Skill of Skidding Equipment Operator in Relation to Productivity, Skidding Cost and Subsidence in Peat Swamp Forest Plantation

doi: 10.5552/crojfe.2023.1724

volume: 44, issue:

pp: 14

- Author(s):

-

- Suhartana Sona

- Yuniawati

- Article category:

- Original scientific paper

- Keywords:

- cost, productivity, skidding, skill, subsidence

Abstract

HTML

Skidding in peat swamp plantation forest requires high skill and alertness, particularly in relation to peat damage, which includes subsidence as such a damage. The objective of this research is to analyze the effect of skidding operator’s skill on productivity, skidding cost and subsidence in peat swamp plantation forest. The method of this research comprised the skidding operation conducted by two different skidding operators with different working experience, followed by measuring the average productivity and skidding cost, measuring the elevation of water table at various points in the peat soil, in the location of logging compartment for 3 years, namely from 2018–2020 (measured every month), and measuring the effect of working skill of the two skidding operators on productivity and cost of skidding and the occurring subsidence rate. Research results show that the average skidding productivity of operator A was higher than that of operator B due to longer working experience of operator A, which was more than 5 years. This high average productivity caused low production cost, namely IDR 28,022 m-3 or EUR 1.653 m-3. Wood volume, skidding distance and operators’ skidding skill affect the average skidding cycle time and cycle time affects the average skidding productivity. Subsidence in 2018 was higher than that in 2019 and 2020, namely 2.8 cm year-1. Wood skidding performed by skidding operators with higher skill can increase skidding productivity and suppress skidding cost.

Skill of Skidding Equipment Operator in Relation to Productivity, Skidding Cost and Subsidence in Peat Swamp Forest Plantation

Sona Suhartana, Yuniawati

Abstract

Skidding in peat swamp plantation forest requires high skill and alertness, particularly in relation to peat damage, which includes subsidence as such a damage. The objective of this research is to analyze the effect of skidding operator’s skill on productivity, skidding cost and subsidence in peat swamp plantation forest. The method of this research comprised the skidding operation conducted by two different skidding operators with different working experience, followed by measuring the average productivity and skidding cost, measuring the elevation of water table at various points in the peat soil, in the location of logging compartment for 3 years, namely from 2018–2020 (measured every month), and measuring the effect of working skill of the two skidding operators on productivity and cost of skidding and the occurring subsidence rate. Research results show that the average skidding productivity of operator A was higher than that of operator B due to longer working experience of operator A, which was more than 5 years. This high average productivity caused low production cost, namely IDR 28,022 m-3 or EUR 1.653 m-3. Wood volume, skidding distance and operators’ skidding skill affect the average skidding cycle time and cycle time affects the average skidding productivity. Subsidence in 2018 was higher than that in 2019 and 2020, namely 2.8 cm year-1. Wood skidding performed by skidding operators with higher skill can increase skidding productivity and suppress skidding cost.

Keywords: cost, productivity, skidding, skill, subsidence

1. Introduction

The aim of wood skidding is to move logs from logging compartment to loading point. Due to the development of technology and increase in the demand for wood as industrial raw material, the activity of skidding has become mechanized. The use of mechanical skidding equipment requires consideration from the aspects of techniques, economy and ecology. From the technical aspect, it is necessary to consider field conditions and silvicultural system being used. From the ecological aspect, efforts are made to reduce environmental damage, and from the economic aspect, it is necessary to consider profit from production target, which can be achieved with operational cost of the equipment, mainly in terms of working productivity of the skidding equipment.

Peat swamp plantation forests which are situated in forest concession area of plantation forest have the potential to be used for cultivating production forest for pulp industry raw materials. One of such production forests is that of Acacia crassicarpa. Akbar et al. (2019) reported that fast growing plant species being planted in industrial plantation forest for pulp and paper were Acacia crassicarpa A. Cunn., Acacia mangium Willd. and Eucalyptus pellita F. Muell. One of the advantages of crassicarpa as substitute for mangium is its ability to grow in peat land in Indonesia. Productivity of crassicarpa is the highest as compared to local wood species, so that crassicarpa became the primary choice for pulp and paper industrial plantation forest company.

Skidding technique applied in peat swamp plantation forests differs from that applied in mineral soil forests. According to Noor et al. (2014) tropical peat soils are formed through paludification process, which is peat thickening through organic matter accumulation under waterlogged condition. The main material in tropical peat is plant biomass, particularly trees. Due to its specific material and formation process, the properties of peat soil are very different from those of mineral soil. Strong domination of organic material as its constituent results in peat soil characteristics which are different from those of mineral soil, so that management of peat soil needs extra care.

Peat swamp forests have fragile soil conditions, so that skidding activities on them require high skill of the skidding equipment operators. Work skill affects working productivity. According to Syahdan (2017), working productivity can be achieved if the working personnel is skilled enough to perform their daily job. An employee with higher work skill will of course better understand what should be done when facing an occurring problem. Besides that, such an employee will be faster in his work and will not need adaptation in doing his job because of skill sufficiency, so that the company will be more efficient in achieving its aim due to the support of skilled and experienced employees in their respective fields. Fagbenle et al. (2012), Germain et al. (2019) explained that operator experience affects production cost. One of the factors which affect employee’s productivity is related to the employee him/herself, namely the human factors which comprise among others the working experience.

Skidding technique applied in peat land differs from that in dry land. Such difference is due to peat characteristics which are soft and fragile, so that skidding technique on peat soil is different from that on other soils. Suhartana et al. (2009) explained that, in general, wood skidding in peat land plantation forest is conducted in three ways, namely:

Þ Manual system skidding (peat swamp land), using ongkak (something like a sled and rail) which is pulled by human power. A squad of skidders comprise two persons who work to load, pull and unload logs. One session of pulling can skid 0.30–0.37 m

Þ Wood skidding with semi mechanical land canoe (on water inundated peat swamp), which is an activity to collect wood from logging site and move it to riverside. This activity uses canoe / cart made from iron, which is specifically designed to skid wood in peat swamp forest, and the wood is pulled by excavator. Woods from logging activity are collected in one pile by human labour and are afterwards loaded to canoe / cart and pulled to canal side by excavator. The piles are arranged in rows at a distance of 15 m between rows to facilitate excavator movement to skid wood

Þ Wood skidding with mechanical land canoe (in water inundated peat swamp), which is an activity to collect woods from logging site and move them to river side using canoe, pulled by excavator. Loading of wood from logging site and canoe pulling are performed by excavator.

Skidding in peat swamp plantation forest has great tendency to cause environmental damage, such as subsidence. Subsidence is the process of lowering of peat soil surface due to shrinkage of peat volume, and this creates the risk of periodic flooding and water inundation, and forest fire, which afterwards tends to reduce productivity. Peat subsidence occurs due to faster peat decomposition rate resulting from land clearing, intensive drainage facility construction, plant development phase, plant population and fire. Subsidence rate will be faster in the first year of land clearing than in later years, and will be stable in the 8th–10th year (Hooijer et al. 2012). Hoyt et al. (2020) reported that the average rate of peat subsidence in Southeast Asia is reported to be around 2.2 cm per year. Maswar and Fahmuddin (2016) mentioned that there were numerous negative effects of subsidence on plant productivity, when connoted to the loss of peat soil. The first impact of subsistence is the loss of specific characteristics of peat that could hold and store water; losing this characteristic would render the plants unable to receive sufficient amount of water. Secondly, at the soil that became solidified (plugged) or even compacted, its organic matters already changed to irreversible dryness, thereby unable to hold anions and cations which were urgently required by plants as their nutrients and for their physiological activities. This situation caused the nutrient adsorption capability to decrease. Finally, at the peat soil that became solidified, plant or vegetation growth even with simple rooting system would be difficult to develop (grow). Meanwhile, Andriani et al. (2018) stated that land subsidence could cause technical and non-technical impacts, causing economic and social losses. People can feel the impact of land subsidence directly and indirectly. In general, technical and environmental impacts are impacts that are felt directly by the community, such as damage to buildings/infrastructure, tidal flooding and sea water intrusion. The economic and social impacts are not directly felt.

Several results of research on skidding of wood in mineral soil forests are as follows:

Þ Proto et al. (2017) state that the average skidding productivity at site A was 30.4 m3 productive machine hour (PMH)-1 and 24.8 m3 SMH-1. At site B, the grapple skidder had an average hourly productivity of 35.1 m3 effective hour-1 and 28.1 m3 gross effective hour-1. There was no significant difference (p-values: 0.94) in the productivity of skidding of the two methods of extraction (cable winch versus grapple) because of the confounding road effect. Winching time at site A was directly related to winching distance. At both sites, productivity has an inverse relationship with skidding distance and a direct relationship with the volume skidded

Þ Gulci et al. (2018) state that the average productivity for two slope classes were 5.72 m3 hr-1 and 4.30 m3 hr-1, respectively. The results indicated that the productivity increased as the volume of skidded logs per turn increased for both slope classes. On the other hand, increasing number of pieces transported in each turn caused reduction in productivity of the tractor skidding operation. The most time consuming work stage was skidding followed by move-out unloaded and choker setting stages

Þ Borz et al. (2015) state that the net production rates for on road skidding of only 5.89 m3 h-1, as well as the net production rate of only 4.71 m3 h-1 for winching and skidding (excluding landing operations) were strongly affected by the increased skidding distances

Þ Jernigan et al. (2016) state that average productivity for the skidder resulted in 112.25 gt PMH-1. The high productivity can be attributed to multiple factors in the study. First, the modified skidder has an oversized grapple, which gives it the ability to grapple larger payloads. As the skidder can acquire more tonnage with each skid without increasing cycle time, the productivity is increased. Also, the tract offered many short skids, which minimize cycle time

Þ Bodaghi et al. (2018) state that the Hyrcanian forest, using extraction by a skidder, and the Camaldoli forest, using extraction by tractors. The system productivity of salvage logging by skidders and tractors was calculated as 1.54 and 0.81 m3 h-1, respectively. In contrast to common logging, system productivity was about 6- to 15-fold lower in salvage logging.

On the basis of such background, the objective of this research is to analyse the effect of skill of skidding equipment operators on productivity, skidding cost and subsidence in peat swamp plantation forest.

2. Materials and Methods

2.1 Research Sites

Research was conducted on February 2021 in the working area of plantation forest concession of PT Satria Perkasa Agung, Logging Block of Annual Working Plan 2021, Logging Compartment No. SKNB041701 and SKNB210B01. This area belongs to the territory of Indragiri Hilir District, Riau Province. Based on the geographic position, this forest complex is situated between 102°39’10”–102°58’50” E and 0°4’10” S–0°12’55” N.

2.2 Research Materials and Equipment

The main equipment used was chainsaw Stihl MS 386 for logging, and excavator of Hitachi brand, type ZX 110MF, with engine power of 84 HP for skidding. Materials used were a stand of Acacia crassicarpa from family Leguminosae, diesel fuel, lubricants, and tally sheet.

2.3 Research Procedure

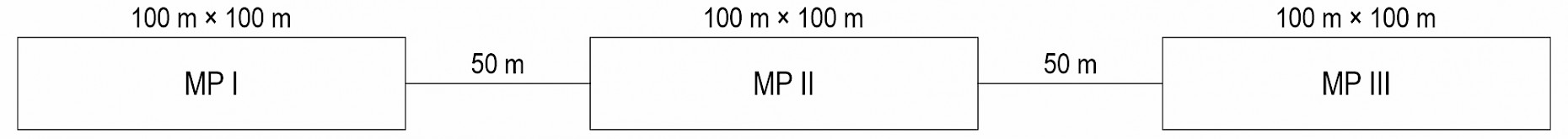

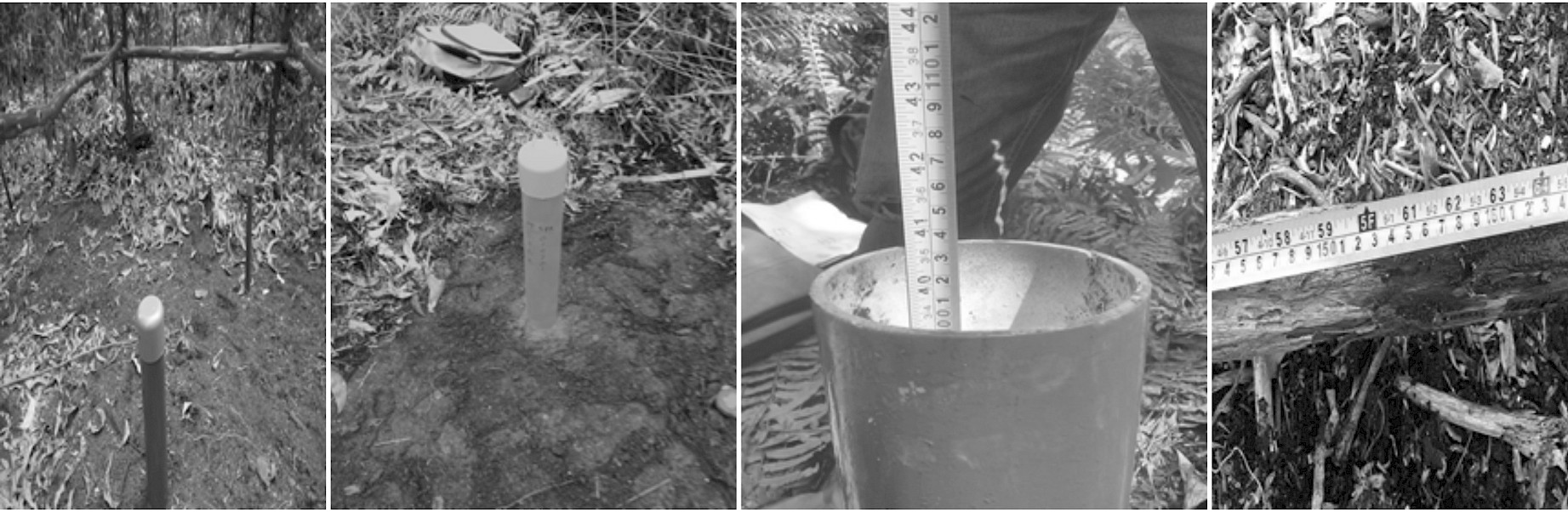

Two logging compartments were purposively determined. In each logging compartment there were 3 measurement plots (MP), 100×100 m (=1 ha) each. The distance between MPs was 50 m, therefore there were 6 MP alltogether. Logging Compartment I (Operator A): MP A1, MP A2, MP A3. Logging Compartment II (Operator B): MP B1, MP B2, MP B3. In each MP, 15 skidding operations were carried out, making a total of 90 trips. The following parameters were measured: productivity and skidding production cost, comprising the following items: Productivity, which measures working time and wood volume. Production cost (FAO 1992): recording all expenditures such as the use of fuels, lubricants, wage, wage/salary, depreciation cost, maintenance/repair cost, financial interest rate, insurance and tax. Subsidence measurements were conducted as follows (Mudiyarso et al. 2004): In the MP, soil depths were measured with measuring sticks made from light material, decay resistant and easily obtained. Measurement sticks were buried / inserted into the soil until 0 mark was precisely at the soil surface. Measurements of decrease of soil surface were conducted by putting the measurement sticks at 2 observation points purposively, and the measurements were conducted each month. Measurements of subsidence are presented in Fig. 1 and 2.

Fig. 1 Placement plot measuring

Fig. 2 Measurements of subsidence

2.4 Data Analysis

Field data in the form of productivity and skidding cost were processed in tabulation. Analysis tool used was the average value. Skidding production cost was calculated by using the formula from FAO (1992).

Skidding productivity is obtained by recording working time and wood volume, which were afterwards processed with the following formula:

(1)

(1)

Where:

PMH productivity machine hour, m3 hour-1

t total time of skidding, hour

V volume of wood skidded, m3

Volume of wood obtained from the following formula:

(2)

(2)

Where:

V wood volume, m3

p length, m

w width, m

h height, m

0.59conversion factor from staple meter (sm) to m3.

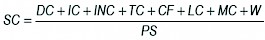

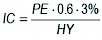

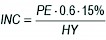

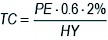

Production cost is obtained by recording all expenditures such as the use of fuel, lubricants, wages, depreciation cost, maintenance / repair cost, interest rate, insurance and tax, which are afterwards calculated using formula from (FAO 1992) as follows:

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

Where:

SC skidding production cost, IDR/m3

LC lubricant cost, IDR hour-1

PE price of equipment, IDR

DC depreciation cost, IDR hour-1

PS skidding productivity, m3 hour-1

IC insurance cost, IDR hour-1

W wage of worker, IDR hour-1

INC interest cost, IDR hour-1

TC tax cost, IDR hour-1

CF cost of fuel, IDR hour-1

MC maintenance cost, IDR hour-1

FP fuel price, IDR liter-1

LSE life span of equipment, hour

HY hours of equipment work, duration per year, hour

CF cost of fuel

CS capacity size.

For learning the difference in skill of the 2 operators of the skidding equipment, and the subsidence, t test is used. For learning the effect of wood volume, skidding distance and operators’ skill skidding on cycle time skidding, and the effect of productivity on skidding cost, multiple and linear regression variable dummy are used, using SPSS 25. Equation model for the regression is

(Janie 2012) (11)

(Janie 2012) (11)

Where:

Y dependent variable

a intercept

b1, 2, nparameters

X1, 2, nindependent variables.

Statement of hypothesis is:

Þ Ha: Wood volume, skidding distance and operators’ skill skidding affect significantly the cycle time skidding

Þ H0: Wood volume, skidding distance and operators’ skill skidding do not significantly the cycle time skidding

Þ Ha: Skidding productivity affects significantly the production cost

Þ H0: Skidding productivity does not significantly affect the production cost

Decision making criteria:

Þ If 0.05 probability value < sig probability value, H0 is accepted, which implies non significance

Þ If 0.05 probability value > sig probability value, H0 is rejected, which implies significance.

3. Results

3.1 General Condition of the Company

Most of the research area have field slope between 0–8% with elevation betweeen 2.0–9.5 m asl. Soil types are peat of Hemic Organosol and Sapric Organosol. Based ond Schmidt & Fergusson criteria, the climate is Type A with monthly rainfall of 147.5 mm month-1, highest rainfall of 252.24 mm month-1 and lowest rainfall of 62.36 mm month-1 and no dry month. Forest stand in this area was dominated by tree species Acacia crassicarpa from the family Leguminosae. Density was 1666 trees /ha (for trees with diameter of 10 cm or more). Most of the trees did not exhibit buttess. Most of the undergrowth vegetation were of medium density. In the current Annual Working Plan, the company harvested wood from area as large as 2309.6 ha, with production target of 371,082.2 m3 and average annual wood production (average of production realization in the past 5 years) of 876,413.0 m3, with maximum AAC of 1,452,542.77 m3, comprising wood species of Acacia crassicarpa (source: Monthly report of Annual Working Plan 2016–2020 PT. SPA Distrik Simpang Kanan).

3.2 Productivity and Cost of Skidding

Average productivity and skidding cost of 2 operators of skidding equipment of forest concession PT Satria Perkasa Agung are presented in Table 1.

Table 1 Average productivity and skidding cost of 2 operators of skidding equipment

|

Operator & Measurement Plot |

Wood volume m3 |

Skidding time hours |

Skidding productivity m3 hour-1 |

Skidding cost IDR m-3 |

Skidding distance m |

|

A |

|||||

|

MP 1 |

17.875 |

1023 |

17.501 |

27,509 |

78.667 |

|

MP 2 |

17.936 |

1070 |

17.011 |

28,585 |

77.333 |

|

MP 3 |

17.337 |

1011 |

17.437 |

27,972 |

78.000 |

|

Average |

17.716 |

1.035 |

17.316 |

28,022 |

78.000 |

|

B |

|||||

|

MP 1 |

17.852 |

1179 |

15.175 |

31,734 |

77.333 |

|

MP 2 |

17.703 |

1086 |

16.334 |

29,502 |

74.667 |

|

MP 3 |

17.873 |

1080 |

16.424 |

29,288 |

80.000 |

|

Average |

17.809 |

1115 |

15.977 |

30,175 |

77.333 |

Analysis results of the effect of wood volume, operators’ skill and skidding distance on skidding cycle time are presented in Table 2, 3 and 4.

Table 2 Model Summary of relation between wood volume, operators’ skill and skidding distance

|

Model |

R |

Determination coefficient, R2 |

Adjusted R square |

Standard error of the estimate |

|

1 |

0.510a |

0.261 |

0.230 |

8.5254 |

|

a – Predictors: (Constant) operators, wood volume, distance b – Dependent Variable: skidding cycle time |

||||

Table 3 Analysis of variance of relation between wood volume, operators’ skill, skidding distance and skidding cycle time

Table 3 shows that sig probability value (0.000) is smaller than error level (0.000 < 0.05), so that it can be concluded that the proposed equation model Y = a + b₁X₁ + b₂X₂, can be accepted.

Table 4 Results of coefficient test

|

Model |

Unstandardized coefficients |

Standardized coefficients |

t calculated |

Probability |

||

|

B |

Std. Error |

Beta |

||||

|

1 |

Constant |

21.702 |

3.120 |

– |

12.340 |

0.000 |

|

Wood volume |

0.181 |

0.069 |

0.138 |

1.118 |

0.003 |

|

|

Distance |

0.192 |

0.061 |

0.032 |

2.205 |

0.000 |

|

|

Operators |

6.175 |

1.434 |

0.437 |

4.874 |

0.000 |

|

|

a – Dependent Variable: skidding cycle time |

||||||

Equipment used for skidding with mechanical system land canoe are presented in Fig. 3.

Fig. 3 Excavator Hitachi ZX110MF

For learning the average cost of skidding with mechanical system land canoe, cost analysis was conducted for the equipment used for wood skidding, namely excavator Hitachi ZX110MF with motor power of 84 HP. Price of the equipment in the year 2019 was IDR 1,100,000,000. Life span of the equipment use is 10 years, working duration of the equipment use is 1000 hours year-1, with working duration of 8 hours day-1, consumption of diesel fuel is 25 liters per hour with price of IDR 10,000 liter-1, oil consumption is 0.1 liter hour-1, and wage of operator + assistant is IDR 400,000 day-1. From these data, the cost of equipment use per hour was obtained and it is presented in Table 5.

Table 5 Machine cost or Scheduled Machine Hours (SMH) of Excavator Hitachi ZX110MF in Riau

|

Cost components |

Amount |

|

|

IDR, hour-1 |

EUR, hour-1 |

|

|

Depreciation cost |

99,000 |

5.841 |

|

Insurance cost |

19,800 |

1.168 |

|

Financial interest cost |

99,000 |

5.841 |

|

Tax cost |

13,200 |

0.779 |

|

Fuel cost |

90,720 |

5.353 |

|

Lubricant cost |

9072 |

0.535 |

|

Maintenance/repair cost |

99,000 |

5.841 |

|

Wage cost |

50,000 |

2.950 |

|

Total cost of machine, SMH |

479,792 |

28.308 |

|

Noted: 1 EUR = IDR 16,821.55 |

||

Average cost of wood skidding in peat swamp plantation forest is presented in Table 6.

Table 6 Average cost of wood skidding in forest concession PT SPA

|

Operator & measurement plot |

Skidding productivity |

Machine cost |

Skidding cost |

|

|

(m3 hour-1) |

(SMH) (x IDR 1000 hour-1) |

(x IDR 1000 m-3) |

EUR (m-3) |

|

|

A |

||||

|

MP 1 |

17.501 |

479.792 |

27.509 |

1.623 |

|

MP 2 |

17.011 |

479.792 |

28.585 |

1.687 |

|

MP 3 |

17.437 |

479.792 |

27.972 |

1.650 |

|

Average |

17.316 |

479.792 |

28.022 |

1.653 |

|

B |

||||

|

MP 1 |

15.175 |

479.792 |

31.734 |

1.872 |

|

MP 2 |

16.334 |

479.792 |

29.502 |

1.741 |

|

MP 3 |

16.424 |

479.792 |

29.288 |

1.728 |

|

Average |

15.977 |

479.792 |

30.175 |

1.780 |

3.3 Subsidence Due to Skidding

Soil-surface subsidence due timber harvesting causes the decrease of peat capability to hold or withstand the water. When the peat dome undergoes the shrinkage of as much as 1 meter, then the peat-soil will lose its capability to hold water up to 90 cm, which is equivalent to 9000 m3 ha-1. It means that the area of 1 hectare and its surrounding will receive more than 9000 m3 of water, if there is a heavy rain. Conversely, due to a lower amount of water reserve stored during rainy season, the water reserve that could be received by the surrounding areas is lesser and such areas is becoming more vulnerable to the drought during dry season (Agus and Subiksa 2008). Average subsidence occurring for three years in this research area is presented in Table 7.

Table 7 Average subsidence for three years (2018–2020) in the research area

|

Year & observation points |

Height of peat surface at last period, cm |

Height of peat surface at present, cm |

Subsidence, cm |

|

2018 |

|||

|

1 |

55.9 |

56.1 |

–0.2 |

|

2 |

55.6 |

55.6 |

–0.1 |

|

3 |

56.8 |

56.9 |

–0.1 |

|

4 |

56.8 |

56.8 |

0.0 |

|

5 |

54.5 |

54.6 |

–0.1 |

|

6 |

53.2 |

53.4 |

–0.1 |

|

7 |

56.5 |

56.3 |

0.1 |

|

8 |

53.5 |

53.4 |

0.1 |

|

9 |

54.9 |

55.0 |

0.0 |

|

10 |

54.4 |

54.5 |

–0.1 |

|

Total |

552.1 |

552.6 |

–0.5 |

|

Average |

55.21 |

55.26 |

–0.05 |

|

2019 |

|||

|

1 |

56.1 |

56.4 |

0.2 |

|

2 |

58.4 |

58.8 |

0.4 |

|

3 |

56.7 |

56.9 |

0.2 |

|

4 |

57.9 |

58.1 |

0.2 |

|

5 |

58.0 |

58.5 |

0.4 |

|

6 |

56.7 |

57.0 |

0.3 |

|

7 |

55.1 |

55.4 |

0.4 |

|

8 |

57.1 |

57.4 |

0.3 |

|

9 |

54.6 |

54.9 |

0.3 |

|

10 |

56.3 |

56.4 |

0.1 |

|

Total |

566.9 |

569.8 |

2.8 |

|

Average |

56.9 |

56.98 |

0.28 |

|

2020 |

|||

|

1 |

62.4 |

62.6 |

0.2 |

|

2 |

59.2 |

59.4 |

0.2 |

|

3 |

60.3 |

60.5 |

0.2 |

|

4 |

63.1 |

63.2 |

0.2 |

|

5 |

59.8 |

60.0 |

0.2 |

|

6 |

60.2 |

60.5 |

0.2 |

|

7 |

60.9 |

61.2 |

0.3 |

|

8 |

58.4 |

58.7 |

0.3 |

|

9 |

59.3 |

59.6 |

0.3 |

|

10 |

58.5 |

58.6 |

0.1 |

|

Total |

602.1 |

604.3 |

2.2 |

|

Average |

60.21 |

60.43 |

0.22 |

Analysis results of the effect of operators’ skill on subsidence are presented in Table 8, 9 and 10.

Table 8 Model Summary of relation between operators’ skill and subsidence

|

Model |

R |

Determination coefficient, R2 |

Adjusted R square |

Standard error of the estimate |

|

1 |

0.827a |

0.607 |

0.675 |

18.319 |

|

a – Predictors: (Constant) operators, wood volume, distance b – Dependent Variable: skidding cycle time |

||||

Table 9 Analysis of variance of relation between operators’ skill and subsidence

Table 9 shows that sig probability value (0.000) is smaller than error level (0.000 < 0.05), so that it can be concluded that the proposed equation model Y = a + b₁X₁, can be accepted.

Table 10 Results of coefficient test

|

Model |

Unstandardized Coefficients |

Standardized Coefficients |

t calculated |

Probability |

||

|

B |

Std. Error |

Beta |

||||

|

1 |

Constant |

62.684 |

22.456 |

– |

6.009 |

0.000 |

|

Operator |

3.053 |

0.669 |

0.627 |

4.527 |

0.000 |

|

|

a – Dependent Variable: Subsidence |

||||||

4. Discussion

4.1 Productivity and Cost of Skidding

Table 1 shows that the average productivity of skidding achieved by the two operators of skidding equipment were different from each other. The average skidding productivity of operator A was higher than that of operator B, with the difference being (17.316–15.977=1.339) m3 h-1 (92.3%). The high difference of productivity shows that skidding requires highly skilled operators. The average wood volume that can be skidded by operator A is higher than that of operator B with shorter average skidding time. Results of t test show that t-calc = 4.466**>t-table 99%, which shows highly significant difference. This implies that in terms of productivity, the working skill of operator A was better than that of operator B. Operator A was 30 years old, with a working experience of more than 5 years, whereas operator B was 20 years old with the working experience of just 2 years.

Spinelli et al. (2020) also state that the type of stand (pure conifer or mixed wood stand) significantly affects the operator’s efficiency. Operating in a mixed wood stand requires strong mental focus and increases mental workload, which leads to mental fatigue. This results in a loss of productivity between 40% and 57% as compared to the productivity of harvesting pure conifer stands. Ghaffariyan (2020) state that the parameters affecting machine productivity included machine type/size, tree volume, average skidding distance and slope of the ground for each reported productivity.

Parajuli et al. (2020) and Carey et al. (2018) state that the efficiency of a skidder is greatly affected by skidding distance because it strongly affects the skidding time. When the skidding distance is long, the skidding time increases, and the overall productivity decreases. Thus, shorter skidding distances lead to higher productivities. The decrease in productivity of the skidder due to longer skid distances can be somewhat counterbalanced by increasing the payload per turn. The hauling distance and skidding capacity significantly affected productivity and costs, while terrain slope, with ranges between 0 and 20%, had no significant effects on productivity.

The average skidding productivity in this research was lower than that shown by the results of Fermana et al. (2019) on skidding in peat swamp plantation forest of PT PSPI; they reported the average productivity of as much as 21.23 m3 hour-1. The low average productivity in this research was due to longer average time of skidding, namely 1.035 hours (62.1 minutes) and 1.115 hours (66.9 minutes). Ozturk et al. (2019) show that it was found that skidding distance had a maximum effect on the total cycle time and productivity. Unlike previous time studies, it was found that the effect of volume on the total cycle time was relatively low. This study presented the analysis of the total time and productivity. The low average skidding time in this research was due to the peat depth that ranged between 2–6 m. This is in line with research results of Suhartana and Yuniawati (2015), who explained that skidding in peat swamp forest faces an important problem, namely low bulk density of the soil. This makes it difficult for skidding to use heavy equipment, operating on soft peat soil (particularly on peat with depth of more than 3 m). There is a need for extra care and skill during skidding.

Table 2 and 3 present the model summary, which shows the correlation (R), determination coefficient (R2), adjusted R2 and standard error. The magnitude of determination coefficient R2 is 0.261, which implies that 26.1% of skidding cycle time can be explained by variables of wood volume, skidding distance and operators’ skill, whereas the rest (100%–26.1% = 73.9%) is explained by other causes. In Table 4, the coefficient was subjected to t test to examine the significance of the constant of each independent variable, while t calculated with probability (sig) 0.000 < 0.05 shows that the effect of wood volume, skidding distance and operators’ skill on cycle time of wood skidding, is significant. It can be concluded from the table that regression calculation equation is Y = 21.702 + 0.181X1 + 0.192X2 + 6.175X3. The result of that equation shows that the positive constant for wood volume, skidding distance and operators’ skill implies that cycle time of skidding would increase. The higher wood volume, the shorter skidding distance and the higher operators’ skill imply shorter cycle time of wood skidding. The shorter the cycle time of skidding, the higher the wood skidding productivity.

Table 6 shows that the average skidding cost of operator A is lower than that of operator B. This is due to the high skidding productivity. Santos et al. (2014) state that assessment of the production costs show that unit costs decrease with increasing productivity in each unit of measurement of the production rate. Such high productivity was due to the operator’s skill. Production cost of skidding is obtained by dividing the cost of the venture by productivity. The difference in average production cost for the two operators was subjected to t test analysis, and the results show that t calculated = 4.261 >t table (99%). Therefore, from the aspect of cost, the wood skidding performance of operator A was better than that of operator B.

Several research results on skidding in mineral soil forests show that not all skidding productivity in those areas were higher than those in peat swamp plantation forest. Many factors affect average skidding productivity, both in mineral soil and in wetland forest. On the whole, the operator’s skill is one of the factors affecting the average productivity. Germain et al. (2019) state that harvesting operations in the Northeast US are characterized by challenging site conditions and unpredictable physical environments. Understanding the factors affecting logging costs and productivity is important for long-term viability of businesses and future management decisions. Without an experienced and skilled logging workforce most forest management activities cannot be implemented.

Physiological characteristics and health may cause differences other than the experience characteristics of the operators. Nascimento et al. (2021) state that there was an influence of safety and physical comfort of workers, which resulted in higher rest breaks, depending on the operation involved. This influence was observed in operations with a higher physical workload (felling and pre-skidding). Wong et al. (2019) state that long working hours were shown to adversely affect the occupational health of workers. The management on safeguarding the occupational health of workers working long hours should be reinforced. Jaskiewicz and Tulenko (2012) state that the health system affects the productivity of community health workers.

4.2 Subsidence Due to Skidding

Table 7 shows that there have been elevation differences of peat soil water table in the last three years, so that the occurring subsidence vary. In the year 2019, subsidence was higher compared to those in 2018 and 2020, namely 2.8 cm year-1 or an average of 0.28 cm year-1 in each 10 observation points. High subsidence in this research was due to elevation fluctuation of peat water table during measurements, which were far different from the previous ones. Such difference could be due to high rainfall occurring during measurement of water table elevation, so that the amount of water that fills the drainage facility or canal is higher. Very great difference in elevation or fluctuation of water table elevation before and during measurement, caused high subsidence in the year 2019.

Excessive subsidence rate causes rapid decrease of soil surface, so that its elevation decreases approaching the highest elevation in the river, and consequently it can no longer be drained (Nugroho 2015). This research results show subsidence which is lower than that found by Lisnawati et al. (2015) who showed that the development of A. crassicarpa Industrial Plantation Forest in the research location caused subsidence rate of 5.5 cm year-1 on the average. Besides that, existence of canal also cause the subsidence. According to Evans et al. (2019), subsidence averaged 4.3 cm year-1 in the Acacia plantations, and extended at least 300 m into adjacent forest. Mean water table depth was the best predictor of subsidence rate in both plantation and forest areas. Lauren et al. (2021) stated that in a scenario assessment, where WT was raised from −0.80 m to −0.40 m, the subsidence rate decreased from 4.4 to 3.3 cm yr-1, and carbon loss from 17 to 9 Mg ha-1 yr-1. Ritzema et al. (2014) stated that the resulting higher water tables did not completely compensate for the negative effects of increased subsidence near the canals.

High subsidence in this research could also be due to the depth of the canal used as facility for wood transportation. The average depth of the canal in this research location was 2.5 m. Aswandi et al. (2017) show that the 0.8 m drainage (e.g. real condition) causes land subsidence of about 52 cm, and reduces the drainable area up to 62.3%. Pronger et al. (2014) state that time since drainage exerts strong control over the rate of peatland subsidence and that ongoing peatland subsidence rates can be predicted to gradually decline with time in the absence of major land disturbance. Study results of Sloan et al. (2019) show that significant subsidence has taken place since drainage, with an average reduction of 56.8 cm (or 13%) in the depth of peat under forest stands. Subsidence of the peat surface was rapid in the initial phase after drainage and planting but has progressively slowed, with relatively little change between the surveys of 1996 and 2016. The subsidence data demonstrate that drainage followed by afforestation led to a considerable reduction in thickness of the peat layer and show how this evolved through time. On the other hand, the research results of Oleszczuk et al. (2020) show that the loss of peat thickness varied from 5 to 41% and depended on drainage intensity rather than on its initial depth. In general, six verified empirical equations were useful in estimating the average subsidence rate. Four equations seemed to be the most useful for deeply drained sites.

A series of recent Indonesian Government regulations (most recently SK.22/PPKL/ PKG/PKL.0/7/2017) also require that water tables be maintained within 40 cm of the peat surface at the centre of each plantation block for half of the year, and within 100 cm of the surface at all times. This represents a significant change to existing operational procedures, which generally involve drainage of the peat to a target depth of around 70 cm.

Based on Table 8 and 9, the model summary shows correlation (R), determination coefficient (R2), adjusted R2 and standard error. The magnitude of determination coefficient R2 is 0.607, which implies that 60.7% of subsidence can be explained by operators’ skill, whereas the rest (100%–60.7% = 39.3%) is explained by other causes. In Table 10, the coefficient was subjected to t test to examine the significance of the constant of each independent variable, while t calculated with probability (sig) 0.000 < 0.05 shows that the effect of operators’ skill on subsidence is significant. It can be concluded from the table that regression calculation equation is Y = 62.684 + 3.053X1. The result of this equation shows that positive constant for operators’ skill affects subsidence.

Agus and Subiksa (2008), Limin et al. (2008) explained that subsidence rate depends on many factors, such as peat maturity, peat type, decomposition rate, peat density and thickness, depth of drainage canal, climate, and land use. The deeper the drainage canal, the more rapid will be the subsidence and peat decomposition, so that peat thickness will quickly decrease as well as its buffering capacity for water. Decreasing the water table in tropical peatland makes the peat surface dry, and the vegetation dies and becomes fire prone. In the dry season, normally the peat layer can burn to a depth of around 50 cm, but can penetrate to 100 cm in some places. The value of subsidence of Histosol, measured by geodetic means, ranges from 9 to 33 cm, while that of Gleysol from 0 to 4 cm. The mean value of subsidence of the peatland in Sosnowica amounted to 24 cm over 38 years, which gives a degree of subsidence of 0.6 cm year-1, i.e. a loss of peat mass amounting to 11.5% of the total resources. The situation is still worse in the case of the peatland in Uhnin, where mineralization and a fire of the peatland caused the peatland area to shrink by 36% (Grzywna 2017).

Wood skidding in peat swamp plantation forest is very different from that on mineral soil. This is because of physical condition of the peat, which is soft and fragile, so that during skidding a land canoe has to be used to facilitate and ease the pulling of wood outside the area. The high average productivity of wood skidding in this research was due to skidding operator’s skill, where working experience of more than 5 years produced higher average skidding productivity. High level working skill resullted in skidding a higher volume of wood in shorter time. This factor significantly affected the skidding productivity. High level productivity could minimize production cost of skidding. Peat swamp forest clearing for Acacia crasicarpa plantation caused soil subsidence, which is a decrease of peat soil surface. The triggering factor for subsidence occurrence in this research was great fluctuation of water table elevation, before and during measurement.

4. Conclusions

The high average productivity of wood skidding in this research was due to the factor – operator’s skill, where working experience of more than 5 years resulted in higher average skidding productivity. High level working skill resullted in skidding a higher volume of wood in shorter time. This factor significantly affected the skidding productivity. High level productivity could minimize production cost of skidding. Peat swamp forest clearing for Acacia crasicarpa plantation caused soil subsidence, which is a decrease of peat soil surface. The triggering factor for subsidence occurrence in this research was great fluctuation of water table elevation, before and during measurement.

Acknowledgements

The authors express their gratitude to Ir. Joko Pramono (Planning Division) and Mr. Sumadi (Harvesting Division), who have helped in this study. Funding of this work was supported by PT. Satria Perkasa Agung. Both authors (Sona Suhartana and Yuniawati) have an equal role as the main contributors who equally discussed the conceptual ideas and the outline, provided critical feedback for each section, and helped shape and write the manuscript. All authors have read and agreed to the published version of the manuscript.

6. References

Agus, F., Subiksa, I.G.M., 2008: Lahan gambut: Potensi untuk Pertanian dan Aspek Lingkungan. Badan Penelitian dan Pengembangan Pertanian, Balai penelitian Tanah dan World Agroforestry Centre (ICRAF), Bogor, 36 p.

Akbar, O.T., Aprianis, Y., Ruspandi, 2019: Perbandingan karakteristik bahan baku dan pulp krasikarpa (Acacia crassicarpa A. Cunn) umur 1 sampai 4 tahun. Jurnal Penelitian Hasil Hutan 37(2): 93–104. https://doi.org/10.20886/jphh.2019.37.2.93-104

Andriani, I.E., Putranto, D.D.A., Affandi, A.K., 2018: Evaluation of Land Subsidence Impact at Lowland Areas Using Analitycal Hierarchy Process (AHP) Method. E3S Web of Conferences 68, 04017. 1st SRICOENV 2018. https://doi.org/10.1051/e3sconf

Aswandi, R.H., Susanto, R.H., Saleh, E., Abdillah, M.R., Iskandar, I., 2017: Simulation of CO2 emission and land subsidence in reclaimed tidal peat swamp in Berbak Delta, Jambi, Indonesia. Geomate 12(29): 186–194. http://dx.doi.org/10.21660/2017.29.97136

Bodaghi, A.I., Nikooy, M., Naghdi, R., Venanzi. R., Latterini, F., Tavanar, F., Picchio, R., 2018: Ground-based extraction on salvage logging in two high forests: a productivity and cost analysis. Forests 9(12): 729. https://doi.org/10.3390/f9120729

Borz, S.A., Ignea, G., Popa, G., Spârchez, G., Iordache, E., 2015: Estimating Time Consumption and Productivity of Roundwood Skidding in Group Shelterwood System – a Case Study in a Broadleaved Mixed Stand Located in Reduced Accessibility Conditions. Croat. j. for. eng. 36(1): 137–146.

Carey, P., Labbé, R., Trincado, G., Thiers, O., Garate, D., 2018: Productivity and costs of two low-investment biomass harvesting systems applied in a situation of mixed forest of semi-natural regeneration. Bosque 39(3): 419–430. https://doi.org/ 10.4067/S0717-92002018000300419

Evans, C.D., Williamson, J.M., Kacaribu, F., Irawan, D., Suardiwerianto, Y., Hidayat, M.F., Laurén, A., Pagee, S.E., 2019: Rates and spatial variability of peat subsidence in Acacia plantation and forest landscapes in Sumatra, Indonesia. Geoderma 338: 410–421. https://doi.org/10.1016/j.geoderma.2018.12.028

FAO, 1992: Cost control in forest harvesting and road construction . FAO Forestry Paper No.99, Rome, Italy.

Fagbenle, O.I., Laval, P.O., Omuh, I.O., 2012: The influence of training on bricklayers productivity in Nigeria. International Journal of Management Scuences and Business Research 1(7): 1–13. http://dx.doi.org/10.2139/ssrn.2701712

Fermana, J.S., Sadjati, E., Ikhwan, M., 2019: Analisis biaya pemanenan dan produktivitas produksi kayu ekaliptus (Studi Kasus: HPHTI PT.PSPI Distrik Petapahan). Wahana Forestra: Jurnal Kehutanan 14(2): 38–55. https://doi.org/10.31849/forestra.v14i2.3516

Germain, R., Regula, J., Bick, S., Zhang. L., 2019: Factors impacting logging costs: A case study in the Northeast, US. The Forestry Chronicle 95(1): 16–23. http://dx.doi.org/10.5558/tfc2019-005

Ghaffariyan, M.R., 2020: Reviewing productivity studies of skidders working in coniferous forests and plantations. Silva Balcanica 21(2): 83–98. https://doi.org/10.3897/silvabalcanica.21.e56071

Grzywn, A., 2017: The degree of peatland subsidence resulting from drainage of land. Environ Earth Sci (76)16: 559. https://doi.org/10.1007/s12665-017-6869-1

Gülci, S., Büyüksakallı, H., Taş, I., Akay, A.E., 2018: Productivity Analysis of Timber Skidding Operation with Farm Tractor. Eur J Forest Eng 4(1): 26–32. https://doi.org/10.33904/ejfe.428397

Hooijer, A., Page, S., Jauhiainen, J., Jauhiainen, W.A., Lu, X.X., Idris, A., Anshari, G., 2012: Subsidence and carbon loss in drained tropical peatlands. Biogeosciences 9(3): 1053–1071. https://doi.org/10.5194/bg-9-1053-2012

Hoyt, A.M., Chaussard, E., Seppalainen, S.S., Harvey, C.F., 2020: Widespread subsidence and carbon emission across Southeast Asian Peatlands. Nature Geoscience 13(6): 435–440. https://doi.org/10.5281/zenodo.3694667

Janie, D.N.A., 2012: Statistik Deskriptif dan Regresi Linier Berganda dengan SPSS. Editor: Ika, A. Semarang, Semarang University Press, 52 p.

Jaskiewicz, W., Tulenko, K., 2012: Increasing community health worker productivity and effectiveness: A review of the influence of the work environment. Human Resources for Health 10(1): 38. https://doi.org/10.1186/1478-4491-10-38

Jernigan, P., Gallagher, T., Mitchell, D., Smidt, M., Teeter, L., 2016: High tonnage harvesting and skidding for loblolly pine energy plantations. Forest Prod J 66(3/4): 185–191. https://doi.org/10.13073/FPJ-D-14-00055

Khakim, M.Y.N., Bama, A.A., Yustian, I., Poerwono, P, Tsuji, T., Matsuoka, T., 2020: Peatland subsidence and vegetation cover degradation as impacts of the 2015 El niño event revealed by Sentinel-1A SAR data. International Journal of Applied Earth Observation and Geoinformation 84: 101953. https://doi.org/10.1016/j.jag.2019.101953

Laurén, A., Palviainen, M., Page, S., Evans, C., Urzainki, I., Hökkä, H., 2021: Nutrient Balance as a Tool for Maintaining Yield and Mitigating Environmental Impacts of Acacia Plantation in Drained Tropical Peatland – Description of Plantation Simulator. Forests 12(3): 312. https://doi.org/10.3390/f12030312

Limin, S.H., Yunsiska, E., Kitso, K., Alim, S., 2008: Restoration of Hydrological Status As the Key to Rehabilitation of Demaged Peatland in Central Kalimantan. Restoration of Tropical Peatlands, Alterra – Wageningen University and Research Centre and the EU – Restorpeat Partnership, the Netherlands, 118–124 p.

Lisnawati, Y., Suprijo, H., Poedjirahajoe, E., Musyafa., 2015: Dampak pembangunan hutan tanaman industri Acacia crassicarpa di lahan gambut terhadap tingkat kematangan dan laju penurunan permukaan tanah. Jurnal manusia dan lingkungan 22(2): 179–186. http://dx.doi.org/10.22146/jml.18740

Maswar, A.F., 2016: Cadangan karbon dan laju subsiden pada beberapa jenis penggunaan lahan dan lokasi lahan gambut tropika Indonesia. In: Prosiding seminar nasional pengelolaan berkelanjutan lahan gambut terdegradasi untuk mitigasi GRK dan peningkatan nilai ekonomi, Badan Penelitian dan Pengembangan Pertanian, Jakarta, 18–19 Agustus 2014, 25–44 p.

Mudiyarso, D., Rosalina, U., Hairiah, K., Muslihat, I., Suryadiputra, N.N.N., Jaya, A., 2004: Petunjuk lapangan pendugaan cadangan karbon pada lahan gambut. Proyek climate change, forest and peatlands in Indonesia. Wetlands International_Indonesia Programmed and Wildlife Habitat Canada. Bogor.

Nascimento, K.A.O., Higuchi, N., DeArmond, D., Robert, R.C.G., Arce, J.E., Carvalho, J.P.F., 2021: Environmental Thermal Conditions Related to Performance, Dynamics and Safety of Logging in the Brazilian Amazon. Croat. j. for. eng. 42(3): 419–435. https://doi.org/10.5552/crojfe.2021.865

Noor, M., 2001: Pertanian Lahan Gambut, Potensi dan Kendala. Kanisius, Yogyakarta, 174 p.

Noor, M., Masganti, A.F., 2014: Pembentukan dan karakteristik gambut tropika Indonesia lahan gambut Indonesia. Pembentukan karakteristik dan potensi mendukung ketahanan pangan (Edisi Revisi). IAARD Press, Jakarta, 1–247 p.

Nugroho, K., 2015: Penurunan Permukaan Lahan Gambut (Presentasi Power Point). IPN Toolbox Tema C Sun Tema C6. www.Cifor.org/ipn.toolbox diakses tanggal 20 Januari 2016

Nusantara, R.W., Hazriani, R., Suryadi, U.E., 2018: Water-table depth and peat subsidence due to land-use change of peatlands. IOP Conf. Ser.: Earth Environ. Sci. 145(1): p 012090. https://doi.org/10.1088/1755-1315/145/1/012090

Oleszczuk, R., Zając, E., Urbański, J., 2020: Verification of empirical equations describing subsidence rate of peatland in Central Poland. Wetlands Ecology and Management 28(3): 495–507. https://doi.org/10.1007/s11273-020-09727-y

Ozturk, T., Varsak, M., Bilici, E., 2019: Evaluating Productivity and Cycle Time Skidding Method with Farm Tractors in Bigadic Forest Enterprise. European Journal of Forest Engineering 5(2): 77–82. https://doi.org/10.33904/ejfe.655241

Parajuli, M., Hiesl, P., Smidt, M., Mitchell, D., 2020: Factors influencing productivity and cost in the whole-tree harvesting system. Land Grand Press 1079. Online at: https://lgpress.clemson.edu/publication/factors-influencing-productivity-and-cost-in-the-whole-tree-harvesting, accessed 2 May 2021

Pronger, J., Schipper, L.A., Hill, R.B., Campbell, I.D., McLeod, M., 2014: Subsidence Rates of Drained Agricultural Peatlands in New Zealand and the Relationship with Time since Drainage. Journal of Environ Quality 43(4): 1442. https://doi.org/10.2134/jeq2013.12.0505

Proto, A.R., Macrì, G., Visser, R., Russo, D., Zimbalatti, G., 2018: Comparison of Timber Extraction Productivity between Winch and Grapple Skidding: A Case Study in Southern Italian Forests. Forests 9(2): 61. https://doi.org/10.3390/f9020061

Ritzema, H.P., Limin, S., Kusin, K., Jauhianen, J., Wösten, H., 2014: Canal blocking strategies for hydrological restoration of degraded tropical peatlands in Central Kalimantan, Indonesia. Catena 114: 11–20. https://doi.org/10.1016/j.catena.2013.10.009

Silayo, D.S.A., Migunga, G.A., 2014: Productivity and costs modeling for tree harvesting operations using chainsaws in plantation forests, Tanzania. International Journal of Engineering & Technology 3(4): 464–472. https://doi.org/10.14419/ijet.v3i4.3407

Sloan, T.J., Payne, R.J., Anderson, A.R., Gilbert, P., Mauquoy, D., Newton, A.J., Andersen, R., 2019: Ground surface subsidence in an afforested peatland fifty years after drainage and planting. Mires and Peat 23(6): 1–12. https://doi.org/10.19189/MaP.2018.OMB.348

Spinelli, R., Magagnotti, N., Labelle, E.R., 2020: The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators. Croat. j. for. eng. 41(2):175–190. https://doi.org/10.5552/crojfe.2020.747

Suhartana, S., Sukanda, S., Yuniawati, Y., 2009: Produktivitas dan biaya penyaradan kayu di hutan tanaman gambut: Studi kasus di salah satu perusahaan hutan di Riau. Jurnal Penelitian Hasil Hutan 27(4): 369–380. https://dx.doi.org/10.20886/jphh.2009.27.4.369-380

Suhartana, S., Yuniawati, Y., 2015: Penerapan RIL guna meningkatkan produktivitas dan meminimalkan biaya penyaradan di hutan tanaman rawa gambut. Jurnal Penelitian Hasil Hutan 33(3): 215–224. https://doi.org/10.20886/jphh.2015.33.3.215-224

Syahdan, F., 2017: Hubungan antara keterampilan kerja dengan produktivitas kerja. Psikoborneo 5(1): 81–88.

Wong, K., Chan, A.H.S., Ngan, S.C., 2019: The Effect of Long Working Hours and Overtime on Occupational Health: A Meta-Analysis of Evidence from 1998 to 2018. International Journal of Environmental Research and Public Health 16(12): 2102. https://doi:10.3390/ijerph16122102

© 2022 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors’ addresses:

Sona Suhartana, *

e-mail: sona.suhartana@gmail.com

Yuniawati,

e-mail: yunia_las@yahoo.co.id

Research Center for Biomass and Bioproducts, National Research and Innovation Agency

Jl. Raya Bogor KM 46, Bogor. 16911

INDONESIA

* Corresponding author

Received: June 13, 2021

Accepted: April 28, 2022

Original scientific paper