Pre-Feasibility Study of Carbon Sequestration Potential of Land Clearing Stumps Buried Underground

doi: 10.5552/crojfe.2023.1685

volume: 44, issue:

pp: 9

- Author(s):

-

- Laitila Juha

- Sikanen Lauri

- Väätäinen Kari

- Article category:

- Original scientific paper

- Keywords:

- carbon storage, climate change, mitigation, CO2 emissions, logistics, stump and root biomass, fuel consumption

Abstract

HTML

Stump harvesting for energy has decreased in Finland, and many heat and power plants no longer accept stumps in their fuel portfolio due to fuel quality problems. However Finland is a forested country, and land clearing stumps need to be extracted, e.g. in infrastructure construction projects. If stumps cannot be used for energy production, they are dumped in landfills, where they start to decay and release CO2 into the atmosphere. One option to avoid CO2 emissions would be the burying of stumps underground so that the decaying process of wood would be inhibited in anaerobic conditions. The aim of this study was to define the carbon sequestration potential of stump burying logistics and calculate their CO2-eq emissions to compare them with the emissions of decaying stumps in piles. The analysis was performed as a spreadsheet-based system analysis at a worksite level as a function of time and size of extracted stumps. As a result of the analysis, the emission effiency of the logistics chain based on stumps stored below the ground was good. The net carbon stock varied between 743.7 and 775.0 kg CO2-eq/m3 as a function of stump diameter, when the emissions of the stump burying logistics chain were 49.0 and 17.7 kg CO2-eq/m3 respectively. In the case of a Finnish municipality with an annual accumulation of 1000 m3 of land clearing stumps, the carbon sequestration potential of stumps buried underground is equivalent to the emissions of between 280,000 and 290,000 liters of diesel fuel consumption, depending on the diameter of the extracted stumps and the diesel fuel emission factors for different engine and diesel fuel types.

Pre-Feasibility Study of Carbon Sequestration Potential of Land Clearing Stumps Buried Underground

Juha Laitila, Lauri Sikanen, Kari Väätäinen

Abstract

Stump harvesting for energy has decreased in Finland, and many heat and power plants no longer accept stumps in their fuel portfolio due to fuel quality problems. However Finland is a forested country, and land clearing stumps need to be extracted, e.g. in infrastructure construction projects. If stumps cannot be used for energy production, they are dumped in landfills, where they start to decay and release CO2 into the atmosphere. One option to avoid CO2 emissions would be the burying of stumps underground so that the decaying process of wood would be inhibited in anaerobic conditions. The aim of this study was to define the carbon sequestration potential of stump burying logistics and calculate their CO2-eq emissions to compare them with the emissions of decaying stumps in piles. The analysis was performed as a spreadsheet-based system analysis at a worksite level as a function of time and size of extracted stumps. As a result of the analysis, the emission effiency of the logistics chain based on stumps stored below the ground was good. The net carbon stock varied between 743.7 and 775.0 kg CO2-eq/m3 as a function of stump diameter, when the emissions of the stump burying logistics chain were 49.0 and 17.7 kg CO2-eq/m3 respectively. In the case of a Finnish municipality with an annual accumulation of 1000 m3 of land clearing stumps, the carbon sequestration potential of stumps buried underground is equivalent to the emissions of between 280,000 and 290,000 liters of diesel fuel consumption, depending on the diameter of the extracted stumps and the diesel fuel emission factors for different engine and diesel fuel types.

Keywords: carbon storage, climate change, mitigation, CO2 emissions, logistics, stump and root biomass, fuel consumption

1. Introduction

Harvesting of tree stumps for energy generation has been done on a large scale for more than fifteen years in Finland in the 2000s (Hakkila 2004, Persson 2012, Laitila and Nuutinen 2015). The environmental benefit of stump harvesting is that it can contribute to the replacement of fossil fuels and thus reduce carbon dioxide (CO2) emissions (Jäppinen et al. 2015). The benefit of replacing fossil fuels with stumps increases in the long term, because the combustion of harvested stumps releases the CO2 locked in stumps through the photosynthesis process immediately, unlike slow decomposition in the forest (Sathre and Gustavsson 2011, Melin 2014, Repo 2015). However, stumps have been found to be challenging feedstock for energy mainly because of the high proportion of soil and stone particles, causing problems in comminution and combustion processes (Anerud and Jirjis 2011, Anerud 2012, Laitila and Nuutinen 2015, Laitila et al. 2019). Stump extraction also causes physical disturbance to the soil and the forest floor through the mixing and redistribution of the soil material, raising concerns about erosion, rutting, and soil compaction (Berg 2014, Helmisaari et al. 2014).

Stump harvesting for energy has decreased in Finland, and many heat and power plants no longer accept stumps in their fuel portfolio (Official Statistics of Finland 2020). Compared with roundwood, stumps have received fluctuating interest, following raw material shortages and changes in demand for certain products (Lindroos et al. 2010). During the 1970s, conifer stumps were harvested for pulp production and biorefining, but the cost was found to be excessive (Hakkila 2004). However, stumps need to be extracted in infrastructure construction projects, and when the land use of forest land or other wooded areas are changed to other purposes, e.g. farmland (Laitila et al. 2013). After trees are cut down and land clearing stumps are uprooted, they start to decay. If stumps are not used for energy production, they are often dumped in landfills or piled somewhere, after which they start to release CO2 »without giving anything in return«. One option for avoiding CO2 emissions would be the burying of stumps underground so that the wood decaying process is halted or markedly inhibited in anaerobic conditions (Kuptz et al. 2020).

This study was instigated by a Finnish municipality (Kontiolahti) with 1000 m3 of stumps accumulating annually through infrastructure development and with no option to utilize them for energy. Kontiolahti is located in a region of North Karelia (63°00′N 30°00′E), in eastern Finland, where 89% of total land area are covered by forests (Wallius et al. 2020). Currently, land clearing stumps are dumped in landfill. On the way to carbon neutrality, the municipality wanted to avoid emissions from decaying piles of stumps and decrease fire load. In an uncontrolled fire, all the carbon stored in the stump wood is released into the atmosphere in a brief moment. The burying of biomass will decrease the emissions of dumped biomass if decaying can be halted or markedly inhibited. In Finland, cutaway peatlands offer an option where the groundwater level is so close to the surface that burying below the groundwater line can be done easily. Wetlands can store wood without marked decay for hundreds or even thousands of years (Koivisto 2017).

The aim of this study was to define the carbon sequestration potential of stump burying logistics and calculate the CO2-eq emissions of burying logistics to compare them with the emissions of decaying stumps in piles. The analysis was performed as a spreadsheet-based system analysis at a worksite level as a function of time and size of the extracted stumps. Emissions from land-use and land-cover change were excluded from the analysis (Houghton et al. 2012).

2. Materials and Methods

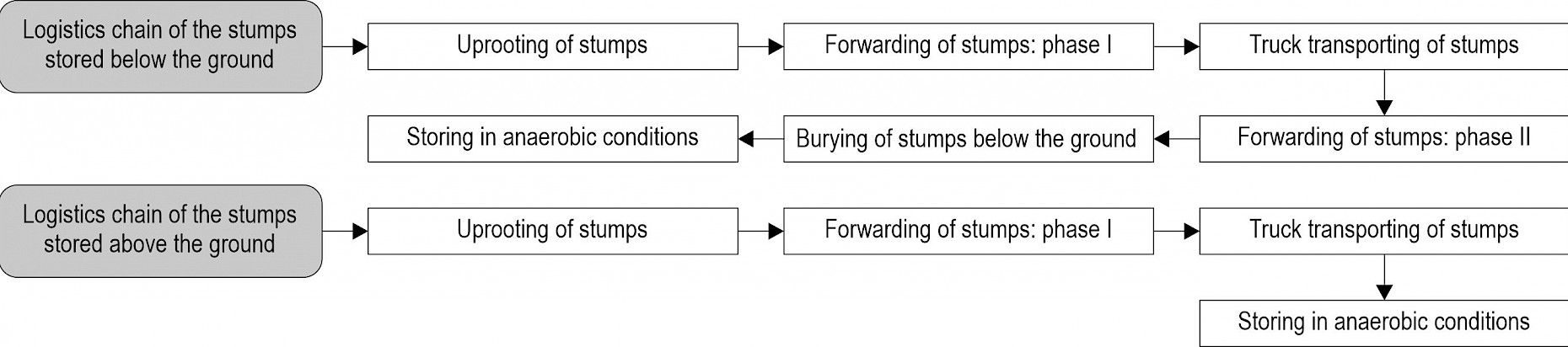

2.1 Productivity and Fuel Consumption

The production stages of this study are demonstrated in Fig. 1. The logistics system starts with stump extraction at the land clearing site and ends when the stumps have been delivered to the storing site, where they are stored either above or below the ground in aerobic or anaerobic conditions. The cubic meters presented in the calculation are solid cubic meters (m3), and the operating time consumption of machines is gross effective time (E15h), i.e. working hours include breaks of up to 15 minutes (Uusitalo 2010). The system comparison was made as a function of stump diameter in the range of 15–45 cm. The CO2-eq emissions of the work phases were calculated on the basis of the amount of diesel fuel consumed per m3, and the quantities are therefore directly proportional to each other. The harvesting volumes of Norway spruce (Picea abies) stumps were determined from stump diameters, using the stump mass model of Hakkila (1976), and the density was 500 extracted stumps per hectare at the land clearing site. The main productivity and fuel consumption parameters of production stages, based on the study Laitila et al. 2015, are described in Table 1.

Fig. 1 Flow chart for logistics chains of stumps stored below and above ground

Table 1 Productivity and fuel consumption parameters for logistics chains of stumps stored below and above ground

|

Stumps stored below the ground |

Stumps stored above the ground |

|

|

Diameter of uprooted Norway spruce stumps, cm |

15–45 |

15–45 |

|

Initial density of uprooted stumps per hectare |

500 |

500 |

|

Gross effective time (E15h) coefficient |

1.3 |

1.3 |

|

Excavator fuel consumption per operating hour, litres |

16.7 |

16.7 |

|

Fuel consumption per uprooted stump m3, liters |

2.1–13.1 |

2.1–13.1 |

|

Forwarding distance at the worksite, m |

350 |

350 |

|

Harvesting removal of stumps at the worksite, m3/ha |

5–111 |

5–111 |

|

Payload of forwarder, m3 |

8.6 |

8.6 |

|

Gross effective time (E15h) coefficient |

1.2 |

1.2 |

|

Forwarder fuel consumption per operating hour, litres |

12.0 |

12.0 |

|

Fuel consumption per forwarded stump m3, litres |

1.0–1.8 |

1.0–1.8 |

|

Truck transporting distance of stumps to storing site, km |

40 |

40 |

|

Payload of stump truck, m3 |

32 |

32 |

|

Fuel consumption of stump truck per 100 km, litres |

58.0 |

58.0 |

|

Fuel consumption of truck during loading & unloading, litres per h |

8.0 |

8.0 |

|

Fuel consumption per transported stump m3, litres |

1.9 |

1.9 |

|

Forwarding distance from the stump pile to the trench, m |

150 |

– |

|

Payload of forwarder, m3 |

8.6 |

– |

|

Gross effective time (E15h) coefficient |

1.2 |

– |

|

Forwarder fuel consumption per operating hour, litres |

12.0 |

– |

|

Fuel consumption per forwarded stump m3, litres |

0.5 |

– |

|

Stump burying capacity of excavator, m3 per operating hour |

16 |

– |

|

Excavator fuel consumption per operating hour, litres |

16.7 |

– |

|

Fuel consumption per buried stump m3, litres |

1.04 |

– |

The productivity of Norway spruce stump extraction was modeled with a crawler excavator equipped with an extraction device (Laitila et al. 2008). Forwarding productivity for stumps was obtained from a study by Laitila (2010), and the payload (Table 1) was set in line with the work of Laitila et al. (2010). At the stump extraction site, the strip road network was assumed to be 450 m per ha due to the pre-piling of stumps during stump extraction (Laitila 2010). The forwarding distance was set at 350 m from the land clearing site to the roadside landing (Phase I in Fig. 1).

From the roadside, landing stumps were transported to the storage site using a biomass truck with a payload of 32 m3 (Ranta and Rinne 2006, Kärhä et al. 2011, Palander et al. 2011). The time consumption of driving, with full and empty loads, was calculated as a function of transportation distance (40 km), according to the speed functions by Nurminen and Heinonen (2007). The loading time at the roadside landing was 62 minutes, and the unloading time at the storage site landing was 56 minutes per load (Ranta and Rinne 2006, Kärhä et al. 2011a, Palander et al. 2011).

After truck transportation, the stumps were forwarded from the storage site landing to the trench, where the system was based on stumps stored below the ground (Phase II in Fig. 1). The forwarding distance was set at 150 m (Table 1), and the work elements were included in the forwarding time consumption in loading at the pile, driving with a load, unloading at the trench, and driving with an empty load (Laitila 2010). The trench was made and filled with an excavator with an estimated stump wood burying capacity of 16 m3 per operating hour (Table 1).

2.2 Emissions of Storage and Logistics Chains

Carbon locked in stumps through photosynthesis is released back into the atmosphere as carbon dioxide when the wood biomass decays in the above ground storage. In this study, the annual CO2-eq emissions were calculated for a twenty-year period, and the annual decomposition rate of Norway spruce stumps was 4% of the dry mass (Nylinder and Thörnqvist 1981). To convert the carbon locked in one solid cubic meter of fresh stumps (gross carbon stock) with the carbon dioxide equivalent (kg CO2-eq/m3), the following equation was used:

(432/2)*3.67 = 792.7 kg CO2-eq/m3 (1)

In the equation above (cf. Karjalainen et al. 1994, Melin et al. 2010, Repo 2015), the carbon content of the stump wood was assumed to be 50% dry mass (Repo et al. 2011), the basic density (dry matter) of fresh Norway spruce (Picea abies) stumps was 432 kg/m3 (Hakkila 1975) at the time of harvest, and one kg of carbon 3.67 kg of carbon dioxide equivalent (Melin et al. 2010). At the below ground storage, stumps were kept in anaerobic conditions, and no CO2-eq emissions occurred during storing.

The CO2-eq emissions of the work phases were calculated based on the amount of diesel fuel consumed per m3. The data source of the emission factors for diesel fuel was VTT’s LIPASTO – a calculation system for traffic exhaust emissions and energy use in Finland (http://www.lipasto.vtt.fi/en/index.htm). Table 2 presents the diesel fuel emission factors (g CO2-eq/diesel fuel litre) for the crawler excavator, forwarder, and stump truck.

Table 2 Diesel fuel emission factors for different machines or vehicles

|

One diesel litre produces CO2-eq emissions in grams, g |

|

|

Crawler excavator |

2672 |

|

Forwarder |

2673 |

|

Stump truck |

2660 |

3. Results

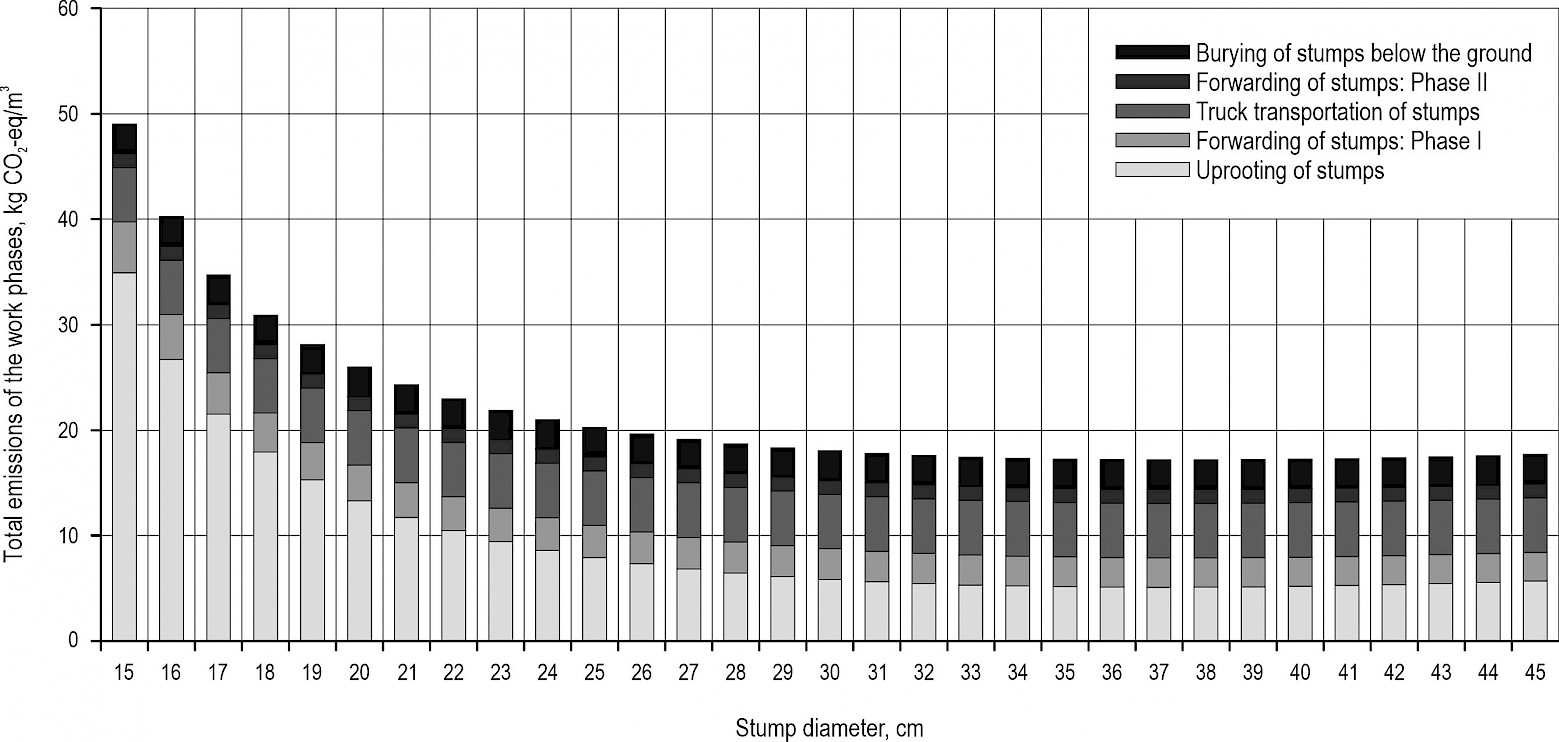

Fig. 2 illustrates the carbon emissions for the logistics chains of the stumps stored below and above the ground (kg CO2-eq/m3) by work phases as a function of stump diameter. An increase in the stump diameter increased stump extraction and forwarding productivity at the land clearing site and decreased the emissions. Stump harvesting productivity increased rapidly until the stump diameter reached 35 cm. The total carbon emissons for the logistics chain of stumps stored below the ground were between 49.0 and 17.7 kg CO2-eq/m3, when the diameter of the extracted stumps was between 15 and 45 cm. For the logistics chain of stumps stored above the ground, the total amount of emissions was between 44.9 and 13.6 kg CO2-eq/m3, when the respective emissions of additional forwarding (Phase II) and stump burying at the storage site were excluded. The truck transportation emissions of the stumps were 5.2 kg CO2-eq/m3 when the distance from the land clearing site to the storage site was 40 km (Fig. 2).

Fig. 2 Carbon emissions of logistics chains of stumps stored below and above ground (kg CO2-eq/m3) by work phases for varying values of stump diameter (15–45 cm). Note that the two last work phases are not included in the logistics chain of stumps stored above the ground

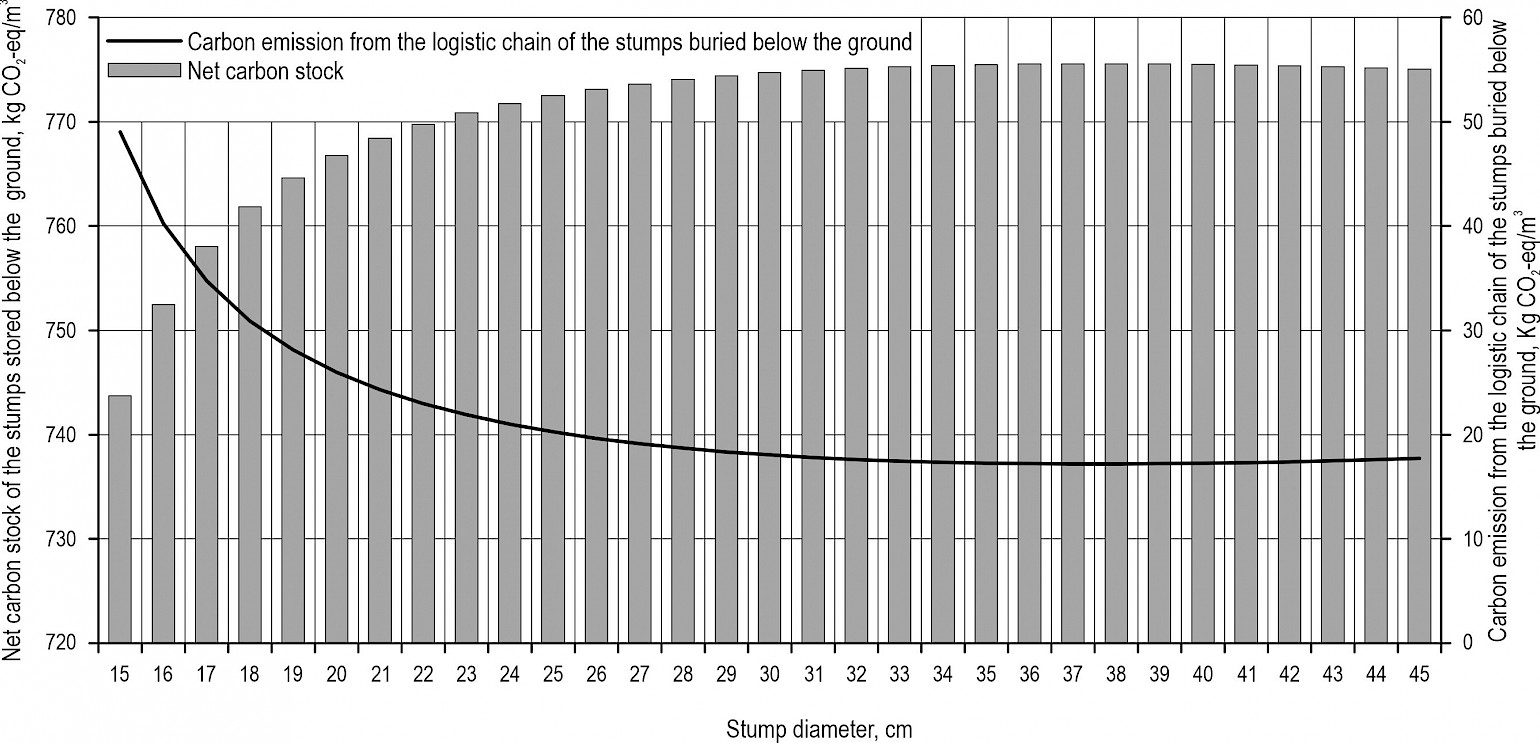

Fig. 3 Impact of logistics chain emissions on net carbon stock of stumps stored below ground (kg CO2-eq/m3) as a function of stump diameter, cm

Fig. 3 illustrates both the net carbon stock of the stumps stored below the ground (kg CO2-eq/m3) and the emissions of the logistics chain as a function of stump diameter (15–45 cm). The gross carbon stock of stumps at the time of harvest was 792.7 kg CO2-eq/m3 (Eq. 1). The net carbon stock varied between 743.7 and 775.0 kg CO2-eq/m3, and was at its lowest in small stump diameter classes due to the highest emissions of the logistics chain and especially stump extraction (Fig. 3).

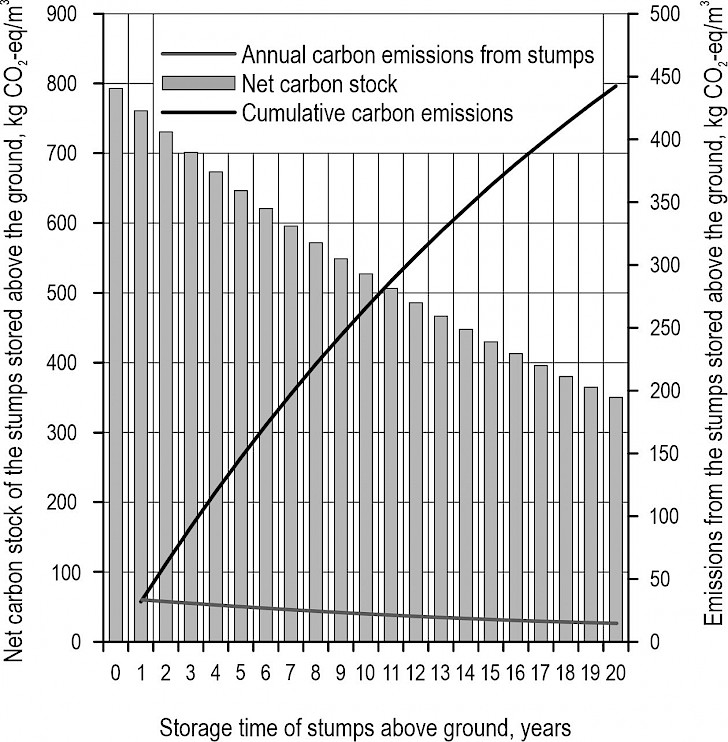

The impact of stump wood decomposition on the net carbon stock of the stumps stored above the ground and annual emissions (kg CO2-eq/m3) as a function of storage time are shown in Fig. 4. During the twenty-year storage period, the net carbon stock of the stumps stored above the ground declined from 792.7 to 350.4 kg CO2-eq/m3, and the total emissions were 442.3 kg CO2-eq/m3. The annual emissions varied between 14.6 and 31.7 kg CO2-eq/m3. The emissions decreased steadily and were at their highest during the first storage years (Fig. 4).

Fig. 4 Impact of stump wood decomposition on net carbon stock of stumps stored above ground and annual emissions (kg CO2-eq/m3) as a function of storage time

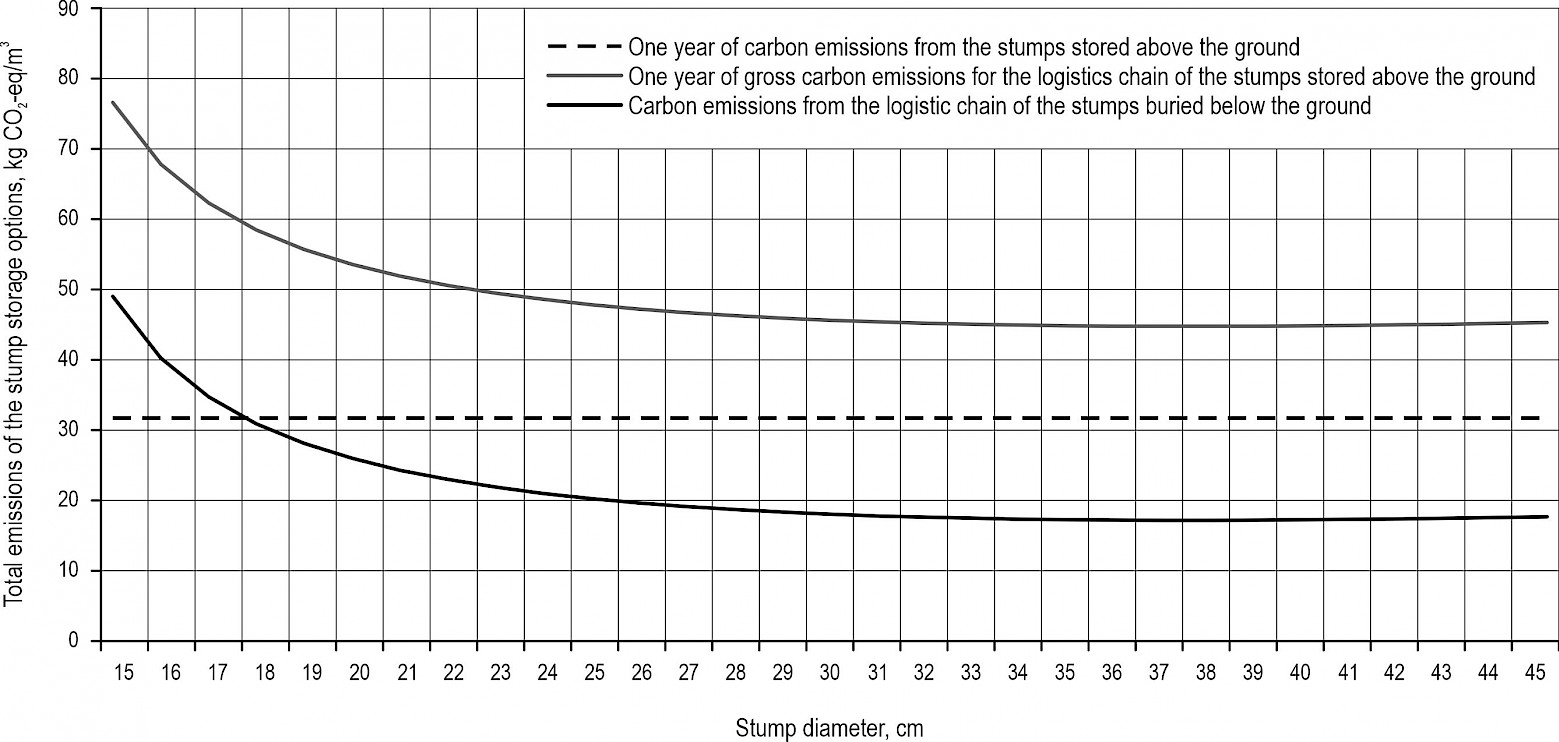

Fig. 5 The first-year total emissions from stump wood decomposition compared with emissions from logistics chain of stumps stored below and above the ground (kg CO2-eq/m3) as a function of stump diameter, cm. One year of gross carbon emissions = emissions of logistics chain & decomposition

The first-year emissions from stumps due to decomposition (kg CO2-eq/m3) were higher than the emissions of the stump burying logistics chain when the stump diameter was 18 cm or more (Fig. 5). When the gross emissions of one year of the storage of stumps above the ground were taken as a reference level (= emissions of the logistics chain & decomposition), the benefits of stump burying for anaerobic conditions were already 27.6 kg CO2-eq/m3 in the first reporting year in all stump diameter classes (Fig. 5). The first year’s gross emissions can be considered the most realistic reference level, because the stumps must in any case be transported from the land clearing site to the storage site, e.g. landfill.

4. Discussion and Conclusions

The emission effiency of the logistics chain based on stumps stored below the ground was good. The net carbon stock varied between 743.7 and 775.0 kg CO2-eq/m3 as a function of stump diameter when the emissions of the stump burying logistics chain were between 49.0 and 17.7 kg CO2-eq/m3, respectively (Fig. 3). These emission parameters for the work phases of the logistics chain were at the same level as earlier studies of the energy efficiency of stump and root wood chips procurement for fuel in Finland or Sweden (Kariniemi et al. 2009, Lindholm et al. 2010, Jäppinen et al. 2014, Ovaskainen 2017). Naturally, the parameters influencing machines’ fuel consumption and productivity are crucial. In addition, many conversion factors related to units of volume or emissions, for example, can afffect the precision of results.

In this study, in which a static spreadsheet-based system analysis was applied, the emissions from machine relocations were excluded from the analyses, because the influence was considered case-specific (size of worksite), and the effect on final results nominal. To obtain more realistic information about the real-life situation, including the locations and sizes of sites, discrete-event modeling of logistics systems in the prevailing operating environment with spatial data will be required to study the topic more comprehensively (Väätäinen 2018).

The reliability of the current results critically depends on the decomposition estimates for the stumps stored above the ground. Factors affecting the decomposition rate of stumps and CO2-eq emissions are e.g. the size of pieces in the storage above the ground, the amount of contaminants, fungal growth, climate conditions, storage location, and the chemical quality of wood, which is associated with tree species and age. Dry matter losses occur in all forest fuel systems, but are less well known in stump systems (Eriksson and Gustavsson 2008).

In this study, the annual decomposition rate of Norway spruce stumps was 4% of the dry mass (Nylinder and Thörnqvist 1981). Compared with other decomposition rates from the litreature, the annual relative Norway spruce decomposition rate recorded for logs, snags, and stumps (not uprooted) was in the range of 3.2–5.2% (Krankina and Harmon 1995, Naesset 1999, Harmon et al. 2000, Yatskov et al. 2003, Anerud and Jirjis 2011, Shorohova et al. 2008, Melin et al. 2009). Further research is needed to define the actual emissions from stumps by tree species in each supply situation and logistics scenario as a function of time. The basic density (dry matter) of Norway spruce stumps is 432 kg/m3 (Hakkila 1975). The corresponding values for the other main Finnish tree species, Scots pine (Pinus sylvestris L.) and birch (Betula spp.), are 475 kg/m3 and 490 kg/m3 (stemwood), respectively.

Anaerobic storage below the ground and water table is a secure way to protect stumps against decay agents in Finnish cutaway peatlands. When developing anaerobic storage systems for sawlogs, where timber is bundled within a double layer of polyethylene tarps, it has been found that the oxygen content must always remain below a 2% threshold to guarantee optimal conservation (Mahler et al. 1998, Riguelle et al. 2017). Today, stationary wooden structures associated with fishing sites represent the most typical wetland archaeological resource in Finland (Koivisto 2012, Koivisto et al. 2018). These wooden archaeological remains yield valuable evidence for the investigation of fishing methods, technological adaptations, and modes of subsistence among prehistoric populations (Koivisto 2017). Further evidence of the good storage properties of wetlands is provided by stump and moor wood lying below the ground in peatland forests and peatlands (Mäkelä 1973).

The carbon sequestration potential of the land clearing stumps stored below the ground was investigated in this study. In the case of a Finnish municipality with an annual accumulation of 1000 m3 of land clearing stumps, the carbon sequestration potential of stumps buried underground was equivalent to the emissions of 280,000–290,000 litres of diesel fuel consumption, depending on the diameter of the extracted stumps (Fig. 3) and the diesel fuel emission factors for different engine and diesel fuel types (Table 2).

The study utilized the results from previous studies examining stump harvesting and procurement costs (Laitila et al. 2015), energy efficiency (Jäppinen et al. 2014), climate impacts (Repo 2011), and ways to prevent energy wood dry matter losses (Laitila et al. 2017). Globally, the climate change mitigation potential of land clearing stumps stored above the ground is almost indistinguishable. Locally, however, storing below the ground improves carbon neutrality, and especially reduces the fire load and the risk of fire in landfill sites, as well as the demand for landfill sites if the stumps cannot be used as a raw material for energy production or biorefining to replace original underground reservoirs of fossil raw materials. Still more powerful actions, such as emission and deforestation cuts or reforestation, must be implemented to see real climate effects globally.

5. References

Anerud, E., Jirjis, R., 2011: Fuel quality of Norway spruce stumps – influence of harvesting technique and storage method. Scandinavian Journal of Forest Research 26(3): 257–266. https://doi.org/10.1080/02827581.2011.561807

Anerud, E., 2012: Stumps as fuel – the influence of handling method on fuel quality. Doctoral thesis. Swedish University of Agricultural Sciences, 60 p.

Berg, S., 2014: Technology and systems for ground harvesting with low ground disturbance. Doctoral thesis. Swedish University of Agricultural Sciences, 83 p.

Eriksson, L.N., Gustavsson, L., 2008: Biofuels from stumps and small roundwood—Costs and CO2 benefits. Biomass and Bioenergy 32(10): 897–902. https://doi.org/10.1016/j.biombioe.2008.01.017

Hakkila, P., 1975: Kanto- ja juuripuunkuoriprosentti, puuaineen tiheys ja asetoniuutteitten määrä [Bark percentage, basic density and amount of acetone extractives in stump and root wood]. Folia Forestalia 224: 14 p.

Hakkila, P., 1976: Kantopuu metsäteollisuuden raaka-aineena. [Stumpwood as industrial raw material]. Folia Forestalia 292: 39 p.

Hakkila, P., 2004: Developing technology for large-scale production of forest chips. Wood Energy Technology Programme 1999–2003. Technology Programme Report 6/2004. National Technology Agency, 98 p.

Harmon, M.E., Krankina, O.N., Sexton, J., 2000: Decomposition vectors: a new approach to estimating woody detritus decomposition dynamics. Canadian Journal of Forest Research 30(1): 76–84. https://doi.org/10.1139/x99-187

Helmisaari, H-S., Kaarakka, L., Olsson, B.A., 2014: Increased utilization of different tree parts for energy purposes in the Nordic countries. Scandinavian Journal of Forest Research (29)4: 312–322. https://doi.org/10.1080/02827581.2014.926097

Houghton, R.A., House, J.I., Pongratz, J., van der Werf, G.R., DeFries, R.S., Hansen, M.C., Le Quéré, C., Ramankutty, N., 2012: Carbon emissions from land use and land-cover change. Biogeosciences 9(12): 5125–5142. https://doi.org/10.5194/bg-9-5125-2012

Jäppinen, E., Korpinen, O-J., Laitila, J., Ranta, T., 2014: Greenhouse gas emissions of forest bioenergy supply and utilization in Finland. Renewable and Sustainable Energy Reviews 29: 369–382. https://doi.org/10.1016/j.rser.2013.08.101

Kärhä, K., Mutikainen, A., Hautala, A., 2011: Saalasti Murska 1224 HF käyttöpaikkamurskauksessa. [Saalasti Murska 1224 HF 5000 stationary grinder operating at the power plant]. Metsätehon tuloskalvosarja 7/2011, 61 p.

Kariniemi, A., Kärhä, K., Heikka, T., Niininen, M., 2009: Feedstock supply chain CO2-eq emissions. A case study on forest biomass for 2nd generation liquid traffic fuel. Metsätehon Katsaus 38/2009, 4 p.

Karjalainen, T., Kellomäki, S., Pussinen, A., 1994: Role of wood-based products in absorbing atmospheric carbon. Silva Fennica 28(2): 67–80. https://doi.org/10.14214/sf.a9163

Koivisto, S., 2012: Subneolithic fishery in the Iijoki river estuary, Northern Ostrobothnia, Finland. Journal of Wetland Archaeology 12(1): 22–47. https://doi.org/10.1179/jwa.2012.12.1.002

Koivisto, S., 2017: Archaeology of Finnish wetlands: With special reference to studies of stone age stationary wooden fishing structures. Doctoral dissertation. University of Helsinki, Faculty of Arts, Department of Philosophy, History, Culture and Art Studies, Archaeology, 100 p.

Koivisto, S., Latvakoski, N., Perttola, W., 2018: Out of the Peat: Preliminary geophysical prospection and evaluation of the mid-holocene stationary wooden fishing structures in Haapajärvi, Finland. Journal of Field Archaeology 43(3): 166–180. https://doi.org/10.1080/00934690.2018.1437315

Krankina, O.N., Harmon, M.E., 1995: Dynamics of the dead wood carbon pool in Northwestern Russian boreal forests. Water Air and Soil Pollution 82(1–2): 227–238. https://doi.org/10.1007/BF01182836

Kuptz, D., Lesche, S., Mendel, T., Mack, R., Rist, E., Schön, C., Hartmann, H., 2020: Fuel properties, dry matter losses and combustion behavior of wood chips stored at aerobic and anaerobic conditions. Biomass and Bioenergy 142: 105745. https://doi.org/10.1016/j.biombioe.2020.105745

Laitila, J., Ranta, T., Asikainen, A., 2008: Productivity of stump harvesting for fuel. International Journal of Forest Engineering 19(2): 37–46. https://doi.org/10.1080/14942119.2008.10702566

Laitila, J., 2010: Kantojen korjuun tuottavuus [Productivity of stump harvesting]. Working Papers of the Finnish Forest Research Institute 150, 29 p.

Laitila, J., Leinonen, A., Flyktman, M., Virkkunen, M., Asikainen, A., 2010: Metsähakkeen hankintaja toimituslogistiikan haasteet ja kehittämistarpeet. [Challenges and development needs of forest chips procurement and delivery logistics]. VTT Research Notes 2564, 143 p.

Laitila, J., Väätäinen, K., Asikainen, A., 2013: Comparison of two harvesting methods for complete tree removal on tree stands on drained peatlands. Suo – Mires and Peat 64(2–3): 77–95.

Laitila, J., Nuutinen, Y., 2015: Efficiency of integrated grinding and screening of stump wood for fuel at roadside landing with a low-speed double-shaft grinder and a star screen. Croatian Journal of Forest Engineering 36(1): 16–32.

Laitila, J., Ranta, T., Asikainen, A., Jäppinen, E., Korpinen, O.-J., 2015: The cost competitiveness of conifer stumps in the procurement of forest chips for fuel in Southern and Northern Finland. Silva Fennica 49(2): 1280. https://doi.org/10.14214/sf.1280

Laitila, J., Ahtikoski, A., Repola, J., Routa, J., 2017: Pre-feasibility study of supply systems based on artificial drying of delimbed stem forest chips. Silva Fennica 51(4): 5659. https://doi.org/10.14214/sf.5659

Laitila, J., Poikela, A., Ovaskainen, H., Väätäinen, K., 2019: Novel extracting methods for conifer stumps. International Journal of Forest Engineering 30(1): 56–65. https://doi.org/10.1080/14942119.2019.1564614

Lindholm, E.-L., Berg, S., Hansson, PA., 2010: Energy efficiency and the environmental impact of harvesting stumps and logging residues. European Journal of Forest Research 129: 1223–1235. https://doi.org/10.1007/s10342-010-0412-1

Lindroos, O., Henningsson, M., Athanassiadis, D., Nordfjell, T., 2010: Forces required to vertically uproot tree stumps. Silva Fennica 44(4): 681–694. https://doi.org/10.14214/sf.135

Mahler, G., Richter, C., Gross, M., Weber, A., Maier, T., Koenig, J., 1998: Method for stocking and preserving green roundwood and sawn timber. Germany, application number PCT/DE97/02966, patent number 0,946,340.

Melin, Y., Petersson, H., Nordfjell, T., 2009: Decomposition of stump and root systems of Norway spruce in Sweden – A modelling approach. Forest Ecology and Management 257(5): 1445–1451. https://doi.org/10.1016/j.foreco.2008.12.020

Melin, Y., Petersson, H., Egnell, G., 2010: Assessing carbon balance trade-offs between bioenergy and carbon sequestration of stumps at varying time scales and harvest intensities. Forest Ecology and Management 260(4): 536–542. https://doi.org/10.1016/j.foreco.2010.05.009

Melin, Y., 2014: Impacts of stumps and roots on carbon storage and bioenergy use in a climate change context. Doctoral thesis. Swedish University of Agricultural Sciences, 74 p.

Mäkelä, M., 1973: Kanto- ja liekopuun korjuu polttoturvesoilta [Harvesting of stump and moor wood from fuel peat bogs]. Folia Forestalia 187: 24 p.

Naesset, E., 1999: Decomposition rate constants of Picea abies logs in southeastern Norway. Canadian Journal of Forest Research 29(3): 372–381. https://doi.org/10.1139/x99-005

Nurminen, T., Heinonen, J., 2007: Characteristics and time consumption of timber trucking in Finland. Silva Fennica 41(3): 471–487. http://dx.doi.org/10.14214/sf.284

Nylinder, M., Thörnqvist, T., 1981: Lagring av stubbved I fingerad miljö [Storage of stumpwood in a simulated environment]. Institutionen för skogsproduktion, Rapport 121.

Official Statistics of Finland, 2020: Wood in energy generation 2019. Natural Resources Institute Finland (Luke). https://stat.luke.fi/en/wood-energy-generation-2019_en

Ovaskainen, H., 2017: CO2-eq emissions and energy efficiency in forest biomass supply chains –impact of terminals Metsätehon tuloskalvosarja 4b/2017, 22 p.

Palander, T., Salonen, J., Ovaskainen, H., 2011: Kanto- ja juuripuun kaukokuljetuksen kustannusrakenne. [Cost structure of stump- and root wood on-road transportation]. Metsätieteen aikakauskirja 4/2011: 294–299.

Persson, T., 2012: Tree stumps for bioenergy – harvesting techniques and environmental consequences. Scandinavian Journal of Forest Research 27(8): 705–708. https://doi.org/10.1080/02827581.2012.726520

Ranta, T., Rinne, S., 2006: The profitability of transporting uncomminuted raw materials in Finland. Biomass and Bioenergy 30(3): 231–237. https://doi.org/10.1016/j.biombioe.2005.11.012

Repo, A., Tuomi, M., Liski, J., 2011: Indirect carbon dioxide emissions from producing bioenergy from forest harvest residues. GCB Bioenergy 2011(3): 107–115. https://doi.org/10.1111/j.1757-1707.2010.01065.x

Repo, A., 2015: Climate impacts of bioenergy from forest harvest residues. Aalto University publication series doctoral dissertations 60/2015, 39 p.

Riguelle, S., Lesire, C., Hébert, J., Jourez, B., 2017: Influence of a long-term storage in anaerobic conditions on Norway spruce (Picea abies L. Karst.) physical and mechanical wood properties. Wood Material Science & Engineering 12(5): 288–294. https://doi.org/10.1080/17480272.2016.1178668

Sathre, R., Gustavsson, L., 2011: Time-dependent climate benefits of using forest residues to substitute fossil fuels. Biomass and Bioenergy 35(7): 2506–2516. https://doi.org/10.1016/j.biombioe.2011.02.027

Shorohova, E., Kapitsa, E., Vanha, M.I., 2008: Decomposition of stumps in a chronosequence after clear-felling vs. clear-felling with prescribed burning in a southern boreal forest in Finland. Forest Ecology and Management 255(10): 3606–3612. https://doi.org/10.1016/j.foreco.2008.02.042

Uusitalo, J., 2010: Introduction to forest operations and technology. Kariston Kirjapaino Oy. Hämeenlinna, 287 p.

Väätäinen, K., 2018: Developing forest chips supply chains by redesigning supply operations and logistics. Dissertationes Forestales 250, 75p.

Wallius, V., Viitanen, J., Konu, H., Mutanen, A., Heräjärvi, H., Kurttila, M., Chen, X., Hälinen, M., den Herder, M., 2020: Pohjois-Karjalan ja Kiinan välisen metsäbiotalouden nykytilanne ja kehitysmahdollisuudet [Current state of forest bioeconomy markets in the region of North Karelia in Finland and China and opportunities for development]. Luonnonvara- ja biotalouden tutkimus 23/2020. Luonnonvarakeskus, Helsinki, 55 p.

Yatskov, M., Harmon, M.E., Krankina, O.N., 2003: A chronosequence of wood decomposition in the boreal forests of Russia. Canadian journal of forest research 33(7): 1211–1226. https://doi.org/10.1139/x03-033

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Assoc. prof. Juha Laitila, PhD*

e-mail: juha.laitila@luke.fi

Assoc. prof. Lauri Sikanen, PhD

e-mail: lauri.sikanen@luke.fi

Kari Väätäinen, PhD

e-mail: kari.vaatainen@luke.fi

Natural Resources Institute Finland (Luke)

Yliopistokatu 6 B

80100 Joensuu

FINLAND

* Corresponding author

Received: April 29, 2021

Accepted: July 08, 2022

Original scientific paper