Productivity and Working Time Structure of Timber Forwarding in Flatland Thinned Pine Stand with the Use of Farm Tractors

doi: 10.5552/crojfe.2023.1656

volume: 44, issue:

pp: 11

- Author(s):

-

- Kulak Dariusz

- Szewczyk Grzegorz

- Stańczykiewicz Arkadiusz

- Article category:

- Original scientific paper

- Keywords:

- late thinning; forest trailers, forwarding; work cycle time; productivity

Abstract

HTML

Farm tractors are very popular in Poland and other European countries. When coupled with trailers equipped with a crane with a grapple, they are also used, especially in easily accessible, flat terrain, for timber forwarding in the CTL (Cut-to-Length) method. A comparative analysis of working time and productivity was performed on two forwarding units, consisting of a farm tractor Ursus and a Farma trailer with the load capacity of 6 tons, as well as a farm tractor Valtra Valmet and a Palms trailer with the capacity of 9 tons, which forwarded wood in a mature pine stand. An analysis was done for 64 work cycles with an average load volume of 2.1 m3 for the former unit, and 36 cycles with an average load volume of 7.9 m3 for the latter. The working time structure of both units was similar. During work, tractor operators spent most time, i.e. over 35%, loading the timber, then travelling with the load and unloading. The lowest share in the work cycle, around 5%, belonged to travelling without a load and forwarding. The average forwarding time for the Farma unit amounted to 33 minutes and was about twice shorter than that for the Palms unit, amounting to 64 minutes. The distance covered during loaded travel was the only factor that had a significant influence on the duration of forwarding cycles. The coefficients of correlation between these variables were 0.56–0.76. The net productivity obtained in the operating time of the Palms unit was 7.5 m3×PMH-1 and was almost twice as high as that of the Farma unit, i.e. 3.8 m3×PMH-1. For both units multiple regression models were developed, in which forwarding cycles productivity is calculated based on the volume of the transported load and the distance of loaded travel.

Productivity and Working Time Structure of Timber Forwarding in Flatland Thinned Pine Stand with the Use of Farm Tractors

Dariusz Kulak, Grzegorz Szewczyk, Arkadiusz Stańczykiewicz

Abstract

Farm tractors are very popular in Poland and other European countries. When coupled with trailers equipped with a crane with a grapple, they are also used, especially in easily accessible, flat terrain, for timber forwarding in the CTL (Cut-to-Length) method. A comparative analysis of working time and productivity was performed on two forwarding units, consisting of a farm tractor Ursus and a Farma trailer with the load capacity of 6 tons, as well as a farm tractor Valtra Valmet and a Palms trailer with the capacity of 9 tons, which forwarded wood in a mature pine stand. An analysis was done for 64 work cycles with an average load volume of 2.1 m3 for the former unit, and 36 cycles with an average load volume of 7.9 m3 for the latter. The working time structure of both units was similar. During work, tractor operators spent most time, i.e. over 35%, loading the timber, then travelling with the load and unloading. The lowest share in the work cycle, around 5%, belonged to travelling without a load and forwarding. The average forwarding time for the Farma unit amounted to 33 minutes and was about twice shorter than that for the Palms unit, amounting to 64 minutes. The distance covered during loaded travel was the only factor that had a significant influence on the duration of forwarding cycles. The coefficients of correlation between these variables were 0.56–0.76. The net productivity obtained in the operating time of the Palms unit was 7.5 m3×PMH-1 and was almost twice as high as that of the Farma unit, i.e. 3.8 m3×PMH-1. For both units multiple regression models were developed, in which forwarding cycles productivity is calculated based on the volume of the transported load and the distance of loaded travel.

Keywords: late thinning; forest trailers, forwarding; work cycle time; productivity

1. Introduction

Timber harvesting systems must be adapted to the specificity of a given country, the topography, tree species encountered, timber assortments preferred and expected by the market, as well as technological, social and economic conditions. Hence, in Europe, a wide variety of technologies and technical means are applied for timber harvesting and extraction, from very modern to traditional ones, used for many decades (Enache et al. 2016, Johansson 1996, 1997, Lindroos 2017, Spinelli et al. 2016, Stańczykiewicz et al. 2016). In many countries, especially in southern and eastern Europe, significant part of timber extraction is carried out with the use of farm tractors (Borz et al. 2015, Kulak et al. 2020, Savelli et al. 2010, Spinelli et al. 2013, Steponavičius and Zinkevičius 2010, Ünver-Okan 2020). Considering that these vehicles have not been designed to be used for timber extraction, it is important to adapt and equip them properly for this operation (Shaffer 2009). Appropriate modifications of farm tractors turn them into useful means of timber extraction, especially under easier off-road conditions (Gülci 2020, Leszczyński et al. 2021). These modifications are related to increasing the safety and comfort of operators’ work, and include the installation of steel frames protecting the cabin in the event of a rollover, a net protecting the windows against damage, or installing a swivel driver seat, which allows for comfortable work in a position that is reverse in relation to the travelling direction. They also concern the protection of the tractor itself against damage in difficult forest terrain, by such means as the installation of engine covers and wheel valves (Akay 2005, Gil 2000). Timber extraction with the use of a tractor without any additional equipment is possible by dragging the timber or by its semi-suspension on a hydraulic lift (Gülci et al. 2018). This, however, requires the vehicle to come near each log, which usually results in a significant damage to the stand (Stańczykiewicz et al. 2012, 2015). Therefore, it is common practice to aggregate farm tractors with devices that facilitate, or even enable, timber extraction. The most popular devices are rope winches, used when skidding of long timber is selected, while in the case of forwarding in the CTL system, these are forest trailers, most often equipped with a hydraulic crane with a grapple for trailer loading and unloading (Grzywiński et al. 2020, Mousavi and Naghdi 2014, Spinelli and Magagnotti 2012, Szewczyk and Iwanicki 2019). Timber extraction with the use of farm tractors has many advantages. The cost of their purchase and subsequent operation is significantly smaller than that required for purchasing specialized forestry tractors, applied in conditions in which the use of larger, professional means of extraction would be uneconomical (Akay 2005, Sowa et al. 2007). They are also valued for their manageability, maneuverability and small size (Gilanipoor et al. 2012). Due to their small size and weight, they can cause less damage to the forest environment than specialized tractors (Shaffer 2009). They also exert lower unit pressure on the ground (Kulak et al. 2015) and can be used in areas where soil protection is important (Šušnjar et al. 2008). Farm tractors are also very versatile, they can be used for numerous tasks carried out not only in forestry but also in many sectors of the economy (Gil 2000). In countries where agriculture is an important branch of the economy with a long tradition, agricultural tractors are widely available and adapting them for forestry work is a rational choice, primarily on an economic basis (Spinelli et al. 2015).

In Poland, farm tractors are the most numerous means of timber extraction (Kocel 2013). This is partly due to historical conditions: after the political transformation in Poland in the early 1990s, forestry work was privatized. Initially, numerous forestry companies were small and undercapitalized. Most often, the farm tractor was their main technical means (Więsik 2017a). Most of the area of Poland is covered by relatively well-accessible lowlands, and in such conditions, farm tractors, now equipped with winches and trailers, cope with their tasks well (Moskalik et al. 2017). Moreover, a large part of the country is dominated by small and scattered woodlands. In such stands, the use of highly-efficient, professional forest machines has no economic justification, whereas properly adapted farm tractors are a reasonable alternative (Zychowicz and Kasprzyk 2014). With the increasing popularity of the CTL system in Poland (Mederski et al. 2016), this adaptation most often consists of creating units consisting of a tractor with a self-loading forest trailer (Moskalik et al. 2017). There are many manufacturers of such trailers; moreover, trailers differ in terms of construction, dimensions, load capacity and drive (Więsik 2017a). In the first decade of the 20th century, the number of forest trailers in Poland was estimated to 1000–1500 (Kocel 2010). The increasing number of trailers used for timber forwarding in Poland and European countries over the last five years and its projected growth (Persistence Market Research 2019) are causing therefore analyses of the working time and productivity of forwarding units based on the fact that these devices are still topical and important from an economic point of view.

The aim of the study was to characterize and compare the working time structure and productivity of forwarding units consisting of a farm tractor and a forest trailer operating in coniferous stand in flat terrain. It was hypothesized that a forwarding unit with a higher payload would be characterized by greater productivity. Furthermore, it was hypothesized that the duration of forwarding cycles and their productivity are influenced by the size of the timber load and the distance of the loaded travel.

2. Materials and Methods

The research was carried out in the Włoszczowa Forest District, located in the southern part of Poland, in a 90-year-old pine stand (Pinus sylvestris L.) in which late thinning was being conducted at the time. The operation area was 12.52 ha, with the geographical coordinates of 50°47'20"N, 19°53'29"E. Other characteristics of the stand are as follows: forest site type – mixed fresh coniferous forest, one-storey structure, stand density index 1.2, intermittent stand density, stand volume of 386 m3×ha-1. The average diameter at breast height was 29 cm and the average height 24 m. The site had an elevation of 241–245 m above sea level and was quite flat. As part of the thinning, a total of 540 m3 of timber was harvested.

Timber harvesting and extraction was performed in May 2019, in rainless weather and at the temperature of 16–20°C. The study analyzed the forwarding of logs with a length of 3.0 m and a minimum at the upper end diameter of 14 cm. The stand was made accessible by means of skid trails with an approximately 30 meters spacing. The timber was stacked in irregular, small piles at the edge of the skid trails. Extraction was performed with the use of two units consisting of farm tractors with trailers equipped with a hydraulic crane (Tab. 1, Figs. 1, 2). In the following parts of this study, these units are abbreviated as Farma and Palms. On the trailer of the Farma unit, logs were stacked to form one bay, while on the trailer of the Palms unit they were stacked as two bays, because the length of the loading space exceeded 5.1 m.

Table 1 Characteristics of trailers and tractors used in the research

|

Trailer |

Farma T6 |

Palms H92 |

|

Load capacity, kg |

6000 |

9000 |

|

Weight, kg |

900 |

1500 |

|

Length, mm |

4390 |

7290 |

|

Loading space length, mm |

2825 |

5155 |

|

Width, mm |

1755 |

2090 |

|

Loading area, m2 |

1.4 |

2.0 |

|

Crane |

Farma C 3.8 |

Palms 670 |

|

Reach, mm |

3800 |

6700 |

|

Weight, kg |

350 |

1100 |

|

Grapple area, m2 |

0.12 |

0.17 |

|

Tractor |

Ursus C-360 |

Valtra Valmet 800 |

|

Engine power, kW |

38 |

60 |

|

Drive type |

4x2 |

4x4 |

|

Weight, kg |

2170 |

3329 |

|

Length, mm |

3570 |

4040 |

|

Width, mm |

1800 |

2100 |

|

Height, mm |

2230 |

2700 |

Fig. 1 Forwarding unit: Ursus C-360 tractor with Farma T6 trailer

Fig. 2 Forwarding unit: Valtra Valmet 800 tractor with Palms H92 trailer

Each forwarding unit was operated by one person. The tractors moved only along skid trails, transporting the timber to the landing located nearby the used stand next to the transport road.

During the work, continuous chronometrics were performed using an electronic stopwatch with the accuracy of 1 second. The duration of each successive observed operation and delay were recorded in the field raptor. All measurement results were entered into a spreadsheet and used for further calculations and analysis.

The forwading cycle was split into the following time elements (operations), which were timed individually:

Þ unloaded travel: included travel without a load from the landing to the loading area. Time measurement started the moment the tractors left the landing for the skid trail and ended when they stopped at the first log pile to be forwarded. The distance of the unloaded travel was measured from the point of unloading at the landing to the point of stopping at the first package in the stand

Þ loading: included lifting the logs with a grapple and placing them on a trailer. Time measurement started when the forwarding unit stopped at the first timber package to be forwarded and ended after the unit moved on to the next operations. The forwarding distance during loading was measured from the point of stopping at the first package in the stand to the point where the full load was formed

Þ loaded travel: included travel with a partially loaded unit over the felling area. Time measurement started the moment the unit moved after loading and ended when it stopped for the next loading

Þ loaded travel with full load: included travel with a full load to the landing. Time measurement started the moment the unit moved after loading and ended when it stopped. The forwarding distance of the full load was measured from the point of formation of the full load to the point of unloading at the landing

Þ unloading: included transferring logs from the trailer with the use of a grapple and stacking them in a pile. Time measurement started when the unit stopped at the landing and ended after the unit moved on to the next operations

Þ daily service: steps taken to prepare the machine for operation and to refuel

Þ breaks: included the time for meals, physiological needs and the operator’s rest.

Productivity of each forwarding cycle was calculated for productive work time (net productivity) and for work place time (gross productivity), based on the IUFRO time classification (Björheden et al. 1995). According to this classification, productive work time included main work time and complementary work time, which were used to calculate net productivity expressed as m3×PMH-1. Work place time included productive work time, supportive work time (maintenance, refuel and repairs), non-work time (rest and personal time and meal time). All measured times were used to calculate gross productivity expressed as m3×SMH-1 (Stańczykiewicz et al. 2021).

An analysis was also performed for complete forwarding cycles, understood as the time necessary to transport a single load of timber, and measured from the start of unloaded travel to the stand, through loading process, forwarding to the landing, until completion of unloading at the landing.

After the timber forwarding cycle was completed, all logs in the load were counted during unloading. In order to calculate the volume of loads, the mid-diameters over the bark were measured on 100 logs in each work shift (a total of 1100 logs). This data enabled the volume of each log to be calculated using Huber's formula as well as the average volume per log. After multiplying it by the number of logs in the load, the timber volume in each forwarding cycle was calculated. The distance of travel during loading and forwarding was determined for each load using a Trimble GPS unit with an accuracy of 1 m. It was read from the screen of the field recorder included in the kit.

Further work included the basic descriptive statistics of the sizes of single loads, loaded travel distances, loaded travel with full load distances, calculations of working times and productivity.

After checking the normality of the distributions with the Shapiro-Wilk's test, the significance of differences in the cycles productivity for the analyzed forwarding units was determined with the use of the Student’s t-test. Multiple regression analysis was applied to model the relationships between the duration of forwarding cycles and work productivity on the one hand (dependent variables), and, on the other, load volume – VOLSL and the distance of loaded travel – DISTLT (independent variables). Calculations were made for parameters of these equations, the significance of individual independent variables was assessed using the Student’s t-test, while the significance of the entire models was assessed by the Fisher test. In the case of determination of a significant influence of only one independent variable on the forwarding cycle time or on forwarding productivity, the relationship between the two variables was characterized by the Pearson correlation coefficient, the significance of which was assessed using the Student’s t-test. The parameters of the regression function were also estimated (Acuna et al. 2012, Stanisz 2007). All statistical analyses were performed using the Statistica 12 package (StatSoft Inc. 2012).

3. Results

The time study covered a total of 91 hours, 5 minutes and 44 seconds, of which 47 hours, 5 minutes and 54 seconds pertained to the Farma unit, and 43 hours, 59 minutes and 50 seconds to the Palms unit. In that period, the former unit performed 64 forwarding cycles, transporting a total of 134 m3 of timber, while the latter performed 36 cycles, transporting 284 m3 of timber. Detailed data on the forwarded loads and forwarding distances are presented in Table 2.

Table 2 Characteristics of loads and forwarding distances

|

Forwarding unit |

Unit |

Mean |

Total |

Minimum |

Maximum |

SD |

|

|

Farma |

Load volume |

m3 |

2.09 |

133.76 |

1.18 |

2.58 |

0.29 |

|

Number of logs in the load |

pcs. |

17 |

1088 |

8 |

24 |

3.96 |

|

|

Unloaded travel distance |

m |

107.49 |

3440 |

41.65 |

366.35 |

65.01 |

|

|

Loaded travel distance |

m |

461.34 |

29,526 |

251 |

595 |

90.37 |

|

|

Loaded travel distance with full load |

m |

143.47 |

4591 |

98 |

197 |

28.88 |

|

|

Palms |

Load volume |

m3 |

7.89 |

283.86 |

5.60 |

8.80 |

0.81 |

|

Number of logs in the load |

pcs. |

65 |

2354 |

38 |

84 |

12.44 |

|

|

Unloaded travel distance |

m |

100.40 |

1707 |

52.70 |

141.10 |

24.14 |

|

|

Loaded travel distance |

m |

1316.67 |

47,400 |

1004 |

1943 |

233.52 |

|

|

Loaded travel distance with full load |

m |

176.39 |

3175 |

101 |

200 |

22.99 |

The average load of timber transported by the Palms unit consisted of about 65 logs for a total volume of nearly 8 m3. The Farma unit transported loads that were nearly 4 times smaller, consisting of an average of 17 logs for a total volume of over 2 m3. The average loaded travel distance of the Palms unit, which was over 1300 meters, was nearly 3 times as long as that of the Farma unit, i.e. about 460 meters. Both units worked in the same stand, in the area where there was a landing. Hence, the differences in the distance of moving to load and loaded travel with a full load, counted from the completion of loading to the moment of reaching the landing, were not so large. With similar maximum and minimum distances, the Farma unit travelled with a load to the landing covering a distance that slightly exceeded 140 meters, while the Palms unit covered a distance that was longer by about 1/4.

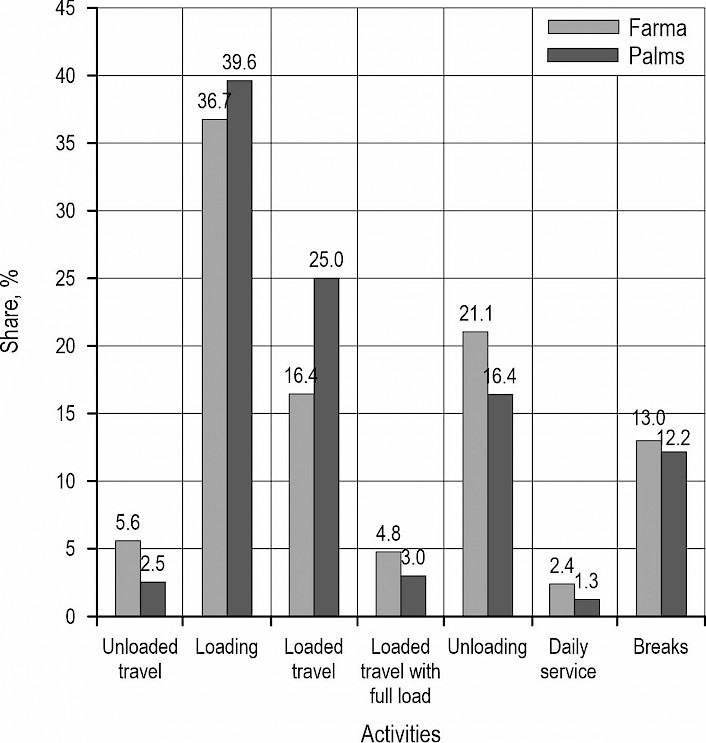

In the structure of working time of both forwarding units, the largest share, i.e. over 36%, was that of loading time (Fig. 3). The longer loaded travel for the Palms unit (by more than 52% compared to the Farma unit) was probably due to the need to collect more logs and load them onto the trailer in two bays. On the other hand, the shorter unloading time (by more than 22%) was due to a larger grapple volume (resulting from its 42% larger area) (Tab. 1). The working time structure presented in Fig. 3 suggests that longer loading and loaded travel times when using forwarding units with higher capacity can be compensated for by shorter unloading times through the use of larger grapples, appropriately matched to the capacity of the hydraulic cranes.

Fig. 3 Share of individual activities in total working time

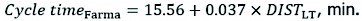

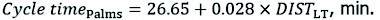

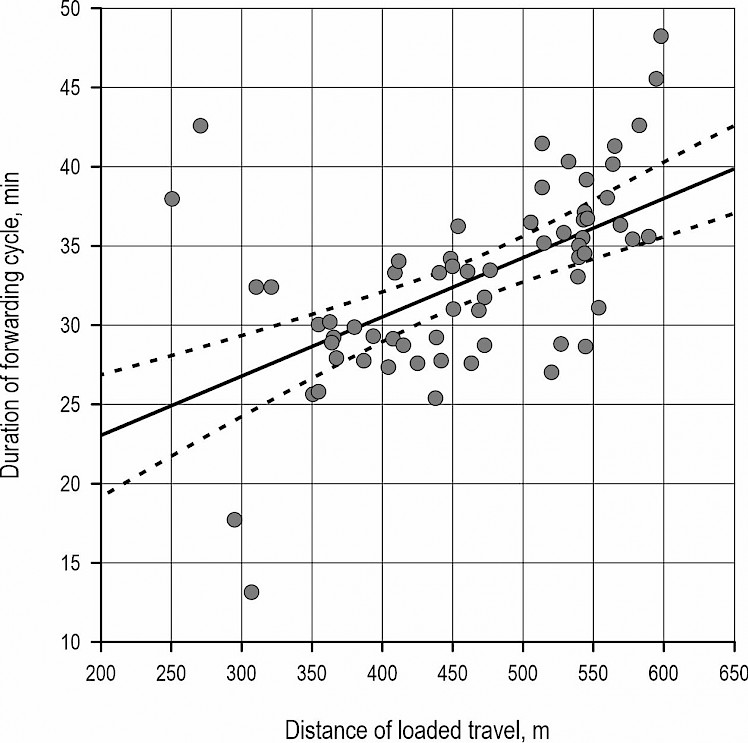

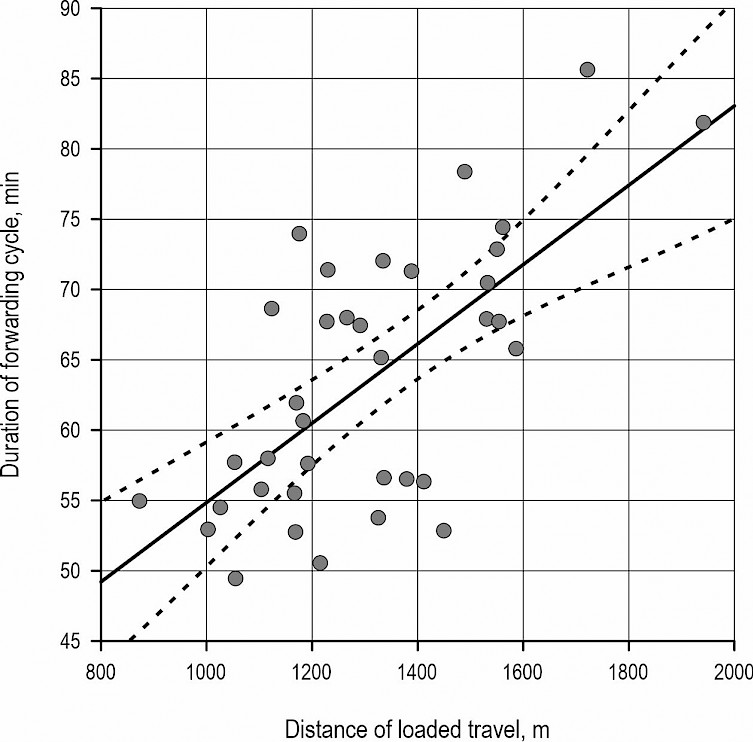

An attempt to construct a multiple regression model showing the impact of variables such as the load volume and the distance of loaded travel on the duration of forwarding cycles showed that only the last of the above characteristics has a significant influence on the duration of those cycles. An analysis of the correlation between the duration of forwarding cycles and the distance of loaded travel (Figs. 4 and 5) showed that these variables are characterized by a moderate correlation: the correlation coefficient is R=0.56 for the Farma unit and R=0.67 for the Palms unit. The Student’s t-tests (t=5.34, p=0.000; t=5.30, p=0.000) showed that it is statistically significant. The resulting regression eqs. take the following forms:

(1)

(1)

(2)

(2)

Where:

DISTLT distance of loaded travel, m

The regression function models presented are characterized by a coefficients of determination R2=0.35 and R2=0.45, respectively.

Fig. 4 Dependence of duration of forwarding cycles on distance of loaded travel (Farma unit)

Fig. 5 Dependence of duration of forwarding cycles on distance of loaded travel (Palms unit)

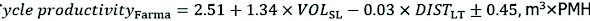

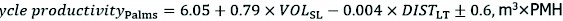

The productivity of the Palms unit obtained both in the productive work time (7.45 m3×PMH-1) and the work place time (total shift time) (6.45 m3×SMH-1) was approximately twice as high as that of the Farma unit: 3.81 m3×PMH-1 and 2.84 m3×SMH-1, respectively. The difference in productivity of both units was statistically significant (t=-15.82, p=0.000). The multiple regression models that characterized the productivity of forwarding cycles in the productive work time have the following forms:

(3)

(3)

(4)

(4)

Where:

VOLSL timber volume in a single load, m3

DISTLT distance of loaded travel, m

The characteristics of the obtained models are presented in Tables 3 and 4.

Table 3 Farma regression analysis: forwarding cycle productivity

|

Equation parameters: R = 0.63; R2 = 0.39; F = 9.32; p = 0.00 |

||||

|

Parameters of independent variables: |

||||

|

β |

Standard error |

t |

p |

|

|

Absolute term |

0.60 |

4.15 |

0.00 |

|

|

VOLSL |

0.70 |

0.32 |

4.17 |

0.00 |

|

DISTLT |

-0.51 |

0.00 |

-3.05 |

0.00 |

Table 4 Palms regression analysis: forwarding cycle productivity

|

Equation parameters: R = 0.82; R2 = 0.67; F = 15.46; p = 0.00 |

||||

|

Parameters of independent variables: |

||||

|

β |

Standard error |

t |

p |

|

|

Absolute term |

1.63 |

3.71 |

0.00 |

|

|

VOLSL |

0.58 |

0.20 |

3.79 |

0.00 |

|

DISTLT |

-0.78 |

0.00 |

-5.04 |

0.00 |

The obtained models are statistically significant. The model for the Palms unit explains nearly 70% of the variation in forwarding productivity. The model for the Farma unit, on the other hand, explains nearly 40% of the variation in forwarding productivity. The values of standardized β regression coefficients indicate that work productivity of Farma unit was most significantly affected by the timber volume in a single load, while the distance of loaded travel was statistically significant but had a smaller impact on productivity. In the case of the Palms unit, the distance of the loaded travels had a greater impact on productivity than the timber volume in a single load.

4. Discussion

The operators of the two forwarding units did not use their full load capacity. The weight of 1 m3 of pine timber in Poland is assumed to amount to an average of 750 kg (Tomczak and Jelonek 2014), and the mean weight for the Farma unit and Palms unit amounted to 1.6 tons and 5.9 tons, respectively. This means using the load capacity at the level of 26% and 66%, respectively. Obviously, full utilization of the load capacity is not possible, which is also confirmed by studies of forwarding machinery in Finland. In one such study, conducted in birch stands, where timber obtained in thinning was extracted with a Timberjack 810B forwarder with a carrying capacity of 8.5 tons, the loads constituted on average less than 60% of that weight (Laitila et al. 2007). Nearly 55% capacity utilization was described by Ghaffarian et al. (2007) in a study on extraction of various coniferous species using a Ponsse forwarder with a capacity of 14 tons. In similar research done in Poland, timber extraction units consisting of a farm tractor with a trailer equipped with a crane were characterized by load capacity utilization starting from almost 40% in mature pine stands similar to those analyzed in our study (Naskrent et al. 2019), to about 75% in alder stands (Kormanek and Fiszer 2018). In our study, smaller utilization of the load capacity of the Farma unit was due to the fact that the trailer with a total length of 4.2 m could only contain one pile of 3 metre-long logs. On the longer trailer of the Palms unit, the timber was placed in two piles. The length of the extracted timber assortments may significantly affect the work productivity achieved. That is why trailer manufacturers offer solutions that make it possible to either change the length of the trailer in order to adapt it to the length of timber assortments, or to change the width of the trailer and the height of its stanchions to allow the transport of larger loads (Więsik 2017b).

Forwarding, with its mechanized timber loading and unloading by means of a crane with a grapple, is characterized by a small number of operations performed. Four operations are typically distinguished: unloaded travel, loaded travel, preceded by loading and interrupted for travel continuation, and unloading (Gagliardi 2020, Manner et al. 2013). The operators of the two analyzed forwarding units spent most of their time on loading: it accounted for 37–39% of their working time. The observed structure of the working time of both forwarding units, with the largest share of loading time, is characteristic of forwarding. Spinelli et al. (2004) report that in a eucalyptus plantation, the forwarder was being loaded for 36% of the shift time. In another study, an analysis of the working time of Ponsse forwarders on a pine plantation showed that the loading time had the largest share in the forwarding cycle and, regardless of the forwarder model, it was slightly over 50% (Gagliardi et al. 2020). According to Proto et al. (2018b), John Deere forwarders with a capacity of 12–14 tons, used for timber forwarding in pine and fir stands, were characterized by forwarding cycles with the share of loading operations very similar to that obtained in our study: at the level of about 35%. For both the Palms and Farma units, the shares of the remaining times that make up a forwarding cycle decreased in the following order: loading, unloading, unloaded travel. The same sequence is presented in many publications. It was observed during timber extraction in pine stands with the use of the forwarder Valmet 840.2 (Maksymiak and Grieger 2008), as well as extraction with the forwarder John Deere 1110E or the MTZ 80 farm tractor coupled with a forest trailer (Pszenny et al. 2019).

Palms unit extracted loads that were 3.7 times larger, and which were picked up during loaded travel over a distance that was 2.8 times longer than in the case of Frama unit. The obtained forwarding cycle duration models explain 35–45% of the cycle time variation based on only one variable, which is precisely the distance of loaded travel. In the literature on the subject, mathematical models of the forwarding cycle duration are constructed on the basis of various variables, depending on the specifics of field research performed. The forwarding cycle duration is often related to loaded travel distance (Mousavi and Naghdi 2014), the load size being extracted (Proto et al. 2018a), and the type of cuts performed (clear cutting, thinning) (Nurminen et al. 2006). Technological factors, such as the number of assortments being extracted or their concentration (Manner et al. 2013), are also sometimes taken into account. The reason why the model of the time consumption of forwarding cycles obtained in our study is based solely on loaded travel distance is probably the fact that this feature is strongly correlated with load size and characteristic for each of the forwarding units.

With regard to the obtained models of forwarding productivity, it is constructed taking into account the size of the transported loads and the loaded travel distance. The obtained models may be useful in practice, despite the well-known relationships between productivity and timber volume in a single load and distance of loaded travel. These models characterize the productivity of the analyzed forwarding units related to their load capacity. Similar models are presented in many studies (Cadei et al. 2020, Ghaffariyan et al. 2019, Hildt et al. 2020, Stankić et al. 2012). In the case of this research, load size was basically affected by the model of the forestry trailer: differences between the load size of the Palms unit (about 8 m3) and the Farma unit (2.1 m3) are very large. This is confirmed by the fact that timber extraction with the use of larger forwarders, with higher load capacity, is more productive (Proto et al. 2018c, Spinelli et al. 2004). From a practical point of view, the results presented in the article should encourage potential buyers (forest entrepreneurs) to make decisions to invest in larger, more efficient forest trailers. The productivity of timber extraction done with the use of farm tractors with trailers shows considerable variability. For example, in a 95 year-old pine stand, forwarding with the Zetor 8045 tractor coupled with a trailer with a capacity of 12 tons was characterized by the net productivity amounting to approx. 5 m3×PMH-1 with an average forwarding distance of nearly 200 meters (Zychowicz and Kasprzyk 2014). In a deciduous stand, the Belarus 820 tractor with a trailer with a capacity of 8 tons achieved the productivity of nearly 5 m3×PMH-1 (Kormanek and Fiszer 2018). The net productivity of the analyzed forwarding units did not differ from that presented in the literature: for the Palms unit it was about 7.5 m3×PHM-1 and for the Farma unit it was close to 4 m3×PMH-1. Such productivities are even similar to the productivity of Vimek 606 miniforwarders, which ranges from 3.5–5.3 m3×PMH-1 (Mederski et al. 2018) to 7.6 m3×PMH-1 (Stempski and Pilarek 2012), depending on the species composition and stand age.

5. Conclusions

The forwarding units compared in the present study, and consisting of farm tractors coupled with self-loading trailers, operating in the same mature pine stand, differed in their load capacity. One of the units, Farma, had a load capacity of 6 tons, and the other, Palms, of 9 tons. This influenced not only the size of the transported loads and the duration of forwarding cycles, but also work productivity, which was about twice higher in the case of the unit with a higher load capacity.

Therefore, in order to shorten the forwarding time, increase its productivity and thus reduce costs, trailers with a larger payload should be used for extracting timber. The different load capacity of the two forwarding units under analysis did not, however, affect the working time structure significantly. The structure of the duration of each activity during work was similar in the case of both units, and was characterized by a dominant share of loading time, which is characteristic of forwarding. For both trailers, mathematical models were developed for the duration of the forwarding cycle, which depends on the loaded travel distance. Mathematical models were also developed for the productivity of the forwarding cycle, which also depends on the loaded travel distance but also on the timber volume in a single load. The models can be used to estimate the time and productivity of forwarding with the use of trailers coupled with farm tractors under conditions similar to those described in this study.

Acknowledgments

This research was financed from the funds of the Ministry of Education and Science for the University of Agriculture in Krakow in 2021.

6. References

Acuna, M., Bigot, M., Guerra, S., Hartsough, B., Kanzian, C., Kärhä, K., Lindroos, O., Magagnotti, N., Roux, S., Spinelli, R., Talbot, B., Tolosana, E., Zormaier, F., 2012: Good practice guidelines for biomass production studies. In: Magagnotti N., Spinelli R. (eds.). CNR IVALSA. Sesto Fiorentino, 51 p.

Akay, A.E., 2005: Using farm tractors in small-scale forest harvesting operations. Journal of Applied Sciences Research 1(2): 196–199.

Björheden, R., Apel, K., Shiba, M., Thompson, M.A., 1995: IUFRO Forest work study nomenclature. Swedish University of Agricultural Science, Dept. of Operational Efficiency, Garpenberg, 16 p.

Borz, S.A., Ignea, G., Popa, B., Spârchez, G., Iordache, E., 2015: Estimating time consumption and productivity of roundwood skidding in group shelterwood system–a case study in a broadleaved mixed stand located in reduced accessibility conditions. Croat. j. for. eng. 36(1): 137–146.

Cadei, A., Mologni, O., Röser, D., Cavalli, R., Grigolato, S., 2020: Forwarder productivity in salvage logging operations in difficult terrain. Forests 11(3): 341. https://doi.org/10.3390/f11030341

Enache, A., Kühmaier, M., Visser, R., Stampfer, K., 2016: Forestry operations in the European mountains: a study of current practices and efficiency gaps. Scandinavian Journal of Forest Research 31(4): 412–427. https://doi.org/10.1080/02827581.2015.1130849

Gagliardi, K., Ackerman, S., Ackerman, P., 2020: Multi-Product Forwarder-Based Timber Extraction: Time Consumption and Productivity Analysis of Two Forwarder Models Over Multiple Products and Extraction Distances. Croat. j. for. eng. 41(2): 1–12. https://doi.org/10.5552/crojfe.2020.736

Ghaffarian, M.R., Stampfer, K., Sessions, J., 2007: Forwarding productivity in southern Austria. Croat. j. for. eng. 28(2): 169–175.

Ghaffariyan, M.R., Acuna, M., Brown, M., 2019: Machine productivity evaluation for harvesters and forwarders in thinning operations in Australia. Silva Balcanica 20(2): 13–25. https://doi.org/10.6084/m9.figshare.9929051

Gil, W., 2000: Naziemna zrywka drewna skiderami w ujęciu kodeksu praktyk pozyskaniowych (Ground skidding of wood from point of view of the logging practice code). Sylwan 144(01): 59–74.

Gilanipoor, N., Najafi, A., Heshmat Alvaezin, S.M., 2012: Productivity and cost of farm tractor skidding. Journal of Forest Science 58(1): 21–26. https://doi.org/10.17221/4804-JFS

Grzywiński, W., Turowski, R., Naskrent, B., Jelonek, T., Tomczak, A., 2020: The Impact of Season on Productivity and Time Consumption in Timber Harvesting from Young Alder Stands in Lowland Poland. Forests 11(10): 1081. https://doi.org/10.3390/f11101081

Gülci, S., 2020: Productivity of a farm tractor with single drum winch during whole-tree timber extraction. Šumarski list 144(1–2): 35–42. https://doi.org/10.31298/sl.144.1-2.4.

Gülci, S., Büyüksakallı, H., Taş, İ., Akay, A.E., 2018: Productivity analysis of timber skidding operation with farm tractor. European Journal of Forest Engineering 4(1): 26–32. https://doi.org/10.33904/ejfe.428397

Hildt, E., Leszczuk, A., Donagh, P.M., Schlichter, T., 2020: Time Consumption Analysis of Forwarder Activities in Thinning. Croat. j. for. eng. 41(1): 13–24. https://doi.org/10.5552/crojfe.2020.615

Johansson, J., 1996: Case studies on farm tractors as base machines for single-grip thinnings harvester heads. Forestry: An International Journal of Forest Research 69(3): 229–244. https://doi.org/10.1093/forestry/69.3.229

Johansson, J., 1997: Small tree harvesting with a farm tractor and crane attached to the front. Journal of Forest Engineering 8(1): 21–33.

Kocel, J., 2010: Development of the forestry services sector in Poland. Folia Forestalia Polonica, series A, 52 (1): 44–53.

Kocel, J., 2013: Firmy leśne w Polsce (Forestry companies in Poland). CILP. DGLP. Warszawa; 332 p.

Kormanek, M., Fiszer, M., 2018: Analysis of performance of short tree logging with farm tractor and logging trailer. Agricultural Engineering 22(2): 29–38. https://doi.org/10.1515/agriceng-2018-0013

Kulak, D., Stańczykiewicz, A., Szewczyk, G., 2020: Influence of the logging season on the condition of topsoil layers. Forestry Letters 113: 1–7.

Kulak, D., Stańczykiewicz, A., Szewczyk, G., Lubera, A., Strojny, T., 2015: Czynniki wpływające na zmiany zwięzłości gleb leśnych podczas pozyskiwania surowca drzewnego (Factors affecting the changes in penetration resistance of forest soils during timber harvesting). Sylwan 159(4): 318–325.

Laitila, J., Asikainen, A., Nuutinen, Y., 2007: Forwarding of whole trees after manual and mechanized felling bunching in pre-commercial thinnings. International Journal of Forest Engineering 18(2): 29–39. https://doi.org/10.1080/14942119.2007.10702548

Leszczyński, K., Stańczykiewicz, A., Kulak, D., Szewczyk, G., Tylek, P., 2021. Estimation of productivity and costs of using a track mini-harvester with a stroke head for the first commercial thinning of a Scots pine stand. Forests 12(7): 870. https://doi.org/10.3390/f12070870

Lindroos, O., La Hera, P., Häggström, C., 2017. Drivers of advances in mechanized timber harvesting–a selective review of technological innovation. Croat. j. for. eng. 38(2): 243–258.

Maksymiak, M., Grieger, A., 2008: Analiza wydajności pracy przy maszynowym pozyskaniu drewna na przykładzie harwestera Valmet 901.3 i forwardera Valmet 840.2 (Analysis of productivity during mechanical timber acquisition on the example of Valmet 901.3 harvester and Valmet 840.2 forwarder). Inżynieria Rolnicza 12: 273–281.

Manner, J., Nordfjell, T., Lindroos, O., 2013: Effects of the number of assortments and log concentration on time consumption for forwarding. Silva Fennica 47(4): 1–19. https://doi.org/10.14214/sf.1030

Mederski, P.S., Karaszewski, Z., Rosińska, M., Bembenek, M., 2016: Dynamika zmian liczby harwesterów w Polsce oraz czynniki determinujące ich występowanie. (Dynamics of harvester fleet change in Poland and factors determining machine occurrence). Sylwan 160(10): 795–804.

Mederski, P.S., Venanzi, R., Bembenek, M., Karaszewski, Z., Rosińska, M., Pilarek, Z., Luchenti, I., Surus, M., 2018: Designing Thinning Operations in 2nd Age Class Pine Stands—Economic and Environmental Implications. Forests 9(6): 335. https://doi.org/10.3390/f9060335

Moskalik, T., Borz, S.A., Dvořák, J., Ferencik, M., Glushkov, S., Muiste, P., Lazdiņš, A., Styranivsky, O., 2017: Timber harvesting methods in Eastern European countries: A review. Croat. j. for. eng. 38(2): 231–241.

Mousavi, R., Naghdi, R., 2014: Comparison of productivity and cost of timber extraction by farm tractor. Skidding vs. forwarding in Northern Iran. HortFlora Research Spectrum 3(3): 201–210.

Naskrent, B., Polowy, K., Grzywinski, W., Sobczak, A., 2019: Zrywka drewna średniowymiarowego w drzewostanach trzebieżowych przy użyciu ciągnika rolniczego z przyczepą nasiębierną (Timber extraction in thinned stands using agricultural tractor coupled with a trailer with a hydraulic crane). Sylwan 163(2): 121–129. https://doi.org/10.26202/sylwan.2018109

Nurminen, T., Korpunen, H., Uusitalo, J., 2006: Time consumption analysis of the mechanized cut-to-length harvesting system. Silva Fennica 40(2): 335–363. https://doi.org/10.14214/sf.346

Persistence Market Research, 2019: Forestry Trailers Market, 179 p. (accessed 06.10.2021) https://www.persistencemarketresearch.com/market-research/forestry-trailers-market.asp

Proto, A.R., Macrì, G., Visser, R., Russo, D., Zimbalatti, G., 2018a: Comparison of timber extraction productivity between winch and grapple skidding: A Case study in Southern Italian Forests. Forests 9(2): 61. https://doi.org/10.3390/f9020061

Proto, A.R., Macrì, G., Visser, R., Harrill, H., Russo, D., Zimbalatti, G., 2018b: A case study on the productivity of forwarder extraction in small-scale Southern Italian forests. Small-scale forestry 17(1): 71–87. https://doi.org/10.1007/s11842-017-9376-z

Proto, A.R., Macrì, G., Visser, R., Harrill, H., Russo, D., Zimbalatti, G., 2018c: Factors affecting forwarder productivity. European Journal of Forest Research 137(2): 143–151. https://doi.org/10.1007/s10342-017-1088-6

Pszenny, D., Giedrowicz, A., Staniszewski, P., Moskalik, T., 2019: Dokładność określania struktury dnia roboczego metodą obserwacji migawkowych przy zrywce drewna (Accurancy of working day structure determining of the timber skidding by snapshot observations). Sylwan 163(04): 292–299. https://doi.org/10.26202/sylwan.2018145

Savelli, S., Cavalli, R., Baldini, S., Picchio, R., 2010: Small scale mechanization of thinning in artificial coniferous plantation. Croat. j. for. eng. 31(1): 11–21.

Shaffer, R.M., 2009: Farm tractor logging for woodlot owners. College of Natural Resources. Virginia Polytechnic Institute and State University, Blacksburg, USA, 5 p.

Sowa, J., Kulak, D., Szewczyk, G., 2007: Costs and efficiency of timber harvesting by NIAB 5–15 processor mounted on a farm tractor. Croat. j. for. eng. 28(2): 177–184.

Spinelli, R., Cacot, E., Mihelić, M., Nestorovski, L., Mederski, P., Tolosana, E., 2016: Techniques and productivity of coppice harvesting operations in Europe: a meta-analysis of available data. Annals of Forest Science 73(4): 1125–1139. https://doi.org/10.1007/s13595-016-0578-x

Spinelli, R., Magagnotti, N., 2012: Wood extraction with farm tractor and sulky: estimating productivity; cost and energy consumption. Small-Scale Forestry 11(1): 73–85. https://doi.org/10.1007/s11842-011-9169-8

Spinelli, R., Magagnotti, N., Facchinetti, D., 2013: Logging companies in the European mountain: an example from the Italian Alps. International Journal of Forest Engineering 24(2): 109–120. https://doi.org/10.1080/14942119.2013.838376

Spinelli, R., Magagnotti, N., Pari, L., De Francesco, F., 2015: A comparison of tractor-trailer units and high-speed forwarders used in Alpine forestry. Scandinavian Journal of Forest Research 30(5): 470–477. https://doi.org/10.1080/02827581.2015.1012113

Spinelli, R., Owende, P.M., Ward, S.M., Tornero, M., 2004: Comparison of short-wood forwarding systems used in Iberia. Silva Fennica 38(1): 85–94. https://doi.org/10.14214/sf.437

Stanisz, A., 2007: Przystępny kurs statystyki z zastosowaniem STATISTICA PL na przykładach z medycyny. Tom 2. Modele liniowe i nieliniowe. Kraków, StatSoft Polska, 868 p.

Stankić, I., Poršinsky, T., Tomašić, Ž., Tonković, I., Frntić, M., 2012: Productivity models for operational planning of timber forwarding in Croatia. Croat. j. for. eng. 33(1): 61–78.

Stańczykiewicz, A., Sowa, J.M., Kulak, D., Leszczyński, K., Szewczyk, G., 2012: Damage to trees and regeneration layer resulting from timber harvesting with the use of equipment aggregated with farm tractors in thinned pine stands. Acta Sci. Pol. Silv. Colendar. Rat. Ind. Lignar 11 (2): 37–51.

Stańczykiewicz, A., Sowa, J.M., Kulak, D., Leszczyński, K., Szewczyk, G., 2015: Uszkodzenia drzew i odnowienia w wyniku pozyskania drewna z użyciem urządzeń agregowanych z ciągnikami rolniczymi w trzebieżowych drzewostanach świerkowych (Damage to trees and regeneration as a result of timber harvesting with an equipment combined to the farm tractors in thinned spruce stands). Sylwan 159 (3): 201–210.

Stańczykiewicz, A., Leszczyński, K., Sowa, J.M., Kulak, D., Szewczyk, G., 2016: The efficiency of timber harvesting using HYPRO 450 processor combined with a farm tractor. From Theory to Practice: Challenges for Forest Engineering, Warszawa, Poland, 330 p.

Stańczykiewicz, A., Leszczyński, K., Kulak, D., Szewczyk, G., Kozicki, P., 2021: Effectiveness and injury risk during timber forwarding with a quad bike in early thinning. Forests 12(12): 1626. https://doi.org/10.3390/f12121626

StatSoft Inc. 2012: STATISTICA (data analysis software system). version 12.5. www.statsoft.com

Stempski, W., Pilarek, Z., 2012: Charakterystyka zrywki drewna miniforwarderem Vimek 606D (Wood extraction with a Vimek 606D miniforwarder). Technika Rolnicza Ogrodnicza i Leśna 3: 8−10.

Steponavičius, D., Zinkevičius, R., 2010: The study of the logging methods prevailed in Lithuania and other countries of Central Europe. EJPAU 13(1): #01.

Šušnjar, M., Horvat, D., Kristić, A., Pandur, Z., 2008: Morphological analysis of forest tractor assemblies. Croat. j. for. eng. 29(1): 41−51.

Szewczyk, K., Iwanicki, P., 2019: Ocena przydatności maszyn podczas zrywki drewna w drzewostanach sosnowych na podstawie podstawowych wskaźników pracy (Evaluating the suitability of machinery use during skidding of wood in pine stands. based on basic work indicators). Leśne Prace Badawcze 80(3): 219−226. https://doi.org/10.2478/frp-2019-0020

Tomczak, A., Jelonek, T., 2014: Green density of Scots pine (Pinus sylvestris L.) sapwood coming from selected stands north-western Poland. Forestry Letters 107(6): 5–9.

Ünver-Okan, S., 2020: Modelling of Work Efficiency in Cable Traction with Tractor Implementing the Least-Squares Methods and Robust Regression. Croat. j. for. eng. 41(1): 109−117. https://doi.org/10.5552/crojfe.2020.677

Więsik, J., 2017a: Jak tworzyć i efektywnie użytkować agregaty zrywkowe z przyczepą nasiębierną. Część 1. Opis procesu zrywki nasiębiernej i zasady tworzenia agregatu (Wood hauling aggregate with self-loading trailer. Principles of creation and effective use. Part 1. Description of wood forwarding process and the principles of machine aggregation). Technika Rolnicza Ogrodnicza i Leśna 4: 18−21.

Więsik, J., 2017b: Jak tworzyć i efektywnie użytkować agregaty zrywkowe z przyczepą nasiębierną. Część 3. Efekty zrywki przy pełnym wykorzystaniu ładowności przyczepy (Wood hauling aggregate with self-loading trailer. Principles of creation and effective use. Part 3. The effects of wood hauling at full utilization of trailer load capacity). Technika Rolnicza Ogrodnicza i Leśna 6: 16−18.

Zychowicz, W., Kasprzyk, K., 2014: Effectiveness of agricultural tractor utilization in the wood skidding and forwarding. Annals of Warsaw University of Life Sciences – SGGW. Agriculture 63: 113–123.

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Assoc. prof. Dariusz Kulak, PhD

e-mail: dariusz.kulak@urk.edu.pl

Assoc. prof. Grzegorz Szewczyk, PhD

e-mail: grzegorz.szewczyk@urk.edu.pl

Arkadiusz Stańczykiewicz, PhD *

e-mail: arkadiusz.stanczykiewicz@urk.edu.pl

Department of Forest Utilization, Engineering and Forest Techniques

al. 29 Listopada 46

31-425 Kraków

POLAND

* Corresponding author

Received: April 6, 2021

Accepted: April 28, 2022

Original scientific paper