos Martínez Torres, from the same public forest enterprise. We are grateful for their financial support to La Caixa, through the Fundación Patrimonio Natural de Castilla y León, and to the European COST Action FP1301 (www.eurocoppice.uni-freiburg.de) within the scope of their program of Short Term Scientific Missions (STSM).

6. References

Albizu, P.M., Tolosana, E., Roman-Jordan, E., 2013: Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. Forest Systems 22(3): 392–400. http://dx.doi.org/10.5424/fs/2013223-02714

Anderson, N., Mitchell, D., 2016: Forest Operations and Woody Biomass Logistics to Improve Efficiency, Value, and Sustainability. Bioenergy Research 9: 518–533. https://doi.org/10.1007/s12155-016-9735-1

Burgi, M., 2015: Coppicing in the past – examples of practice, context and consquences. In Coppice forests: past, present and future. International Conference. Brno, Czech Republic, 9–11 April.

Carvalho, J., Magagnotti, N., Nicolescu, V.N., Ruch, P., Spinelli, R., Tolosana, E., 2017: Active management of traditional coppice forests: An interface between silviculture and operations. In Unrau, A., Becker, G., Spinelli, R., Lazdina, D., Magagnotti, N., Nicolescu, V.N., Buckley, P., Bartlett, D., Kofman, P.D. (Eds.), Coppice Forests in Europe. Freiburg i. Br., Germany: Albert Ludwig University of Freiburg, 72–76.

Chakroun, M., Bouvet, A., Ruch, P., Montagny, X., 2016: Performance of two shear heads for harvesting biomass in hardwood stands in France. Biomass Bioenergy 91: 227–233. https://doi.org/10.1016/j.biombioe.2016.05.029

Ciancio, O., Corona, P., Lamonaca, A., Portoghesi, L., Travaglini, D., 2006: Conversion of cleaarcut beech coppices into high forests with continuous cover: A case study in central Italy. Forest Ecology and Management 224(3): 225–240. https://doi.org/10.1016/j.foreco.2005.12.045

Corona, P., Ascoli, D., Barbati, A., Bovio, G., Colangelo, G., Elia, M., Garfì, V., Iovino, F., Lafortezza, R., Leone, V., Lovreglio, R., Marchetti, M., Marchi, E., Menguzzato, G., Nocentini, S., Picchio, R., Portoghesi, L., Puletti, N., Sanesi, G., Chianucci, F., 2015: Integrated forest management to prevent wildfires under Mediterranean environments. Annals of Silvicultural Research 39(1): 1–22. https://dx.doi.org/10.12899/asr-946

Enache, A., Kühmaier, M., Visser, R., Stampfer, K., 2015: Forestry Operations in the European Mountains: A study of current practices and efficiency gaps. Scandinavian Journal of Forest Research 31(4): 1–39. https://doi.org/10.1080/02827581.2015.1130849

Erber, G., Holzleitner, F., Kastner, M., Stampfer, K., 2017: Effect of multi-tree handling and tree-size on harvester performance in small-diameter hardwood thinning. Silva Fennica 50(1): 1428. https://doi.org/10.14214/sf.1428

Fabbio, G., 2016: Coppice forests, or the changeable aspect of things, a review. Annals of Silvicultural Research 40(2): 108–132. https://dx.doi.org/10.12899/asr-1286

Ghaffariyan, M.R., Acuna, M., Brown, M., 2019: Machine productivity evaluation for harvesters and forwarders in thinning operations in Australia. Silva Balcanica 20(2): 13–25.

Kofman, P.D., 1995: User Guide. Danish Forest and Landscape Research Institute, Vejle, Denmark, 37 p.

Laina, R., Tolosana, E., Ambrosio, Y., 2013: Productivity and cost of biomass harvesting for energy production in coppice natural stands of Quercus pyrenaica Willd. in central Spain. Biomass Bioenergy 56: 221–229. https://doi.org/10.1016/j.biombioe.2013.04.016

Magagnotti, N., Schweier, J., Spinelli, R., Tsioras, P., Rossney, D., Tolosana, E., Rodrigues, A., Vanbeveren, S., 2017: Silvicultural guidelines for European coppice forests. COST Action FP1301 Reports. Freiburg, Germany: Albert Ludwig University of Freinurg, 22 p.

Magagnotti, N., Spinelli, R., Acuña, M., Bigot, M., Guerra, S., Hartsough, B., Kanzian, C., Kärhä, K., Lindroos, O., Roux, P., Talbot, B., Tolosana, E., Zormaier, F., 2012: Good Practice Guidelines for Biomass Production Studies. Magagnotti, N., Spinelli, R., Eds.; CNR – IVALSA. Florence (Italy), 50 p.

Magagnotti, N., Nati, C., Picchi, G., Spinelli, R., 2011: Mechanized thinning of walnut plantations established on ex-arable land. Agroforestry Systems 82(1): 77–86. https://doi.org/10.1007/s10457-010-9348-1

Mc Mahon, S., 1995: Accuracy of two ground survey methods for assessing site disturbance. Journal of Forest Engineering 6(2): 27–33. https://doi.org/10.1080/08435243.1995.10702669

Müllerová, J., Hédl, L., Szabó, P., 2015: Coppice abandonment and its implications for species diversity in forest vegetation. Forest Ecology and Management 343(1): 88–100. https://doi.org/10.1016/j.foreco.2015.02.003

Nicolescu, V., Pyttel, P., Barlett, D., Eds., 2015: Evolution and perspectives of coppice forests in European Countries and Soth Africa. Brasov (Romania). University of Transilvania, 57 p.

Piqué, M., Laina, R., Vericat, P., Beltrán, M., Busquets, E., Tolosana E., 2017: Spain. In Unrau, A., Becker, G., Spinelli, R., Lazdina, D., Magagnotti, N., Nicolescu, V.N., Buckley, P., Bartlett, D., Kofman, P.D., Eds., 2017: Coppice Forests in Europe. Freiburg i. Br., Germany: Albert Ludwig University of Freiburg, 331–336.

Pyttel, P.L., Fischer, U.F., Suchomel, C., Gärtner, S.M., Bauhus, J., 2013: The effect of harvesting on stump mortality and re-sprouting in aged oak coppice forests. Forest Ecology and Management 289: 18–27. https://doi.org/10.1016/j.foreco.2012.09.046

Ruiz-Peinado, R., Montero, G., del Rio, M., 2012: Biomass models to estimate carbon stocks for hardwood tree species. Forest Systems 21(1): 42–52. http://dx.doi.org/10.5424/fs/2112211-02193

Salomon, R.L., 2015: Unearthing the roots of degradation of Quercus pyrenaica coppices: an integrative perspective from clonal structure to carbon budgets. PhD Tesis, E.T.S.I. Montes (Universidad Politécnica de Madrid). Available in: https://oa.upm.es/38560/

Schelhaas, M.J., Nabuurs, G.J., Schucks, A., 2003: Natural disturbances in the European forests in the 19th and 20th centuries. Global Change Biology 9(11): 1620–1633. https://doi.org/10.1046/j.1365-2486.2003.00684.x

Schweier, J., Spinelli, R., Magagnotti, N., Becker, G., 2015: Mechanized coppice harvesting with new smallscale feller-bunchers: Results from harvesting trials with newly manufactured felling heads in Italy. Biomass and Bioenergy 72: 85–94. https://doi.org/10.1016/j.biombioe.2014.11.013

Seidl, R., Schelhaas, M.J., Rammer, W., Verkerk, P.J., 2014: Increasing forest disturbances in Europe and their impact on carbon storage. Nature Climate Change 4(9): 806–810. https://doi.org/10.1038/nclimate2318

SOMACYL, García, R.’ Personal communication from the operational responsible of biomass supply from the Company, 2021.

Spinelli, R., Magagnotti, N., Tuomasjukka, D., 2021: Rationalization of coppice management in Mediterranean Europe: the sustainability effects of changing product strategy and technology level. International Journal of Forest Engineering 32(1): 53–62. https://doi.org/10.1080/14942119.2021.1913710

Spinelli, R., Magagnotti, N., Schweier, J., 2017a: Trends and perspectives in coppice harvesting. Croatian journal of forest engineering 38(2): 219–230.

Spinelli, R., Pari, L., Aminti, G., Magagnotti, N., Giovannelli, A., 2017b: Mortality, re-sprouting vigor and physiology of coppice stumps after mechanized cutting. Annals of Forest Science 74(1): article number 5. https://doi.org/10.1007/s13595-016-0604-z

Spinelli, R., Cacot, E., Mihelić, M., Nestorovski, L., Mederski, P., Tolosana, E., 2016: Techniques and productivity of coppice harvesting operations in Europe: a meta-analysis of available data. Annals of Forest Science 73(4): 1125–1139. https://doi.org/10.1007/s13595-016-0578-x

Spinelli, R., Lombardini, C., Magagnotti, N., 2014a: The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations. Silva Fennica 48(1): article id 1003. https://doi.org/10.14214/sf.1003

Spinelli, R., Ebone, A., Gianella M., 2014b: Biomass production from traditional coppice management in northern Italy. Biomass and Bioenergy 62: 68–73. http://dx.doi.org/10.1016/j.biombioe.2014.01.014

Spinelli, R., Cuchet, E., Roux, P., 2007: A new feller-buncher for harvesting energy wood: Results from a European test programme. Biomass and Bioenergy 31(4): 205–210. https://doi.org/10.1016/j.biombioe.2006.08.002

Spinelli, R., Nati, C., Magagnotti, N., 2006: Biomass harvesting from buffer strips in Italy: Three options compared. Agroforest Syst 68(2): 113–121. https://doi.org/10.1007/s10457-006-9002-0

Tavankar, F., Majnounian, B., Bonya, A.E., 2013: Felling and skidding damage to residual trees following selection cutting in Caspian forests of Iran. Journal of Forest Science 59(5): 196–203. https://doi.org/10.17221/53/2012-JFS

Tolosana, E., Spinelli, R., Aminti, G., Laina, R., López-Vicens, I., 2018: Productivity, Efficiency and Environmental Effects of Whole-Tree Harvesting in Spanish Coppice Stands Using a Drive-to-Tree Disc Saw Feller-Buncher. Croatian journal of forest engineering 39(2): 163–172.

Tolosana, E., Laina, R., Martínez-Ferrari, R., Martín, M., Ambrosio, Y., 2017: Economic evaluation of mechanized and motormanual options for selective felling of Quercus pyrenaica coppices in Leon (NW Spain). EuroCoppice Final Conference: Coppice Forests in Europe: a traditional natural resource with great potential. Limoges, France, 19-21 June. Available online https://www.researchgate.net/publication/318228241_ Economic_evaluation_of_mechanized_and_motormanual_options_for_selective_felling_of_Quercus_pyrenaica_coppices_in_Leon_NW_Spain (accessed 14 09 2021)

Tolosana, E., Vignote, S., Ambrosio, Y., 2002: Rendimientos, costes y efectos ambientales de las claras mecanizadas sobre repoblaciones de Pinus sylvestris L. en España. In Spanish, English Summary. Sistemas y Recursos Forestales (now Forest Systems) 11(1): 39–65.

Unrau, A., 2018: Summary of Data from the 35 Country Reports. In A. Unrau, G. Becker, R. Spinelli, D. Lazdina, N. Magagnotti, V.N. Nicolescu, P. Buckley, D. Bartlett, P. D. Kofman, Eds., Coppice Forests in Europe. Freiburg i. Br., Germany: Albert Ludwig University of Freiburg, 365–368.

Väätäinen, K., Asikainen A., Sikanen, L., Ala-Fossi, A., 2006: The cost effect of machine relocation on logging costs in Finland. Forestry studies 45: 135–141.

Visser, R., Spinelli, R., 2012: Determining the shape of the productivity function for mechanized felling and felling-processing. Journal of Forest Research 17(5): 397–402. https://doi.org/10.1007/s10310-011-0313-2

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Prof. Eduardo Tolosana, PhD *

e-mail: eduardo.tolosana@upm.es

Assoc. prof. Rubén Laina, PhD

e-mail: ruben.laina@upm.es

Ignacio López-Vicens, MSc

e-mail: ignasi@boscat.cat

Universidad Politécnica de Madrid

ETSI Montes, Forestal y del medio Natural

Ingeniería y Gestión Forestal y Ambiental

José Antonio Novais 10

E28005, Madrid

SPAIN

Raffaele Spinelli, PhD

e-mail: raffaele.spinelli@ibe.cnr.it

Giovanni Aminti, PhD

e-mail: aminti@ivalsa.cnr.it

CNR

Istituto per la BioEconomia

c/o Area di Ricerca di Firenze

via Madonna del Piano, 10

50019 Sesto Fiorentino, Florence

ITALY

* Corresponding author

Received: February 14, 2021

Accepted: June 22, 2022

Original scientific paper