Challenges in Forestry and Forest Engineering – Case Studies from Four Countries in East Europe

doi: 10.5552/crojfe.2021.838

volume: 42, issue:

pp: 20

- Author(s):

-

- Mederski Piotr S.

- Borz Stelian Alexandru

- Đuka Andreja

- Lazdiņš Andis

- Article category:

- Subject review

- Keywords:

- forest management, forest utilisation, forest operations, innovations

Abstract

HTML

The forestry and timber industry are strong sectors in the economies of European countries. The current trend of introducing forestry management that respects the various functions of the forest has created new challenges. However, forestry itself, as well as those challenges, varies in different regions in Europe. The aim of this review paper was to describe forest resources and their potential as well to define challenges in forestry and forest engineering in regions of East Europe. Case studies were selected from four countries: Croatia, Latvia, Poland and Romania. The background data and information of the forest-based sector included: forest resources and forest productivity, forest utilisation, development of forest operations and difficulties in forest management. In the analysed countries, state-owned forestry was represented by at least 45%. Forestry is an important sector in all four countries and future challenges are observed in forest management and forest engineering mainly including: an increase in timber resources, improvement in species composition for better productivity and the introduction of effective mechanised forest operations in pre-commercial thinning. Further improvement of harvester heads is expected for the harvesting of broadleaved species and for young stands. Issues linked to the environment were also recognised as challenging factors: mild winters make it difficult to use CTL technology on wet and sensitive sites. Additionally, dry seasons have a high impact on forest fire frequency, but this can be controlled by effective monitoring systems. Improvement in IT systems used in forest operations should limit the carbon footprint by optimising transport, machine use and limiting fuel use. Finally, innovations are recognised as key issues in the improvement of forest management and forest engineering; therefore, special budgets have been allocated to support science and development.

Challenges in Forestry and Forest Engineering – Case Studies from Four Countries in East Europe

Piotr S. Mederski, Stelian A. Borz, Andreja Đuka, Andis Lazdiņš

Abstract

The forestry and timber industry are strong sectors in the economies of European countries. The current trend of introducing forestry management that respects the various functions of the forest has created new challenges. However, forestry itself, as well as those challenges, varies in different regions in Europe. The aim of this review paper was to describe forest resources and their potential as well to define challenges in forestry and forest engineering in regions of East Europe. Case studies were selected from four countries: Croatia, Latvia, Poland and Romania. The background data and information of the forest-based sector included: forest resources and forest productivity, forest utilisation, development of forest operations and difficulties in forest management. In the analysed countries, state-owned forestry was represented by at least 45%. Forestry is an important sector in all four countries and future challenges are observed in forest management and forest engineering mainly including: an increase in timber resources, improvement in species composition for better productivity and the introduction of effective mechanised forest operations in pre-commercial thinning. Further improvement of harvester heads is expected for the harvesting of broadleaved species and for young stands. Issues linked to the environment were also recognised as challenging factors: mild winters make it difficult to use CTL technology on wet and sensitive sites. Additionally, dry seasons have a high impact on forest fire frequency, but this can be controlled by effective monitoring systems. Improvement in IT systems used in forest operations should limit the carbon footprint by optimising transport, machine use and limiting fuel use. Finally, innovations are recognised as key issues in the improvement of forest management and forest engineering; therefore, special budgets have been allocated to support science and development.

Keywords: forest management, forest utilisation, forest operations, innovations

1. Introduction

Forests, which cover about a third of Europe, are highly valued as natural ecosystems and for the various services that they provide. Many of the forest services and functions (i.e. soil and water protection, biodiversity, and carbon sequestration) are potentially at risk under a changing climate due to changes in the water budgets of forest ecosystems (Bredemeier 2011a, 2011b). In addition, forestry is a traditional supplier for various industries of renewable raw materials, household fuelwood and increasingly of biofuels (Đuka et al. 2017).

In the past century, due to agriculture, deforestation has wiped out 90% of Europe’s floodplain forests (Hughes 2003). The remnants of relatively natural forests can mostly be found in East and South East Europe (Schneider-Jacoby 2006). Today forests in Europe have a stable size covering 210.9 mln ha (161.1 mln ha in the European Union, SP 2019), which is 32.2% of the total land mass (UN 2011). Taking into account forest utilisation, the area available for wood supply covers 168.9 mln ha, which is ca 80% of European forests. The average growing stock is 155 m3 ha-1, with the highest values achieved in Central Europe: 227 m3 ha-1 in West – Central and 217 m3 ha-1 in East – Central Europe. The net annual increment is 5.4 m3 ha-1, the highest being in the West – Central part at 7.8 m3 ha-1 and the lowest in the South West at 3.3 m3 ha-1. European forest resources make it possible to harvest over 500 mln m3 of timber, which guarantees a good supply for the forest-based sector (UN 2011).

The data presented concerning forestry in Europe shows that the potential varies in different regions. Overall, Central and Northern countries contribute the biggest amount of timber for industry. However, the distribution of the forest-based sector and timber industry is not strictly connected with timber resources. The furniture industry, for example, is concentrated in Central Europe (Germany and Poland) and in Southern Europe (Italy). These countries are also three of the four biggest furniture exporters in the world, with China taking the leading position (PKO 2019).

Considering the issue of ownership in Europe, on average half of the forests belong to private owners and half are under state management. Generally, in West Europe, the majority of the forest land is in private hands, while there is a larger representation of state forests in East Europe. Again, there are exceptions: Germany and Latvia have an ownership structure similar to the European average, which is 50% private and 50% state owned (UN 2011).

Taking into account regional differences, this paper focuses on the potential of forestry in selected countries in the East of Europe: Croatia, Latvia, Poland and Romania. The objective of the paper was to present forest resources and forest utilisation in these countries, while indicating the challenges faced in forest management and forest engineering. Due to the limited volume of the paper, the presented work takes the form of case studies rather than a full study of the forest sector in the whole of East Europe.

2. Material and Methods

The information concerning the development of the forest sector in the selected countries was derived from the literature, including published materials such as statistical and inventory data about forest-based sector in each country. This initially included: forest resources and forest productivity, forest utilisation, and the development of forest operations and forestry infrastructure, as well as difficulties in forest management. These key words were used to find suitable published sources, publications being further selected based on authors knowledge and experience.

In the last part of this paper, the challenges faced by each country were highlighted in and discussed.

In the chosen countries, there are differences in the forestry potential, as well as in the main issues in forest management. Therefore, there may be a different set of information presented for each country according to its importance in that region. Finally, the challenges were defined according to the situation in each country in the forest sector and in forest engineering.

3. Results

3.1 Forest Resources and Forest Utilisation

3.1.1 Croatia

In Croatia, four of the main European biogeographical regions are overlapping: Continental, Pannonian, Alpine and Mediterranean. Consequently, 11 of a total of 14 European forest types appear, placing Croatia second in Europe (after France) in the forest diversity ranking (EEA 2007).

The total area of forests and forest land in the Republic of Croatia is 2.69 mln ha, which is 47% of the entire country area. Out of this, 78.4% (2.11 mln ha) are state forests, while 21.6% (0.58 mln ha) are private forests. According to the current National Forest Management Plan, it is estimated that growing stock in the Republic of Croatia is 398 mln m3, of which 302 mln m3 is in state forests, managed by the company Croatian Forests Ltd. and slightly over 78 mln m3 is in private forests. (www.hrsume.hr). The company Croatian Forests Ltd. is the state-owned forest company, which manages 2 mln hectares of forests and forest land (about 73% of the total forest area), employs approximately 7000 employees, and represents, along with a much smaller proportion of private and other forest owners, the main entity in Croatian forest management (Šporčić et al. 2018).

The forest structure consists of high forests (53%), various degradation structures (44%), and plantations (3%). The largest part of the timber stock (80%) consists of 7 economically most important tree species: Fagus sylvatica L. (36%), Quercus petraea (Matt.) L. (12%), Quercus robur L. (10%), Carpinus betulus L. (9%), Abies alba Mill. (8%), Fraxinus angustifolia Vahl. (3%) and Picea abies (L.) Karsten (2%, www.hrsume.hr).

From an economic perspective, selective and even-aged forests are the most optimal high silvicultural form in Croatia and according to FAO (2015) forestry contributes to GDP at a level of 1.96%. Timber extraction is mechanised, while felling and processing are mostly motor-manual and carried out using chainsaws (Bojanin and Krpan 1997). The first harvester (a Timberjack 1070) was introduced in Croatia in 2001 for scientific research, and a second one a year later (a Timberjack 1270B). However, the state-owned company Croatian Forests Ltd. purchased their first harvester in 2018 – before that, there were few machines owned by private contractors. In Croatian pre-mountainous selective forests (Fig. 1), skidders are used for timber extraction (Sabo and Poršinsky 2005), while in even-aged forests in hilly and lowland areas, depending on the stand and terrain conditions, skidders and forwarders are used to extract timber (Fig. 1). Cable yarding is rare, due to specific management of selective forests where highly productive systems as cable yarders would not be efficient; still cable-based systems in Croatia can have a potential on flat terrain where soil-sensitive areas prevail. The long-distance transportation of processed wood is mainly performed by truck and trailer assemblies (85%) while the other 15% of timber transport is by railway (Zorić et al. 2014).

The use of harvesters is increasing in both coniferous and hardwood stands. While forwarders are used in lowland forests of oak and ash, skidders are in use in hilly and pre-mountainous terrain of beech, fir and spruce. Timber scaling is carried out in accordance with several regulations (by-laws) and standards, which prescribe the specifics of each log produced: tree species, length, middle diameter, log volume, place (origin) of scaling and person responsible for timber scaling, as in the EU Timber Regulation, i.e. the Forest Law Enforcement, Governance and Trade (FLEGT) Action Plan (Đuka et al. 2019).

Fig. 1 From harvesting to timber transport (photos: A. Đuka)

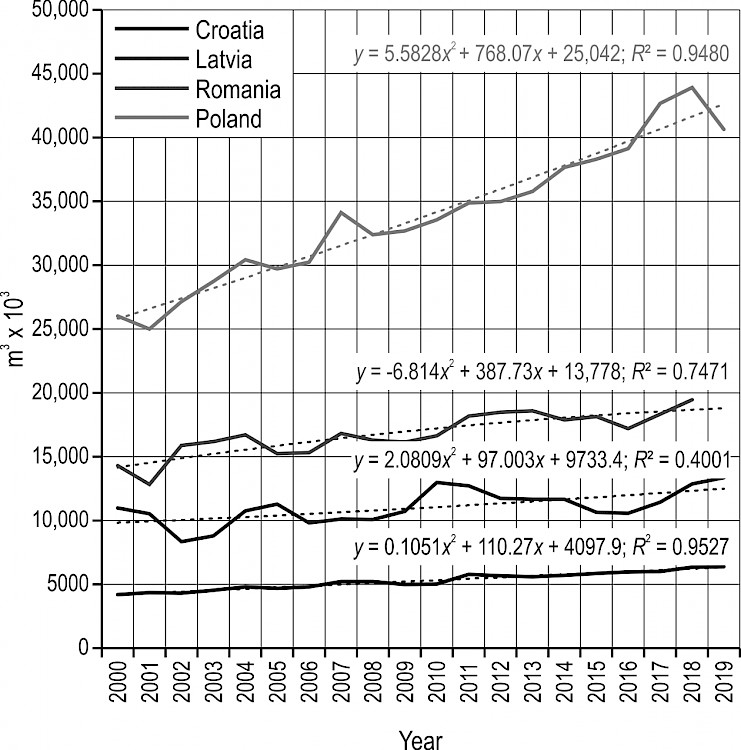

Annual increment is 10.5 mln m3, of which 8.4 mln m3 is found in state forests and 2.1 mln m3 in private forests. In the last 20 years, the increase of harvesting volume has been observed (Fig. 2).

Fig. 2 Changes of annual timber harvesting volume under bark (over bark for Romania) in the analysed countries; Croatia: state forests only (www.hrsume.hr), Latvia: state forests only (SFS 2020), Romania: state and private forests (ASFOR 2019, NIS 2020), Poland: state and private forests (CSO 2005, 2009, 2015, SP 2019)

Croatia is faced with the highest frequency of drought events in Europe; after the year 2000, significant droughts and heatwaves were observed in 2002, 2003, 2007, 2008, 2011 and 2012 (EEA 2012). Apart from heatwaves, climatic extremes in terms of strong winds, ice storms, heavy snow, etc. are more and more common. This presents a major problem in terms of sustainable forest management and the production of high-quality timber assortments, and results in differences between the planned assortment structure of processed timber and what is actually produced, as well as between the planned and subsequent production revenues. The aforementioned differences show that the silvicultural operations are carried out at the very limits of cost-effectiveness (Paladinić et al. 2011).

According to data from the company Croatian Forests Ltd. in cooperation with the Faculty of Forestry at the University of Zagreb and the Croatian Forestry Institute, the estimated damage caused during the ice-storm in Gorski Kotar region in 2014 amounted to € 231.18 mln, which includes damage in both the state and private forests together with further damage caused by floods and torrents resulting from melted ice and affecting the traffic infrastructure network.. The loss of the growing stock amounted to an estimated € 161.12 mln, while the damage to traffic infrastructure network amounted to € 3.19 mln. The same source states that the recovery will be long-lasting and challenging and that costs will rise to € 66.86 mln.

Due to an increase in temperature extremes in the past few decades in the Mediterranean and the higher frequency of heatwaves with a maximum daily air temperature above 30°C, there has been an upsurge in the number of fire-affected areas, a higher frequency of fire, as well as fires with a greater intensity and severity. In Croatia, this trend is also evident, especially in the karst areas, and the fact is that the area of fire risk in the dry and hot period extends from the Adriatic coast to the Croatian inland (Bakšić et al. 2015). The monitoring and processing of data related to the occurrence of forest fires in the period from 1995 to 2014, showed that a total of 5377 forest and other fires broke out, affecting a total of 259,003 ha of the surface. In this period, an average of 269 fires broke out per year, with an average burning area of 12,950 ha per year.

According to data released in 2017 by the Fire and Rescue Centre of the State Protection and Rescue Service (www.data.gov.hr), there were 6230 fires (55% more than the annual average for the previous 11 years), in which 100,767 ha of vegetation were burned. According to Croatian Forests Ltd., the amount of damage caused by forest fires in the period 2008–2014 was € 216 mln, which included loss in timber value and in non-market forest values (Bakšić et al. 2015). Also, high costs of firefigting should not be overlooked. Regent et al. (2018) state that one of the largest costs of firefighting in Croatia is the cost of aerial firefighting, where the majority of the costs are incurred by the procurement, maintenance and actual operation of the hydroplane Bombardier CL-415.

3.1.2 Latvia

The total forested area in Latvia in 2018 was 3.4 mln ha equal to 52% of the land area. Latvia is the 4th most forested country in Europe (MA 2019a). In comparison to the beginning of the 20th century, the forested area has nearly doubled (Saliņš 1999) due to the afforestation of pastures and low grade croplands after the 1st and 2nd world wars, and later, in the 1990s, due to a reduction in husbandry in Latvia (Lazdiņš et al. 2010).

On average, 12 mln m3 of timber have been harvested annually during the recent decade according to the stand-wise forest inventory data (SFS 2020). The forest sector in Latvia is one of the cornerstones of the national economy. Forestry, wood processing and furniture production represented 4.8% of gross domestic product (GDP) in 2017, while exports amounted to € 2.2 bln, 20% of the total value of export. Wood processing companies are often the most important employers in rural areas, thus being the main support of local economies. The turnover of the forest sector is continuously increasing, and reached € 3.2 bln in 2017 (MA 2019a).

There are ca 135,000 private forest owners in Latvia. The area of an average holding is continuously increasing and reached 13 ha per owner in 2018. A half of all forests are public and managed by the Joint Stock Company Latvia’s State Forests (LSF), which, for several years, has been recognised as one of the most attractive companies for employees to work. Latvia is one of the largest exporters of wood pellets in Europe with considerable development potential in local and export markets (Krasavcevs 2018). The share of energy wood assortment in the harvest stock over the past 5 years has been 21% (Lazdiņš et al. 2019).

In 2018, the growing stock in forests in Latvia reached 670 mln m3 (205 m3 ha-1 on average), in comparison with 432 mln m3 in 1988 and 176 mln m3 in 1935. The area of mature forests accessible for regenerative felling is 33% of all forests and is continuously increasing. The growing stock accessible for regenerative felling is 48% of the total growing stock (for aspen Populus tremula (L.) and grey alder Alnus incana (L.) Moench) equal to 91%, Lazdiņš et al. 2019). According to the NFI, in 2017, the gross increment was 26 mln m3, the mortality rate 6 mln m3 and the total harvest rate 17 mln m3 resulting in a net increment of growing stock of 1 mln m3. Mortality in forests is continuously increasing due to the ageing of forest stands and insufficient implementation of forest management measures, e.g. thinning and salvage logging in private forests (MEPRD 2019b). Approximately 36% of the roundwood produced in 2017 was coniferous sawnwood, 9% deciduous sawnwood, 37% pulpwood and industry timber, and 17% firewood (Lazdiņš et al. 2019).

The soil bearing capacity is one of the most critical issues in management of forest operations. The excessive wetness and low bearing capacity of organic and wet mineral soils limit access to significant forest areas for the implementation of regenerative felling and other forest management measures (Petaja et al. 2017; Prindulis et al. 2016). Forests with insufficient soil bearing capacity are the main contributors to an increase in the proportion of mature forests in Latvia, thus this issue is becoming increasingly urgent and a solution is needed in the near future. According to the NFI data, extreme conditions (movement of machinery is possible on frozen soil) are found in 10% of forest stands and unfavourable road conditions (residues and low value assortments have to be used in strip roads and forest machines should use tracks on all axles to move) persist in 33% of forests. This estimation does not include main-roads, e.g. ditch-sides, where soil bearing capacity can also be critical for the transportation of logs (Lazdiņš and Petaja 2016).

The development of forest machines in Latvia almost ceased in early ‘90s and companies producing experimental forwarders, mounders, loaders and other equipment transformed and specialised in order to produce e.g. rotators for harvesters and forwarders. However, new companies entered the market with specialised equipment adapted to the local market: the company, Ciedra Limited, for instance, produces on small scale the Deep Forest 621D forwarder for regenerative felling. It has large wheels to reduce pressure on the soil while working in forests with low bearing capacity soils. UOT Limited Company produces a series of forest trenchers and mounders for skidders, forwarders and farm tractors, as well as pneumatic seeders for the regeneration of pine stands. LSFRI Silava has recently produced a mounder and stump extracting unit for an excavator (Lazdiņa et al. 2012, Lazdiņš and Zimelis 2012, Lazdiņš et al. 2012, Zimelis et al. 2013, Zimelis et al. 2018). Several companies specialise in the transformation of farm tractors into forwarders or soil scarifiers commonly used in forest regeneration for local and external markets.

According to the State Register of Forest and Agriculture Machines, there are 2093 forest machines in Latvia, including 343 forwarders and 242 harvesters. These numbers include machines operating abroad, but do not include forest machines owned by Estonian and Lithuanian companies operating in Latvia. The most common brand of forest machines include John Deere with 249 machines, followed by Ponsse with 138 machines and Komatsu with 100 machines. There are 226 companies owning or using forest machines that are less than 10 years old, and the average number of machines per company is 2.7. The largest companies with more than 10 machines less than 10 years old manage 74% of the forest machines.

There is a different situation in private and public forests. In private forests, harvesting reports are usually issued using the manual measurement of material transported to the roadside or customer. However, harvester reporting systems are also used, particularly by contractors, to control the productivity and efficiency of machine use.

The implementation of StanForD 2010 in the LSF is planned for 2020, including forwarder production files, which are not currently in use. There is also a plan to use StanForD 2010 to estimate thinning quality and forest inventory data in commercial thinning, as well as to plan the forwarding of logs and further forest management operations (Olivera and Visser 2016).

Regenerative felling is carried out using harvesters (100% in public forests managed by the LSF); the exception is small or distant felling sites, where the transportation of a harvester is too expensive. Commercial thinning is 100% mechanised in the forests managed by the LSF and partly mechanised in private forests. On average, 70% of roundwood logs are produced using mechanised cut-to-length (CTL) harvesting methods (Moskalik et al. 2017), while the remaining logs are extracted using the CTL method with chainsaws. Pre-commercial thinning is usually done by chainsaws and bush-saws, except delayed thinning, where the production of biofuel and pulpwood is possible. In such places, it is more common to use compact class forest machines, e.g. Vimek or Malwa harvesters and forwarders (Lazdiņš et al. 2016, Petaja et al 2017, Zimelis et al. 2017).

There is a shortage of personnel for the timely implementation of pre-commercial thinning; therefore, the area of non-thinned over-dense stands, especially in private forests, is continuously increasing, requiring urgent action to increase productivity or the level of mechanisation in pre-commercial thinning. There are currently on-going studies evaluating the use of Vimek C.12 and Cutlink felling heads in pre-commercial thinning. Early tending of young stands (the cutting of ground vegetation competing with target trees over the 3–5 years after planting or sowing) is carried out using bush-saws. Soil scarification before forest regeneration is usually done by disc trenchers; however, in recent years, mounding with excavators has become widespread for soil preparation in nutrient-rich stand types including soils with low bearing capacity (Dzerina et al. 2016, Makovskis and Lazdiņa 2014). The most common type of artificial forest regeneration is the planting of containerised or bare-root seedlings. Mechanised planting was introduced in 2018 in the public forests managed by the LSF (Risutec 2019). The sowing of pine in nutrient-poor soils is uncommon (Lazdiņa et al. 2017).

A considerable area of the forests in Latvia have been ameliorated to improve growth conditions, especially during the spring and during rainy periods, when excessive water can significantly affect forest growth due to the formation of anaerobic conditions in the soil. The total area of ameliorated soils in Latvia is approximately 800,000 ha, including 395,000 ha of forests with organic soils. The maintenance and modernisation of amelioration systems takes place mainly in the public forests managed by the LSF. Modernisation includes the restoration of a ditch network, establishing of new ponds and filtration fields to avoid the leaching of nutrients. The ditch network is usually restored every 30 years or before regenerative felling in order to ensure optimal growth conditions in the next forest regeneration (Kļaviņš et al. 2019, Zālītisn et al. 2010).

Two certification systems dominate in Latvia: Forest Stewardship Council (FSC) and Programme for Endorsement of Forest Certification (PEFC). These systems mostly cover forests of large owners, e.g. the LSF. PEFC and FSC systems also provide certification of supply chains.

3.1.3 Poland

Forest cover in Poland amounting to 40% at the end of the 18th century (within historical borders) was as low as 20.8% in 1945. Deforestation and the introduction of coniferous species, mainly spruce, impacted on lower forest biodiversity, leading to landscape fragmentation, erosion and changes in water conditions (Zajączkowski et al. 2019). Significant changes in this process took place between 1945 and 1970, when, due to the reforestation of 933,500 ha, forest cover enlarged to 27%. The average annual reforestation area amounted to 35,900 ha, and in the most effective period (1961–1965), more than 55,000 ha per year were planted in order to convert post-agricultural areas into forestry land (Mederski et al. 2009).

Further reforestation up to the present day has currently provided 9.25 mln ha of forests under all forms of ownership in Poland, covering 29.6% of the total land area (SP 2019). According to international statistics, forest cover in Poland amounts to 30.9%, although the calculation only includes land cover without water resources. The State Forests administration and management includes 76.9% of forests, the share of other public forests is 3.8%, and private forests take the remaining 19.3% (SP 2019). Coniferous species cover the majority of the area at 70.1%, Scots pine Pinus sylvestris (L.) takes 60.2% of the area and the second largest contributor is silver birch Betula pendula (Roth) with 6.7% of the area (BFMG 2019). Private forests have a lower share of coniferous species (64.2%), with Scots pine (Pinus sylvestris L.) covering 54.4% of the area and silver birch (Betula pendula Roth) taking 10.1%. In 2018, the average timber stocking in the State Forests was 288 m3 ha-1, larger by 16% than the stocking in private forests, which was 249 m3 ha-1 (Statistics 2019).

The State Forests harvested timber in 2018 amounted to 41.63 mln m3 (merchantable timber under bark), which is 73% more than in 2000, when 24.09 mln m3 was harvested (Fig. 2). In the last two decades, an increase in the wood supply to the market has been observed (CSO 2015, SP 2019).

The majority of roundwood is processed in the country. Taking into account the available data from 2017 (SP 2019), only ca 7% of timber is exported (2.96 mln m3), while the volume of imports amounts to 1.74 mln m3, which is ca 4% of extra timber in relation to the annual harvested volume.

Cut-to-length technology in Poland has been used for the harvesting of nearly 40% of timber (Bodył 2019). The highest concentration of harvesters and forwarders depends on the region, northern and western Poland having the highest representation of these machines. Otherwise, chainsaws are in use, although the popular use of forwarding (there are ca. twice as many forwarders as harvesters) makes the short wood system popular. Species composition and mountains are the limiting factors for wider harvester use (Mederski et al. 2016a). The long wood system, where chainsaws and skidders are in use, is being replaced by the short wood system (Bouriaud et al. 2011). The application of harvesters and forwarders in the first commercial thinning may be difficult from an economic point of view due to the competitive price of early thinning. However, low interest in the motor-manual tending of young stands has meant the introduction of mechanised operations to process timber of smaller sizes, mainly pulp wood (Mederski et al. 2018a).

Overall, forest enterprises providing forest operations, forest tending and other services are a source of employment for over 30,000 people (SP 2019). The forest sector has a good impact on the timber industry. In the private sector of the furniture industry, there were 198,486 employees, and the pulp and paper industry employs a further 67,068 (SP 2019). Poland is one of the biggest furniture producers in Europe and the value of furniture exports places Poland third in the ranking of the biggest furniture exporters in Europe (PKO 2019).

3.1.4 Romania

Romania is considered to be highly diverse from an ecological point of view, including parts of five major European ecological regions (EEA 2003) hosting eight out of fourteen European forest types (EEA 2007). The total area of forests is 6.93 mln ha with growing stock estimated at 2,354.80 mln m3, with close to 2000 mln m3 shared by beech, oaks and coniferous species (NFI 2019). The average volume is ca. 340 m3 ha-1 and annual growth is close to 8.5 m3 ha-1 per year (NFI 2019). Traditionally, the production forests of Romania were seen to be multifunctional even though they were and still are mainly used to provide raw materials for industry and household use, i.e. half of the existing rural households (ca. 4 mln) still use wood for heating (ASFOR 2019).

State forests, which are managed exclusively by the National Forest Administration – RNP Romsilva, cover 45.3%, equal to 3.14 mln ha (ROMSILVA 2019a), while the remaining 54.7% are private forests. Romsilva is a state-owned forest company that also manages, based on contracts, ca. 0.4 mln ha of private forests and provides forestry services for approximately 0.6 mln ha of private forests. Roughly 2.5 mln ha managed by Romsilva are certified under the FSC system (ROMSILVA 2019b). From the functionality point of view, the Romanian system divides the forests in two main groups: protection and production forests. However, production forests are predominantly managed as continuous cover forestry. The Romanian forests have always played a key role in supporting the national economy, and the contribution of the forest sector to Gross Domestic Product (GDP) is close to 4% (World Bank 2014), employing directly and indirectly more than 300,000 people (ASFOR 2019). About 60% of forest growth is harvested, covering 17–18 mln m3 (from all forms of ownership, Fig. 2). There are several challenges that harvesting companies have to face, and the main one is the excessive price of standing timber (ASFOR 2019).

The two main actors that carry out harvesting operations in the Romanian state forests are the companies affiliated to the Romanian Association of Harvesting and Wood Processing Companies (ASFOR) as well as Romsilva. Although some companies hold fully-mechanised state-of-the-art machines and equipment, their share should be increased in the nearest future. Motor-manual tree felling – processing and skidding (Moskalik et al. 2017) is implemented as the tree-length harvesting method (Oprea 2008). The use of skidders is popular (Borz et al. 2013, Borz et al. 2015), mainly those produced in Romania by IRUM (www.irum.ro). Transportation of wood is mainly done on the existing public and forest road network (Oprea 2008, Vişan 2017).

Typical disturbances occurring in Romanian forests are those related to different diseases and pests (MEWF 2016) as well as those produced by wind, snow storms and freezing rains. Another issue is that related to the occurrence and area affected by forest fires. As such, in the period 2006–2015, the number of forest fires doubled compared to the period 1956–2005, affecting ca. 22,000 ha (Lorenţ et al. 2018).

4. Discussion – Challenges in Forestry and Forest Engineering

The development of region-specific, practically relevant, performance criteria is highly desirable, the ones that meet local needs and maintain the flexibility to evolve and be capable of incorporating ever-changing work environments and challenges (Marchi et al. 2018). Three critical drivers currently steer the global trend for the production of biofuels and bioproducts from renewable resources:

Þ increasing demand for and prices of petroleum-derived fuel

Þ increasing food needs

Þ increasing greenhouse gas emissions.

Biomass is the one renewable resource that has the potential to supplant the use of liquid transportation fuels now and help create a more stable energy future (Christopher 2012). At the present time, when tree biomass, primarily as a raw material for energy production, is becoming the main interest of domestic and foreign markets, systematic research is needed on the potential of the total tree biomass and growing stock in forests (Szewczyk and Polowy 2020). Of the available alternative energy sources (water, sun, wind, etc.) biomass is the only sustainable resource based on carbon use. As such, it plays a vital role in the emission of greenhouse gases, stimulating domestic industry development and securing and diversifying energy supply (Ćosić et al. 2011). Demand for energy wood has been increasing in recent years partly due to the rise in fossil fuel prices, but also because of the European Union's incentive to use renewable energy sources.

Stand conditions affect the selection of harvesting system, the characteristics of the vehicles and the methods of timber harvesting, thus directly affecting the environmental suitability and economic viability of harvesting operations (Đuka et al. 2018b). The energy efficiency of the harvesting system for both timber and biomass largely depends on stand characteristics, machine or load characteristics, and operator experience (Vusić et al. 2013, Pandur et al. 2019), as well as the traffic infrastructure network (Đuka et al. 2017) and planning (Picchio et al. 2019, 2020).

Taking into account forestry features in countries analysed (Table 1), there is economic potential at the European market level and further competitiveness can be achieved when solving regional challenges.

Table 1 Forest resources characteristics in analysed countries

|

Forestry characteristics |

Croatia |

Latvia |

Poland |

Romania |

|

Share of state forests, % of total area |

80 |

50 |

80 |

50 |

|

Forest cover, % |

47 |

52 |

31 |

27 |

|

Forest cover, mln ha |

2.7 |

3.4 |

9.3 |

6.9 |

|

Harvested volume (all ownerships), mln m³ |

6 |

15 |

41 |

18 |

|

Share of certified state forests, % |

80 |

50 |

80 |

60 |

|

Contribution to GDP |

1,96 |

4,8 |

0,33 |

4 |

|

Dominant species group |

Broadleaved |

Coniferous/broadleaved |

Coniferous |

Broadleaved |

|

Mechanisation (dominant system) |

Chainsaw and skidder/forwarder |

Harvester and forwarder |

Chainsaw and forwarder/ harvester+forwarder |

Chainsaw and skidder |

|

Dominant silvicutural system |

Selective/even-aged |

Clearcut |

Selective |

Selective |

|

Dominant harvesting system |

Long wood system/ short wood system |

Short wood system |

Short wood system |

Long wood system |

|

Critical factors for full mechanisation |

Broadleaved species |

Soil bearing capacity |

Terrain slope and broadleaved species |

Terrain slope and broadleaved species |

4.1 Croatia

The beginnings of mechanisation in Croatian forestry were characterised by the wide introduction of chainsaws in 1961, agricultural tractors in 1950, skidders in 1961, and forwarders in 1971 (Krpan 1992). When trees are felled and bucked using chainsaws (Kranjec and Poršinsky 2011), operators remain in high-risk sector category (Landekić et al. 2018), therefore mechanised operations are in demand.

The core of planning timber harvesting is sustainability and promotion of the so-called 5-E standards: economic, environmental, energy-efficient, ergonomic and asthetic (Đuka et al. 2018a). In the wood supply chain, the production of particular timber assortments is one of the most critical operations. This process decides how and where timber will be delivered and used, but from the technical point of view, only a certain quality of timber can be used for specific purposes, i.e. veneer logs, sawlogs, cellulose and pulpwood (Paluš and Paroblek 2013).

In the altered habitat conditions, tree species, such as oak, silver fir and European beech, as well as transitional species, such as Norway spruce, result in physiological deformations causing tree crown transparency, the incidence of secondary insects and then finally the drying of trees. Invasive species of insects represent a challenge in forests protection in FSC certified areas (state forests managed by the company Croatian Forests Ltd.) in which the use of insecticides is restricted (Franjević et al. 2019). In Europe, natural lowland floodplain forests have all but vanished, and with them, a very important research reference point for forestry and ecology (Mikac et al. 2018). The favourable weather conditions (for example, mild winters) over several consecutive years may play a triggering role in the oak lace bug (Corythucha arcuate Say) outbreak, a native North American species which is already responsible for many problems in the oak stands of most Central and Eastern European countries (Csóka et al. 2019). The authors conclude that suitable hosts for oak lace bug are present in most of Europe and Asia. This means that a lack of hosts will likely not restrict further range expansion and that one of the major determinants regarding a non-native insect potential to become invasive is the availability of its hosts, which have definitely been under stress in the past decade.

The study by Šporčić et al. (2018) presented the status of innovation in Croatian forestry in the state company Croatian Forests Ltd. Although the majority of employees (66%) consider innovation to be of crucial importance for business efficiency, they see their company as only partially innovative. A positive example from Croatian forestry is the Regulation on Innovation Activity in Croatian Forests Ltd., which was introduced to stimulate innovation as it represents a formal framework for evaluating and rewarding innovations. The Regulation defines the mutual rights and obligations of the company and its employees regarding innovation, and as one of the main provisions, determines benefits for the authors of accepted innovations.

In the future, we can expect harvesting operations in more sensitive areas due to changing climate conditions, especially in regions with unfavourable natural-geographic and socio-economic conditions and negative demographic projections for the future (Lajić and Klempić Bogadi 2010), which will also cause labour shortage. Prka and Krpan (2007) state that the quality of the stand is the result of different abiotic and biotic factors, and that the total stand volume cannot serve as the basis for the planning of harvesting operations (cutting, timber extraction and transport) nor for calculating the financial inflow. The authors further argue that the available volume of stands varies greatly from ca 30% to 80% of the total volume of stands, and that the distribution of wood assortments in individual trees is conditioned by the variety of their habitats and the occurrence of wood defects and characteristics. Altered stand conditions, which we are facing now and presumably will in the future, will represent another challenge not just from the operational point of view (harvesting system, work safety and work-force), but also from the economic perspective.

4.2 Latvia

The future challenges in forest engineering in Latvia are determined by today's shortcomings, as well as new quality requirements and environmental standards determined by the developing bioeconomy sector. Future harvests depend on market demand because the available resources are considerably bigger than the current market demand. The production of energy wood in low value forests is limited due to the low cost of biofuel in the market. It is particularly relevant to deciduous biomass, which is not in demand by the pellet industry. The future projections elaborated for the national forest reference level do not really consider an increase in domestic demand, either in the wood-processing industry or the bioenergy sector. However, these projections may underestimate demand in export markets (Krasavcevs 2018, Lazdiņš et al. 2019).

The technologies and work methods for biofuel production in commercial felling need to be developed and implemented, e.g. the extraction of harvesting residues in commercial thinning and extraction of stumps in regenerative felling. The extraction of stumps can contribute to a reduction in root rot distribution, as well as a reduction of forest regeneration costs and pest damage (Lazdinš and von Hofsten 2009, Zaluma et al. 2019).

Pre-commercial thinning requires the implementation of new work principles ensuring higher productivity and mechanisation of operations. This target may be reached through the utilisation of compact class machines. However, new work methods and forest management principles should be introduced to make this technology feasible. IT based solutions are necessary for the better planning of operations and quality control which does not require additional measures. New types of harvester heads need to be developed to increase productivity and quality, e.g. high precision GPS marking of planted trees for automation of early tending and thinning.

In the early tending of young stands, the lack of labour is a crucial issue, which can be solved by the mechanisation of operations, e.g. by the utilisation of compact class forest machines, and by an increase in productivity by using improved planning tools and the automation of operations. Automation can include the utilisation of high precision GPS for planted trees, as well as tracking guides ensuring that operators select the most optimal paths during thinning.

In forest regeneration, mechanised planting has already demonstrated its efficiency and cost-saving potential. This technology, as well as planning tools ensuring selection of the most efficient forest regeneration method for specified conditions, should be developed to respond to the shortage of planting material and to reduce forest regeneration costs. Pre-conditions for efficient mechanised sowing are the adaptation of soil scarification and site selection methods, the post-processing of seeds and development of weather forecasting tools in order to select suitable sowing periods in certain regions.

Forest fertilisation and ash recycling are efficient solutions to improve forest growth, contributing to climate change mitigation targets and the growing demand for raw materials, requiring more efficient planning solutions to increase the economic and environmental efficiency of these measures. Technologies for the hardening and palletisation of wood ash should be developed considering that most wood ash in Latvia is produced in boilers with moving furnace bars (Okmanis et al. 2018, Petaja et al. 2018).

4.3 Poland

Development of the forest sector in Poland is carried out paying attention to its multifunctional role: economic aspects can be developed with regard to environmental issues. Currently, there are challenges in several areas, and improvements are expected in forest management and forest operations. For this reason, the State Forests have invested in innovation and research projects, supporting leading universities and institutes in 2018 with € 12.27 mln (PLN 52.91 mln, GDSF 2019).

One aim is to increase forest productivity for the future growth of timber harvesting and meet the demands of the timber sector. Currently, the annual increment of the State Forests is 9.8 m3 ha-1, 8% higher in comparison with the increment (9.1 m3 ha-1 year-1) calculated from the inventory between 2010 – 2014 (BFMG 2015, BFMG 2018). It is expected that the increment may be increased by converting coniferous forests to mixed/broadleaved forests as well as improving forest management (MEP 1997). This also includes the introduction of an understory in premature stands to increase stocking per hectare.

Another issue linked to an increase in stocking is the introduction of narrow strip roads in the stands where a first commercial thinning is planned. An increasing share of mechanised forest operations (Mederski et al. 2016a) allows the harvesting of nearly 40% of timber using the harvester-forwarder system (Bodył 2019). The harvester-forwarder system requires forest access – strip roads, which are established during the first commercial thinning in stands aged 20–30 years. At this age, trees with small diameters (ca. 12 cm, Mederski et al. 2018a) can be harvested and, therefore, harvesters of smaller sizes can be used (Mederski et al. 2018a). This leads to another challenge – small harvesters usually have shorter cranes, ca. 6 m, and establishing strip roads every 20 m requires the additional help of a chainsaw to cut trees beyond the reach of the harvester crane. However, these trees can be processed further by a harvester in combined operation (Mederski et al. 2018a).

Usually, one tree row is cut to make a strip road for the first commercial thinning, giving a width of ca. 3 m. Therefore, at this stage of stand growth, narrower machines are required. For that purpose, Polish manufacturer OTL Jarocin introduced to the market a new F6 forwarder for timber extraction in premature stands, mainly for pulpwood. The machine is 2.24 m wide (fitting 3 m-wide strip roads) with a maximum load of 6 t and is an optimal economic choice for timber extraction in thinned stands. It is at the later stage of stand growth, when strip roads can be widened, that bigger machines are introduced, mainly forwarders. In this case, one more tree row has to be removed for efficient machine driving with limited damage to the remaining stand. Therefore, from the first commercial thinning until late thinning, one tree row can be saved next to each strip road for additional timber production, higher stocking and annual increments.

As mentioned above, nearly 40% of timber is acquired by harvesters. However, it was found that there are particular restrictions limiting the wider use of harvesters in Poland: the presence of broadleaved species and mountain forests (Mederski et al. 2016a, Mederski et al. 2018b). Further studies have shown that hardwood species especially, i.e. birch and oak, may restrict effective harvester use due to the natural morphological features of tree trunks: sweeps and thick branches (Mederski 2013, Bembenek et al. 2015, Mederski et al. 2016b). The observed difficulties are the low quality of delimbing, limited use of trunks for logs (due to thick branches that cannot be delimbed) and the inaccuracy of log lengths. Another issue to be solved in harvester use is damage to the outer layer of high value logs (Karaszewski et al. 2016, Karaszewski et al. 2018). Detailed studies in this context have found that up to 4% of wood can be lost (wasted) in veneer or plywood timber (logs) due to damage from feed roller spikes (Karaszewski et al. 2016).

Difficulties in obtaining a high quality of timber in the processing of hardwoods and dealing with customers’ complaints regarding feed roller spike damage are examples of challenges that may be solved by alteration of harvester heads. Even though there have been attempts to construct new harvester heads dedicated to broadleaves, for instance the CTL 40 HW (Mederski et al. 2011), there is still work to be done in this area. It seems that the harvesting of broadleaved species is rather a problem for Central European countries, where the share of broadleaved species is higher. At the same time, the concentration of harvester head manufacturers is in Northern European countries, where the problem of broadleaved species is not observed. In fact, birch and other broadleaved species are present in Scandinavian countries, but they have different morphological features: they are rather straight and generally have thinner branches. Bearing in mind the above set of circumstances, the increasing share of cut-to-length (CTL) technologies and bigger share of broadleaved species are rather tricky issues to be tackled by improved forest management.

A further difficulty linked to harvester utilisation is the use of timber volume measurement for the wood trade. The State Forests (public institution) require certification from the Polish Committee for Standardization guaranteeing that the timber is measured according to standard/s that can give the same results. Unfortunately, by using a harvester head and computer software, it is not possible to get the same results after a second measurement/processing of the log. In this case, it is much easier to introduce harvester measurement in practice between two private entrepreneurs: the forest owner and timber industry, as they can agree to the use of a harvester-calculated volume for the timber trade. In fact, volume calculated by harvesters is often used by entrepreneurs, but it is only for estimation of the harvested volume and a comparison with the measurements provided by the forest and timber owner – the State Forests in this case.

The timber industry is well developed in Poland and over 90% of harvested wood is processed domestically. The road transportation of round timber to customers is popular, and prices are fairly similar in different regions in the country; however, the timber industry has a high potential in timber processing, which makes the market highly competitive. Therefore, large industry partners may transport wood long distances due to the lack of timber in the local area. Therefore, a new system has been introduced by the State Forests for industry partners: geography of trade. The timber selling system promotes the purchase of wood locally – the system calculates the final price considering the distance between the place of purchase and the final destination - the shorter the distance, the lower the price.

In 1992, there were two large forest fires in August that destroyed 15,000 ha in total. Since that time, precautions have been introduced to limit the frequency and area of fires. Firstly, areas vulnerable to fire were identified throughout the whole country and the most susceptible regions were indicated. A detection system has been developed, which includes the building of new monitoring towers. Eventually more than 600 towers have been built to monitor forests throughout the country. A network of reservoirs (retention system) has been built, which includes recreation or the creation of small water ponds in forests. The aim of this was to improve the water system and boost the level of moisture in the forests. Additionally, the existing forest roads have been improved and a newly built system of roads has been introduced to guarantee access to remote and endangered forest areas. Cooperation with fire brigades has been encouraged together with training of forest administrations. Maps with detailed networks of forest roads have been made available for fire brigades in advance to enable the study of access to remote areas and to recognise the difficulties in terrain configuration. When necessary, it was also decided by the State Forests that small fire engines should be made available for monitoring and for quick reactions in the event of small fires, e.g. in 2019, 67 new monitoring-fire engines were bought for € 2.6 mln. Additionally, specialised aeroplanes have been hired for fire monitoring and immediate extinguishing of small fires (i.e. the heavy-duty Dromader M18B, produced in Poland, is able to carry a load (water) of up to 2.2 tonnes). All of the measures described above have made it possible to effectively limit fires in the State Forests. In 2018, 2994 fires were recorded in the State Forests on a total area of 586 ha, with a mean fire area of only 0.2 ha. There has only been one big fire (understood as >10 ha), which covered 13.22 ha. In comparison, there were eight big and one very big (>100 ha) forest fires on areas with other forms of ownership, where the mean area burnt amounted to 0.36 ha (Zajączkowski et al. 2019).

According to the current Forest Stewardship Council (FSC) standard used in Poland for audits (and finally certification), 5% of the forest compartment area planned for final felling should be excluded from utilisation in order to fulfil environmental needs, such as contributing to large-size timber decomposition (FSC 2013). Currently, 40% of timber is harvested from final felling (an extra 5% on average is harvested from final felling stands after windstorms and other calamities). This means that every year, ca. 840,000 m3 of timber from final felling has to be left without utilisation until it decomposes naturally in order to fulfil FSC criteria expectations. As more timber beyond the annual harvested volume is in the interests of the wood industry, it is an awkward situation as to some extent FSC certification is in the interests of the wood sector, but at the same time FSC certification limits industry partners’ access to timber. It is also worth adding that 840,000 m3 currently has a market value of at least € 44 mln, which is considered an additional loss of opportunity borne by the State Forests.

4.4 Romania

There are many challenges to be faced under the umbrella of forest engineering in the future state forests of Romania. One of the main challenges is related to the improvement and future development of the forest road network. As such, some progress has been made in terms of evaluating the effect of developing forest roads on the microclimate (Tiţă et al. 2019), as well as on lowering the ecological impact (Iordache et al. 2012, Enache et al. 2012). Still other questions need to be addressed since for the moment wood extraction distances are frequently too high, thereby contributing to increased harvesting costs (Fornea et al. 2018). Additional environmental burdens appear due to the need to develop bladed skid roads in steep terrain (Oprea and Borz 2007) and increased fossil fuel use in harvesting operations.

The situation also acts as a technical limitation in the use of environmentally sound technology (Borz et al. 2014a, Munteanu et al. 2019) and contributes to a low responsiveness in case of natural disturbances. By improving forest accessibility, the stage could be set for productivity increment supported by state-of-art technology (Apafaian et al. 2017, Borz et al. 2014a), mitigating the actual (Rauch et al. 2015) and forecasted drop in labour availability and other issues related to self-awareness and training of personnel (Borz et al. 2014b, Banciu et al. 2018), to name just a few. However, these needs have to be supported by some changes in institutional acceptability of highly-performant harvesting systems, which could be difficult, as well as by developments of purpose-built timber harvesting machines.

The level of technology implementation in both, the business and operational processes flows, could be seen as a second major challenge. For instance, wood scaling and measurement as an interface between business processes and flows, as well as other types of forestry data, rely on traditional measurement and estimation, which were highly discussed (Vasilescu 2017, Trella 2019) and criticised using undocumented non-informed statements by NGOs (Borz et al. 2019a). That situation can have negative impact on the market, economy and social dimension of forestry. In this last regard, such challenges may be approached in the future by a transition to precision forestry techniques and instruments, which should provide more accurate, easy to check information. Some steps have been taken to produce it in forest operations (Borz et al. 2018, Cheta et al. 2018, Marogel-Popa et al. 2019). The issue also applies to the institutional framework and its associated business model, where improvements are needed to save money and time. In particular, the flow of information could be improved by interlinking IT solutions (Rauch and Borz 2020). In terms of innovation orientation, at least in the case of Romsilva, the study of Malai et al. (2019) showed needs for the development of innovative processes and products.

Finally, the use of wood for heating and other energy applications is important for rural communities. Since wood prices have continued to rise, sometimes not sustained by market laws (Fornea et al. 2018), future challenges will be those encompassing the development of policy instruments to sustain the procurement of wood assortments at acceptable prices. Such an endeavour is related to most of the challenges described above. While the tactical part of improving the status quo in this regard has been discussed by Rauch et al. (2015), operational, planning, mechanisation and environmental research still needs to be addressed with regards to Romanian conditions since so far only the alternative short rotation crops have been addressed in studies (Borz et al. 2019b, Borz et al. 2019c).

5. Conclusions

In the analysed countries, there are different ownership structures, from an almost equal share of private- and state-owned forests (Latvia, Romania) to a larger proportion (ca 80%) of state-owned forests (Croatia, Poland). Despite some differences in ownership, in all countries the forest-based sector is an important part of the economy, and demand for timber is high from industry partners. In this regard, one of the challenges is to increase timber resources by improving stand species composition and enhancing increment. Further improvement of stand structure is also planned through the introduction of narrow strip roads (leaving more area for production) for mechanised forest operations, and the introduction and manufacture of smaller, more compact machines for pre-commercial thinning and early thinning. Whenever CTL technologies are introduced for pre-commercial thinning, it is difficult to keep costs reasonable for operations in young stands due to the low-value of the harvested timber.

Whenever possible, mechanised forest operations are in use; however, further expansion of mechanised operations may face difficulties due to species composition (an increasing share of broadleaved species). Generally, broadleaved species are a limiting factor for the use of larger harvesters, and an improvement in harvester heads is expected. Other limiting factors include terrain conditions: mountains and wet ground (but not frozen due to changes in weather conditions) exclude the use of harvesters and forwarders. New solutions are expected, such as powerful winches for machines in mountain conditions and the further development of machine tracks for wet and sensitive sites.

Beyond wider use of CTL technology, the need to improve productivity and safety in traditional systems, based on manual felling and skidding, is an aim in areas where it is not possible to use the harvester-forwarder system. Therefore, innovations in forest operations are expected along with suitable budgets from forest owners (state forests) to enhance progress and technological changes. Particular goals to improve forest operations include the integration of IT systems and reduction in fuel consumption and increase in productivity. Reduction in environmental footprint (soil compaction and fuel consumption) is expected by introducing new solutions such as new types of tracks, load transfer solutions, improvements in bucking systems, improvements in data flow for a higher efficiency in CTL operations, automation and improved operator skills. Moreover, the scaling system for harvesters is expected to improve. The state forests have difficulties with the implementation of the current timber volume measurement systems in harvesters, as official, administrative procedures require a high level of accuracy.

Environmental factors, such as issues linked to lower fuel use, are recognised as challenging. Limitations in timber transport distances have been introduced by offering more attractive prices for timber when delivered over shorter distances by wood suppliers. In addition, the optimisation of the road network for wood harvesting and transport has been introduced. The use of biofuels and wood for households has been promoted as being more environmentally-friendly and policies have been introduced to regulate prices to make biofuels more affordable. Forest fires can be controlled very well and a strict monitoring system can make it possible to limit fires efficiently.

Wood demand remains very high – the timber industry has the potential to consume more wood, but at the same time the FSC certification system expects some areas to be excluded from utilisation for environmental reasons. Moreover, the FSC system includes restrictions on pesticide use, which means that new solutions are needed for regulating pests’ populations that endanger valuable tree species.

6. References

Apafaian, A.I., Proto, A.R., Borz, S.A., 2017: Performance of a mid-size harvester-forwarder system in integrated harvesting of sawmill, pulpwood and firewood. Annals of Forest Research 60(2): 227–241. https://doi.org/10.15287/afr.2017.909

ASFOR, 2019: Starea sectorului forestier din România (State of the Forest Sector in Romania). Asociația Forestierilor din România. https://asfor.ro/starea-sectorului-forestier-din-romania/#sdfootnote1sym

Bakšić, N., Vučetić, M., Španjol, Ž., 2015: Potencijalna opasnost od požara otvorenog prostora u Republici Hrvatskoj (A potential risk of fire on open space in the Republic of Croatia). Vatrogastvo i upravljanje požarima 2: 30-40.

Banciu, T., Borz, S.A., Marcu, M.V., Iordache, E., Liampas, S.-A.G., Drosos, V., 2018: An evaluation of risk-taking behavior in motor-manual tree felling and processing operations. Bulletin of the Transilvania University of Braşov, Series II: Forestry-Wood Industry-Agricultural Food Engineering 11 60(2): 1–20.

Bembenek, M., Mederski, P.S., Karaszewski, Z., Łacka, A., Grzywiński, W., Węgiel, A., Giefing, D.F., Erler, J., 2015: Length accuracy of logs from birch and aspen harvested in thinning operations. Turk. J. Agric. For. 39(6): 845-850. https://doi.org/10.3906/tar-1406-39

BFMG, 2015: The National Forest Inventory. Results of cycle II (2010–2014). Bureau for Forest Management and Geodesy, State Forests National Forest Holding. Sękocin Stary, 176 p. (in Polish)

BFMG, 2018: The National Forest Inventory. Results for period 2013–2017. Bureau for Forest Management and Geodesy, State Forests National Forest Holding. Sękocin Stary, 557 p. (in Polish)

BFMG, 2019: The National Forest Inventory, Results for period 2014–2018. Bureau for Forest Management and Geodesy, State Forests National Forest Holding. Sękocin Stary, 553 p. (in Polish)

Bodył, M., 2019: Rozmiar pozyskania maszynowego w Polsce (Share of mechanised timber harvesting in Poland). Drwal 3(166): 5–9. (in Polish)

Bojanin, S., Krpan, A.P.B., 1997: Mogućnost tzv. visokoga i potpunog mehaniziranja sječe i izrade te mehaniziranja privlačenja drva u šumama Hrvatske (Possibilities for high level and complete mechanization in felling operations and mechanization in skidding in Croatian forests). Šumarski list 121(7–8): 371–381.

Borz, S.A., Birda, M., Ignea, G., Popa, B., Campu, V.R., Iordache, E., Derczeni, R.A., 2014a: Efficiency of a Woody 60 processor attached to a Mounty 4100 tower yarder when processing coniferous timber from thinning operations. Annals of Forest Research 57(2): 333–345. https://doi.org/10.15287/afr.2014.258

Borz, S.A., Dinulica, F., Birda, M., Ignea, G., Ciobanu, D.V., Popa, B., 2013: Time consumption and productivity of skidding Silver fir (Abies alba Mill.) round wood in reduced accessibility conditions: a case study in windthrow salvage logging from Romanian Carpathians. Annals of Forest Research 56(2): 363–375.

Borz, S.A., Ignea, G., Popa, B., Sparchez, G., Iordache, E., 2015: Estimating time consumption and productivity of roundwood skidding in group shelterwood system – a case study in a broad leaved mixed stand located in reduced accessibility conditions. Croatian Journal of Forest Engineering 36(1): 137–146.

Borz, S.A., Ignea, G., Vasilescu, M.M., 2014: Small gains in wood recovery rate when disobeying the recommended motor-manual tree felling procedures: another reason to use the proper technical prescriptions. Bioresources 9(4): 6938–6949.

Borz, S.A., Nita, M.D., Talagai, N., Scriba, C., Grigolato, S., Proto, A.R., 2019b: Performance of small-scale technology in planting and cutback operations of short-rotation willow crops. Transactions of the ASABE 62(1): 167–176. https://doi.org/10.13031/trans.12961

Borz, S.A., Rommel, D., Ziesak, M., Vasiliauskas, G., 2019a: Operational requirements and preferences towards forwarder technology. Bulletin of the Transilvania University of Braşov, Series II: Forestry-Wood Industry-Agricultural Food Engineering 12(1): 1–12. https://doi.org/10.31926/but.fwiafe.2019.12.61.1.1

Borz, S.A., Talagai, N., Cheta, M., Chiriloiu, D., Montoya, A.V.G., Vizuete, D.D.C., Marcu, M.V., 2019c: Physical strain, exposure to noise and postural assessment in motor-manual felling of willow short rotation coppice: results of a preliminary study. Croatian Journal of Forest Engineering 40(2): 377–388. https://doi.org/10.5552/crojfe.2019.550

Borz, S.A., Talagai, N., Cheta, M., Montoya, A.V.G., Vizuete, D.D.C., 2018: Automating data collection in motor-manual time and motion studies implemented in a willow short rotation coppice. Bioresources 13(2): 3236–3249. https://doi.org/10.15376/biores.13.2.3236-3249

Bouriaud, L., Kastenholz, E., Fodrek, L., Karaszewski, Z., Mederski, P., Rimmler, T., Rummukainen, A., Sadauskiene, L., Salka, J., Teder, M., 2011. Policy and Market-related Factors for Innovation in Forest Operation Enterprises. W: Weiss, G., Pettenella, D., Ollonqvist, P., Slee, B. (Red.), Innovation in Forestry. CABI, Oxfordshire, 276–293. https://doi.org/10.1079/9781845936891.0276

Bredemeier, M., 2011a: Forest management and the water cycle – Introduction to the challenge. In: Bredemeier, M., Cohen, S., Goldbold, D.L., Lode, E., Pichler, V., Schleppi, P. (Eds.), Forest Management and the Water Cycle, An EcosystemBased Approach. Springer, Heidelberg, 9–15.

Bredemeier, M., 2011b: Forest, climate and water issues in Europe. Ecohydrology 4(2): 159–167. https://doi.org/10.1002/eco.203

CSO, 2005: Forestry. Central Statistical Office, Warszawa, 260 p.

CSO, 2009: Forestry. Central Statistical Office, Warszawa, 287 p.

CSO, 2015: Forestry. Central Statistical Office, Warszawa, 325 p.

Cheta, M., Marcu, M.V., Borz, S.A., 2018: Workload, exposure to noise and risk of musculoskeletal disorders: a case study of motor-manual tree felling and processing. Forests 9(6): 300. https://doi.org/10.3390/f9060300

Christopher, L., 2012: Adding value prior to pulping: bioproducts from hemicellulose. In Global perspectives on sustainable forest management. IntechOpen, ed. C.L.Okia, Rijeka, Croatia, ISBN 978-95351-0569-5, 225–246 p.

Ćosić, B., Stanić, Z., Duić, N., 2011: Geographic distribution of economic potential of agricultural and forest biomass residual for energy use: case study Croatia. Energy 36(4): 2017–2028. https://doi.org/10.1016/j.energy.2010.10.009

Csóka, G., Hirka, A., Mutun, S., Glavendekić, M., Mikó, A., Szöcs, L., Paulin, M., Eötvös, C.B., Gáspár, C., Csepelényi, M., Szénási, A., Franjević, M., Gninenko, Y., Dautbašić, M., Mujezinović, O., Zubrik, M., Netoiu, C., Buzatu, A., Bălăcenoiu, F., Jurc, M., Jurc, D., Bernardinelli, I., Streito, J.-C., Avtzis, D., Hrašovec, B., 2019: Spread and potential host range of the invasive oak lace bug [Corythucha arcuata (Say, 1832) – Heteroptera: Tingidae] in Eurasia. Agricultural and Forest Entomology 22(1): 61–74. https://doi.org/10.1111/afe.12362

Đuka, A., Grigolato, S., Papa, I., Pentek, T., Poršinsky, T., 2017: Assessment of timber extraction distance and skid road network in steep karst terrain. iForest-Biogeosciences & Forestry 10(6): 886–894. https://doi.org/10.3832/ifor2471-010

Đuka, A., Poršinsky, T., Pentek, T., Pandur, Z., Janeš, D., Papa, I., 2018b: Soil Measurements in the Context of Planning Harvesting Operations and Variable Climatic Conditions. South-east European forestry 9(1): 61–71. https://doi.org/10.15177/seefor.18-04

Đuka, A., Poršinsky, T., Pentek, T., Pandur, Z., Vusić, D., Papa, I., 2018a: Mobility Range of a Cable Skidder for Timber Extraction on Sloped Terrain. Forests 9(9): 526. https://doi.org:10.3390/f9090526

Đuka, A., Poršinsky, T., Pentek, T., Sertić, M., Vusić, D., 2019: European Standard for Round and Sawn Timber (Method of Measurement of Dimensions) – Influence on Volume Losses. Proceedings of 52nd International Symposium on Forestry Mechanisation (FORMEC), Exceeding the Vision: Forest Mechanisation of the Future, Sopron/Forchtenstein, Hungary/Austria, October 6–10, 304–312.

Dzerina, B., Girdziusas, S., Lazdina, D., Lazdins, A., Jansons, J., 2016: Influence of spot mounding on height growth and tending of Norway spruce: Case study in Latvia. Forestry Studies 65(1): 24–33. https://doi.org/10.1515/fsmu-2016-0009

EEA, 2003: Digital map of European ecological regions. European Environment Agency. http://www.eea.europa.eu/data-andmaps/figures/dmeer-digital-map-of-european-regions

EEA, 2007: European forest types, Categories and types for sustainable forest management reporting and policy. EEA Technical report No. 9/2006, European Environment Agency, 111 p.

EEA, 2012: Water scarcity and drought events in Europe during the last decade, European Environment Agency. http://www.eea.europa.eu/data-and-maps/figures/main-drought-events-in-europe

Enache, A., Ciobanu, V., Pertlik, E., 2012: Approaches regarding the environmental impact assessment of forest roads with a special emphasis on the Romanian forest sector. Bulletin of the Transilvania University of Braşov, Series II: Forestry-Wood Industry-Agricultural Food Engineering 5(1): 63–72.

FAO, 2015: Global forest resources assessment 2015. Country report – Croatia, FAO, Rome, Italy, 105 p.

Fornea, M., Bîrda, M., Borz, S.A., Popa, B., Tomašić, Ž., 2018: Harvesting conditions, market particularities or just economic competition: a Romanian case study regarding the evolution of standing timber contracting rates. Šumarski list 142(9–10): 499–508. https://doi.org/10.31298/sl.142.9-10.5

Franjević, M., Šikić, Z., Hrašovec, B., 2019: First occurrence of Xylosandrus germanus (Blandford, 1894) – black steam borer in pheromone baited panel traps and population build up in Croatian oak stands. Šumarski list 143(5–6): 215–219. https://doi.org/10.31298/sl.143.5-6.2

FSC, 2013: FSC National Standard of Forest Management in Poland, 2013: Forest Stewardship Council, A.C., Bonn, 80 p.

GDSF, 2018: Sprawozdanie finansowo-gospodarcze za 2018 rok (Financial report for 2018), General Directorate of the State Forests, Warszawa, 4p3. (in Polish)

Hughes, F.M.R., 2003: The flooded forest: Guidance for policy makers and river managers in Europe on the restoration of floodplain forests. UK: FLOBAR2, Department of Geography, University of Cambridge, UK, 96 p.

Iordache, E., Nita, M.D., Clinciu, I., 2012: Planning forest accessibility with a low ecological impact. Croatian Journal of Forest Engineering 33(1): 143–148.

Karaszewski, Z., Łacka, A., Bembenek, M., Mederski, P.S., 2016: Wood damage and value loss of alder plywood harvested by Valmet 911.4 harvester with a 360.2 head. Sylwan 160(12): 1002–1009. https://doi.org/10.26202/sylwan.2016060

Karaszewski, Z., Łacka, A., Mederski, P.S., Bembenek, M., 2018: Impact of season and harvester engine RPM on pine wood damage from feed roller spikes. Croatian Journal of Forest Engineering 39(2): 183–191.

Karaszewski, Z., Łacka, A., Mederski, P.S., Noskowiak, A., Bembenek, M., 2016: Damage caused by harvester head feed rollers to alder, pine and spruce. Drewno 59(197): 77–88. https://doi.org/10.12841/wood.1644-3985.C36.08

Kļaviņš, I., Bārdule, A., Lībiete, Z., Lazdiņa, D., Lazdiņš, A., 2019: Impact of biomass harvesting on nitrogen concentration in the soil solution in hemiboreal woody ecosystems. Silva Fennica 53(4): 1–25. https://doi.org/10/ggcfwr

Kranjec, J., Poršinsky, T., 2011: Povijest razvoja motorne pile lančanice (History of chainsaw development). Nova meh. šumar. 32(1): 23–37.

Krasavcevs, I., 2018: Meža references līmeņa aprēķinu atbalsta datu sagatavošana. Draft No. 2018-04–1, 32 p. https://drive.google.com/open?id=1MoyOyRGEx8DFpU-ITX61qe4YiysYNDPT

Krpan, A.P.B., 1992: Iskorišćivanje šuma. Monography Šume u Hrvatskoj, Faculty of Forestry University of Zagreb and Hrvatske šume Ltd., 153–170.

Lajić, I., Klempić Bogadi, S., 2010: Demografska budućnost Gorskoga kotara (Demographic Future of Gorski Kotar). Migracijske i etničke teme 26(2): 191–212.

Landekić, M., Martinić, I., Bakarić, M., Pentek, T., Poršinsky, T., Šporčić, M., 2018: Current State and Improvement Potential of Forestry Workers Training in Croatia. Croatian Journal of Forest Engineering 39(2): 289–298.

Lazdiņa, D., Lazdiņš, A., Zimelis, A., 2012: Comparison of Productivity of soil scarification with conventional excavator bucket and mounder MPV-600. Mežzinātne. Special Issue. Abstracts for International Conferences Organized by LSFRI Silava in Cooperation with SNS and IUFRO 25(58): 131–134. Riga: LSFRI Silava.

Lazdiņa, D., Liepiņš, K., Lazdiņš, A., Bebre, I., 2017: Research activities of planting and sowing mechanization in Latvia. Proceedings from Joint Seminar Arranged by NB – NORD and NOFOBE, 43 p. http://www.metsateho.fi/wp-content/uploads/Proceedings-2017.pdf

Lazdiņš, A., Petaja, G., 2016: Classification of forwarding conditions in Latvia, 7 p. https://www.researchgate.net/publication/338213750_Classification_of_forwarding_conditions_in_Latvia

Lazdiņš, A., Von Hofsten, H., 2009: Technical and environmental issues of stump harvesting for biofuel production in Latvia. Annual 15th International Scientific Conference Proceedings, Jelgava, 155–162.

Lazdiņš, A., Lazdiņa, D., Liepa, I., 2010: Characterization of naturally afforested farmlands in Latvia. Annual 16th International Scientific Conference Proceedings, Jelgava, 176–183.

Lazdiņš, A., Lupiķis, A., Butlers, A., Bārdule, A., Kārkliņa, I., Šņepsts, G., Donis, J., 2019: Latvia’s national forestry accounting plan and proposed forest reference level 2021–2025, 200 p. https://www.researchgate.net/publication/338187883_Latvia's_national_forestry_accounting_plan_and_proposed_forest_reference_level_2021-2025

Lazdiņš, A., Prindulis, U., Kalēja, S., Daugaviete, M., Zimelis, A., 2016: Productivity of Vimek 404 T5 harvester and Vimek 610 forwarder in early thinning. Agronomy Research 14(2): 475–484.

Lazdiņš, A., Zimelis, A., 2012: Productivity of stump lifting head MCR-500. Mežzinātne. Special Issue. Abstracts for International Conferences Organized by LSFRI Silava in Cooperation with SNS and IUFRO, Riga: LSFRI Silava 25(58): 42–45.

Lazdiņš, A., Zimelis, A., Gusarevs, I., 2012: Preliminary data on productivity of stump lifting head MCR-500. Proceedings of the International Scientific Conference, Jelgava, 150–155.

Lorenţ, A., Neagu, Ş., Petrila, M., Apostol, B., Gancz, V., Mitsopoulos, I., Mallinis, G., 2018: Evaluarea hazardului la incendii de pădure la nivel de unitate administrativ-teritorială în perioada 2006–2015. Revista Pădurilor 133(4): 53–74.

Makovskis, K., Lazdiņa, D., 2014: Environmental impacts of mounding method in forest site preparation. Proceedings of the Nordic Baltic Conference OSCAR, Knivsta, Sweden, 38–40 p.

Malai, M., Talpă, N., Popa, B., 2019: Evaluarea comparativă a Agenției Moldsilva și a Regiei Naționale a Pădurilor – Romsilva în baza unui model de analiză instituțională (Comparative Evaluation of Moldsilva Agency and National Forest Administration – Romsilva Based on an Institutional Analysis Model). Revista Pădurilor 134(4): 15–28.

Marchi, E., Chung, W., Visser, R., Abbas, D., Nordfjell, T., Mederski, P.S., McEwan, A., Brink, M., Laschi, A., 2018: Sustainable Forest Operations (SFO): A new paradigm in a changing world and climate. Science of the Total Environment 634: 1385–1397. https://doi.org/10.1016/j.scitotenv.2018.04.084

Marogel-Popa, T., Cheta, M., Marcu, M.V., Duta, C.I., Ioras, F., Borz, S.A., 2019: Manual cultivation operations in poplar stands: a characterization of job difficulty and risks of health impairment. International Journal of Environmental Research and Public Health 16(11): 1911. https://doi.org/10.3390/ijerph16111911

Mederski, P.S., Jakubowski, M., Karaszewski, Z., 2009: The Polish landscape changing due to forest policy and forest management. iForest 2: 140–142. https://doi.org/10.3832/ifor0503-002

Mederski, P.S., Karaszewski, Z., Rosińska, M., Bembenek, M., 2016a: Dynamics of harvester fleet change in Poland and factors determining machine occurrence. Sylwan 160(10): 795–804. https://doi.org/10.26202/sylwan.2016030

Mederski, P.S, Bembenek, M., Karaszewski, Z., Łacka, A., Szczepańska-Álvarez, A., Rosińska, M., 2016b: Estimating and modelling harvester productivity in pine stands of different ages, densities and thinning intensities. Croatian Journal of Forest Engineering 37(1): 27–36.

Mederski, P.S., Bembenek, M., Karaszewski, Z., Rosińska, M., Pilarek, Z., Łacka, A., 2018b: Investigation of Log Length Accuracy and Harvester Efficiency in Processing of Oak Trees. Croatian Journal of Forest Engineering 39(2): 173–181.