Pavement Engineering for Forest Roads: Development and Opportunities

doi: 10.5552/crojfe.2021.860

volume: 42, issue:

pp: 17

- Author(s):

-

- Heinimann Hans Rudolf

- Article category:

- Subject review

- Keywords:

- forest roads, pavement design, pavement systems

Abstract

HTML

Pavement is an essential component of roads as it carries the traffic and provides the required riding comfort. Considering that numerous forest roads are approaching their end of life, the critical issue is identifying the best rational pavement design methods to reengineer existing and build new pavement structures. The purpose of this contribution was (1) to review the big development lines of pavement systems, (2) to have a critical look at the pavement engineering framework, and (3) to bring selected empirical design equations into a comparable scheme. The study resulted in the following significant findings. First, the Trésaguet and McAdam pavement systems represented the state of the art from the beginning of a formal forest road engineering discipline at the beginning of the 19th century and remained for almost 150 years. Second, the emergence of soil mechanics as a scientific discipline in the 1920s resulted in the optimal grading of aggregates and improvement of soils and aggregates with binders, such as lime, cement, and bitumen. Third, the rational pavement design consists of five essential components: (1) bearing resistance of the subsoil, (2) bearing resistance of the pavement structure, (3) lifecycle traffic volume, (4) uncertainties that amplify deterioration, and (5) the limit state criterion, defining thresholds, above which structural safety and serviceability are no longer met. Fourth, rational, formal pavement design approaches used for forest roads were »downsized« from methodologies developed for high-volume roads, among which the approaches of the American Association of State Highway and Transportation Officials (AASHTO) and US Army Corps of Engineers (USACE) are of primary interest. Fifth, the conversion of the AASHTO '93 and USACE '70 methods into the SI system indicated that both equations are sensitive to soil bearing resistance, measured in California Bearing Ratio (CBR). However, there is a lack of validation for the AASHTO and USACE equations for forest road conditions. Consequently, a factorial observational study to gain a basis for validation should be developed and implemented. Additionally, the conversion of simple soil bearing resistance measures, such as CBR, into the resilient modulus will be improved.

Pavement Engineering for Forest Roads: Development and Opportunities

Hans Rudolf Heinimann

Abstract

Pavement is an essential component of roads as it carries the traffic and provides the required riding comfort. Considering that numerous forest roads are approaching their end of life, the critical issue is identifying the best rational pavement design methods to reengineer existing and build new pavement structures. The purpose of this contribution was (1) to review the big development lines of pavement systems, (2) to have a critical look at the pavement engineering framework, and (3) to bring selected empirical design equations into a comparable scheme. The study resulted in the following significant findings. First, the Trésaguet and McAdam pavement systems represented the state of the art from the beginning of a formal forest road engineering discipline at the beginning of the 19th century and remained for almost 150 years. Second, the emergence of soil mechanics as a scientific discipline in the 1920s resulted in the optimal grading of aggregates and improvement of soils and aggregates with binders, such as lime, cement, and bitumen. Third, the rational pavement design consists of five essential components: (1) bearing resistance of the subsoil, (2) bearing resistance of the pavement structure, (3) lifecycle traffic volume, (4) uncertainties that amplify deterioration, and (5) the limit state criterion, defining thresholds, above which structural safety and serviceability are no longer met. Fourth, rational, formal pavement design approaches used for forest roads were »downsized« from methodologies developed for high-volume roads, among which the approaches of the American Association of State Highway and Transportation Officials (AASHTO) and US Army Corps of Engineers (USACE) are of primary interest. Fifth, the conversion of the AASHTO '93 and USACE '70 methods into the SI system indicated that both equations are sensitive to soil bearing resistance, measured in California Bearing Ratio (CBR). However, there is a lack of validation for the AASHTO and USACE equations for forest road conditions. Consequently, a factorial observational study to gain a basis for validation should be developed and implemented. Additionally, the conversion of simple soil bearing resistance measures, such as CBR, into the resilient modulus will be improved.

Keywords: forest roads, pavement design, pavement systems

1. Introduction

Road networks are an essential part of our critical infrastructure systems, which provide essential services to move goods and people between origins and destinations. In the classification of roads, the traffic volume is generally used as an indicator, thus defining a spectrum from »high-volume« to »low-volume« roads. A former chairman of the Committee on Low-Volume Roads (Coghlan 2000) estimated that low-volume roads carry only about 20% of the overall traffic.

Contrarily, they include about 80% of the total length. Low-volume roads have several definitions, including that of the American Association of State Highway and Transportation Officials (AASHTO), which refers to a traffic volume from 10000 to 100,000 equivalent single axle loads (ESALs) over a road lifecycle (AASHTO 1993). Assuming that about 50% of low-volume roads are urban, rural, and forest roads have a share in the overall road network length of about one third, which is incredible, considering that the relative value added flowing over this network is quite low. Forest road networks were designed for trucks after World War II, which means that many of the roads in use passed a lifespan of about 40 to 70 years. We are facing the challenge of reengineering and upgrading road networks, which is a different problem from developing road networks from scratch. The pavement is a crucial component of roads and is one of the core components of the rehabilitation/upgrade work. The pavements of forest roads were built with rules of thumb that usually emerged in local contexts. To our knowledge, there is no unifying pavement design approach for forest roads, which aims to carry the road traffic without unexpected degradation while minimizing construction and maintenance cost. An exception is the US Forest Service (Yapp et al. 1991), which evaluated and further developed methods for the structural design of aggregate-surfaced roads.

Here, we have taken up the forest pavement engineering challenge to:

Þ review the big development lines of pavement systems

Þ have a critical look at the pavement engineering framework, in particular the pavement design parameters

Þ bring selected empirical design equations into a comparable scheme.

The present contribution first discusses the basic concepts, based on which pavement engineering systems are built. It then looks at legacy pavement systems that can still be found in our environment and that has also been used for forest roads. After that, it analyzes empirical design approaches to pavement systems with an emphasis on the design framework and procedures for aggregate-surfaced low-volume roads.

2. Basic Concepts

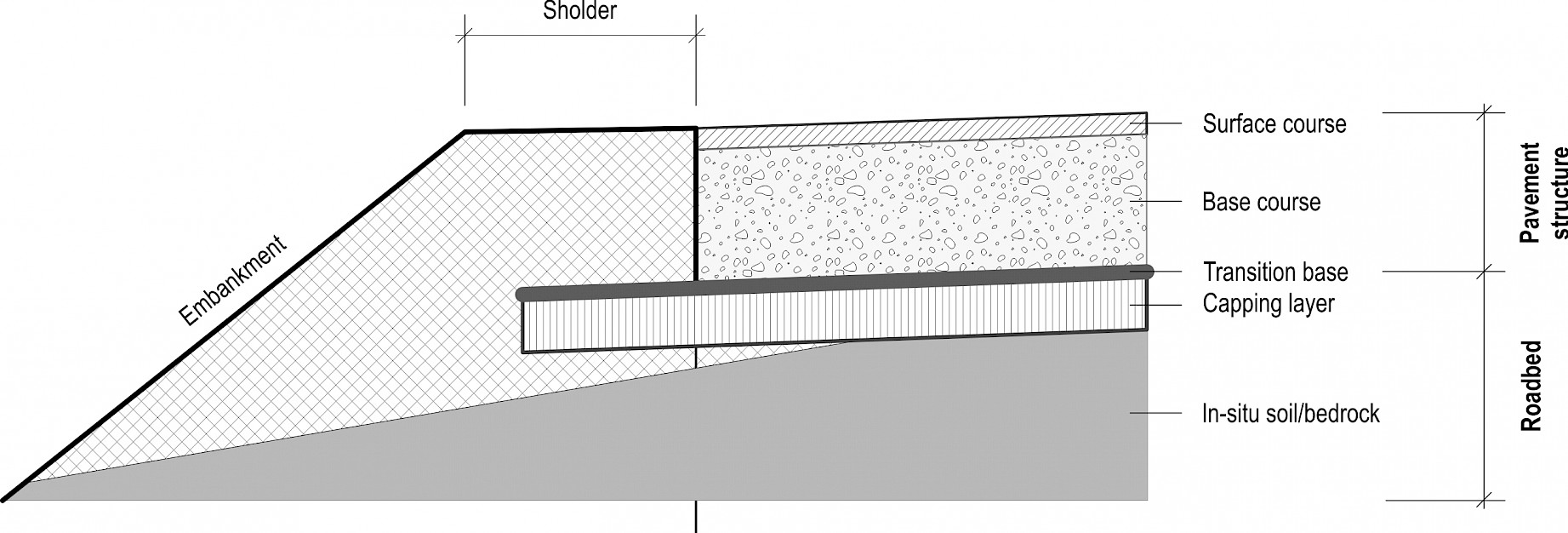

A road consists of an embankment built of local granular materials; it carries the pavement structure, which consists of several layers of geotechnical materials. Here, we introduce a conceptual model of the embankment and pavement structures (Fig. 1) and the corresponding terminology.

Fig. 1 presents an idealized structure of a road embankment and pavement, which undergoes modifications for practical implementations. Forest roads often have a minimalistic structure, consisting of one layer (base course) or two layers (base course, surface/wearing course) only. In most cases, forest roads have surface (wearing) courses built of unbound aggregate material. In those cases, the term »aggregate-surfaced roads« has been used, and a whole body of literature addresses this specific type of roads. Forest roads are additionally a subset of »low-volume roads« (LVR), which are characterized, as mentioned before, by a lifecycle traffic volume from 10000 to 100,000 ESALs. Recognizing that LVR have requirements that are different from high-volume facilities, a low-volume road community emerged in the 1970s that has been active up to now (Trb 1975). Experts concluded that the design standards for high-volume roads were neither economical nor feasible for LVR. Additionally, LVR faced severe economic or financial constraints (Oglesby 1975), which called for specific pavement design approaches that guided our thoughts.

Fig. 1 Typical elements of an embankment and a pavement structure. For forest roads, the capping layers and transition bases have been used on low-bearing capacity ground where a stabilization of the subsoil reduces the thickness of the base layer and cost

Our conceptual model (Fig. 1) goes along with a set of technical terms that we will define below. We follow the terminology of AASHTO (1993) and Chou (1989) and have adapted the definitions to make the whole system coherent where necessary.

Embankment: an artificial body built from in situ soil or bedrock that fulfills horizontal, vertical, and cross-sectional geometrical design requirements to carry the pavement structure.

Pavement: the engineered geotechnical structure founded on an embankment, which aims to support traffic loads, to provide the required riding comfort, and to withstand the actions of water, such as precipitation, surface runoff, subsurface flow, and frost.

Roadbed: the graded portion of a road embankment between the side slopes, prepared as a foundation for the pavement structure and the shoulders.

Capping layer: a layer of in situ soil, the mechanical properties of which are improved with lime, cement, or other binding agents.

Transition base: a thin layer, often consisting of a geotextile, to separate the subgrade soil from the base course, and of dissipating excess pore water pressure in the subgrade. Separating means preventing the migration of fines from the subgrade into the base course and/or penetration of aggregate into the subgrade. Geotextiles additionally have the capability of reinforcing the pavement structure.

Base course: the layer or layers of unbound and/or bound aggregate materials, which aim to resist the traffic load over a road lifecycle and transfer the stresses into the subgrade in such a way that deformations remain within acceptable limits.

Surface course: the top layer of the pavement, building the direct interface to wheeled vehicles, which aims to (1) provide traction resistance, (2) resist traffic abrasion, (3) resist disintegration due to climate effects, and (4) improve the riding comfort of vehicles.

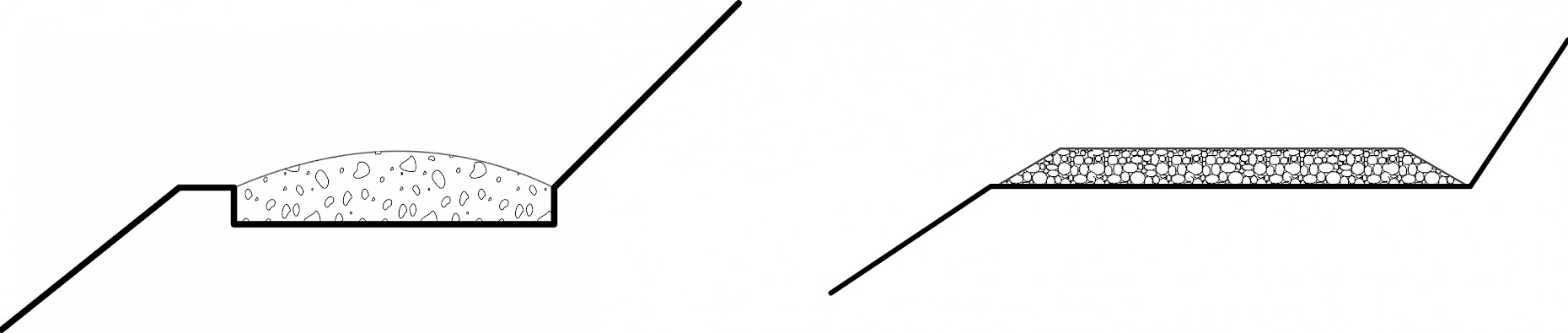

The design of the interface between the roadbed and the pavement structures is an essential feature of the pavement cross-section design. Fig. 2 presents the two basic types that are important for LVR: trench type (Fig. 2, left) and trapezoid type (Fig. 2, right). The trench-type design had its origin in the 18th century (Trésaguet 1831 (1775)), when the first modern-time pavement designs emerged.

Fig. 2 Types of Pavement Cross Section. Trench-type (left) designs were popular as long as the base layer material had to be put by hand, whereas trapezoid-type (right) designs were a result of mechanization. A cambered or crowned leveling layer can be added to the trapezoid-type design to improve surface drainage

The guiding idea was to build a trench with two sidewalls that function as a container to accommodate the base course material. The primary purpose was to minimize the volume of the base course material and prevent it from spreading during the compaction process (Agg 1940). The mechanization of earthwork after World War II resulted in the emergence of the trapezoid-type (also called »feather-edge«) design, for which the interface between the roadbed and the pavement structure became a straight line, or a cambered line, respectively. Whereas the trench-type roadbed between the side slopes geometrically consists of four planes, the trapezoid-type roadbed consists of one single plane only, which can be easily shaped by construction machinery, such as graders. One disadvantage of the trapezoid-type design is the increase in base layer material. Although the overall advantage of the trapezoid-design seems evident, we can still find trench-type designs among the current practices.

3. Legacy Pavement Systems

Roads are structures that have been used for decennia, or even longer. Pavement engineering has a history of more than 2000 years, and legacy pavement systems can still be found in our environment, whereas what we call »modern pavement engineering« only emerged in the 1950s. Therefore, we will discuss the historical, non-engineered pavement structures below before moving to modern pavement engineering.

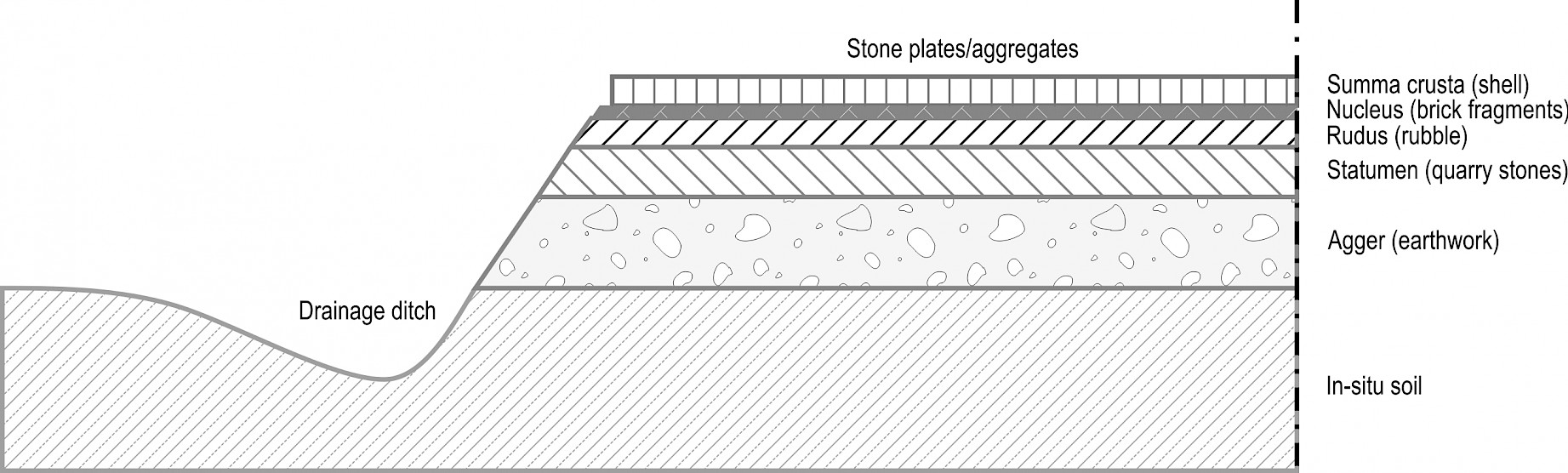

3.1 Roman Pavement Systems

The Roman pavement system (Fig. 3) represents the state of the art between about 500 BC and 1880 AD. We inherited technical concepts that are still the basis of modern pavement engineering. First, it made the pavement structure resistant to the actions of water through systematic drainage and by binding the granular base course material with lime–pozzolana mortars (Massazza 1998), which made the pavement »waterproof« (Berechman 2003). Second, it introduced a systematic layered structure, consisting of bound aggregates, the maximum grain size of which decreases from the roadbed to the surface. Unfortunately, there is only limited written information left from the Romans directly, but there is a consistent view of how a Roman pavement scheme looked like (Bekker‐Nielsen 2013).

Fig. 3 Scheme of a Roman Pavement System. It consists of four layers: (1) the lower base course of quarry stones, (2) the medium base course of crushed rock, (3) the upper base course of brick fragments or gravel, and (4) the surface layer of stone plates or rammed gravel. The base layers were bound with lime–pozzolana mortar

Roman road construction started with the excavation of ditches, whose material was used to build the road embankment (agger; see Fig. 3), providing the graded roadbed structure to carry the pavement (Bekker‐Nielsen 2013). A base course was laid on the roadbed, which consisted of three layers. The lower layer (statumen) was built of quarry stones that were cut-fit and placed by masons (Berechman 2003). The medium layer (rudus) consisted of crushed rock, which is a coarse aggregate (EN13242 2007), also known as ballast, whereas the upper layer (nucleus) was built of brick fragments or gravel. The three layers were bound with lime–pozzolana mortars that harden due to the pozzolanic reaction (Massazza 1998), thus creating concrete-type materials, in particular in the medium (rudus) and upper (nucleus) layers. Finally, the surface course (summa crusta) was built from polygonal stone plates or rammed gravel (Bekker‐Nielsen 2013). Romans flexibly adapted the standard scheme to local conditions. Overall, Roman pavements usually had a pavement thickness of about 1 m, indicating the enormous volume of building material and construction effort required to build roads.

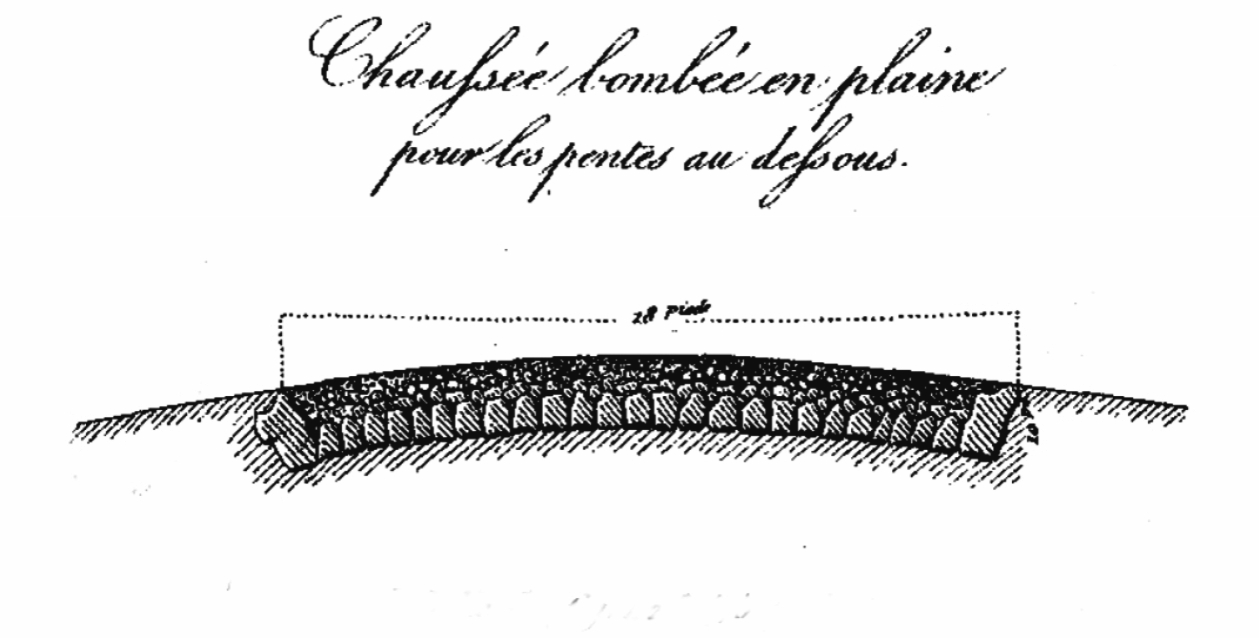

3.2 Trésaguet‘s Pavement System

In the 17th century, Colbert – a minister under King Louis XV of France – developed and implemented fundamentally new economic policies that required, among others, the development of a French national road network. He was convinced that scientific thinking was important for this fundamental change. He initiated the foundation of the French Academy of Sciences (1666) and the French Bridge and Highway Corps (Corps des Ingénieurs des Ponts et Chaussées) in 1716, out of which the National School of Bridges and Highways (École Nationale des Ponts et Chaussées) grew in 1747. Pierre-Marie-Jérôme Trésaguet was an engineer of this Corps, and he followed scientific principles to develop a new pavement structure (Trésaguet 1831 (1775)). The fundamental problem was how to build a physically effective pavement structure at a minimum cost. Roman pavements were physically highly effective but were far from optimal from the cost point of view.

Fig. 4 Trésaguet's Pavement Scheme. It consists of three layers: (1) a base layer of quarry stones with a hedgehog surface, (2) a transition layer of stone fragments to smooth the hedgehog surface, and (3) a surface layer of broken, nut-sized stones

Fig. 4 – Trésaguet’s original scheme – illustrates the elements of the new French pavement structure. Trésaguet concluded that a cambered surface (Fig. 4) of the pavement would increase the resistance of pavements to precipitation and surface flow. Contrarily, the gradient perpendicular to the road axis should not exceed 3% to 5%. The construction of a cambered roadbed surface that is parallel to the pavement surface is a strategy to minimize the pavement material volume. Trésaguet proposed a base course consisting of quarry stones, which had to be set by hand in such a way that the pointed end was facing upwards. The surface of this quarry stone layer, which had a thickness of 15 to 20 cm, looked like a hedgehog. Surplus stone fragments were broken and used to fill the hedgehog surface, making it smooth and compact, which was somewhat of an upper base course layer. Finally, the surface course consisted of broken stones that had the size of nuts. Trésaguet observed that traffic that, at that time, consisted of horse carriages with iron bands chopped broken rocks at the pavement surface, and the resulting rock flour acted as a binding agent that transformed the unbound into a self-bound surface course. The overall thickness of the Trésaguet pavement structure was about 25 cm. This pavement structure became a standard for forest roads, which is documented in textbooks, such as Jägerschmid (1827) and Stoetzer (1877, 1903), and was used up to the 1950s when mechanization of forest road construction work started to prevail (Hafner 1956).

3.3 McAdam’s Pavement System

John Loudon McAdam developed an improved pavement system about 30 years after Trésaguet. The camber shape and the thickness were more or less the same as Tésaguet’s system, but he came up with a new concept for pavement materials (Fig. 5).

Fig. 5 McAdam’s Pavement Scheme. It consists of two layers: a compacted base course of crushed stones with a uniform particle size of about 5 cm and a surface course of stone chips with an equal particle size of about 2.5 cm

Seeing that bad road conditions were mainly the result of unsuitable materials, he proposed to build the base layer of crushed stone using a uniform size of the particles of about 5 cm (Mcadam 1824). This coarse aggregate, which is similar to railway ballast but with smaller particle size, will spread on the compacted roadbed and will then be compacted as well. A surface course layer consists of stone chips with a particle size of about 2.5 cm. Similar to Trésaguet’s observation, the iron bands of the horse carriages chopped the stones, and the resulting stone flour acted as a binding agent, thus creating a bound, quite smooth surface. Later, the chopping process on the surface course was replaced with a sluicing process that fills the gaps between the surface stones with a mixture of stone dust and water, thus actively binding the surface layer. This modified procedure was known as »water-bound macadam.« McAdam’s pavement became widely used and even more became the »McAdam« brand. The most significant advantage was that all the pavement materials could be spread and that manual setting of quarry stones was no longer needed. This approach somewhat paved the way for the mechanization of road construction that started in the United States. The integrity of the surface depends on the cementing properties of the stone dust used. However, it usually does not hold together under self-propelled vehicle traffic (Agg 1940) due to the abrasion effect of driven wheels and the partial vacuum effect under fast-moving vehicles. In 1940, Agg concluded that the macadam system has little place within modern pavement systems (Agg 1940).

4. Design Approaches for Pavement Systems

4.1 Emergence of Modern Pavement Engineering

Modern pavement engineering emerged in the aftermath of World War I, mainly driven by the following trends:

Þ rise of motorized road traffic

Þ mechanization of earthwork

Þ establishment of soil mechanics as a scientific discipline

Þ development of a scientific road pavement community.

Until World War I, horse-drawn vehicles were the dominant form of road transport, with a vehicle mass of about 2 tons and an axle load of about 10 kN. The spread of cars and trucks started around 1900, and the number of vehicles in the United States reached about 10 million by 1925. Contrarily, the number of horses began to drop around 1910, decreasing to nearly 1 million in 1925 (Nakicenovic 1986). Maximum axle loads and vehicle speed increased by order of magnitudes, and the new traffic regime called for new roads and new pavement requirements. Whereas US aggregate-surfaced roads had a share of about 90% in 1910, their stock decreased to about 50% in 1945. The number of roads with bound surface layers consequently increased from 10% in 1910 to 50% in 1945 (Nakicenovic 1986). In 1925, the Caterpillar Company was born, and it produced track-type tractors that were used as traction engines for different purposes. Equipped with attachments, such as blades or shovel loaders, construction machinery emerged: dozers, graders, and tracked shovel loaders. In addition, cable-operated excavators became popular. Altogether, this new set of machinery had a significant consequence: handling of bulk material was easy, whereas the manipulation of piece goods was difficult or even impossible.

Soil is a three-phase material, consisting of a mixture of solid particles, water, and air, the behavior of which mainly depends on a two-phase subsystem, the water content and density. Although soil is a granular material, it sometimes shows the behavior of a solid, and sometimes of a fluid, which is the reason why we use terms such as »fill« or »damp« for granular soil material as well. Traditional approaches from mechanics of materials were necessary but insufficient to appropriately characterize the mechanical behavior of soil. Karl von Terzaghi is the father of soil mechanics (Malyshev 1973). He detected the principle of effective stresses in the soil and developed basic concepts, such as consolidation, bearing capacity, and stability, based on it. Together with his collaborator – Arthur Casagrande – he laid the foundation for the quantitative characterization of the engineering properties of soil. In the beginning, there were two significant challenges: the development of the soil classification system and the reliable assessment of the shearing resistance of soils (Casagrande 1948). Standard methods to identify and characterize the particle-size distributions of soils and their plasticity properties were followed. At the beginning of the 1940s, a standard soil classification system was established, nowadays known as the Unified Soil Classification System (Casagrande 1932, 1934 and 1948). A thorough understanding of natural soils was the basis for the mechanical characterization of granular material to be used in pavement construction. A granular material that is mechanically stable has a minimum void ratio, which means, for example, that the recommendation of Trésaguet and McAdam to use aggregates consisting of uniform particle size was no longer valid. Another stream of development focused on the improvement of natural soils and aggregates with binding agents, in particular lime, cement, and bitumen. Overall, modern pavement engineering used materials that could be characterized by methods of soil mechanics.

The wave of automobile revolution first emerged in the United States and went along with the emergence of a road pavement research community. Since 1915, the »Purdue Road School« has been bringing scientists and practitioners together to share the latest insights and experiences. In 1936, the year of the first world Congress in soil mechanics, a progress report on modern road-building techniques emphasized that there were new developments on the insights of soil mechanics. The contribution defined the concept of stability as »methods to combine soil, aggregates and binders to provide evidence, particularly impervious material, which may be laid and compacted for use as subgrade or surface.« The contribution also emphasized that well-graded aggregates that can be compacted to the highest possible density are the most suitable materials for pavement engineering. It also discussed experiences with bitumen and lime stabilization of aggregates. World War II required the construction of substantial road networks and airfields. In November 1940, the US Army Corps of Engineers (USACE) started with the development of a pavement design method, aiming to build roads and airfields that were highly cost effective (Ahlvin 1991). This initiative released a stream of pavement design research that is still active today. Since a rational pavement design method based on stress–strain behavior of materials was beyond reality, the USACE developed a series of empirical approaches to identify the thickness of pavements.

Since the wheel loads of airplanes increased overtime by order of magnitudes, the USACE pavement design methods had to be developed continuously. Around 1950, modern pavement technologies reached a considerable level of maturity, and the body of knowledge was documented in textbooks (Agg 1940, USAES 1951, USFS 1954). Experimentation is an essential scientific approach to improve the understanding of a subject of interest. The »Bates Road Test« was the first controlled traffic test (Older 1924) that yielded essential insights into the deterioration of concrete, brick, and bituminous surfaces, resulting in the disappearance of brick surfaces. Between 1958 and 1960, the American Association of State Highway Officials (AASHO, later AASHTO) designed and conducted a large-scale experiment to understand the association between traffic and deterioration of pavements (AASHO 1961). About 1.1 million axle load cycles acted on six test sections with different pavement designs. Until today, it is still the most massive pavement experiment influencing pavement design approaches.

4.2 Pavement Design Framework

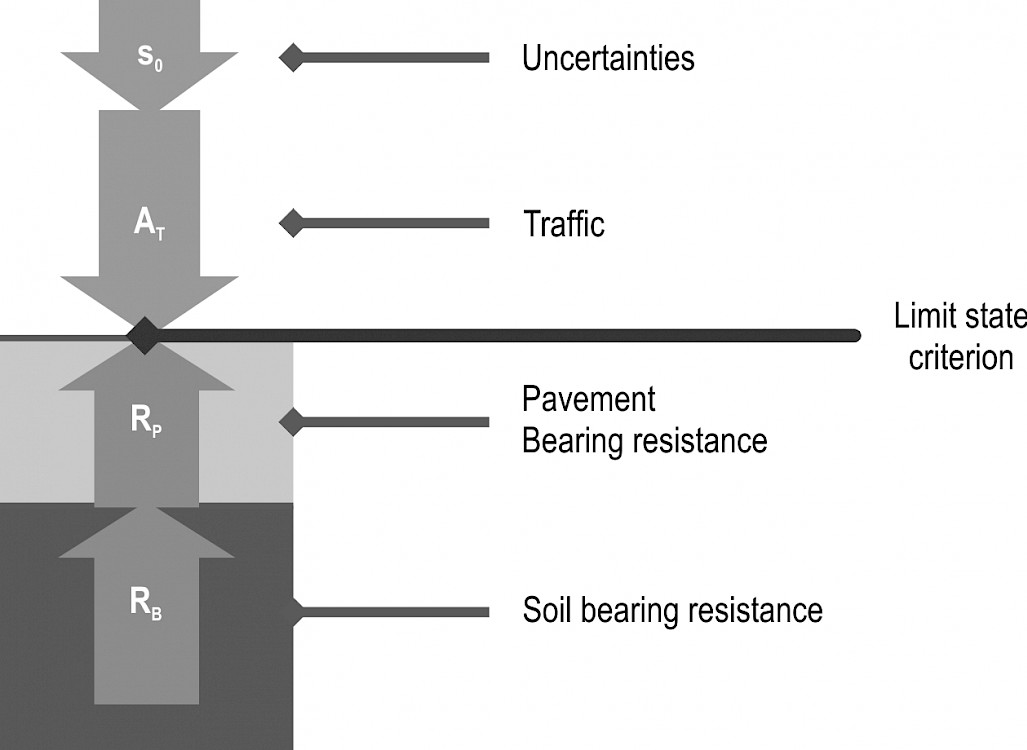

Balancing the resistance of a structure with the characteristic values of the straining actions is the guiding idea of structural design. The ultimate requirement is to make sure that the overall resistance remains higher than the action effects. The transfer of this concept to the pavement structure (Fig. 6) results in two resisting components, the bearing capacities of the soil and the pavement structure, and in two straining parts, traffic loads, and additional sources of variation. Further variation may arise through the actions of water (frost, precipitation, surface, and subsurface flows) and non-anticipated deviations of traffic loads, or insurgencies in the design values.

Fig. 6 Design components of a pavement design system

Fig. 6 illustrates how this design concept is transferred to pavement structures. Traffic load AT is the principal action, its magnitude varying significantly with time and its prediction being uncertain. Different kinds of uncertainties amplify the traffic actions, such as actions of water (frost, precipitation, surface flow, and subsurface flow), non-predictable changes of traffic patterns, or uncertainties in the prediction of pavement performance. There are two bearing reactions: the resistance of the in situ soil and the resistance of the pavement structure. Whereas the resistance of the soil is given, pavement engineers will design the bearing resistance of the pavement so that the overall resisting forces are slightly higher than the acting forces. A rational design approach additionally requires one or several limit state criteria that define a threshold state of the system, at beyond which design and/or serviceability requirements are no longer met. The design relies on two primary limit state criteria: structural safety and serviceability. Structural safety refers to physical states of the structure, which approaches the collapse of a structure. It rarely happens in a pavement system. Serviceability refers to the usefulness criteria, such as riding comfort, water tightness, durability, appearance, etc. It is the predominant design criterion for pavement structures because deformation and disintegration of the pavement occur before structural safety is at risk.

4.3 Pavement Design Parameters

A rational design approach relies on the specification of design parameters that are quantitative characteristics of a structure and respective straining actions. Below, we will discuss the defined parameters for the soil bearing resistance, pavement bearing resistance, traffic, and uncertainties (Fig. 6).

The first question is how much mechanical resistance can be mobilized by in situ soils. Engineering mechanics describe material behavior with two basic concepts: deformation resistance (stress–strain behavior) and material failure (breaking strength). Shear fracture is the critical mechanism explaining the failure of soils and is characterized by the shear strength parameters, cohesion (c) and friction angle (f) that can be determined using a triaxial test, which is quite effortful. California road engineers recognized that a much simpler test was required to obtain a good proxy measure for shear strength (Porter 1943). In 1929, he developed the California Bearing Ratio (CBR) test that was to become a success story. The plunger with a cross section of 3 in.² is penetrated 2.54 mm into the test material (1/10 inch), at which their penetration stress is related to a reference stress, resulting in a percentage value. The USACE had to develop a pavement design method for heavier loading in November 1940 (Ahlvin 1991). Recognizing that the rational process, based on limited stress–strain behaviour (shear fracture), was not feasible within the period of need, the USACE concluded to adapt and further develop the empirical California highway design method. Porter, the developer of the CBR method, and Casagrande, a leading scholar of soil mechanics, became members of the board of consultants, who aimed to guide the CBR-based pavement methodology. Porter (Porter 1943) realized that the CBR-test is a static test that might not correctly represent the dynamic, cyclic loading of moving wheels. More recently, the resilient modulus (MR) replaced the CBR metric. The resilient modulus test applies a series of cyclic, axial loadings using the triaxial test, which is used to more accurately simulate cyclic traffic loading. It is a measure of deformation resistance (stiffness) and not a metric for material strength. Since 1993, the widely used AASHTO pavement design guidelines have been using the resilient modulus metric. However, it seems that the resilient modulus is primarily used in the United States.

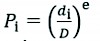

The first question is how much mechanical resistance can be mobilized by the types of aggregate materials that are used for pavement structures. At the beginning of the 20th century, scientific evidence demonstrated that the grading – the particle-size distribution – of aggregates is crucial to achieving high density, which goes along with a high bearing resistance. In a previous work (Fuller and Thompson 1907), Talbot provided a quantitative description of an ideally graded material (Talbot et al. 1923).

(1)

(1)

Where:

PI mass fraction that passed through the i-th sieve

di size of the i-th sieve, mm

D upper size of particles, represented by an upper sieve size, mm

e exponent, generally 0.45

I i-th sieve of size di.

Eq. (1) is a mathematical particle-size distribution function that takes the form of a parabola for an exponent of 0.5. Talbot’s group concluded that the optimal exponent for unbound mixtures (UBMs) is 0.45, whereas for unbound, crashed mixtures, it is 0.4.

Ideal gradation of granular mixtures is necessary but insufficient to obtain the highest possible compaction density. Proctor discovered that there is an optimal moisture content for volume-specific compaction efforts (compaction energy) that, together with the ideal gradation, results in the best possible compaction density (Proctor 1933b). His work suggested that the moisture content of a soil controls the density of a compacted soil and that higher compaction efforts reduce the optimal moisture content with an increased density. He also developed laboratory and field methods to identify the optimal water content (Proctor 1933a), based on which technical standards emerged. At present, there are two standards for the Proctor test:

Þ standard test, based on a compaction effort of 0.6 MN.m.m-3 (ASTM 2012b)

Þ modified test, based on a compaction effort of 2.7 MN.m.m-3 (ASTM 2012a).

The modified Proctor test was designed for applications, such as airfields, that are compacted with high-performance equipment. For LVR, the standard Proctor compaction test is appropriate.

Standardization refined the quality characterization of UBMs. The European standard (EN13242 2007) defines the following geometrical requirements:

d/D lower and upper particle sizes of a UBM, mm

GA85 mass fraction passing through the upper limiting sieve (oversize requirements, here 85%), which means that there is 15% oversized material

f3 mass fraction passing the 0.063 mm sieve, here 3%

C50/30 percentage of crashed or broken particles/percentage of the total of rounded particles, here 50% and 30%, respectively.

The above geometrical requirements define the four points of the particle-size distribution function: the lower bound, the upper bound, the tolerable oversize limit, and the mass fraction of fines. Table 1 presents three examples of UBMs, ordered along a gradient of increasing quality requirements. The first example, an unbound, non-standardized mixture, has no requirements for the mass fraction of fines and the percentage of crushed or broken particles. Such material is usually taken on-site, having the quality of »bank gravel«. The introduction of a fine requirement (fine mass fraction < 12%, f12) resulted in better overall grading and in a decrease of frost susceptibility. Casagrande concluded that soils with a mass fraction of less than 3% at a sieve size of 0.02 mm are not susceptible to frost (Casagrande 1931). He proposed a relaxed version of this rule: soils with a mass fraction of less than 10% at a sieve size of 0.02 mm for well-graded aggregates. A further increase in the bearing resistance can be achieved by introducing a constraint on the minimum proportion of crushed or broken particles (Table 1, row 3). The AASHTO pavement design philosophy introduced a bearing resistance coefficient (layer coefficient, a) for different kinds of pavement materials (AASHO 1961); the typical values of these materials are presented in Table 1. Whereas bank gravel has a value of 0.07, the UBM with a constraint shows an increase in bearing resistance of about 60%. Finally, after introducing a crashed/broken particle constraint, the bearing resistance increases by nearly 100%. These simple figures indicate that well-graded UBMs with a high share of crushed particles can reduce material consumption by about 50% and that even in areas where forest roads were built on traditional rules of thumb, the purposeful use of unbound aggregate mixture has a considerable potential.

Table 1 Unbound aggregate materials and bound mixtures for pavement construction, including their bearing resistance (AASHTO layer coefficients, CBR values, and ACE equivalency factors[1]). Characterization of unbound aggregates following EN 14232: limiting, lower, and upper particle sizes, d/D; oversize part, GAxx; maximum value of fines content, fxx; percentage of crushed or broken particles, Cxx. UBM, unbound mixtures; HBM, hydraulic bound mixtures

|

Specification |

AASHTO layer coefficient a |

CBR % |

ACE equivalency factors |

Other designations |

|

|

Unbound mixtures UBM N13242 |

Unbound mixture, non-standardized UBM 0/63, GA85 (89 mm), CNR/70, fNR |

0.07 |

20 |

– |

Bank gravel |

|

Unbound mixture UBM 0/45, GA85 (63 mm), CNR/70, f12 |

0.11 |

45 |

1.0 |

Sand–gravel, standard quality |

|

|

Unbound mixture UBM 0/45, GA85 (63 mm), C90/3, f3 |

0.14 |

100 |

1.4 |

Crushed sand–gravel, high quality |

|

|

Hydraulic bound mixtures HBM EN14227 |

Lime bound mixtures HBM (capping layer) |

0.15 |

105 |

1.15 |

– |

|

Cement-improved granular mixtures HBM (main course, mixed in place process) |

0.2 |

– |

1.6 |

– |

|

|

Cement-bound granular mixtures HBM (main course, mixed in plant process) |

0.3 |

– |

– |

– |

Modern pavement engineering developed methods to bind pavements and capping layers (Fig. 1) using hydraulic or bituminous binders, with the aim of improving the bearing and erosive and abrasive resistance of the pavement structure. As an example, Table 1 shows three types of hydraulic bound mixtures (HBM) in rows 4 to 6. The stabilization of the roadbed soil with lime resulted in a capping layer that had an improved bearing resistance, which is in the same order of magnitude as the bearing resistance of well-graded aggregates with a high share in crushed particles. Processing granular mixtures on-site with cement and water results in a cement-improved bound mixtures with a bearing resistance of about three times that of gravel (Table 1). Off-site processing of UBMs with cement and water results in high-quality cement-bound granular mixtures with a bearing resistance about four times higher than that of bound, non-standardized mixtures. There are excellent references for soil treatment and stabilization (Winterkorn and Pamukcu 1975), as well as standards for binder-bound granular mixtures (CEN 2015). However, a more detailed description would go beyond the scope of the present contribution.

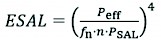

The third question is how to find a meaningful metric that characterizes the traffic volume acting on the pavement over the whole lifecycle. There is a considerable variety of vehicle configurations with a variation of vehicle-specific load profiles. A significant result from the AASHO road test (AASHO 1962) was the so-called Fourth Power Law, which indicates that the damage caused by the axle to the road pavement is increasing with the fourth power of the axle load. This means, for example, that doubling the axle load will increase the damage by a factor of 16 compared with the reference load.

(2)

(2)

Where:

ESAL equivalent single axle loads

Peff effective axle load, kN

PSAL standard axle load, 80 kN

n axle group, consisting of n axles

fn axle group factor [f1 = 1.0, f2 = 0.92, f3 = 0.88]i

Eq. (2) presents this relationship for single, tandem, and tridem axle configurations, whereas the axle group factor decreases with the number of axles arranged per group. Eq. (2) allows the conversion of the expected axle load profiles to one standard metric, called »equivalent single axle loads« by the AASHTO (ESAL), corresponding to an 80 kN load (AASHO 1962). One would expect that a tridem axle configuration, with each of the three axles loaded to a standard axle load (80 kN), would have a damaging effect on the three single axles. Eq. (2) suggested that a tandem axle configuration reduces the detrimental impact by about 30% and tridem axles by about 45%. This is the main reason why tridem axle configurations are so popular.

The fourth question is how to consider uncertainties and risks of failure. Since a significant number of pavement design approaches are empirical, being based on statistical relationships, only a few approaches explicitly consider uncertainties and risks. The AASHTO pavement design approach introduced a »regional factor R« to consider local environmental and other considerations. In 1993, it introduced a reliability factor, representing two types of uncertainties (AASHTO 1993), traffic projections and pavement performance predictions, which offer engineers the possibility to consider uncertainties based on a probabilistic approach.

4.4 Design Approaches for LVR

Almost 70 years have passed since the USACE developed the first pavement design methods, and we are now facing a whole set of pavement design approaches, which cover the entire range from empirical to purely analytical. Here, we focus on the approaches that have been used for LVR with »aggregate-surfaced« or »thin-surfaced« pavements. Aggregate-surfaced roads consist of unbound aggregate material as the surface course (Chou 1989). Contrarily, thin-surfaced roads include unbound base courses, covered by the surface course consisting of a bituminous surface treatment or a thin layer of asphalt concrete (Geoffroy 1998). The US Forest Service (Yapp et al. 1991) reviewed nine design methods that were used for aggregate-surfaced roads, whereas the USACE (Chou 1989) did the same for aggregate-surfaced roads and airfields. Another review focused on thin-surfaced road design approaches (Geoffroy 1998), concluding that there were no pavement design approaches developed explicitly for thin-surfaced roads, only adaptations either of the USACE methods or the AASHTO philosophy. Thus, in this study, we will focus on those two lines of developments.

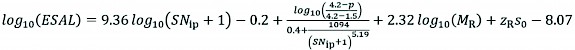

The AASHTO 1993 (AASHTO 1993) methodology is still used worldwide, and its simplicity will probably allow its continued use in the future (Thom 2014). Although the worldwide forest road network has an extraordinary length, it seems that rules of thumb designed most of its pavements and that formal pavement engineering methods have only been used in a few cases (Burlet 1980, Hirt 1972, Yapp et al. 1991). Here, we present and adapt the AASHTO 1993 methodology (AASHTO 1993), with the basic design equation as given below in Eq. (3):

(3)

(3)

Where:

ESAL traffic action (equivalent standard axle loads)

SNip resistance, bearing reaction of the pavement (imperial dimension)

p serviceability of the road

MR resistance, bearing reaction of the soil (resilient modulus)

zR desired reliability level (z score of a standardized normal distribution, representing the exceedance probability)

s0 standard error of the combined traffic and performance prediction.

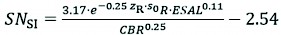

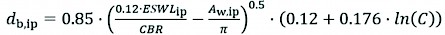

Eq. (3) includes the four design components of a pavement design system (Fig. 6): two straining variables (ESAL traffic action in equivalent standard axle loads; reliability factor zrs0) and two resisting variables (MR bearing reaction of the soil; structural number (SN) bearing response of the pavement). The serviceability of the road (p) is the limit state criterion, which was initially rated by a group of panelists and was mainly a measure of ride quality. It intuitively integrated different types of distresses, such as roughness, cracking, rutting, corrugation, etc. However, Eq. (3) has some disadvantages for a broader use: the resilient modulus MR takes too much effort to be measured. Moreover, Eq. (3) is cumbersome and does not directly give the value for the bearing resistance (SN) that will guide the minimum structural resistance of the pavement. Additionally, it is based on imperial units, whereas the International Unit System (SI) is the standard of science, which was adapted by most of the countries in the world, except Liberia, Myanmar, and the United States. We simplify and convert Eq. (3) to SI by replacing the variables {p, SNip, MR} with {1.5, SNSI/2.54, 1500*CBR} and solving it for SNSI, which yields Eq. (4):

(4)

(4)

Where:

ESAL traffic action (equivalent standard axle loads)

SNSI resistance, bearing reaction of the pavement (SI dimension)

CBR resistance, bearing reaction of the soil (CBR)

zR desired reliability level (z score of a standardized normal distribution, representing the exceedance probability)

s0 standard error of the combined traffic and performance prediction.

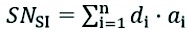

The terminal serviceability pt is a criterion based on public acceptance (AASHTO 1993) that is not a concisely measurable design variable. The AASHTO-93 guidelines recommend terminal serviceability values of 2.0 and above for the range of local to interstate roads. Following the experiences in Central Europe (Burlet 1980, Hirt 1972) and considering the fuzziness of the pt variable, we used a pt value of 1.5. The relationship that we used to convert the resilient modulus into CBR was recommended by the AASHTO (1993). We are aware that this is an approximation. The bearing resistance of the pavement is expressed by the »structural number (SN)« metric, which results from the bearing resistance of the compound of all pavement layers. Each layer has a thickness di and a layer coefficient ai that represent the specific material bearing resistance. The overall pavement bearing resistance, expressed in SNSI metric, equals the product of layer thickness and layer coefficient, which is summed up over all pavement layers in Eq. (5):

(5)

(5)

Where:

SNSI resistance, bearing reaction of the pavement (SI dimension)

I i-th layer of a pavement structure

di thickness of the i-th layer, cm

ai layer coefficient (specific material bearing resistance), following AASTHO, see Table 1.

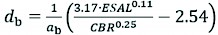

Pavements of forest roads often have only one base course layer, which means that Eq. (3) is reduced to one thickness and one layer of coefficient value. Additionally, the recommendation of the AASHTO 1993 guide (AASHTO 1993) to use a reliability level of 50% results in a zR value of 0. Setting zR to 0, replacing SNSI with d.a, and solving the equation for db, result in Eq. (6):

(6)

(6)

Where:

ESAL traffic action (equivalent standard axle loads)

CBR resistance, bearing reaction of the soil (CBR)

ab layer coefficient of the base course material (see Table 1)

db thickness of the base course, cm.

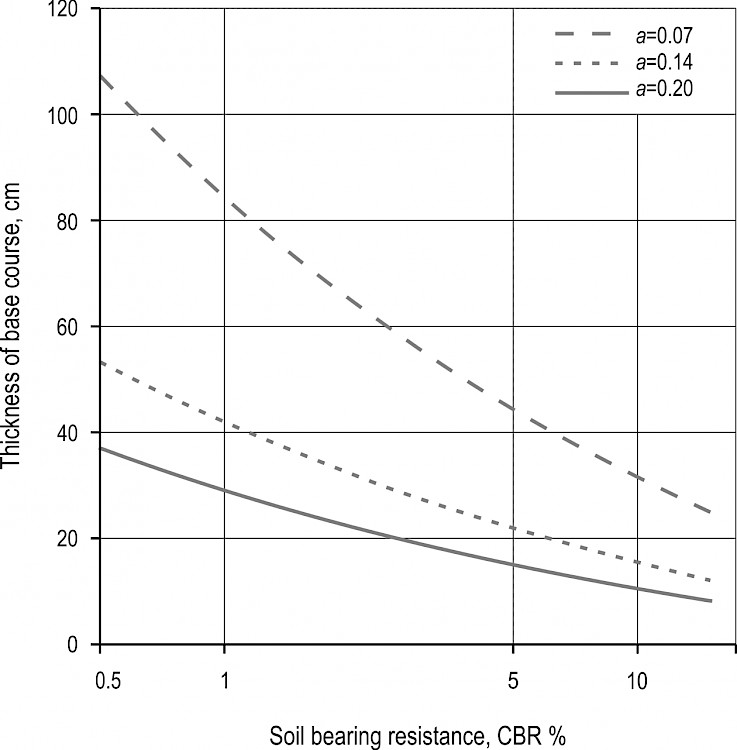

Fig. 7 presents Eq. (6) for a lifecycle traffic volume of 30000 equivalent standard axle loads (ESAL), which is within the boundaries that define low-volume roads (10,000 to 100,000).

Fig. 7 Influence of Soil Bearing Resistance (CBR) on Base Course Thickness. Assumptions: (1) Lifecycle traffic volume 30,000 ESALs. (2) Base course materials: (a) bank gravel (a=0.07), (b) well-graded, crushed aggregates (a=0.14), and (c) cement-stabilized aggregates (a=0.20)

Fig. 7 presents the influence of soil bearing resistance (CBR), which results in a nonlinear increase in the pavement thickness with decreasing CBRs. It also demonstrates the effect of the quality of the material used to build pavements. Bank gravel material quality (a=0.07) requires double thickness of well-graded, crushed aggregates (a=0.14). If aggregate material is hydraulically stabilized with cement (a=0.2), the thickness of the pavement is reduced by one third. Due to environmental concerns, access to aggregate material for road construction has become more difficult. Stabilized and bound materials (see Table 1), together with the rational pavement design approach, have the potential to save material and cost and to make road building more eco-efficient.

The USACE has been developing methods for the design of aggregate-surfaced pavements. Going back to the 1940s, pavement research yielded basic design equations based on the CBR methodology for subsoil characterization. A useful review focused on the historical lines of development (Ahlvin 1991), demonstrating that the equation for the flexible pavement design emerged in 1956 when traffic action was characterized by three parameters: wheel load, the contact pressure of the tire, and the contact area of the wheel. This empirical approach experienced a continuous adaptation and development, mainly driven by the increasing wheel loads of airplanes, which affected the design of airfields. The refinement of the method to prevent failure of the subgrade material due to traffic loading yielded an adapted pavement design equation (Hammitt 1970), based on which a 50% reduction of pavement thickness was imposed for flexible road pavements at a later date, as shown by Eq. (7) (Chou 1989).

(7)

(7)

Where:

ESWLip traffic action (equivalent standard wheel load)

CBR resistance, bearing reaction of the soil (CBR)

Aw,ip contact area of a wheel, inch2

db,ip thickness of the base course, inch

C coverage (number of loading cycles).

Eq. (7) represents the traffic action with three variables, the equivalent standard wheel load (ESWLip), contact area of a wheel (Aw,ip), and coverage (C), which indicates the central accumulation of wheel passes developed for aircraft traffic. It also describes the two components of a pavement design system (Fig. 6), the soil bearing resistance (CBR) and the bearing resistance of the base course (db,ip). Eq. (7) implicitly assumes that the base course material consists of unbound granular mixtures that have an equivalency factor of 1.0 (see Table 1). If the base course consists of materials of higher quality (see Table 1), the calculated thickness will be reduced by a factor of 1/(equivalency factor). Eq. (7) is based on imperial units, which restricts its application. It is converted to SI units by replacing the variables {db,ip, Pw,ip, ESWLip} with {db,SI/2.54, Pw,SI*224.8, ASI/6.45} and solving it for SNSI, which yields Eq. (8):

(8)

(8)

Where:

ESWLSI traffic action (equivalent standard wheel load, kN

CBR resistance, bearing reaction of the soil (CBR)

Aw,SI contact area of a wheel, cm2

db,SI thickness of the base course, cm

C coverage (number of loading cycles).

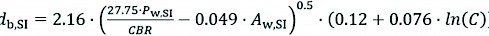

Fig. 8 presents the thickness of the base course, calculated using the AASHTO (6) and ACE (8) equations. The functions are based on the same assumptions: lifecycle traffic volume of 30,000 equivalent axle/wheel loads, unbound aggregate mixture (a=0.11, equivalency factor = 1; see Table 1), and tire contact area of 700 cm² (normal pressure, loaded) and 1200 cm² (heavily reduced pressure, loaded). Those values were estimated by a Swedish study (Granlund 2006).

Fig. 8 Comparison of the AASHTO and ACE Design Approaches. Assumptions: (1) Lifecycle traffic volume 30,000 ESALs/ESWLs and (2) tire contact area under normal pressure (ACEhigh), 700 cm2, and under heavily reduced pressure (ACElow), 1200 cm2

The results are quite similar, in particular, if the soil bearing resistance is higher than 3% CBR. For a CBR of 10%, the AASHTO Eq. (6) yields a base course thickness of 27 cm, whereas the ACE Eq. (8) results in 17 cm. The effect of a tire inflation system, which reduces the inflation pressure by about 50% and increases the tire contact area to about 1200 cm² (Brito 2011), has a small effect on CBR values higher than 6%. Contrarily, there is no significant difference in the lower CBR values. One would expect a substantial difference in the base course for low and high tire contact areas. An explanation is that the variability of contact area pressures was relatively small and that the contact pressure range might be out of the scope of the statistical model. Overall, the ACE design equation is more sensitive to the soil bearing resistance, yielding higher base course thickness than the AASHTO equation for CBR values lower than 3%. For CBR values higher than 3%, the AASHTO equation yields slightly higher base course thickness.

4.5 Mechanistic-Empirical Design Approaches

The above methods followed the philosophy of empirical design approaches. They have been developed from experimental or observational data, based on which statistical models were developed. They are limited to the scope of the original data and do not allow the evaluation of pavement designs with novel materials. This is why the second category of design approaches emerged, called »mechanistic-empirical«; they consist of two parts – a mechanistic part to analyze the material response and the load, and an empirical part to link the pavement response to distress (Mallick and El-Korchi 2018). The lines of developments in those two fields will be presented below.

The mechanics of materials provides the theoretical framework for analyzing the stress–strain behavior of the pavement layers under a specific load. The traditional approach is based on linear-elastic assumptions, which means that a linear relationship occurs between strain and stress. Young’s modulus of elasticity Me is the conventional metric for characterizing the stress–strain relationship that represents the material stiffness. Boussinesq presented an analytical approach to analyze the propagation of stresses in a single-layer system (Boussinesq 1885), demonstrating that stress decreases with increasing distance from a point load. Contrarily, lines of constant stress indicate onion-type shapes. Pavements are multilayer systems, and it was Burmister who presented the first solution for a multilayer elastic system (Burmister 1945a, b, c). Later, Acum and Fox included deformations and stresses for three-layer systems (Acum and Fox 1951). The multilayer elastic theory is based on a set of strong assumptions, in particular (1) uniform loading to one or more circular areas on the surface; (2) linear elastic, homogeneous, and isotropic material properties; and (3) layers with finite thickness, but with an infinite horizontal extension (Hakim 2011). Real-world pavement systems are violating most of those assumptions. Traffic loads are pulse loadings with a high number of cycles, which resulted in the development of the resilient modulus MR (AASHTO 1999) to characterize the material responses to this type of loading, thus replacing Young’s modulus of elasticity. Finite element analysis is an approach to overcome the assumption of the nearest stress–strain behavior (Hakim 2011).

Stress–strain relationships characterize the response of materials to loading. Pavement systems face cyclic pulse loadings, resulting in fatigue phenomena, referred to as »distresses«. As mentioned earlier, critical serviceability – characterized by the AASHTO as terminal serviceability – is the limit state criterion, for which pavements have to be designed. The stress modes depend on the primary pavement material, and concrete, asphalt concrete, and aggregate-surfaced pavements demonstrate different deterioration patterns (Mallick and El-Korchi 2018). The most basic distress modes are rutting, cracking, surface raveling, and loss of evenness (Thom 2014). The challenge is to predict those distress notes from the outcomes of the mechanistic stress–strain analyses, which has to be done with statistical-empirical models. The AASHTO mechanistic-empirical pavement design guide (MEPDG) (NCHRP 2004) comprised a set of empirical distress models that have to be calibrated for the region-specific conditions. The research report demonstrates how this calibration process works for fatigue cracking, rutting, and loss of evenness (roughness) (Souliman et al. 2010). The report documents a rutting model for unbound layers with the number of traffic load cycles, effective vertical strain in the pavement layer, and thickness of the layer as the primary input variables. However, the maximum allowable rutting depth is about 2 cm for high-volume roads, whereas deformations for forest roads are much higher. Assessment of permanent deformation remains beyond the scope of the leading pavement design guides for LVR, which do not allow the use of mechanistic-empirical design approaches for forest roads at present (Brito 2011).

Additionally, MEPDG (NCHRP 2004) is quite complicated and only available as a computer program. Whereas some of the underlying algorithms are excellent, others seem to be questionable (Thom 2014). The MEPDG method is, to some extent, the black box with the risk of being misused due to a lack of understanding of the required input and algorithms (Thom 2014).

5. Discussion and Conclusions

This study aimed to review the big development lines of pavement systems, to have a critical look at the pavement engineering framework, and to bring the selected empirical design equations into a comparable scheme. The investigation yielded five significant findings. First, the Trésaguet system, based on a quarry stone base course layer, and the McAdam system, based on a base course layer of uniform broken aggregate, were the state-of-the-art pavements for almost 150 years. Moreover, these systems were documented in old forest road textbooks. Second, the emergence of soil mechanics as a scientific discipline in the 1920s resulted in the mechanical characterization of soils and aggregates and their improvement with binders, such as lime, cement, and bitumen. Optimal grading results in a higher density of a UBM, following Talbot’s law (see eg. (1)). Contrarily, cement-improved or cement-bound granular mixtures improve the bearing resistance of the material at a factor of 3 to 4 compared to untreated bank gravel. Third, the rational pavement design consists of five essential components: the bearing resistance of the subsoil, bearing resistance of the pavement structure, lifecycle traffic volume, different uncertainties that amplify deterioration, and limit state criterion. It uses at least one limit state criterion that defines a threshold, beyond which structural safety or serviceability is no longer met. Fourth, there are no rational, formal pavement design approaches especially developed for forest roads and even LVR in general. The few rational methods used were »downsized« from methodologies developed for high-volume roads, among which the AASHTO and the USACE were the most visible. Fifth, the conversion of the AASHTO ’93 (AASHTO 1993) and the USACE ’70 (Chou 1989, Hammitt 1970) into the SI system and their simplification resulted in the formulation of two design equations that yield comparable thicknesses of a pavement for similar design parameters. Both equations are sensitive to soil bearing resistance, which is measured in CBR. The AASHTO equation additionally offers the opportunity to evaluate the effect of different pavement material qualities on the overall pavement thickness.

Pavement construction in LVR emerged from local experience and was, therefore, more of craftsmanship than science. The findings of this contribution build a bridge from rules of thumb to rational pavement design. The International System of Units (SI) is a scientific standard and most of the world’s countries adopted it. The conversion of both the AASHTO and USACE design equations to the SI system makes it easily understandable and might eliminate obstacles to use rational pavement design approaches. Below, we will discuss some implications of our findings, with the awareness that some aspects might call for discussion. Rational pavement design has the potential to improve the effectivity and efficiency of both the rehabilitation of the system and configuration of a new pavement. Forest agencies often have standard cross sections with a standard thickness of the base layer, e.g., 30 cm. Such standards are overdesigned for soil bearing resistances higher than 5% CBR and consequently underdesigned for CBR values less than 5%. Fundamental relationships on the effects of soil bearing resistance and base course material quality (Figs. 7 and 8) can raise awareness and help adjust the previous practices. Another implication is that the CBR value of the subsoil needs to be measured as one of the leading design parameters. The CBR metric is a proxy for the soil bearing resistance that has its drawbacks. This motivated the AASHTO to replace it with the resilient modulus (AASHTO 1993), considering that traffic loads consist of a series of distinct load pulses instead of a static load only. The sophistication of the MR test equipment and procedures resulted in the development of conversion relationships between immeasurable soil properties and the MR-value, among which the CBR value has been particularly popular. We used the relationship suggested by AASHTO (AASHTO 1993), which seems to overpredict the resilient modulus (Sukumaran et al. 2002). Similar investigations concluded that the estimation of resilient moduli with CBR values should be used with caution (George 2004) and that the relationship developed by the Long-Term Pavement Performance Program (Yau and Von Quintus 2002) provides a more reliable conversion if the unconfined compressive strength is used instead of the CBR value. However, to our knowledge, there is no CBR–MR relationship that could be used to convert the AASHTO equations. The AASHTO and USACE design equations used in our analysis do not represent the latest state-of-development, because computer-based mechanistic-empirical design methods represent the frontier of development. A disadvantage of those methods is that they are considered »black boxes«, which goes along with the risk of misuse without a full understanding of the required inputs (Thom 2014). Empirical methods, such as the AASHTO '93 approach, are therefore still in use and will continue to be in use worldwide owing to their simplicity, which is a key advantage (Thom 2014).

The lack of field validation is one of the major disadvantages of the AASHTO and USACE design procedures, particularly for the forest road conditions (Yapp et al. 1991). The so-called RUTT (Roads Under Timber Transport) project is one of the rare attempts to systematically collect pavement performance data for forest roads that were used between 2006 and 2008 in Northern Scotland (Brito 2011). The field campaign collected data on weather, traffic, and pavement deformation at 15 sites, but the study layout was too narrow to generate sufficient variability for drawing general conclusions (Brito 2011). Future work should develop and implement a factorial observational study of forest roads and traffic and climate actions to validate the empirical design approaches presented here. Instrumentation and automatic data collection could stem from the experience of the RUTT project, considering that a balanced study layout is more important than a high sophistication of data collection on a few sites only. The estimation of the resilient modulus of soils with easily measurable stiffness and bearing resistance metrics (CBR) is another area of future work that should be based on a careful review of the state of the art.

6. References

AASHO, 1961: The AASHO road test. History and Description of Project. Special report / Highway Research Board. National Academy of Sciences - National Research Council. Washington, D.C., 61A, 56 p.

AASHO, 1962: The AASHO Road Test-Pavement Research. Report 5 (HRB Special Report 61E). National Academy of Sciences - National Research Council. Washington DC.

AASHTO, 1993: AASHTO Guide for Design of Pavement Structures, Vol. 1, AASHTO.

AASHTO, 1999: Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials (T 307-99 (2017)). Washington DC: American Association of State Highway and Transportation Officials.

Acum, W.A., L. Fox., 1951: Computation of load stresses in a three-layer elastic system. Geotechnique 2(4): 293 –300. https://doi.org/10.1680/geot.1951.2.4.293

Agg, T.R., 1940: The Construction of Roads and Pavements, 5.ed. 5.impr. Ed. New York, London: McGraw-Hill, 483 p.

Ahlvin, R.G., 1991: Origin of Developments for Structural Design of Pavements. Technical Report. GL-91-26. Waterways Experiment Station, Corps of Engineers. Vicksburg, MS 39181, 150 p.

ASTM, 2012a: Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). Compass. ASTM International. Accessed [Aug-05-2020]

ASTM, 2012b: Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kNm/m3)). Compass. ASTM International. Accessed [Aug-05-2020]

Bekker-Nielsen, T., 2013: Roads, Roman Empire. In The Encyclopedia of Ancient History, R.S. BAGNALL, et al., Editors. John Wiley & Sons: online.

Berechman, J., 2003: Transportation–economic aspects of Roman highway development: the case of Via Appia. Transportation Research Part A: Policy and Practice 37(5): 453–478. https://doi.org/10.1016/S0965-8564(02)00056-3

Boussinesq, M.J., 1885: Applications des potentiels à l'étude de l'équilibre et du mouvement des solides élastiques, principalement au calcul des déformations et des préssions que produisent, and ces solided, des efforts quelconques exercés sur une petite partie de leur surface our de leur intérieur. Mémoires de la Société des Sciences de l'agriculture et des arts de Lille 13(4): 704.

Brito, L.A.T., 2011: Design Methods for Low Volume Roads. Department of Civil Engineering, The University of Nottingham. Nottingham. Doctor of Philosophy, 223 p.

Burlet, E., 1980: Dimensionierung und Verstärkung von Strassen mit geringem Verkehr und flexiblem Oberbau. Zürich, 81 p. https://doi.org/10.3929/ethz-a-000207974

Burmister, D.M., 1945a: The general theory of stresses and displacements in layered soil systems. II. Journal of Applied Physics 16(3): 126–127. https://doi.org/10.1063/1.1707562

Burmister, D.M., 1945b: The general theory of stresses and displacements in layered soil systems. III. Journal of applied Physics 16(5): 296–302. https://doi.org/10.1063/1.1707590

Burmister, D.M., 1945c: The general theory of stresses and displacements in layered systems. I. Journal of applied physics 16(2): 89–94. https://doi.org/10.1063/1.1707558

Casagrande, A., 1931: Discussion on frost heaving. In Proceedings, Highway Research Board 11: 168–172.

Casagrande, A., 1932: Research on the Atterberg limits of soils. Public roads 13(8): 121–136.

Casagrande, A., 1934: Araeometer-Methode zur Bestimmung der Kornverteilung von Boeden und anderen Materialien. Berlin: Springer, 56 p.

Casagrande, A., 1948: Classification and identification of soils. Transactions of the American Society of Civil Engineers 11 (1): 901–930.

CEN, 2015: EN 14227-5 Hydraulic bound mixtures. Specifications. Hydraulic road binder bound granular mixtures. Brussels: European Committee for Standardization.

Chou, Y.T., 1989: Design Criteria for Aggregate-surfaced Roads and Airfields. Technical Report. GL-89-5. Waterways Experiment Station, Corps of Engineers. Vicksburg, MS 39181, 91+App p.

Coghlan, G.T., 2000: Opportunities for low-volume roads. TRB Online Publications. Transportation Research Board, Committee on Low-Volume Roads. Accessed [Mar-16-2020]

EN13242, 2007: Aggregates for unbound hydraulically bound materials for use in civil engineering work and road construction. CEN European Committee for Standardization. Brussels, Belgium, 41 p.

Fuller, W.B., Thompson, S.E., 1907: The laws of proportioning concrete. Transactions of the American Society of Civil Engineers 59: 67–143.

Geoffroy, D.N., 1998: Synthesis of Highway Practice 260: Thin-Surfaced Pavements. National Cooperative Highway Research Program. Transportation Research Board, National Research Council. Washington, DC, 112 p.

George, K., 2004: Prediction of resilient modulus from soil index properties. Mississippi Department of Transportation, Research Division. Jackson MS, FHWA/MS-DOT-RD-04-172, 64 p.

Granlund, P., 2006: CTI pa virkesfordon [CTI on roundwood haulage vehicles]. Redogörelse. 3. Skogforsk. Uppsala, 40 p.

Hafner, F., 1956: Mechanisierter Wegebau auch im Gebirge. In Maschinen für den Bergwald, C. Auer, Editor. Bündner Forstverein und SELVA: Chur: 81–104.

Hakim, B.A., 2011: Chapter 39 Analytical pavement design. In ICE manual of highway design and management, I.D. Walsh, Institution of Civil Engineers (Great Britain), Editor. Thomas Telford Ltd: London: 383–393.

Hammitt, G.M., 1970: Thickness Requirements for Unsurfaced Roads and Airfields. Technical Report. S-70-5. Waterways Experiment Station, Corps of Engineers. Vicksburg, MS 39181, 139 p.

Hirt, R., 1972: Dimensionierung und Verstärkung von schwach beanspruchten Strassen. Schweizerische Zeitschrift für Forstwesen, 3.

Jägerschmid, K.F.V., 1827: Handbuch für Holztransport- und Flosswesen zum Gebrauche für Forstmänner und Holzhändler und solche die es werden wollen. Karlsruhe: Ch. Fr. Müller'sche Hofbuchhandlung, 391 p.

Mallick, R.B., T. El-Korchi, 2018: Pavement engineering principles and practice, 3rd Ed. Boca Raton, Fla.: Taylor & Francis, 747 p.

Malyshev, M., 1973: Karl Terzaghi (1883–1963). Soil Mechanics and Foundation Engineering 10(4): 257–259. https://doi.org/10.1007/BF01704946

Massazza, F., 1998: Pozzolana and Pozzolanic Cements. In Lea's Chemistry of Cement and Concrete (Fourth Edition), P.C. Hewlett, Editor. Butterworth-Heinemann: Oxford: 471–635.

McAdam, J.L., 1824: Remarks on the present system of road-making; with observations deduced from practice and experience, with a view to a revision of the existing laws, and the introduction of improvement in the method of making, repairing and preserving roads, and defending the road funds from misapplication, 8th, carefully revised and with appendix Ed. London: Longman, Hurst, Rees, Orme, Brown, and Green, Paternoster Row, 236 p.

Nakicenovic, N., 1986: The automobile road to technological change: diffusion of the automobile as a process of technological substitution. Technological Forecasting and Social Change 29(4): 309–340. https://doi.org/10.1016/0040-1625(86)90021-1

NCHRP, 2004: Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures. Champaign, IL: National Cooperative Highway Research Program, Transportation Research Board, National Research Council. [Accessed Aug-07-2020]

Oglesby, C.H., 1975: Dilemmas in the Administration, Planning, Design, Construction, and Maintenance of Low-Volume Roads. In Workshop on Low-volume Roads, Boise, Idaho, Vol. Special Report 160. ed. E.J. YODER, 7–16. Washington, DC 20418. Transportation Research Board, National Research Council.

Older, C., 1924: Bates Experimental Road – Highway Research in Illinois. Division of Highways. State of Illinois, Department of Public Works and Buildings, 51 p.

Porter, O.J., 1943: Foundations for flexible pavements. In Proceedings of the Twenty-Second Annual Meeting of the Highway Research Board, Vol. 22: 100–143. Hotel Statler, St. Louis, Missouri December 1-4, 1942. Highway Research Board.

Proctor, R.R., 1933a: Description of Field and Laboratory Methods. Engineering News-Record 111(9):286–289.

Proctor, R.R., 1933b: Fundamental Principles of Soil Compaction. Engineering News-Record 111(9): 245–248.

Souliman, M.I., Mamlouk, M.S., El-Basyouny, M.M., Zapata, C.E., 2010: Calibration of the AASHTO MEPDG for flexible pavement for arizona conditions. In Proceedings of the Transportation Research Board 89th Annual Meeting, Vol. 22. Transportation Research Board Washington, DC, USA.

Stoetzer, H., 1877: Waldwegebaukunde. Ein Handbuch für Praktiker, 1st Ed. Frankfurt a.M.: J.D. Sauerländer, 170 p.

Stoetzer, H., 1903: Waldwegebaukunde nebst Darstellung der Waldeisenbahnen. Ein Handbuch für Praktiker und den Unterricht, 4th Ed. Frankfurt a. M.: J.D. Sauerländer, 245 p.

Sukumaran, B., Kyatham, V., Shah, A., Sheth, D., 2002: Suitability of using california bearing ratio test to predict resilient modulus. In Proceedings: Federal Aviation Administration Airport Technology Transfer Conference, 9 p.

Talbot, A.N., Brown, H.A., Richart, F.E., 1923: The strength of concrete: its relation to the cement aggregates and water. University of Illinois Bulletin 137, 116 p.

Thom, N., 2014: Principles of pavement engineering, 2nd Ed. London: ICE Publishing, 403 p.

TRB, 1975: Low-volume Roads. Workshop on Low-volume Roads, Boise, Idaho. Special Report 160. Transportation Research Board, National Research Council. Washington, DC 20418, 396 p.

Tresaguet, P.M.J., 1831 (1775): Mémoire sur la construction et l'entretien des chemins de la généralité de Limoges (reprint of the original paper). Annales des Ponts et Chaussées 1(1): 243–286.

USAES, 1951: Roads and Airfields. Engineer School Special Text, Vol. ST-5-250-1. Fort Belvoir, Virginia: The Engineer School, 717 p.

USFS, 1954: Road Handbook: Standards, Construction, Maintenance Structures, Transportation Planning. Washington, DC: United States, Forest Service.

Winterkorn, H.F. Pamukcu, S., 1975: Soil Stabilization and Grouting. In Foundation engineering handbook, H.F. Winterkorn, H.-Y. Fang, Editors. Van Nostrand Reinhold: New York: 317–378.

Yapp, M.T., Steward, J., Whitcomb, W.G., 1991: Existing Methods for the Structural Design of Aggregate Road Surfaces on Forest Roads. Transportation Research Record 1–2(1291): 41–57.

Yau, A., Von Quintus, H.L., 2002: Study of LTPP laboratory resilient modulus test data and response characteristics. Office of Infrastructure Research and Development. Federal Highway Administration. McLean, VA, 173 p.

© 2020 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Author’s address:

Prof. Emeritus Hans Rudolf Heinimann, PhD

e-mail: hans.heinimann@frs.ethz.ch

ETH Zürich

Department of Environmental Systems

Universitätsstrasse 22

8092 Zürich

SWITZERLAND

Received: March 18, 2020

Accepted: June 08, 2020

Subject review

[1] US Army Corps of Engineers (ACE)